|

市場調查報告書

商品編碼

1910711

工業用桶:市場佔有率分析、產業趨勢與統計、成長預測(2026-2031)Industrial Drums - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

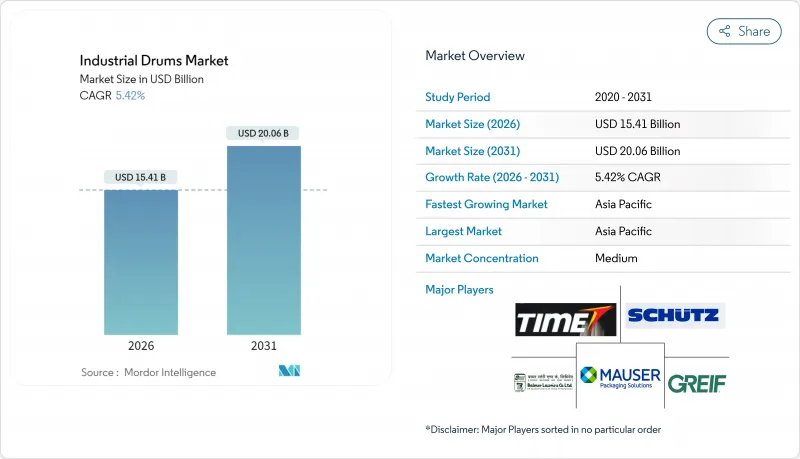

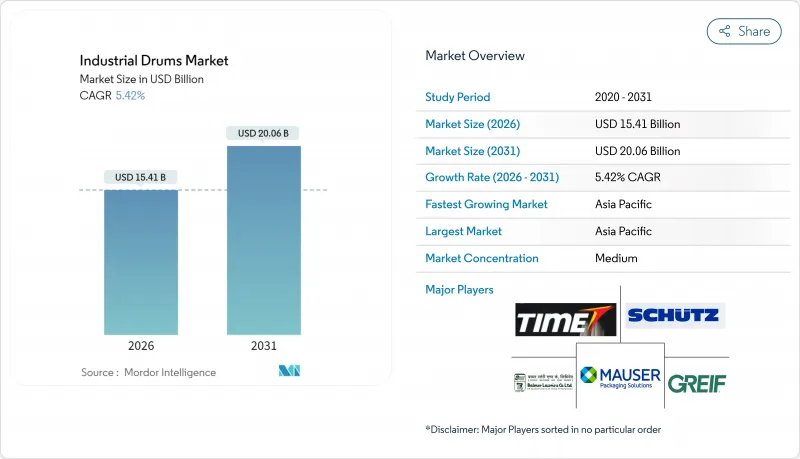

預計工業用桶市場將從 2025 年的 146.2 億美元成長到 2026 年的 154.1 億美元,並預計到 2031 年將達到 200.6 億美元,2026 年至 2031 年的複合年成長率為 5.42%。

穩定的化學產品生產、不斷成長的石化投資以及食品級產品出口量的擴大是需求的根本驅動力。可重複使用包裝的監管力道不斷加大,例如康明斯的RFID可回收包裝項目,正在推動消費者逐步淘汰一次性散裝袋。隨著注重重量的托運人尋求耐腐蝕的包裝方案,複合桶的市場佔有率正在不斷擴大;同時,RFID技術在危險品運輸車輛中的應用也日益普及,以提高可追溯性。亞太地區是推動銷售成長的主要動力,這主要得益於中國裂解裝置的擴建以及印度設定的到2030年化工產品年成長率達到12%的目標。同時,北美和歐洲則優先考慮合規性主導的高階包裝形式。諸如貝瑞世界(Berry World)與安姆科(Amcor)在2025年的合併等整合,正在創造規模經濟效益,並擠壓小規模競爭對手的生存空間。

全球工業桶市場趨勢與洞察

化工和石油化工產品產量增加

中國特種化學品市場的強勁擴張、中東裂解裝置的擴建以及日本大型企業間的併購,都在推動對桶裝物料的需求。美國化學理事會(ACC)指出,儘管面臨物流瓶頸,美國化學品生產仍展現韌性。同時,印度的目標是實現12%的複合成長率,這將確保桶裝物料的需求持續成長。大規模一體化工廠更大的批量生產,推動了運輸商對容量100加侖及以上、且內襯複合塗層、能夠耐受腐蝕性中間體的桶裝物料的需求。 SysKem Chemie公司便是這項成長需求的典型例證,該公司專門使用符合聯合國測試標準的塗層桶運輸辛酸(8類化學品)。

