|

市場調查報告書

商品編碼

1910530

鹽酸:市場佔有率分析、產業趨勢與統計、成長預測(2026-2031)Hydrochloric Acid - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

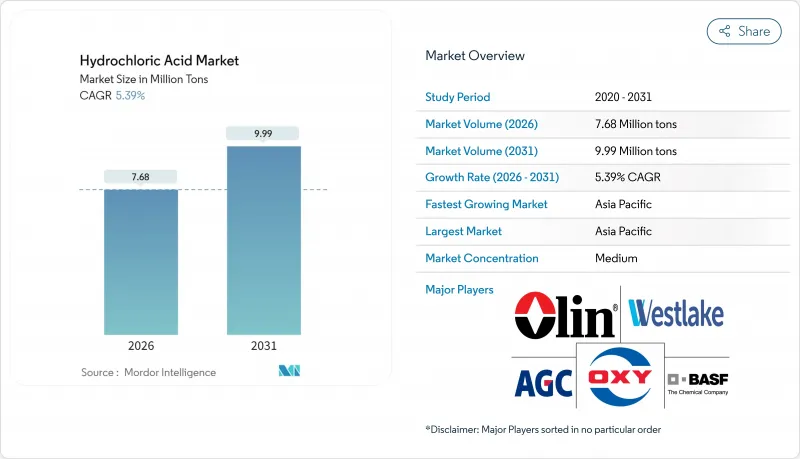

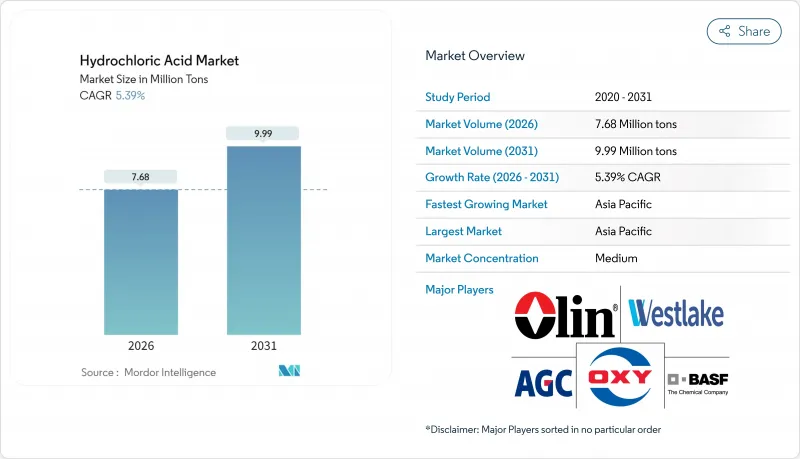

預計到 2026 年,鹽酸市場規模將達到 768 萬噸,高於 2025 年的 729 萬噸。預計到 2031 年,市場規模將達到 999 萬噸,2026 年至 2031 年的複合年成長率為 5.39%。

該化合物在油氣井增產處理、半導體製造、水處理以及眾多中間體合成中的效用,為全球需求提供了堅實支撐。鹽酸的雙重作用確保了其供應的穩定性:它既是專用裝置的主要產品,也是氯鹼電解的輔助產品,這使得生產商能夠靈活應對苛性鈉和氯循環的波動。儘管墨西哥灣沿岸停產和亞洲半導體產能擴張會吸收部分現貨需求,造成短期供應緊張,但憑藉規模經濟、可靠的原料供應和分散的物流網路,一體化生產商在長期合約市場仍保持優勢。

全球鹽酸市場趨勢及展望

油氣井增產需求激增

傳統型油氣儲存的開發為鹽酸市場奠定了堅實的基礎,壓裂和基質酸處理計畫推動了這個市場的發展。作業者使用濃度在15%至28%之間的酸來溶解碳酸鹽、重新開啟堵塞的射孔並延長油井壽命。在二疊紀盆地和阿曼進行的現場測試表明,與未經處理的儲存井相比,處理後的油井流量提高了18%。乳化和延遲酸處理技術使得在高溫深層地層中作業成為可能,從而擴大了傳統上難以開採的油藏對鹽酸的需求。綜合服務公司現在將腐蝕抑制劑、除鐵劑和界面活性劑打包出售,雖然增加了油井成本,但提高了基質滲透效率,間接提高了單井鹽酸消費量。隨著頁岩油生產商實施增產技術以抵消自然衰減曲線,儘管新完井數量下降,但鹽酸的基準採購量仍在增加,預計這種成長趨勢至少會持續到2029年。

