|

市場調查報告書

商品編碼

1910516

不沾塗層:市場佔有率分析、產業趨勢與統計、成長預測(2026-2031)Non-stick Coatings - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

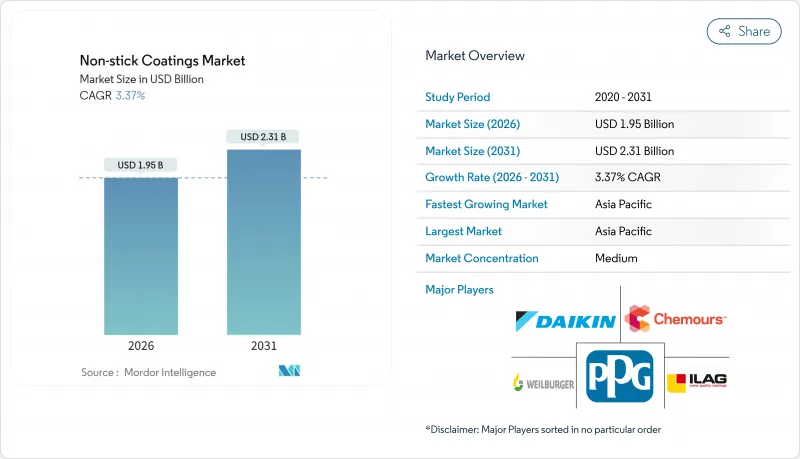

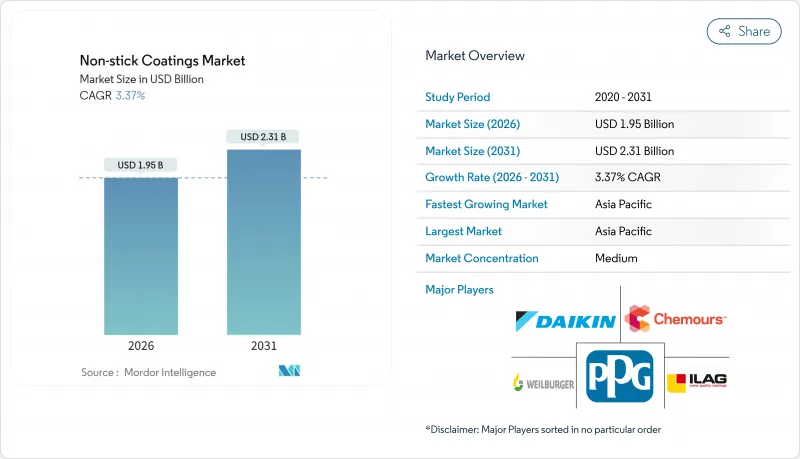

預計不沾塗料市場將從 2025 年的 18.9 億美元成長到 2026 年的 19.5 億美元,到 2031 年將達到 23.1 億美元,2026 年至 2031 年的複合年成長率為 3.37%。

這一成長反映了炊具、食品加工和先進電子行業穩定的市場需求,以及向無 PFAS 化學品的持續轉型。儘管氟化鈣價格波動對供應鏈的影響仍然令人擔憂,但擁有多元化原料組合的製造商仍具備競爭優勢。產品創新重點在於開發符合監管要求且不影響釋放性能的陶瓷和混合體系,亞太地區的強勁勢頭支撐著銷售成長,儘管北美和歐洲的銷售有所放緩。製造業自動化程度的提高以及家庭中低油烹飪方式的持續偏好,將支撐工業和消費領域的長期消費。

全球不沾塗料市場趨勢及洞察

家庭對不沾鍋的需求不斷成長

都市區和快節奏的生活持續推動消費者對用油量少、清潔方便的廚具的偏好。廚具品牌擴大在廣告中強調其產品表面不含PFOA的認證,零售商也積極推廣這些聲明以建立消費者信任。在中國和東南亞,中高級產品憑藉電商折扣縮短了更換週期,主導了線上銷售管道。大型製造商正抓住這一趨勢,推出耐磨性堪比PTFE的多層陶瓷塗層。對於進口產品而言,符合FDA 21 CFR 175.300及歐盟同等法規的認證已成為關鍵的行銷要素。隨著可支配收入的成長和整體廚房的普及,不沾塗層市場已擁有穩定的消費群,並朝著更高階化的產品線發展。

