|

市場調查報告書

商品編碼

1581323

LIB溫度控管/熱逸散防止模組包裝的技術開發與市場預測(~2035年)<2024> LIB Thermal Management /Thermal Runaway Prevention Module Pack Technology Development and Market Outlook (~2035) |

||||||

儘管近期電動車銷售下滑導致市場成長放緩,但電動車產業的樂觀前景依然沒有改變。

隨著各國加強二氧化碳排放法規,汽車製造商必須銷售電動車才能避免法規帶來的處罰。因此,向電動車的轉型勢必會取得進展。然而,由於消費者無法輕易忽視買家對電動車的各種負面評價,電動車製造商面臨許多課題,例如充電便利性、續航里程以及電池起火安全性。尤其值得一提的是,電動車的電池起火問題不僅僅是一個技術問題,而是一個直接關係到社會安全的關鍵問題,因此徹底的驗證必不可少。

歐盟執委會計畫於2026年實施新的電池法規,而電池護照正是其中的核心。

本報告對二次電池產業進行了調查和分析,並探討了電動車電池模組組的最新技術趨勢,特別是製造商應對熱失控的對策和技術。

影像

目錄

第1章 電池組的概念和定義

- 電池組的基本概念

- 電動車中電池組的意義

- 電池單元、電池模組、電池組的意義

- 電動車平台、電池組、模組

- 電動車平台中電池組的基本配置

- 如何連接電芯和模組(串聯/並聯)

- 電池容量/電池可用能量

- 電池SOC、SOH、DOD的意義

- 電池充放電(C速率)

- 電池組的規格

- 電池組的熱管理

- 如何管理電池組的熱管理

- 最佳電池組熱管理(設計係數)

- 如何冷卻/加熱電池組

第2章 電池組結構與開發趨勢

- 電池組結構

- 電池組結構(分解圖)

- 電池組組件

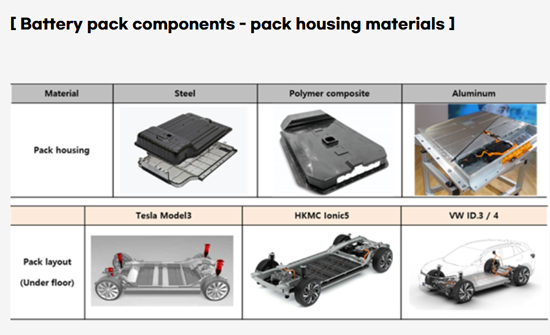

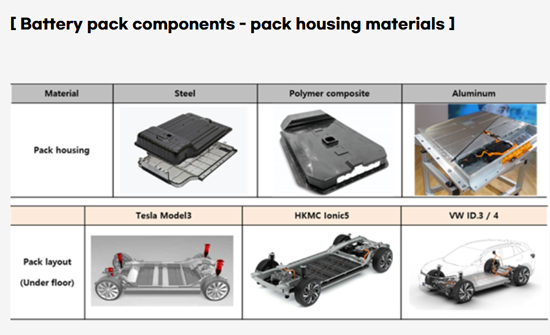

- 電池組外殼材料

- 不同 xEV 車型的電池外殼使用情況(蓋板、托盤)

- 電池組密封墊

- 電池組完整性與驗證(CAE、IP 測試)

- CMA(電芯模組組裝)結構(方形、軟包、圓柱形)

- CMA 蓋板

- 壓縮墊

- 冷卻系統類型1

- 冷卻系統類型2

- 冷卻系統類型3

- 冷卻系統類型4

- TIM(熱感介面材料)的結構和特性:各材料

- 模組用TIM(熱感介面材料)

- BMS(電池管理系統)結構與特徵

- PRA(電力繼電器集合)

- MSD(手動服務隔離開關)

- HVIL連接器(高壓連鎖連接器)

- 感測器(溫度感測器,電流感測器)