水處理和食品加工中的衛生需求

由於鹽酸在常用劑量下不會產生氯酸鹽或溴酸鹽等副產物,因此地方政府和食品加工商繼續採用鹽酸進行pH值調節和二氧化氯生成。澳洲飲用水指南強制要求使用鹽酸進行絮凝和軟化,這反映了全球監管機構的普遍認可。在肉類加工和乳製品生產線中,電解水系統將鹽與稀鹽酸混合,現場生成次氯酸。這可在不到60秒的時間內實現5個對數單位的細菌減少,並將殘留氯化物含量保持在1 ppm以下,符合潔淨標示的要求。小規模加工商則採用滑座式電解按需產生10-15%的鹽酸,進而降低酸的運輸成本(最高可達150美元/噸)。

工人安全與環境毒理學法規

美國職業安全與健康管理局 (OSHA) 將 15 分鐘容許暴露限值收緊至 2 ppm,要求鋼鐵廠和食品廠升級局部排氣通風系統和耐酸地板材料,導致每個場所的合規相關資本投資增加 20 萬至 50 萬美元。歐洲化學品管理局的候選清單遴選程序將高氯化物含量的廢物流置於嚴格審查之下,迫使生產商證明其在整個生產過程中都採取了負責任的管理措施,否則將面臨認證障礙。德國和義大利的小規模鍍鋅廠已開始將酸洗製程外包給第三方承包商,而不是維修其老化的酸洗槽,從而減少了直接購買酸的需求。

細分市場分析

工業級產品是鋼材酸洗、氧化鋁分解和大宗有機合成的關鍵試劑,在2025年佔鹽酸出貨量的52.90%。這一細分市場保護了鹽酸市場免受高純度下游產品週期性疲軟的影響。即使在2024年半導體產業調整期間,建築用鋼的訂單也維持了工業級鹽酸出貨量的正成長。濃度為33-35%的鹽酸在細分市場,特別是內陸油田,保持需求,因為在這些地區,單位酸度的運輸成本決定了採購量。超高純度產品僅佔供應量的4.14%,但其價格溢價超過普通級產品的12倍,佔總價值的18%。在亞洲晶圓廠擴張的帶動下,超高純度鹽酸市場預計將以5.71%的複合年成長率成長,到2031年達到38.9萬噸。

數字背後,等級體係正在改變。在歐洲三個工廠維修節能型膜電解槽,使變動成本降低了28%,並在無需新增資本投資的情況下,巧妙地突破了工業級到電子級之間的瓶頸。 De Nora公司的雙極板電極將每噸35%鹽酸的單位能耗降低至2000千瓦時,為剩餘工業廢液的升級改造開闢了道路。此外,該綜合煉油廠還安裝了真空蒸餾塔,從先前被視為中和廢酸的酸中回收了價值。

鹽酸市場報告按等級(工業級、濃縮級、超純級)、終端用戶行業(化學、石油天然氣、鋼鐵冶金、食品飲料、紡織皮革及其他終端用戶行業)和地區(亞太、北美、歐洲、南美、中東和非洲)進行細分。市場預測以噸為單位。

區域分析

中國在亞太地區的主導地位歸功於其覆蓋Delta和Delta的氯鹼一體化生產網路。此網路不僅為自用提供鹽酸,還為氯乙烯、聚碳酸酯和環氧氯丙烷生產線提供原料。中國的「雙重替代」計畫淘汰了汞電解槽,同時核准了一個膜分離計劃,該項目每年可生產超過300萬噸鹽酸,從而實現了區域自給自足。印度阿圖爾化學公司(Atul Chemicals)的投資使該地區每天新增100噸商用鹽酸,降低了該地區對海灣地區昂貴進口鹽酸的依賴。韓國和台灣透過與半導體生產指數掛鉤的長期合約採購高純度鹽酸,這種避險結構在大宗化學品領域較為罕見。

