|

市場調查報告書

商品編碼

1910679

工業橡膠:市場佔有率分析、產業趨勢與統計、成長預測(2026-2031)Industrial Rubber - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

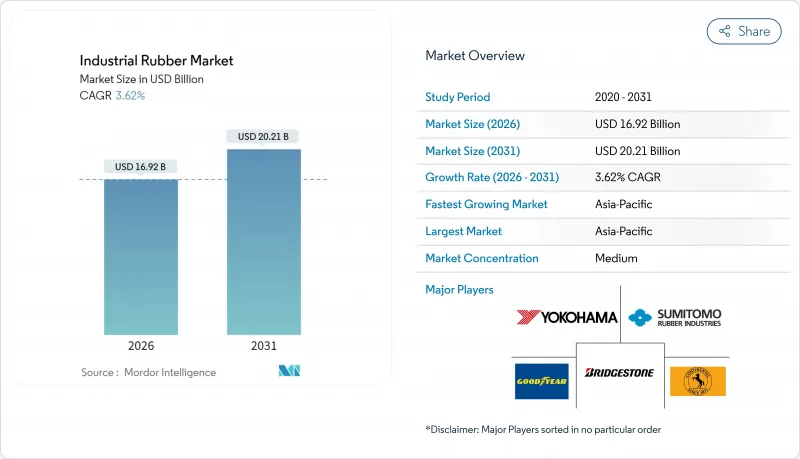

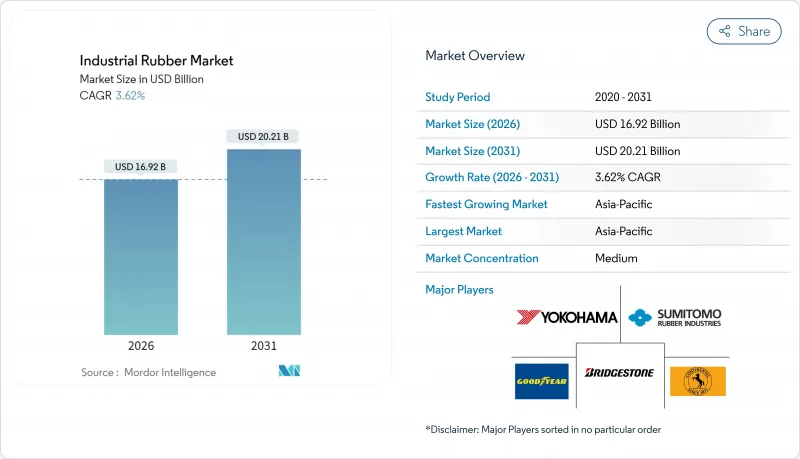

預計工業橡膠市場規模將從 2025 年的 163.3 億美元成長到 2026 年的 169.2 億美元,到 2031 年將達到 202.1 億美元,2026 年至 2031 年的複合年成長率為 3.62%。

汽車、建築、採礦和一般工業供應鏈對橡膠需求仍然強勁,合成橡膠憑藉其穩定的品質和規模優勢,持續推動橡膠市場的發展。輸送系統、傳動設備和高壓軟管組件繼續成為銷售的主要驅動力,而生物基和再生橡膠替代品則穩步擴大了潛在需求。原油衍生原料價格波動和天然橡膠短缺影響橡膠供應的穩定性,能夠平衡原料選擇和回收能力的生產商可以降低收入波動。亞太地區佔了市場的大部分佔有率,並受益於其集中的上游原料基地和下游製造地;而北美和歐洲則憑藉特種橡膠和監管方面的領先優勢脫穎而出。

全球工業橡膠市場趨勢與洞察

擴充用途:用作傳送帶和傳動帶

輸送和動力傳輸系統是自動化物料搬運策略的基礎,能夠降低營運成本、減少事故發生率並提高能源效率。硬岩礦山、散貨港口和小包裹分揀中心都指定使用多層阻燃輸送帶,即使在超過 200°C 的高溫下也不會加速磨損。改良的橡膠化合物,例如丁腈橡膠混合物和芳香聚醯胺增強材料,與傳統輸送帶相比,可將輸送帶壽命延長高達 25%。領先的製造商正在加速將智慧感測器陣列整合到輸送帶汽車胎體中,預測性維護計劃已將計劃外停機時間減少了約 35%。亞太地區的礦業和建築材料供應商是最大的客戶群體,但北美蓬勃發展的倉庫和歐洲的回收設施也帶來了不斷成長的增值需求。