- 電池組開發情形:各OEM平台

- 電池組概念變更:按電動車平台

- 電池組特性:依電動車平台

- 大眾汽車的MEB平台

- 現代汽車的E-GMP平台

- 通用汽車的Ultium平台

- 無模組電池組的技術趨勢

- 寧德時代、比亞迪的CTP技術

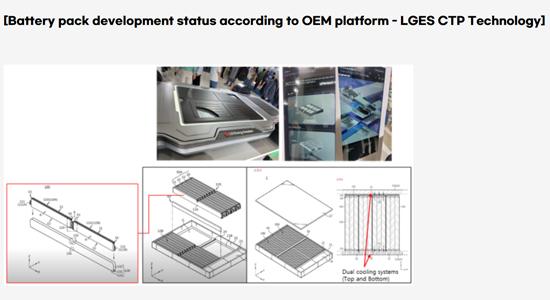

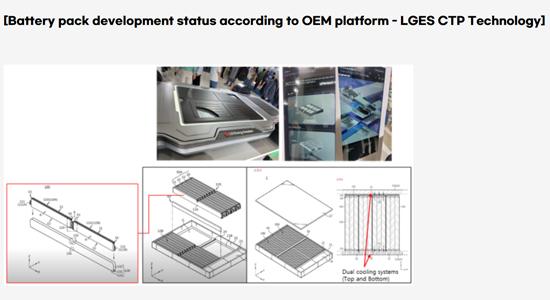

- LGES的CTP技術

- SK on的CTP技術

- 特斯拉的新型電池組結構(Cell to Vehicle)

- 混合動力電池組的使用(蔚來NCM-LFP電池單元CTP)

- 混合動力電池組的使用(寧德時代AB電池組)

第3章 電動車用電池組的規格分析與摘要

- 電動車用電池組的規格分析

- EV電池電池單元·包裝的銷售價格的預測

- 小客車電動車用電池組的平均容量(kWh)

- 電動車用電池組的能量密度的分析(kWh/kg)

- 電動車用電池組的使用可能的能源的分析

- 電池組的主要零組件的重量比

- 電池組的主要零組件的成本結構

- EV用電池組的主要的規格的摘要1

- EV用電池組的主要的規格的摘要2

- EV用電池組的主要的規格的摘要3(使用可能的電池組容量)

第4章 電動車電池組趨勢電池熱失控預防技術

- 熱失控現象及其成因

- 電池組的阻燃需求

- 熱失控預防解決方案(熱失控屏障)

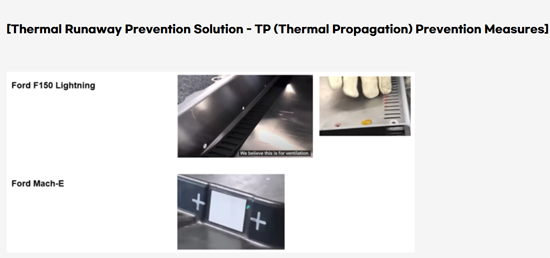

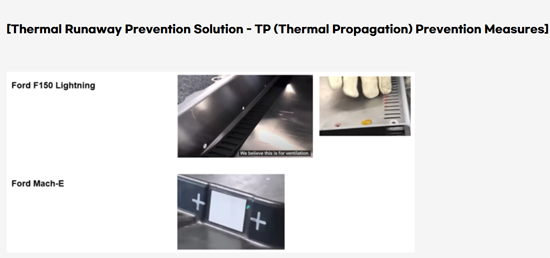

- 防止熱擴散(TP)的措施

- 模組內部TBA(熱障組件)的應用

- 模組外部TBA(熱障組件)的應用

- 特性:依TP材料分類

- 模組/電池組級TP解決方案:透氣技術

- 兩種電池組透氣解決方案(1級、2級)

- 電池組透氣的典型設計(1級、2級)

- 電芯/模組/電池組級氣體透氣孔的應用

- 關鍵設計與效能考量

- 產品需求:1級、2級透氣

- 測試要求

- 基準案例分析

- 雲母絕緣替代品

- 雲母材料特性

- TRP 紙產品特性

- 其他替代材料

第5章 電池組的主要元件供應商

- 電池組零組件廠商(世界/國內)

- KET

- Younghwa Tech

- LS EV Korea

- WOORY INDUSTRIAL

- Hyunwoo Industrial

- YURA CORPORATION

- Kyungshin

- Mobase Electronics (Seoyeon Electronics)