在北美,受提高石油採收率技術推廣的宣傳活動,壓裂酸的需求穩定成長。颶風艾達暴露了該行業的脆弱性。其三次登陸導致美國沿岸地區超過80%的氯鹼名目產能停產,現貨價格指數在不到兩週的時間內飆升了40%。地域多元化是關鍵的因應措施。 Chloram Solutions公司在亞利桑那州卡薩格蘭德投資7000萬美元建造了一座膜分離裝置,以供應西部石化和礦業叢集。能源緊張的歐洲正在轉向更高價值的應用,例如PFAS樹脂回收和醫藥中間體。預計2025年經由安特衛普-鹿特丹港的進口量將成長12%,加拿大產量將填補德國電解運作下降期間的季節性供不應求。東歐的鍍鋅鋼生產商繼續採購大宗商品級氯鹼,但正在投資建造零排放酸洗設施,以符合更嚴格的氯化物排放法規。由於採礦、油砂和海水淡化計劃的增加,南美洲、中東和非洲的石油產量雖小規模但正在成長。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 油氣井增產需求激增

- 水處理和食品加工中的衛生需求

- 用於先進製程(蝕刻)的半導體級鹽酸

- PFAS去除樹脂再生要求

- 鋰離子電池回收浸出化學

- 市場限制

- 工人安全與環境毒理學法規

- 氯鹼產品價格波動

- 酸洗浴中有機酸的替代品

- 價值鏈分析

- 波特五力模型

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

第5章 市場規模與成長預測

- 按年級

- 產業

- 集中

- 超高純度

- 按最終用戶行業分類

- 化學

- 石油和天然氣

- 鋼鐵冶金

- 食品/飲料

- 紡織品和皮革

- 其他終端用戶產業

- 按地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 東南亞國協

- 亞太其他地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 俄羅斯

- 北歐國家

- 其他歐洲地區

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 其他中東和非洲地區

- 亞太地區

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率(%)/排名分析

- 公司簡介

- AGC Inc.

- BASF SE

- Coogee

- Covestro AG

- Detrex Corporation

- DONGYUE GROUP

- ERCO Worldwide

- Ercros SA

- INEOS Group

- Jones-Hamilton Co.

- Merck KGaA

- Occidental Petroleum Corporation(OxyChem)

- Olin Corporation

- TOAGOSEI CO.,LTD.

- Vynova Group

- Westlake Corporation

第7章 市場機會與未來展望

Hydrochloric Acid Market size in 2026 is estimated at 7.68 Million tons, growing from 2025 value of 7.29 Million tons with 2031 projections showing 9.99 Million tons, growing at 5.39% CAGR over 2026-2031.

The compound's utility in oil-and-gas well stimulation, semiconductor fabrication, water treatment, and countless intermediate syntheses places a durable floor under global demand. Supply resilience derives from the dual role hydrochloric acid plays: it is both a primary product in dedicated units and a co-product of chlor-alkali electrolyzers, giving producers flexibility to respond to shifts in caustic-soda and chlorine cycles. Short-term tightness appears whenever Gulf-Coast outages or Asian semiconductor expansions absorb spot volumes, yet integrated producers continue to dominate long-term contracts thanks to scale economics, secure feedstock access, and distributed logistics networks.

Global Hydrochloric Acid Market Trends and Insights

Oil and Gas Well-Stimulation Demand Surge

Unconventional oil and gas reservoir development keeps the hydrochloric acid market firmly anchored to fracturing and matrix-acidizing programs. Operators employ 15%-28% acid concentrations to dissolve carbonates, reopen plugged perforations, and extend well life; field trials in the Permian and in Oman show 18% higher flow rates versus untreated offsets. Emulsified-acid and retarded-acid chemistries allow work in high-temperature, deep formations, pushing demand into reservoirs once considered too challenging. Integrated service companies now bundle corrosion inhibitors, iron controllers, and surfactants that raise well-cost line items but improve matrix penetration efficiency, indirectly lifting per-well HCl consumption. As shale producers pursue enhanced oil recovery to offset natural decline curves, baseline purchasing volumes rise despite fewer new completions, sustaining volume growth through at least 2029.