高壓軟管的需求不斷成長

化學、石油天然氣和先進製造業的擴張推動了對能夠承受極端壓力、快速彎曲和腐蝕性介質的軟管的需求。領先的供應商正在開發氟橡膠、三元乙丙橡膠 (EPDM) 和氫化丁腈橡膠混合物,這些混合物能夠承受超過 300 PSI 的壓力和多種化學品的侵蝕,同時滿足美國食品藥物管理局 (FDA) 和歐盟食品接觸法規的要求。製造商在開發複合材料的同時,也正在開發壓接接頭技術,以縮短組裝時間並提高脈衝循環壽命。諸如Bridgestone在 2024 年收購 Klein Hose & Hydraulics 等策略性收購,標誌著企業正在努力建立產品和服務能力。客製化工程組件、現貨產品和本地認證中心進一步增強了企業在這個多品種、小批量細分市場的競爭優勢。

嚴格的環境法規

美國環保署 (EPA) 加強了輪胎和混合橡膠加工過程中有害空氣污染物排放量限制在每噸 64 克以內,並強制要求工廠在 2027 年前維修。歐洲的反森林砍伐法規要求天然橡膠進口必須完全可追溯,這增加了採購成本和文件負擔。加州對 6PPD 輪胎添加劑的調查引發了關於配方改良的討論,因為人們擔心其耐久性問題。同時,全球逐步淘汰 PFAS 的提案正在推動氟橡膠的開發平臺。合規成本對中小規模的橡膠生產商構成挑戰,但對於率先採用清潔溶劑、閉合迴路清潔系統和生物基原料的企業而言,卻能帶來許多好處。

細分市場分析

合成橡膠(主要為苯乙烯-丁二烯基橡膠)將繼續佔據工業橡膠市場的主導地位,預計到2025年將佔市場佔有率的70.54%,這主要得益於汽車製造商、機械設備製造商和基礎設施建設者對在寬溫度範圍內保持穩定性能的需求。催化劑和工藝的重大創新提高了橡膠的拉伸強度、耐磨性和耐油性,使其性能能夠滿足嚴格的OEM規格要求。從廢棄輪胎和拋光材料中回收的再生橡膠正以4.78%的複合年成長率成長,這主要得益於其與原生材料相比可節省30-50%的成本,以及對循環經濟日益成長的需求。混煉商正在重新設計配方,以在不影響硫化速度的前提下,容納高達25%的再生橡膠含量,有助於減少整體廢棄物。天然橡膠供應對於搭乘用輪胎的耐用性和重型越野車的抓地力仍然至關重要,但東南亞的生產商正面臨著因病害導致的產量下降問題。由植物來源的生物基合成橡膠(特別是生物丁二烯和聚異戊二烯)正在進行中試規模測試,有望緩解資源壓力並減少碳足跡。

到2025年,擠出成型將佔據工業橡膠市場44.70%的佔有率,尤其適用於軟管、型材和密封條的連續生產,這些產品對尺寸精度和廢品率要求極高。現代螺桿設計可將產量提高15%,而即時黏度監測系統則可加快換模速度。射出成型成型和壓縮成型受益於多腔模具和自動脫模機器人,在汽車襯套和隔振裝置的大量生產中仍然發揮關鍵作用。積層製造作為一項新興技術,預計將以4.05%的複合年成長率實現最快成長,其利用3D列印熱塑性聚氨酯晶格製造輕量化、複雜形狀的零件,應用於航太、國防和醫療領域。光聚合異戊二烯樹脂的進步使得斷裂伸長率超過200%的彈性體零件成為可能,並將功能原型生產時間從數週縮短至數天。壓延製程憑藉精密輥壓系統提供的精確厚度控制,持續為特種板材市場、屋頂膜材、儲槽襯裡和隔膜板提供支援。

