|

市場調查報告書

商品編碼

1910432

包裝薄膜:市佔率分析、產業趨勢與統計、成長預測(2026-2031)Packaging Film - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

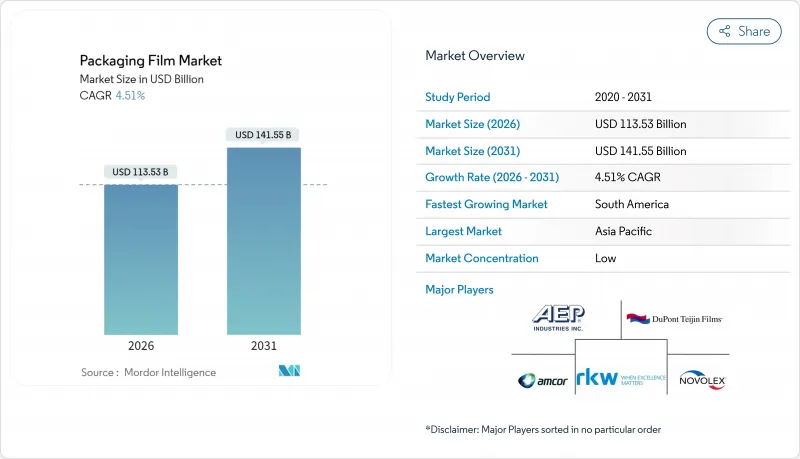

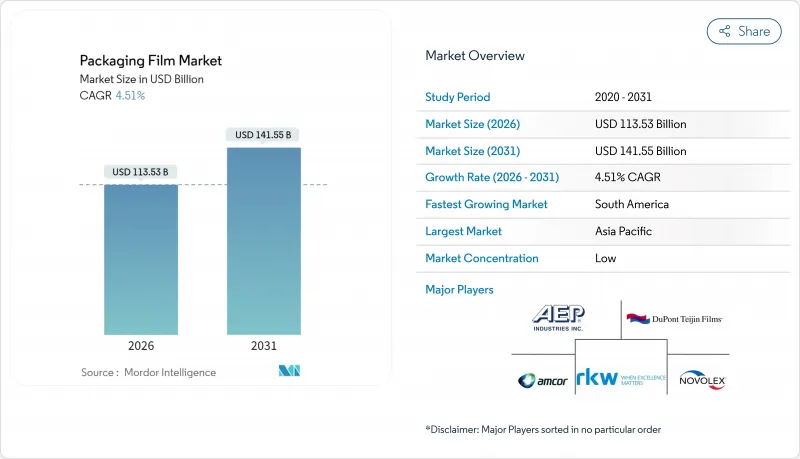

2025年包裝薄膜市值為1,086.3億美元,預計從2026年的1135.3億美元成長到2031年的1,415.5億美元,在預測期(2026-2031年)內複合年成長率為4.51%。

對輕量化電商運輸材料的需求不斷成長、歐洲日益嚴格的回收法規以及亞太地區新興經濟體低溫運輸的快速擴張,共同支撐著該行業的穩步成長勢頭。多層阻隔技術創新、抗菌母粒和化學再生原料等方面的合作協議,為高階細分市場提供了支持,而策略併購則進一步凸顯了全球領先加工商之間的規模優勢。

全球包裝薄膜市場趨勢與洞察

電子商務的快速成長推動了對輕型運輸薄膜的需求。

隨著小包裹數量的成長,品牌商正致力於開發更輕薄的運輸包裝,在保持抗摔性能的同時,將體積重量降低高達30%。 PAC Worldwide的Eco PAC封套系統實現了運輸信封的自動化,降低了履約中心的人事費用,在成本效益和回收目標之間實現了平衡。雙層密封的宅配袋為逆向物流專案提供了支持,而逆向物流對於維繫客戶忠誠度至關重要。快速製作的圖形利用數位印刷技術,能夠實現主題促銷活動,從而增強品牌互動,並避免高昂的製版成本。這些因素共同作用,使包裝薄膜市場成為全球零售業數位化的主要受益者之一。