Water-Treatment and Food-Processing Hygiene Needs

Municipal utilities and food processors continue adopting HCl for pH adjustment and chlorine-dioxide generation because the acid leaves no chlorate or bromate by-products at typical dosing rates. Australia's drinking-water guidelines codify its use for coagulation and softening, reflecting worldwide regulatory acceptance. In meat-packing and dairy lines, electrolyzed-water systems combine salt and dilute HCl to form on-site hypochlorous acid that delivers five-log bacterial reductions in under 60 seconds while leaving sub-1 ppm residual chloride, satisfying clean-label expectations. Smaller processors embrace skid-mounted electrolyzers that generate 10-15% HCl on demand, cutting transport-cost premiums of up to USD 150 per ton for packaged acid.

Worker-Safety and Environmental-Toxicity Regulations

OSHA's tightened permissible-exposure limit of 2 ppm over 15 minutes compels steel mills and food plants to upgrade local exhaust ventilation and acid-proof flooring, raising compliance capex by USD 200,000-USD 500,000 per site. The European Chemical Agency's candidate-list process channels scrutiny toward chloride-rich waste streams, obliging producers to demonstrate cradle-to-gate stewardship or face authorization hurdles. Smaller galvanizers in Germany and Italy now outsource pickling to third-party tollers rather than retrofit aging on-site tanks, trimming direct acid purchases.

Other drivers and restraints analyzed in the detailed report include:

- Semiconductor-Grade HCl for Advanced Node Etching

- PFAS-Removal Resin Regeneration Requirements

- Chlor-Alkali Co-Product Price Volatility

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Industrial-grade product anchored 52.90% of 2025 shipments as the workhorse reagent for steel pickling, alumina digestion, and bulk organic synthesis. The segment cushioned the hydrochloric acid market against cyclical softness in high-purity downstreams: even during 2024's semiconductor correction, construction steel orders kept industrial-grade volumes positive. Concentrated 33%-35% grades retain niche appeal where freight cost per unit of acidity dictates sourcing, especially in inland oilfields. Ultra-high-purity supply, although just 4.14% of tonnage, now captures 18 % of total value thanks to premium pricing that exceeds commodity grades by 12-fold. The hydrochloric acid market size for ultra-high-purity is projected to reach 389 kt in 2031 on a 5.71% CAGR anchored in Asia's fab expansions.

Behind headline numbers, the grade hierarchy is fluid. Energy-efficient membrane-cell retrofits at three European sites shaved variable cost by 28%, enabling strategic debottlenecking from industrial to electronic quality without new greenfield units. De Nora's bipolar-plate electrodes reduced specific power consumption to 2 000 kWh per ton of 35% HCl, opening space to upgrade surplus industrial streams. Integrated refineries also deploy vacuum-distillation polishing columns, capturing value from what was formerly neutralized waste acid.

The Hydrochloric Acid Market Report is Segmented by Grade (Industrial, Concentrated, and Ultra-High Purity), End-User Industry (Chemical, Oil and Gas, Steel and Metallurgy, Food and Beverage, Textiles and Leather, and Other End-User Industries), and Geography (Asia-Pacific, North America, Europe, South America, and Middle East and Africa). The Market Forecasts are Provided in Terms of Volume (Tons).

Geography Analysis

Asia-Pacific's leadership stems from the integrated chlor-alkali grids along the Yangtze and Pearl River Deltas, where captive hydrochloric acid volumes feed vinyl chloride, polycarbonate, and epichlorohydrin lines. China's dual-replacement program has shut mercury-cell units yet simultaneously green-lighted membrane projects topping 3 million tpa HCl co-product, locking in regional self-reliance. India's Atul Ltd. investment added 100 TPD of merchant acid, cutting western-India's dependence on high-freight Gulf imports. Korea and Taiwan draw in high-purity barrels via term contracts that link to semiconductor output indexes, a hedging structure seldom seen in bulk chemicals.