應用於工業機械和食品加工領域

烘焙用品、包裝輥和工業攪拌機的製造商指定使用先進塗層,以滿足衛生標準並減少停機時間。 PPG 於 2024 年 9 月在馬來西亞投資,新增五條生產線,專門生產用於烤盤和能源組件的水性及溶劑型塗層系統。設備整合商青睞光滑、易於清潔且能承受腐蝕性清洗循環和熱衝擊的表面,從而降低大型工廠的衛生成本。在石油和天然氣閥門領域,低摩擦氟聚合物薄膜可降低扭矩並防止在酸性氣體環境中腐蝕。政府法規要求更嚴格的食品安全審核,這間接刺激了對合規表面的需求,使向全球提供技術支援的供應商受益。工業組件較長的更換週期確保了塗層的持續採購,從而支撐了該領域的價格穩定。

加強 PFAS 法規的影響

強制揭露和對現有 PFAS 的徹底禁令正在造成即時的生產缺口。 3M 公司 2023 年 PFAS銷售量下降了 20%,並計劃在 2025 年底前逐步停止所有含氟化學品的生產。因此,該公司累計了8 億美元的稅前資產減損費用。科慕公司在多個司法管轄區面臨訴訟,這阻礙了其對新的 PTFE 生產能力的資本投資,並延遲了高純度等級產品的供應。下游混配商被迫承擔因配方重新設計和重新認證 NSF 和 EFSA 食品接觸標準而增加的合規成本。小規模塗料代工公司正努力資金籌措,用於安裝修訂後的《清潔空氣法》法規要求的新型烤箱和煙氣捕集系統。預計這些干擾因素將導致不沾黏塗料市場在短期內需求下降,直到替代化學品得到更廣泛的供應。

細分市場分析

到2025年,含氟聚合物將佔據不沾塗層市場41.32%的佔有率,這充分證明了其卓越的熱穩定性和脫模耐久性。儘管監管日益嚴格,但以美元計價,含氟聚合物市場的成長速度仍高於其他同類化學品。不含PFOA的PTFE產品,由於與現有應用設備具有良好的兼容性,目前佔據了復購量的主導地位。大金和科慕正利用這一市場需求,提供專為靜電噴塗設計的低VOC分散體和粉末級產品。同時,陶瓷塗層不受PFAS法規的約束,且深受注重健康的消費者青睞,預計到2031年將以3.62%的複合年成長率快速成長。商業應用採用溶膠-凝膠工藝,並以奈米氧化鋯或二氧化鈦增強,以降低脆性。矽酮塗層則佔據了烘焙用具和醫療設備等較為狹窄的細分市場,在這些市場中,柔軟性和生物相容性比極致的脫模性能更為重要。混合有機-無機材料目前市場佔有率較小,但兼具抗污染性和抗衝擊性,預計從 2028 年開始將導致市場佔有率的重組。

專用於半導體載體的第二代含氟聚合物價格居高不下,使供應商免受炊具市場週期性波動的影響。同時,3M的產能最佳化導致大量供應中斷,迫使下游複合材料供應商必須從多個管道採購關鍵等級的材料。亞洲的二級複合材料供應商正透過與尋求穩定塗層生產線的家電OEM廠商簽訂多年供貨協議來爭取市場佔有率。隨著終端買家對永續性聲明的審核,ISO 14001認證已成為一項重要的資格,促使供應商投資於廢熱和溶劑回收。整體而言,監管壓力和特定應用性能之間的相互作用,維持了該領域兩極化的成長軌跡:陶瓷材料加速成長,而含氟聚合物則繼續鞏固其現有的工業地位。

區域分析

預計到2025年,亞太地區將佔全球營收的49.62%,複合年成長率達3.53%,進一步鞏固其在不沾塗層市場的主導地位。中國浙江和廣東叢集的產能擴張正在縮短炊具OEM廠商的前置作業時間,而稅收優惠政策則吸引了越南和印尼等國投資建設新的噴塗生產線。印度的都市區中產階級青睞透過限時搶購平台銷售的高階煎鍋,而隨著印度標準局(BIS)標準的實施,預計對進口聚四氟乙烯(PTFE)的監管審查力度將加大。日本在先進機器人和半導體設備需求的推動下,繼續進口高純度塗層,抵消了家用產品更換週期放緩的影響。