區域分析

預計到2025年,亞太地區將佔據工業橡膠市場58.60%的佔有率,年複合成長率達4.00%。這得歸功於從人工林到橡膠化合物的完整供應鏈、大規模的輪胎生產能力以及廣泛的基礎設施規劃。在中國,電動車的普及(約佔新車銷售的三分之一)正在推動對特種輪胎和密封膠的需求。泰國和印尼的天然橡膠產量佔全球總產量的60%以上,但病蟲害爆發和勞動力短缺給產量帶來了壓力。兩國政府正透過機械化支持樹液採集和下游加工的現代化。印度正透過擴大國內橡膠化合物生產廠規模和推廣再生橡膠回收網路來改善其進出口平衡。

北美經濟維持約5%的年成長率,這主要得益於航太、頁岩能源和物流基礎建設的推動。美國約90%的天然橡膠需求依賴進口,而關於國內銀膠菊種植的政策討論正在升溫,以增強供應的韌性。在加拿大,關鍵礦產開採的擴張帶動了對傳送帶和軟管的需求,而墨西哥則正吸引原始設備製造商(OEM)的投資,以使其供應鏈更靠近美國消費區。

歐洲的需求結構正受到嚴格的環境法規和生物基材料快速商業化的影響。歐盟的反森林砍伐法規要求橡膠進口必須可追溯,並鼓勵貿易商採用電子帳簿。德國和法國率先引入了蒲公英天然橡膠試點農場,與東南亞橡膠相比,減少了運輸排放。東歐的輪胎工廠正獲得大量資金注入,用於在國內生產大尺寸電動車輪胎,從而在運輸不確定性加劇的情況下減少對亞洲進口的依賴。

隨著基礎設施計劃開闢新的需求通道,拉丁美洲和中東/非洲在全球市場的佔有率正穩步成長。巴西已恢復公共工程支出,主要用於橋樑維修和港口擴建,從而推動了對橡膠軸承和軟管組件的需求。波灣合作理事會(GCC)正在加速擺脫對油氣的依賴,實現經濟多元化,其石化聯合企業指定使用耐酸性氣體的三元乙丙橡膠(EPDM)密封件和丁腈橡膠軟管。撒哈拉以南非洲的銅礦和鋰礦開採前景支撐了對輸送帶的需求,但計劃開發取決於政治穩定和資金籌措管道。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 擴展用途,用作傳送帶和動力傳輸帶

- 高壓軟管的需求不斷成長

- 電動主導對輕量化汽車零件的需求正在成長。

- 新興國家基礎建設發展進展

- 向生物基合成橡膠過渡

- 市場限制

- 嚴格的環境法規

- 原物料價格波動與原油價格相關

- 再生橡膠的迅速普及正在蠶食新的需求。

- 價值鏈分析

- 波特五力模型

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

第5章 市場規模與成長預測

- 按橡膠類型

- 天然橡膠

- 合成橡膠

- 再生橡膠

- 透過流程

- 擠出成型

- 模具和鑄造

- 日曆管理

- 3D列印/積層製造

- 透過使用

- 輸送機

- 動力傳動帶

- 高壓軟管

- 其他用途(屋頂材料、管材、捲材等)

- 按最終用戶行業分類

- 汽車/運輸設備

- 建築和基礎設施

- 採礦和金屬

- 工業機械及設備

- 化工/石油化工

- 航太/國防

- 電氣和電子設備

- 其他

- 按地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 泰國

- 印尼

- 越南

- 馬來西亞

- 菲律賓

- 亞太其他地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 俄羅斯

- 北歐國家

- 土耳其

- 其他歐洲地區

- 南美洲

- 巴西

- 阿根廷

- 哥倫比亞

- 南美洲其他地區

- 中東和非洲

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 卡達

- 南非

- 奈及利亞

- 埃及

- 其他中東和非洲地區

- 亞太地區

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率(%)/排名分析

- 公司簡介

- Bando Chemical Industries, LTD.