- Aluco

- Hanon Systems

- Saint-Gobain PPL

- INZI CONTROLS

- SEBANG GLOBAL BATTERY

- 溫度控管材料廠商

- Alkegen

- Morgan

- Rogers

- Laird

- ASPEN

- Pamica

- Glory

第6章 EV·包裝市場預測

- EV市場預測

- 全球搭乘用EV市場預測:BEV/PHEV

- 全球xEV電池的需求與預測

- 全球EV電池電池單元·包裝的市場規模

- 全球主要EV製造商預測

- 包裝市場預測

- 電動車的包裝的市場規模及預測

- 包裝零組件市場預測

- 電動車的包裝零組件的市場規模預測

- 包裝材料市場預測

- 電池組外殼材料市場規模展望

- 電池組熱管理材料市場規模展望

- 熱管理解決方案材料市場規模展望

- 電芯間結構材料市場規模展望

- 溫度控管材料的市場規模預測

第7章 包裝的專利趨勢

- 國內電池企業的專利申請情形

- 國內電池企業的專利案例

- 電池組結構安全領域專利案例

- 電池組熱失控領域專利案例

- 電池組熱失控領域專利案例

Although the recent slump in electric vehicle sales has slowed things down a bit, the optimistic outlook for the electric vehicle industry remains.

As each country strengthens its carbon emissions, automakers will not be able to afford the penalties imposed by the regulations unless they sell electric vehicles. Therefore, it is clear that the transition to electric vehicles will continue. However, since consumers cannot lightly overlook the various negative views of buyers regarding electric vehicles, electric vehicle manufacturers have issues to solve, such as easy charging, long driving range, and safety from battery fires. In particular, the issue of electric vehicle battery fires is not a simple technical issue, but rather an important issue directly related to social safety, so it cannot help but be thoroughly verified.

The EU executive is planning to implement a new battery regulation in 2026, and the core of this is the Battery Passport. Therefore, battery manufacturers also need to strengthen battery safety and transparency to respond to international regulations. Accordingly, this report will examine recent technology trends in battery modules and packs for electric vehicles, and in particular, examine the response measures and technologies of each manufacturer related to thermal runaway.

This report not only explains the basic concepts of secondary battery packs and the basic concepts of thermal management, but also describes the battery pack structure, development trends, and battery pack components, and also analyzes and summarizes the development status of battery packs according to the major OEM platforms, major EV electric vehicle battery pack specifications, trends in battery thermal runaway response technologies, and a detailed description of the thermal runaway prevention solution (Thermal Runaway Barrier), introduces major battery pack component companies and thermal management, thermal runaway companies, and provides an outlook on the EV market, pack market, and thermal management material market. The last chapter covers the current status and cases of related battery pack patent trends.

Strong Points of This Report:

- 1. Easy to understand explanation of basic concepts of battery packs and battery pack thermal management

- 2. Easy to understand pack technology trends of major OEMs such as VW, Hyundai, GM, CATL, BYD, LGES, Skon, Tesla, and NiO

- 3. Summary of major EV battery pack specifications (usable battery pack capacity) and detailed analysis of sales price and energy density

- 4. Detailed analysis of battery thermal runaway response technology trends and prevention solutions that have recently emerged as issues

- 5. Detailed information on development trends of domestic and foreign battery pack component manufacturers and thermal runaway companies

- 6. EV market outlook, pack market outlook, and pack thermal management material market outlook

- 7. Understanding pack patent trends through patent cases in pack structural safety, thermal runaway, and CTP fields

VISUALS

Table of Contents

1. Battery pack concept and definition

- 1.1. Basic concept of battery pack

- Meaning of battery pack in electric vehicles

- Meaning of battery cell, battery module, and battery pack

- Electric vehicle platform and pack, module

- Basic configuration of pack in electric vehicle platform

- Cell and module connection method (Serial / Parallel)

- Battery capacity / Usable energy in battery

- Meaning of battery SOC, SOH, DOD

- Battery charge/discharge (C-rate)

- Battery pack specification

- 1.2. Thermal management of battery pack

- Pack thermal management method

- Optimal pack thermal management (design factor)

- Cooling and heating method of pack

2. Battery pack structure and development trends

- 2.1. Battery pack structure

- Pack structure (Exploded view)

- 2.2. Battery pack components

- Pack housing material

- Battery housing application status by xEV vehicle type (Cover, Tray)

- Pack Sealing Gasket

- Pack Integrity and Validation (CAE, IP test)