北美地區按以金額為準排名第二,但面臨最具挑戰性的 PFAS 法規。各州的禁令正在加速陶瓷研發,美國塗料製造商正投資於廢氣捕集和銷毀系統,以獲得美國環保署 (EPA) 的核准。在墨西哥,美國State Electric 品牌的近岸外包效應正在推動當地對爐灶烤架和烤盤用粉末塗料的需求。歐洲在 REACH 法規的指導下繼續逐步淘汰長鏈 PFAS,德國推廣水性分散劑,法國則透過綠色經濟津貼支持溶膠-凝膠技術新興企業。東歐工廠正在將炊具組裝業務集中起來,並採用在地採購的塗料以降低運輸成本。

中東和非洲地區正湧現出小規模但充滿活力的機會。當地蓬勃發展的旅館業正在推動商用廚房設備的升級換代。南美洲的家禽和糖果甜點加工商正在採用符合美國食品藥物管理局(FDA)標準的薄膜以應對出口審核,而巴西的本地化塗層業務也在不斷擴張。這種地理多元化有助於供應商減輕單一監管或宏觀經濟衝擊的影響,但紅海貿易路線的物流中斷情況值得密切關注。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 家用不沾鍋需求不斷成長

- 應用於工業機械和食品加工領域

- 監管主導的向無PFOA陶瓷過渡

- 用於電子和醫療設備

- 水性低VOC氟樹脂分散液

- 市場限制

- 加強 PFAS 法規

- 微塑膠引發的健康問題

- 螢石供應價格飆升

- 價值鏈分析

- 波特五力模型

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

第5章 市場規模與成長預測

- 按類型

- 氟樹脂

- 陶瓷製品

- 矽酮

- 其他類型

- 透過使用

- 炊具

- 食品加工

- 布料和地毯

- 醫療保健

- 電氣和電子設備

- 工業機械

- 車

- 其他用途

- 按地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 東南亞國協

- 亞太其他地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 北歐國家

- 俄羅斯

- 其他歐洲地區

- 南美洲

- 巴西

- 阿根廷

- 哥倫比亞

- 其他南美洲

- 中東和非洲

- 沙烏地阿拉伯

- 土耳其

- 阿拉伯聯合大公國

- 南非

- 其他中東和非洲地區

- 亞太地區

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率/排名分析

- 公司簡介

- 3M

- AGC Chemicals

- Cavero Coatings

- DAIKIN INDUSTRIES, Ltd.

- Endura Coatings

- ILAG-Industrielack AG

- Metal Coatings

- Metallic Bonds Ltd

- PPG Industries, Inc.

- Rhenotherm Kunststoffbeschichtungs GmbH

- Showa Denko KK

- Solvay

- The Chemours Company

- Weilburger

- Zhejiang Pfluon Technology Co., Ltd

第7章 市場機會與未來展望

The Non-stick Coatings Market is expected to grow from USD 1.89 billion in 2025 to USD 1.95 billion in 2026 and is forecast to reach USD 2.31 billion by 2031 at 3.37% CAGR over 2026-2031.

This expansion reflects steady demand from cookware, food-processing, and advanced electronics alongside the ongoing shift toward PFAS-free chemistries. Supply chains remain vulnerable to fluctuations in fluorspar costs, yet producers with diversified raw-material portfolios hold a competitive edge. Product innovation centers on ceramic and hybrid systems that meet regulatory mandates without compromising release performance, while regional momentum in the Asia-Pacific sustains volume growth despite moderating sales in North America and Europe. Rising automation in manufacturing and sustained household preference for low-oil cooking sustain long-term consumption across industrial and consumer verticals.

Global Non-stick Coatings Market Trends and Insights

Rising Household Demand for Non-Stick Cookware

Urban living patterns and increasingly busy lifestyles have sustained consumer preference for cookware that minimizes oil use and simplifies cleaning. Kitchenware brands are increasingly advertising certifications that guarantee PFOA-free surfaces, and retailers are highlighting such labels to build trust. Mid-tier and premium products now dominate online sales channels in China and Southeast Asia, where e-commerce discounts shorten replacement cycles. Large-scale producers capitalize on this shift by launching multi-layer ceramic finishes that rival PTFE in abrasion resistance. Certification to FDA 21 CFR 175.300 and equivalent EU frameworks has become a core marketing feature for imported offerings. With disposable incomes rising and modular kitchens proliferating, the non-stick coatings market enjoys a stable consumer base that absorbs upgraded product lines.