擴大食品級出口物流

原料來源多角化正在延長甜味劑、植物性蛋白質和濃縮液果汁的供應鏈。 CDF公司於2025年2月推出了符合美國標準的內襯,顯示供應商已準備好應對更嚴格的污染容忍度。根據國際食品轉碼器 Alimentarius)制定的統一文件規範,可以實現多區域認證,並支持大規模生產食品級桶的製造商實現規模經濟。優質有機產品出口商現在願意為具有防篡改密封和QR碼追溯數據的桶支付差價,從而增強其在目標市場的原產地聲明。

原物料價格波動

由於鋼鐵和塑膠價格波動擠壓利潤空間,製桶製造商難以使合約與客戶價格表保持一致。瑞爾森公司2025年的預測指出,亞洲熱軋捲板可能面臨反傾銷稅,進一步加劇了不確定性。為了抵銷不斷上漲的捲板成本,巴爾默卡車公司已開始試用0.5毫米厚的製桶,每個標準箱可裝載80捲捲板,比之前的標準多4卷。該公司2024年的銷售額預計為233.9億印度盧比(約2.808億美元),因此這項成本節約意義重大。

細分市場分析

鋼桶佔最大佔有率,達46.68%,這主要得益於煉油廠和農化生產商對其機械強度和易於回收的重視。同時,複合材料桶的市佔率也呈現7.21%的成長態勢,買家正在權衡運輸成本的節省與前期投入成本。近期對印度港口的審核顯示,輕型鋼桶佔危險化學品出口量的37%,凸顯了薄壁帶來的成本優勢。工業桶市場正受益於全球廢鋼回收激勵政策,這些政策使得低合金鋼成為可回收資產,而原生高密度聚乙烯(HDPE)樹脂的價格則日益與丙烯價格掛鉤。

塑膠和纖維材質的容器種類繁多,分別針對不同的溶質相容性和重量限制。雖然纖維容器尚未獲得聯合國液體容器認證,但目前已採用防潮內襯來延長乾粉食品的保存期限。複合材料容器則將聚合物阻隔層與鋼肋結合,專門針對對水分敏感的黏合劑成分的配方設計。這些新出現的產品表明,工業用桶市場的發展趨勢是材料混合而非簡單的二元轉換。

容量為 60-100 加侖的桶裝產品,由於其符合堆高機作業要求,仍佔據市場主導地位,市場佔有率達 35.21%。然而,全自動化工叢集更傾向於使用 110 加侖的桶裝產品,因為這種桶裝產品可以減少每噸物料的裝卸次數。預計到 2031 年,100 加侖以上的桶裝產品將保持最快的成長速度,年成長率達 6.08%。 Camco Chemical 公司價值 300 萬美元的生產線配備了雙灌裝頭,可同時滿足 30 加侖和 110 加侖兩種規格的桶裝產品需求,這反映了買家對多容量柔軟性的需求。受無托盤機器人搬運單元日益普及的推動,預計到 2031 年,容量超過 100 加侖的工業桶裝產品市場規模將達到 45.5 億美元。

小型桶用於盛裝特殊香精、活性藥物原料藥和實驗室試劑,在這些情況下,批次分離比散裝經濟性更為重要。然而,隨著直接從儲罐填充的微型混合設備的引入,減少了現場中間庫存,小型桶的市場佔有率正在下降。總體而言,容量的選擇反映了操作安全、貨物利用率以及空運對每件包裝單位允許品質的監管限制之間的權衡。

區域分析

2025年,亞太地區貢獻了39.55%的收入,主要得益於中國的裂解裝置計劃和印度的化學發展藍圖。 Balmer Lawrie利用其八家工廠,並與國內農業化學品出口商簽訂了契約,實現了233.9億印度盧比(約2.808億美元)的銷售額。地方政府為煉油廠走廊附近的包裝產業叢集提供土地折扣,這有助於加快交貨速度並減少運輸過程中的凹痕損壞。

北美受益於頁岩原料,並受到美國交通部 (DOT) 的嚴格監管,推動了對高規格鋼桶的需求。康明斯的可回收系統展示了美國原始設備製造商 (OEM) 如何將包裝內部化以提高循環利用率。歐洲正致力於遵守《包裝和包裝廢棄物法規》規定的循環經濟,並計劃從 2023 年起將其試點租賃規模擴大三倍,主要用於食品和個人護理原料。南美、中東和非洲雖然規模較小,但成長迅速。巴西生物柴油出口商正在轉向複合材料桶以減少大豆油氧化,而墨西哥灣沿岸的石化中心則在採購能夠承受極端環境溫度的更厚鋼桶。區域間的貨物套利也促進了鋼桶回收網路的發展,並加強了工業鋼桶市場的全球合作。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 增加化學和石油化學產品的產量