North America posts steady growth where enhanced-oil-recovery campaigns require stable fracturing acid volumes. Hurricane Ida spotlighted vulnerability: three successive landfalls shuttered more than 80% of U.S. Gulf Coast chlor-alkali nameplate capacity, jolting spot price indices by 40% in under two weeks. Response strategies now include regional diversification: Chlorum Solutions chose Casa Grande, Arizona, for a USD 70 million membrane plant serving western petrochem and mining clusters. Europe, constrained by energy costs, pivots toward secondary uses that command premium pricing, such as PFAS-resin regeneration and pharmaceutical intermediates. Import flows through Antwerp and Rotterdam rose 12% in 2025, with Canadian cargoes filling seasonal gaps when German electrolyzers throttled down. Eastern-European steel galvanizers still lift commodity grades but invest in zero-liquid-discharge pickling to navigate tightening chloride-emission limits. South America and Middle-East-and-Africa remain volume-small but trend-positive as mining, oil-sands, and desalination projects proliferate.

- AGC Inc.

- BASF SE

- Coogee

- Covestro AG

- Detrex Corporation

- DONGYUE GROUP

- ERCO Worldwide

- Ercros S.A

- INEOS Group

- Jones-Hamilton Co.

- Merck KGaA

- Occidental Petroleum Corporation (OxyChem)

- Olin Corporation

- TOAGOSEI CO.,LTD.

- Vynova Group

- Westlake Corporation

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Oil and Gas Well-Stimulation Demand Surge

- 4.2.2 Water-Treatment and Food-Processing Hygiene Needs

- 4.2.3 Semiconductor-Grade HCL for Advanced Node Etching

- 4.2.4 PFAS-Removal Resin Regeneration Requirements

- 4.2.5 Lithium-Ion Battery Recycling Leaching Chemistry

- 4.3 Market Restraints

- 4.3.1 Worker-Safety and Environmental-Toxicity Regulations

- 4.3.2 Chlor-Alkali Co-Product Price Volatility

- 4.3.3 Organic-Acid Substitution in Pickling Baths

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts (Volume)

- 5.1 By Grade

- 5.1.1 Industrial

- 5.1.2 Concentrated

- 5.1.3 Ultra-high Purity

- 5.2 By End-user Industry

- 5.2.1 Chemical

- 5.2.2 Oil and Gas

- 5.2.3 Steel and Metallurgy

- 5.2.4 Food and Beverage

- 5.2.5 Textiles and Leather

- 5.2.6 Other End-user Industries

- 5.3 By Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 South Korea

- 5.3.1.5 ASEAN Countries

- 5.3.1.6 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 France

- 5.3.3.4 Italy

- 5.3.3.5 Russia

- 5.3.3.6 NORDIC Countries

- 5.3.3.7 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Rest of South America

- 5.3.5 Middle East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 South Africa

- 5.3.5.3 Rest of Middle East and Africa

- 5.3.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share (%)/Ranking Analysis

- 6.4 Company Profiles (includes Global overview, Market level overview, Core segments, Financials, Strategic information, Market rank/share, Products and services, Recent developments)

- 6.4.1 AGC Inc.

- 6.4.2 BASF SE

- 6.4.3 Coogee

- 6.4.4 Covestro AG

- 6.4.5 Detrex Corporation

- 6.4.6 DONGYUE GROUP

- 6.4.7 ERCO Worldwide

- 6.4.8 Ercros S.A

- 6.4.9 INEOS Group

- 6.4.10 Jones-Hamilton Co.

- 6.4.11 Merck KGaA

- 6.4.12 Occidental Petroleum Corporation (OxyChem)

- 6.4.13 Olin Corporation

- 6.4.14 TOAGOSEI CO.,LTD.

- 6.4.15 Vynova Group

- 6.4.16 Westlake Corporation

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-need Assessment