Industrial Machinery and Food-Processing Uptake

Manufacturers of bakeware, packaging rollers, and industrial mixers specify advanced coatings to meet hygiene mandates and reduce downtime. PPG's September 2024 investment in Malaysia added five production lines dedicated to waterborne and solvent-borne systems tailored for bakery trays and energy components. Equipment integrators favor smooth, easy-clean surfaces that endure caustic wash cycles and thermal shocks, which lowers sanitation costs across large plants. In oil and gas valves, low-friction fluoropolymer films cut torque and prevent corrosion under sour-gas conditions. Governments that legislate stricter food-safety audits indirectly stimulate demand for compliant surfaces, benefiting suppliers with global technical support. The long replacement interval for industrial parts locks in recurrent coating purchases and underpins price stability across this segment.

PFAS Regulatory Clamp-Down

Mandatory disclosure and outright bans on legacy PFAS generate immediate production gaps. 3M recorded a 20% decline in PFAS volumes during 2023 and will exit all fluorochemical manufacturing by the end of 2025, booking a USD 800 million pre-tax charge tied to asset write-downs. Chemours faces multi-jurisdictional litigation that diverts capital away from new PTFE capacity, slowing the supply of high-purity grades. Downstream blenders absorb higher compliance costs as they redesign formulations and requalify them under NSF and EFSA food-contact standards. Small contract coaters struggle to fund new ovens and fume-capture systems required under evolving Clean Air Act rules. Collectively, these disruptions reduce short-term volumes in the non-stick coatings market until alternative chemistries are scaled.

Other drivers and restraints analyzed in the detailed report include:

- Regulation-Driven Shift to PFOA-Free Ceramics

- Electronics and Medical Device Adoption

- Fluorspar-Supply Price Shocks

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Fluoropolymers held 41.32% non-stick coatings market share in 2025, underscoring their supremacy in thermal stability and release longevity. The non-stick coatings market size for fluoropolymers outstripped USD-denominated growth in rival chemistries even as regulatory headwinds intensified. PTFE variants free of PFOA now dominate reorder volumes, thanks to their proven compatibility with existing application equipment. Daikin and Chemours capitalize on this reliance by offering low-VOC dispersions and powder grades engineered for electrostatic spray. In contrast, ceramic finishes post the fastest 3.62% CAGR to 2031 because they bypass PFAS scrutiny and appeal to health-conscious consumers. Commercial roll-outs employ sol-gel routes reinforced with nano-zirconia or titania to curb brittleness. Silicone coatings occupy a narrower niche serving bakeware and medical devices, where flexibility and biocompatibility trump extreme release. Although hybrid organic-inorganic systems currently account for a small slice of the market, they promise a convergence of stain resistance and impact toughness that could realign market shares after 2028.

Second-generation fluoropolymers purpose-built for semiconductor carriers maintain premium pricing, cushioning suppliers from cookware cyclicality. Conversely, capacity rationalization by 3M removes a sizeable volume and prompts downstream formulators to dual-source critical grades. Tier-two Asian compounds secure share gains by signing multi-year supply deals with appliance OEMs seeking stable coating lines. ISO 14001 certification emerges as a credential when end buyers audit sustainability claims, nudging suppliers to invest in waste-heat recovery and solvent capture. Overall, the interplay of regulatory pressure and application-centric performance sustains a dual-speed trajectory in this segment, with ceramics accelerating yet fluoropolymers defending entrenched industrial roles.

The Non-Stick Coatings Market Report is Segmented by Type (Fluoropolymer, Ceramic, Silicone, and Other Types), by Application (Cookware, Food Processing, Fabrics and Carpets, Medical, Electrical and Electronics, Industry Machinery, Automotive, and Other Applications), and by Geography (Asia-Pacific, North America, Europe, South America, and Middle-East and Africa). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific accounted for 49.62% of 2025 revenue and is projected to advance at a 3.53% CAGR, reinforcing its primacy in the non-stick coatings market. Capacity additions in China's Zhejiang and Guangdong clusters shorten lead times for cookware OEMs, while tax incentives draw new spray-line investments to Vietnam and Indonesia. India's urban middle class is embracing premium pans sold via flash-sale portals, although regulatory oversight on imported PTFE will tighten under pending BIS standards. Japan leverages advanced robotics and semiconductor equipment demand to sustain high-purity coating imports, offsetting slower household replacement cycles.