- 擴大食品級出口物流

- 加強供應鏈韌性的必要性

- 逐步淘汰一次性散裝袋

- 循環經濟中的租賃與再製造模式

- 採用RFID技術的油桶追蹤系統,符合危險物品法規

- 市場限制

- 原物料價格波動

- 遵守與廢棄物處理相關的環境法規的成本

- 利用IBC和軟性罐進行自我改造

- 現場微混合減少了對攪拌桶的需求

- 產業價值鏈分析

- 監管環境

- 技術展望

- 波特五力分析

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 競爭對手之間的競爭

- 替代品的威脅

- 宏觀經濟因素如何影響市場

第5章 市場規模與成長預測

- 材料

- 鋼鼓

- 塑膠桶

- 紙板桶

- 複合/混合鼓

- 按產能

- 少於30加侖

- 30至60加侖

- 60至100加侖

- 超過100加侖

- 按封閉類型

- 緊頭/封閉式頭

- 開頭

- 按最終用戶行業分類

- 化學品和肥料

- 石油和潤滑油

- 食品/飲料

- 製藥

- 油漆、塗料、黏合劑

- 建築/施工

- 其他終端用戶產業

- 按地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 南美洲

- 巴西

- 阿根廷

- 智利

- 其他南美洲

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 其他歐洲地區

- 亞太地區

- 中國

- 日本

- 印度

- 韓國

- 澳洲

- 亞太其他地區

- 中東和非洲

- 中東

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 土耳其

- 其他中東地區

- 非洲

- 南非

- 奈及利亞

- 肯亞

- 其他非洲地區

- 中東

- 北美洲

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率分析

- 公司簡介

- Greif, Inc.

- Mauser Packaging Solutions Holding Company

- SCHUTZ GmbH & Co. KGaA

- Time Technoplast Ltd.

- Balmer Lawrie & Co. Ltd.

- Sicagen India Ltd.

- TPL Plastech Ltd.

- Peninsula Drums(Pty)Ltd.

- Eagle Manufacturing Company(Justrite Safety Group)

- US Coexcell Inc.

- Industrial Container Services, Inc.

- Hoover Ferguson Group, Inc.

- Berry Global Group, Inc.

- Brambles Ltd.

- Myers Industries, Inc.

- Orlando Drum & Container Corp.

- Rahway Steel Drum Co., Inc.

- Re-Gen Drums Ltd.

- Palm Containers(Pty)Ltd.

- Schutz DSL(Asia)Pte Ltd.

第7章 市場機會與未來展望

The industrial drums market is expected to grow from USD 14.62 billion in 2025 to USD 15.41 billion in 2026 and is forecast to reach USD 20.06 billion by 2031 at 5.42% CAGR over 2026-2031.

Steady chemical output, rising petrochemical investments, and widening food-grade export flows anchor demand. Regulatory momentum toward reusable packaging, demonstrated by Cummins' RFID-enabled returnable program, reinforces the shift away from single-use bulk bags. Composite drums win share as weight-sensitive shippers pursue corrosion-resistant options, while RFID adoption spreads across hazardous-materials fleets to improve traceability. Asia-Pacific drives volume on the back of China's cracker additions and India's 12% annual chemical growth target through 2030, whereas North America and Europe prioritize premium, compliance-led formats. Consolidation such as Berry Global's 2025 merger with Amcor adds scale advantages that squeeze smaller rivals.

Global Industrial Drums Market Trends and Insights

Growth in Chemical and Petrochemical Output

Robust specialty-chemical builds in China, cracker expansions in the Middle East, and mergers among Japanese majors collectively increase drum throughput requirements. The American Chemistry Council notes sustained resilience in U.S. chemical production despite logistics bottlenecks, while India is targeting 12% compound growth, which keeps drum demand firmly on an upward path. Larger integrated complexes process greater batch sizes, pushing shippers toward 100-plus gallon formats and composite linings that withstand aggressive intermediates. SysKem Chemie ships Class 8 caprylic acid exclusively in coated drums that meet United Nations test codes, illustrating the higher specification trend.