- Bridgestone Industrial

- China Petrochemical Corporation(Sinopec)

- ContiTech Deutschland GmbH

- Denka Company Limited

- ENEOS Materials Corporation

- Parker Hannifin Corp

- SIBUR Holding PJSC

- Sumitomo Rubber Industries, Ltd.

- The Goodyear Tire & Rubber Company

- THE YOKOHAMA RUBBER CO., LTD.

- Trelleborg AB

- Trinseo

- TSRC

- UBE Corporation

第7章 市場機會與未來展望

The industrial rubber market is expected to grow from USD 16.33 billion in 2025 to USD 16.92 billion in 2026 and is forecast to reach USD 20.21 billion by 2031 at 3.62% CAGR over 2026-2031.

Demand remains firmly anchored in automotive, construction, mining and general-industrial supply chains, with synthetic grades supplying consistent quality and scale advantages. Conveyor systems, transmission equipment and high-pressure hose assemblies continue to pull large volumes, while bio-based and reclaimed alternatives steadily widen addressable demand. Supply-side resilience is shaped by volatile crude-derived feedstocks and natural-rubber shortages; producers that balance raw-material optionality with recycling capabilities reduce earnings volatility. Asia-Pacific, holding a decisive majority share, benefits from integrated upstream raw-material bases and downstream manufacturing density, whereas North America and Europe differentiate through specialty rubber grades and regulatory compliance leadership.

Global Industrial Rubber Market Trends and Insights

Increasing application as conveyor & transmission belts

Conveyor and transmission systems underpin automated material-handling strategies that lower operating costs, cut accident frequency and boost energy efficiency. Hard-rock mining, bulk-cargo ports and parcel-sorting hubs specify multi-ply, flame-retardant belts that handle temperatures exceeding 200 °C without accelerated abrasion. Upgraded rubber compounds, often nitrile-blended or aramid-reinforced, extend belt life by up to 25% compared with conventional compounds. Major producers increasingly integrate smart-sensor arrays into belt carcasses, enabling predictive-maintenance programs that reduce unscheduled downtime by nearly 35%. Asia-Pacific miners and construction material suppliers represent the largest customer pool, but value-added demand is rising in North America's warehousing boom and Europe's recycling facilities.

Growing demand for high-pressure hoses

Expanding chemical, oil-and-gas and advanced-manufacturing activity elevates the need for hoses that tolerate extreme pressure, rapid flexing and aggressive media. Leading suppliers formulate fluoroelastomer, EPDM and hydrogenated nitrile blends to withstand over 300 PSI and multi-chemical exposure while meeting FDA and EU food-contact regulations. Producers complement compound development with crimp-coupling innovations that shorten assembly times and improve impulse-cycle life. Strategic acquisitions-such as Bridgestone's 2024 purchase of Cline Hose & Hydraulics-illustrate the push to own both product and service footprints. Custom-engineered assemblies, ship-to-stock delivery models and local certification centers round out competitive advantages in this high-mix application space.

Stringent environmental regulations

The U.S. EPA tightened National Emission Standards for Hazardous Air Pollutants in tire and mixed-rubber processing, capping volatile organics at 64 g per tonne and compelling plant retrofits by 2027. Europe's Deforestation Regulation obliges full traceability for natural-rubber imports, raising procurement costs and documentation burdens. California's investigation into 6PPD tire additives forces compound reformulation discussions amid durability concerns, while global proposals to phase out PFAS push fluoroelastomer R&D pipelines. Compliance outlays challenge smaller compounders but reward early adopters of cleaner solvents, closed-loop wash systems and bio-based feedstocks.

Other drivers and restraints analyzed in the detailed report include:

- EV-led boom in lightweight automotive components

- Infrastructure build-out in emerging economies

- Volatile crude-oil-linked feedstock prices

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Synthetic grades, dominated by styrene-butadiene, retained a commanding 70.54% share of the industrial rubber market in 2025 as automakers, machinery OEMs and infrastructure builders demanded consistent performance across broad temperature windows. Extensive catalyst and process innovations boost tensile strength, abrasion resistance and oil tolerance, aligning properties with stringent OEM specifications. Reclaimed rubber, harvested from devulcanized end-of-life tires and buffings, expands at a 4.78% CAGR on the back of 30-50% cost savings versus virgin feedstocks and mounting circular-economy mandates. Compounders re-engineer formulations to accommodate reclaimed content of up to 25% without compromising cure kinetics, thereby moderating overall scrap. Natural-rubber supply remains central to passenger-tire elasticity and heavy-haul off-road grip, yet producers wrestle with disease-related yield drops in Southeast Asia. Bio-based synthetic routes, particularly bio-butadiene and polyisoprene from plant sugars, advance pilot-scale trials that promise to ease resource pressures while shrinking carbon footprints.