North America ranks second by value but confronts the most disruptive PFAS legislation. State-level bans accelerate ceramic R&D, and US coaters invest in capture-destroy exhaust systems to secure EPA approvals. Mexico benefits from near-shoring by US appliance brands, lifting regional powder demand for stovetop grates and bakeware sheets. Europe continues to migrate away from long-chain PFAS under REACH, with Germany championing water-based dispersions and France encouraging sol-gel start-ups through green economy grants. Eastern European plants attract cookware assembly operations that source coatings locally to sidestep shipping costs.

Smaller yet dynamic opportunities emerge in the Middle East and Africa, where hospitality expansion spurs commercial-kitchen upgrades. South American processors of poultry and confectionery adopt FDA-compliant films to meet export audits, driving localized toll-coating ventures in Brazil. Geographic diversification thus cushions suppliers from any single regulatory or macro-economic shock, although logistics disruptions in the Red Sea trade lane remain a watchpoint.

- 3M

- AGC Chemicals

- Cavero Coatings

- DAIKIN INDUSTRIES, Ltd.

- Endura Coatings

- ILAG - Industrielack AG

- Metal Coatings

- Metallic Bonds Ltd

- PPG Industries, Inc.

- Rhenotherm Kunststoffbeschichtungs GmbH

- Showa Denko K.K.

- Solvay

- The Chemours Company

- Weilburger

- Zhejiang Pfluon Technology Co., Ltd

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions & Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Rising household demand for non-stick cookware

- 4.2.2 Industrial machinery and food-processing uptake

- 4.2.3 Regulation-driven shift to PFOA-free ceramics

- 4.2.4 Electronics and medical device adoption

- 4.2.5 Water-based low-VOC fluoropolymer dispersions

- 4.3 Market Restraints

- 4.3.1 PFAS regulatory clamp-down

- 4.3.2 Micro-plastic health perception

- 4.3.3 Fluorspar-supply price shocks

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Degree of Competition

5 Market Size & Growth Forecasts (Value)

- 5.1 By Type

- 5.1.1 Fluoropolymer

- 5.1.2 Ceramic

- 5.1.3 Silicone

- 5.1.4 Other Types

- 5.2 By Application

- 5.2.1 Cookware

- 5.2.2 Food Processing

- 5.2.3 Fabrics and Carpets

- 5.2.4 Medical

- 5.2.5 Electrical and Electronics

- 5.2.6 Industry Machinery

- 5.2.7 Automotive

- 5.2.8 Other Applications

- 5.3 By Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 South Korea

- 5.3.1.5 ASEAN Countries

- 5.3.1.6 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 France

- 5.3.3.4 Italy

- 5.3.3.5 Spain

- 5.3.3.6 Nordic

- 5.3.3.7 Russia

- 5.3.3.8 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Colombia

- 5.3.4.4 Rest of South America

- 5.3.5 Middle-East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 Turkey

- 5.3.5.3 UAE

- 5.3.5.4 South Africa

- 5.3.5.5 Rest of Middle-East and Africa

- 5.3.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products & Services, and Recent Developments)

- 6.4.1 3M

- 6.4.2 AGC Chemicals

- 6.4.3 Cavero Coatings

- 6.4.4 DAIKIN INDUSTRIES, Ltd.

- 6.4.5 Endura Coatings

- 6.4.6 ILAG - Industrielack AG

- 6.4.7 Metal Coatings

- 6.4.8 Metallic Bonds Ltd

- 6.4.9 PPG Industries, Inc.

- 6.4.10 Rhenotherm Kunststoffbeschichtungs GmbH

- 6.4.11 Showa Denko K.K.

- 6.4.12 Solvay

- 6.4.13 The Chemours Company

- 6.4.14 Weilburger

- 6.4.15 Zhejiang Pfluon Technology Co., Ltd

7 Market Opportunities & Future Outlook

- 7.1 White-space and Unmet-need Assessment