Expansion of Food-Grade Export Logistics

Diversification of ingredient sourcing has lengthened supply chains for sweeteners, plant proteins, and fruit concentrates. CDF Corporation launched USDA-compliant liners in February 2025, showing suppliers' response to stricter contamination thresholds. Harmonized documentation under the Codex Alimentarius enables multi-regional certification, supporting scale economies for manufacturers producing food-grade drums in bulk. Premium organic exporters have begun to pay price differentials for drums embedded with tamper-evident seals and QR-code lineage data, enhancing provenance claims in destination markets.

Raw-Material Price Volatility

Steel and resin swings squeeze margins as drum makers struggle to synchronize contracts with customer price lists. Ryerson's 2025 forecast flags potential anti-dumping duties on Asian hot-rolled coil, adding another layer of unpredictability. Balmer Lawrie is piloting 0.5 mm-wall drums that allow 80 units per TEU, four more than traditional gauges, to offset rising coil costs; at INR 23.39 billion (USD 280.8 million) 2024 sales, the savings are material.

Other drivers and restraints analyzed in the detailed report include:

- Strengthening Supply-Chain Resiliency Needs

- Regulatory Phase-Out of Single-Use Bulk Bags

- Cannibalization by IBCs and Flexitanks

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Steel captured the lion's share at 46.68% because refinery and agrochemical players favor its mechanical strength and straightforward reconditioning loops. At the same time, composite drums are on a 7.21% trajectory as buyers weigh freight savings against initial premiums. Recent audits at Indian ports show that lightweight steel accounted for 37% of outbound haz-chem shipments, underscoring cost reductions from thinner gauges. The industrial drums market benefits from global scrap incentives that make low-alloy steel a closed-loop asset, whereas virgin HDPE resin tracks propylene prices more closely.

Plastic and fiber variants address niche solute compatibility or weight constraints. Although fiber units lack UN credentials for liquids, they now incorporate moisture-resistant liners that extend shelf life for dry food powders. Composite models combine polymer barriers with steel ribs, targeting formulators of moisture-sensitive adhesive ingredients. Their rise illustrates how the industrial drums market evolves through hybridization rather than a binary material switch.

Sixty-to-one-hundred-gallon drums align with forklift clearance and remain the workhorse at 35.21% share. However, fully automated chemical clusters prefer 110-gallon drums that support fewer lifts per ton processed. Through 2031, above-100-gallon formats hold the fastest 6.08% expansion rate. Camco Chemical's USD 3 million line allows dual fill heads for 30 and 110 gallon SKUs, underlining buyers' preference for multi-volume flexibility. The industrial drums market size for capacities beyond 100 gallons is projected to touch USD 4.55 billion by 2031, reflecting wider adoption of palletless robotic handling cells.

Smaller drums serve specialty flavors, pharma actives, and lab reagents where lot segregation trumps bulk economics. Yet their share erodes as tank-to-fill micro-blending units shrink on-site intermediate inventories. Overall, capacity choice mirrors a trade-off between ergonomic safety, freight utilization, and regulatory caps on allowable mass per package in airborne routes.

The Global Industrial Drums Market Report is Segmented by Material (Steel Drum, Plastic Drum, and More), Capacity (Up To 30 Gallons, 30-60 Gallons, and More), Closure Type (Tight-Head/Closed-Head, and Open-Head), End-User Industry (Chemicals and Fertilizers, Petroleum and Lubricants, and More), and Geography (North America, South America, and More). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific contributed 39.55% revenue in 2025, propelled by Chinese cracker projects and India's chemicals roadmap. Balmer Lawrie leveraged eight plants to secure national contracts for agrochemical exporters and logged INR 23.39 billion (USD 280.8 million) turnover. Regional governments offer land rebates for packaging clusters adjacent to refinery corridors, shortening delivery lead times and reducing dent damage.

North America benefits from shale-based feedstock and maintains stringent DOT oversight that drives demand for high-specification steel drums. Cummins' returnable system illustrates how U.S. OEMs internalize packaging for circularity gains. Europe emphasizes circular economy compliance under the Packaging and Packaging Waste Regulation and has seen pilot leasing pools triple since 2023, mostly for food and personal-care ingredients. South America and the Middle East and Africa remain smaller but high-growth nodes. Brazilian biodiesel exporters pivot to composite drums to mitigate soy-oil oxidation, whereas Gulf petrochemical hubs procure thick-gauge steel variants to withstand extreme ambient temperatures. Cross-regional freight arbitrage also stimulates backhaul drum reconditioning networks, reinforcing global linkages within the industrial drums market.

- Greif, Inc.

- Mauser Packaging Solutions Holding Company

- SCHUTZ GmbH & Co. KGaA

- Time Technoplast Ltd.

- Balmer Lawrie & Co. Ltd.

- Sicagen India Ltd.