- CMA (Cell Module Assembly) structure (prismatic, pouch, cylindrical type)

- CMA Cover

- Compression pad

- Cooling system Type 1

- Cooling system Type 2

- Cooling system Type 3

- Cooling system Type 4

- TIM(Thermal Interface Material) configuration and characteristics by material

- TIM(Thermal Interface Material) for module

- BMS(Battery Management System) structure and characteristics

- PRA (Power Relay Assembly)

- MSD (Manual Service Disconnector)

- HVIL connector (High Voltage Interlock connector)

- Sensors (Temperature and current sensors)

- 2.3. Battery pack development status by OEM platform

- Concept change of pack by EV platform

- Pack features by EV platform

- VW's MEB platform

- Hyundai Motor's E-GMP platform

- GM's Ultium platform

- Technology trends of module-free battery packs

- CATL, BYD's CTP Technology

- LGES's CTP Technology

- SK on's CTP Technology

- Tesla's New structural battery pack (Cell to Vehicle)

- Application of Hybrid Battery Pack (NIO NCM-LFP battery cell CTP)

- Application of Hybrid Battery Pack (CATL AB battery Pack)

3. Electric vehicle battery pack specification analysis and summary

- 3.1. Electric vehicle battery pack specification analysis

- 3.2. EV battery cell and pack sales price forecast

- 3.3. Passenger car electric vehicle battery pack average capacity (kWh)

- 3.4. Electric vehicle battery pack energy density analysis (kWh/kg)

- 3.5. Electric vehicle battery pack usable energy analysis

- 3.6. Weight ratio of major battery pack components

- 3.7. Cost composition of major battery pack components

- 3.8. Summary of major EV battery pack specifications 1

- 3.9. Summary of major EV battery pack specifications 2

- 3.10. Summary of major EV battery pack specifications 3 (Usable battery pack capacity)

4. Battery thermal runaway response technology trends

- 4.1. Thermal runaway phenomenon and causes

- 4.2. The need for battery pack flame retardancy

- 4.3. Thermal runaway prevention solutions (Thermal Runaway Barrier)

- TP (Thermal Propagation) prevention measures

- TBA (Thermal Barrier Assembly) applied inside the module

- TBA (Thermal Barrier Assembly) applied outside the module

- Characteristics by TP material

- TP solutions at module and pack levels: Venting technology

- Two types of battery pack venting solutions (Level 1, Level 2)

- General design of battery pack venting (Level 1, Level 2)

- Vent application for De-gas at cell, module and pack level

- Key design and performance considerations

- Product requirements: Level 1, Level 2 venting

- Test requirements

- Benchmark case analysis

- Insulating materials for Thermal Barriers that can replace Mica

- Mica material properties

- TRP Paper product properties

- Other alternative materials

5. Battery Pack Major Component Suppliers

- 5.1. Battery Pack Component Manufacturers (Global / Domestic)

- KET

- Younghwa Tech

- LS EV Korea

- WOORY INDUSTRIAL

- Hyunwoo Industrial

- YURA CORPORATION

- Kyungshin

- Mobase Electronics (Seoyeon Electronics)

- Aluco

- Hanon Systems

- Saint-Gobain PPL

- INZI CONTROLS

- SEBANG GLOBAL BATTERY

- 5.2. Thermal management material manufacturers

- Alkegen

- Morgan

- Rogers

- Laird

- ASPEN

- Pamica

- Glory

6. EV & Pack Market Outlook

- 6.1. EV market outlook

- Global passenger EV market outlook by BEV/PHEV

- Global xEV battery demand and outlook

- Global EV battery cell and pack market size

- Outlook by global EV major maker

- 6.2. Pack market outlook

- Pack market size and outlook for electric vehicles

- 6.3. Pack component market outlook

- Market size outlook for electric vehicle pack components

- 6.4. Pack material market outlook

- Market size outlook for pack housing materials

- Market size outlook for pack thermal management materials

- Market size outlook for TP solution materials

- Market size outlook for cell-to-cell structure materials

- 6.5. Market size outlook for thermal management materials

7. Pack Patent Trends

- 7.1. Status of domestic battery company patent applications

- 7.2. Domestic battery company patent cases

- Patent cases in the field of pack structural safety

- Patent cases in the field of pack thermal runaway

- Patent cases in the field of pack CTP