歐盟推廣單一材料再生薄膜

《包裝及包裝廢棄物法規》要求到2030年,塑膠食品包裝的再生材料含量必須達到30%,並且完全可回收,這加速了向聚烯單層複合材料的過渡。 Mopac公司經認證的80%再生聚乙烯(rPE)結構已展現出商業性可行性,加工商正在實施脫墨和清潔系統以促進合規。生產者延伸責任制(EPR)成本推高了材料成本,促使企業採用閉合迴路回收設計。隨著法規期限的臨近,包裝薄膜市場正在採用兼顧性能和可回收性的標準設計規則。

北美和歐洲的塑膠禁令和課稅

一次性產品課稅和 PFAS 禁令迫使企業快速修訂產品規格,這給中型工廠的研發預算帶來了壓力,並延長了客戶的認證週期。由於各品牌需要應對舊式層壓板在不同地區的淘汰期限,因此政策執行的不均衡也使庫存計劃變得更加複雜。

細分市場分析

聚乙烯憑藉其優異的成本績效和多功能加工性能,預計到2025年將維持42.10%的包裝薄膜市佔率。高密度聚乙烯將用於半硬質包裝,而低密度聚乙烯(LDPE)和線性低密度聚乙烯(LLDPE)將主導吹膜應用。受政策趨勢和品牌承諾加強的推動,生質塑膠預計到2031年將維持7.75%的強勁複合年成長率。假設原料規模化生產成功,生質塑膠包裝薄膜市場預計10年將達到數十億美元。雙向拉伸聚丙烯具有極具競爭力的透明度和剛性,適用於高階糖果甜點包裝。聚對苯二甲酸乙二醇酯(PET)層為蒸餾應用提供尺寸穩定性,並通常與氧化鋁塗層結合使用,以實現高氣體阻隔性能。化學回收技術的進步使得閉合迴路聚乙烯(PE)的性能能夠與原生原料相媲美,其中矽酸鈦觸媒技術目前處於中試階段。嵌段共聚物聚乳酸(PLA)的創新降低了脆性,為生鮮食品包裝袋提供了80%生物基的替代方案。

聚乙烯加工商正投資茂金屬催化劑以提高密封滲透性能,這對於高速成型-填充-封口生產線至關重要。包裝薄膜市場力求在成本效益和永續性之間取得平衡,傳統製造商在維持產量的同時,特種生物聚合物也在努力滿足不斷變化的監管要求和消費者偏好。

多層結構透過各層的功能性最佳化機械、光學和阻隔性能,預計到2025年將佔銷售額的56.20%。隨著醫藥物流和蒸餾食品對長期儲存的需求日益成長,含有EVOH或AlOx層的阻隔層壓板正以6.14%的複合年成長率快速擴張。同時,單層薄膜在需要簡化回收流程的化學成分的領域仍然發揮著重要作用,尤其是在北美地區的店內回收領域。

共擠出機增加了在線連續拉伸單元,用於生產沿著機器方向取向的聚乙烯(PE)複合材料,在滿足可回收性要求的同時,保持了抗穿刺性能。奈米黏土分散體在相同厚度下可氧氣透過率降低60%,為製造更薄的壁厚鋪平了道路。層厚掃描儀提高了輪廓精度,並最大限度地減少了啟動廢棄物,提高了產量比率,直接轉化為包裝薄膜市場參與企業盈利。

區域分析

預計到2025年,亞太地區將維持37.00%的包裝薄膜市場佔有率,這得益於其豐富的樹脂供應、具有競爭力的勞動力和龐大的消費群。中國新的過度包裝法規GB/T 31268-2024推動了對符合小包裹重量限制的超輕包裝袋的需求。泰國和印尼正在協調食品接觸法規,規範檢測通訊協定,並推動本地擠出技術的進步。印度企業,例如JPFL Films,已新增6萬噸年雙向拉伸聚丙烯(BOPP)薄膜產能,以抓住國內和出口機會。日本和韓國正在推動阻隔塗層的研究與開發,而澳洲則致力於提高消費後回收材料的使用率。

歐洲正面臨一場變革性的投資週期,以滿足聚丙烯廢料(PPWR)的可再生和再生材料含量標準。康斯坦蒂亞軟性包裝公司(Constantia Flexibles)收購Aluflexpack後,整合了鋁箔加工技術,並鞏固了其在東南亞的地位。各品牌正在引進QR碼的消費後處理說明,以提高回收產品的純度。英國和德國已試驗設立化學回收投放點,推動了再生聚乙烯(rPE)的整合。