- TPL Plastech Ltd.

- Peninsula Drums (Pty) Ltd.

- Eagle Manufacturing Company (Justrite Safety Group)

- U.S. Coexcell Inc.

- Industrial Container Services, Inc.

- Hoover Ferguson Group, Inc.

- Berry Global Group, Inc.

- Brambles Ltd.

- Myers Industries, Inc.

- Orlando Drum & Container Corp.

- Rahway Steel Drum Co., Inc.

- Re-Gen Drums Ltd.

- Palm Containers (Pty) Ltd.

- Schutz DSL (Asia) Pte Ltd.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Growth in chemical and petrochemical output

- 4.2.2 Expansion of food-grade export logistics

- 4.2.3 Strengthening supply-chain resiliency needs

- 4.2.4 Regulatory phase-out of single-use bulk bags

- 4.2.5 Circular-economy leasing and re-conditioning models

- 4.2.6 RFID-enabled drum tracking for haz-mat compliance

- 4.3 Market Restraints

- 4.3.1 Raw-material price volatility

- 4.3.2 Environmental compliance cost for disposal

- 4.3.3 Cannibalization by IBCs and flexitanks

- 4.3.4 On-site micro-blending cutting drum demand

- 4.4 Industry Value Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Threat of New Entrants

- 4.7.4 Intensity of Competitive Rivalry

- 4.7.5 Threat of Substitutes

- 4.8 The Impact of Macroeconomic Factors on the Market

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Material

- 5.1.1 Steel Drum

- 5.1.2 Plastic Drum

- 5.1.3 Fiber Drum

- 5.1.4 Composite/Hybrid Drum

- 5.2 By Capacity

- 5.2.1 Up to 30 Gallons

- 5.2.2 30 - 60 Gallons

- 5.2.3 60 - 100 Gallons

- 5.2.4 Above 100 Gallons

- 5.3 By Closure Type

- 5.3.1 Tight-Head / Closed-Head

- 5.3.2 Open-Head

- 5.4 By End-user Industry

- 5.4.1 Chemicals and Fertilizers

- 5.4.2 Petroleum and Lubricants

- 5.4.3 Food and Beverage

- 5.4.4 Pharmaceuticals

- 5.4.5 Paints, Coatings and Adhesives

- 5.4.6 Building and Construction

- 5.4.7 Other End-user Industries

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 South America

- 5.5.2.1 Brazil

- 5.5.2.2 Argentina

- 5.5.2.3 Chile

- 5.5.2.4 Rest of South America

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Spain

- 5.5.3.6 Rest of Europe

- 5.5.4 Asia-Pacific

- 5.5.4.1 China

- 5.5.4.2 Japan

- 5.5.4.3 India

- 5.5.4.4 South Korea

- 5.5.4.5 Australia

- 5.5.4.6 Rest of Asia-Pacific

- 5.5.5 Middle East and Africa

- 5.5.5.1 Middle East

- 5.5.5.1.1 Saudi Arabia

- 5.5.5.1.2 United Arab Emirates

- 5.5.5.1.3 Turkey

- 5.5.5.1.4 Rest of Middle East

- 5.5.5.2 Africa

- 5.5.5.2.1 South Africa

- 5.5.5.2.2 Nigeria

- 5.5.5.2.3 Kenya

- 5.5.5.2.4 Rest of Africa

- 5.5.5.1 Middle East

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Greif, Inc.

- 6.4.2 Mauser Packaging Solutions Holding Company

- 6.4.3 SCHUTZ GmbH & Co. KGaA

- 6.4.4 Time Technoplast Ltd.

- 6.4.5 Balmer Lawrie & Co. Ltd.

- 6.4.6 Sicagen India Ltd.

- 6.4.7 TPL Plastech Ltd.

- 6.4.8 Peninsula Drums (Pty) Ltd.

- 6.4.9 Eagle Manufacturing Company (Justrite Safety Group)

- 6.4.10 U.S. Coexcell Inc.

- 6.4.11 Industrial Container Services, Inc.

- 6.4.12 Hoover Ferguson Group, Inc.

- 6.4.13 Berry Global Group, Inc.

- 6.4.14 Brambles Ltd.

- 6.4.15 Myers Industries, Inc.

- 6.4.16 Orlando Drum & Container Corp.

- 6.4.17 Rahway Steel Drum Co., Inc.

- 6.4.18 Re-Gen Drums Ltd.

- 6.4.19 Palm Containers (Pty) Ltd.

- 6.4.20 Schutz DSL (Asia) Pte Ltd.

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-Need Assessment