Extrusion held 44.70% share of the industrial rubber market size in 2025, favored for continuous production of hoses, profiles and sealing strips where dimensional accuracy and low scrap rates are critical. State-of-the-art screw designs increase throughput 15% and support real-time viscosity monitoring systems that cut change-over time. Injection and compression molding retain vital roles for high-volume automotive bushings and vibration isolators, benefitting from multi-cavity tooling and automated demolding robotics. Additive manufacturing, while only emerging, records the fastest 4.05% CAGR as aerospace, defense and medical users exploit 3D-printed thermoplastic polyurethane lattices for lightweight, complex geometries. Advances in photopolymerizable isoprene resins yield elastomeric parts with elongation at break surpassing 200%, bringing functional prototypes within days rather than weeks. Calendaring sustains specialty sheet markets, roofing membranes, tank linings and diaphragm sheets, thanks to microscopic gauge control afforded by precision-roll systems.

The Industrial Rubber Market Report is Segmented by Rubber Type (Natural Rubber, Synthetic Rubber, and More), Process (Extrusion, Molding and Casting, and More), Application (Conveyor Belts, Transmission Belts, and More), End-User Industry (Automotive and Transportation, Construction and Infrastructure, and More), and Geography (Asia-Pacific, North America, and More). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific retained 58.60% share of the industrial rubber market in 2025 and is advancing at a 4.00% CAGR, underscored by its integrated plantation-to-compound supply chains, large-scale tire capacities, and vast infrastructure programs. China drives demand through EV adoption rates approaching one-third of new car sales, heightening traction for specialty tire and sealing compounds. Thailand and Indonesia together account for more than 60% of global natural-rubber output, but yields are strained by disease incidence and labor shortages, prompting government support for mechanized tapping and downstream processing upgrades. India tightens its import-export balance by expanding domestic mixing houses and encouraging reclaimed-rubber collection networks.

North America sustains mid-single-digit growth anchored in aerospace, shale-energy and logistics construction. The U.S. imports roughly 90% of its natural-rubber needs, sparking policy discourse around domestic guayule cultivation to improve supply resilience. Canada's mining expansion in critical minerals feeds conveyor-belt and hose demand, while Mexico captures OEM investments relocating supply chains closer to U.S. consumer bases.

Europe's demand profile is shaped by strict environmental regulations and rapid commercialization of bio-based materials. The EU Deforestation Regulation compels traceability for rubber imports, catalyzing digital ledger adoption among traders. Germany and France pioneer dandelion-based natural-rubber pilot farms that lower transport emissions compared with Southeast-Asian supply. Eastern European tire plants receive significant capital infusions to produce larger-rim EV tires domestically, reducing reliance on Asian imports amid shipping volatility.

Latin America and Middle East & Africa collectively contribute a modest but rising share as infrastructure projects launch new demand corridors. Brazil restarts public-works spending focused on bridge retrofits and port expansion, increasing calls for rubber bearings and hose assemblies. The Gulf Cooperation Council accelerates industrial diversification beyond hydrocarbons, with petrochemical complexes specifying EPDM seals and nitrile hoses resistant to sour gas exposure. Sub-Saharan African mining prospects in copper and lithium underpin conveyor-belt demand, yet project rollouts hinge on political stability and financing access.

- Bando Chemical Industries, LTD.

- Bridgestone Industrial

- China Petrochemical Corporation (Sinopec)

- ContiTech Deutschland GmbH

- Denka Company Limited

- ENEOS Materials Corporation

- Parker Hannifin Corp

- SIBUR Holding PJSC

- Sumitomo Rubber Industries, Ltd.

- The Goodyear Tire & Rubber Company

- THE YOKOHAMA RUBBER CO., LTD.

- Trelleborg AB

- Trinseo

- TSRC

- UBE Corporation

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions & Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Increasing application as conveyor & transmission belts

- 4.2.2 Growing demand for high-pressure hoses

- 4.2.3 EV-led boom in lightweight automotive components

- 4.2.4 Infrastructure build-out in emerging economies

- 4.2.5 Shift to bio-based synthetic rubbers

- 4.3 Market Restraints

- 4.3.1 Stringent environmental regulations

- 4.3.2 Volatile crude-oil-linked feedstock prices

- 4.3.3 Rapid uptake of reclaimed rubber cannibalising virgin demand

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Degree of Competition

5 Market Size & Growth Forecasts (Value)

- 5.1 By Rubber Type

- 5.1.1 Natural Rubber

- 5.1.2 Synthetic Rubber

- 5.1.3 Reclaimed Rubber

- 5.2 By Process

- 5.2.1 Extrusion

- 5.2.2 Molding and Casting

- 5.2.3 Calendaring

- 5.2.4 3-D Printing / Additive Manufacturing

- 5.3 By Application

- 5.3.1 Conveyor Belts

- 5.3.2 Transmission Belts

- 5.3.3 Pressure Hoses

- 5.3.4 Other Application (Roofing, Tubes, Rolls, etc.)

- 5.4 By End-User Industry

- 5.4.1 Automotive and Transportation

- 5.4.2 Construction and Infrastructure

- 5.4.3 Mining and Metals

- 5.4.4 Industrial Machinery and Equipment

- 5.4.5 Chemical and Petrochemical

- 5.4.6 Aerospace and Defence

- 5.4.7 Electrical and Electronics

- 5.4.8 Others

- 5.5 By Geography

- 5.5.1 Asia-Pacific

- 5.5.1.1 China

- 5.5.1.2 India

- 5.5.1.3 Japan

- 5.5.1.4 South Korea

- 5.5.1.5 Thailand

- 5.5.1.6 Indonesia

- 5.5.1.7 Vietnam

- 5.5.1.8 Malaysia

- 5.5.1.9 Philippines

- 5.5.1.10 Rest of Asia-Pacific

- 5.5.2 North America

- 5.5.2.1 United States

- 5.5.2.2 Canada

- 5.5.2.3 Mexico

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Spain

- 5.5.3.6 Russia

- 5.5.3.7 NORDIC Countries

- 5.5.3.8 Turkey

- 5.5.3.9 Rest of Europe

- 5.5.4 South America

- 5.5.4.1 Brazil

- 5.5.4.2 Argentina

- 5.5.4.3 Colombia

- 5.5.4.4 Rest of South America

- 5.5.5 Middle East and Africa

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 United Arab Emirates

- 5.5.5.3 Qatar

- 5.5.5.4 South Africa

- 5.5.5.5 Nigeria

- 5.5.5.6 Egypt

- 5.5.5.7 Rest of Middle East and Africa

- 5.5.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share(%)/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products & Services, and Recent Developments)

- 6.4.1 Bando Chemical Industries, LTD.

- 6.4.2 Bridgestone Industrial

- 6.4.3 China Petrochemical Corporation (Sinopec)

- 6.4.4 ContiTech Deutschland GmbH

- 6.4.5 Denka Company Limited

- 6.4.6 ENEOS Materials Corporation

- 6.4.7 Parker Hannifin Corp

- 6.4.8 SIBUR Holding PJSC

- 6.4.9 Sumitomo Rubber Industries, Ltd.

- 6.4.10 The Goodyear Tire & Rubber Company

- 6.4.11 THE YOKOHAMA RUBBER CO., LTD.

- 6.4.12 Trelleborg AB

- 6.4.13 Trinseo

- 6.4.14 TSRC

- 6.4.15 UBE Corporation

7 Market Opportunities & Future Outlook

- 7.1 White-space & unmet-needs assessment

- 7.2 Introducing New Manufacturing Techniques to Reduce Hazardous Waste