北美擁有成熟的電子商務網路和日趨明朗的政策。 PFAS(全氟烷基物質)的禁用日期促使加工商轉向使用金屬化雙向拉伸聚丙烯(BOPP)和氧化鋁聚對苯二甲酸乙二醇酯(AlOx PET)。加拿大憑藉其原料成本優勢,繼續保持領先出口國的地位。墨西哥的工廠既供應國內零食市場,也供應美國南部價值鏈。

到2031年,南美洲將以7.60%的複合年成長率實現最快增速,主要得益於高阻隔薄膜需求的農產品出口。 OPP FILM COLOMBIA和GDM Plasticos的投資將擴大雙向拉伸聚丙烯(BOPP)和共混聚丙烯(CPP)的生產基地。區域性資助機構將支持生態設計研究所,使其成為包裝薄膜市場的新成長點。

預計中東和非洲地區將出現強勁的兩位數銷售成長,主要得益於都市區零售業的擴張。沙烏地阿拉伯和阿拉伯聯合大公國推出了可再生塑膠強制性規定,以指導採購選擇;而南非成熟的加工商則以成本最佳化的產品服務於更廣泛的非洲大陸市場。

其他福利:

- Excel格式的市場預測(ME)表

- 分析師支持(3個月)

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 電子商務的快速成長推動了對輕型運輸薄膜的需求。

- 歐盟推廣單一材料可回收薄膜

- 新興亞太地區低溫運輸包裝食品的成長

- 數位印刷技術可實現小批量個人化包裝。

- 肉類膜用抗菌添加劑母粒

- 食品級再生聚乙烯(rPE)化工再生原料供應合約

- 市場限制

- 北美和歐洲的塑膠禁令/課稅

- 原生樹脂價格波動

- 生物基薄膜的阻隔性能極限

- 超薄膜導致轉換器停機

- 產業價值鏈分析

- 監管環境

- 技術展望

- 波特五力分析

- 新進入者的威脅

- 買方的議價能力

- 供應商的議價能力

- 替代品的威脅

- 競爭對手之間的競爭

- 宏觀經濟因素如何影響市場

第5章 市場規模與成長預測

- 依材料類型

- 聚乙烯

- 高密度聚苯乙烯(HDPE)

- 低密度聚乙烯(LDPE)

- 線型低密度聚乙烯(LLDPE)

- 聚丙烯

- 聚酯纖維(雙向拉伸聚酯薄膜)

- 生質塑膠

- 其他材料類型

- 聚乙烯

- 透過薄膜結構

- 單層

- 多層結構(2-3層)

- 多層阻隔結構(3層或以上)

- 透過使用

- 食品/飲料

- 藥品和醫療保健

- 個人護理和化妝品

- 消費耐久財和電子產品

- 工業和機構

- 農業和園藝

- 其他應用

- 特定用途的格式

- 袋子和小袋

- 包裝膜和封蓋膜

- 標籤和封套

- 泡殼和袋裝包裝

- 收縮膜和拉伸膜

- 按地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 南美洲

- 巴西

- 阿根廷

- 智利

- 其他南美洲

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 荷蘭

- 其他歐洲地區

- 亞太地區

- 中國

- 日本

- 印度

- 韓國

- 澳洲

- 新加坡

- 馬來西亞

- 亞太其他地區

- 中東和非洲

- 中東

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 土耳其

- 其他中東地區

- 非洲

- 南非

- 奈及利亞

- 埃及

- 其他非洲地區

- 中東

- 北美洲

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率分析

- 公司簡介

- Amcor plc

- Sealed Air Corporation

- Mondi plc

- Jindal Poly Films Ltd

- Cosmo Films Ltd

- Uflex Ltd

- Huhtamaki Oyj

- ProAmpac Holdings

- Novolex Holdings

- AEP Industries

- RKW SE

- Toray Plastics

- Coveris Holdings

- Sigma Plastics Group

- SRF Limited

- Klockner Pentaplast

- Taghleef Industries

- Polyplex Corporation

- Transcontinental Inc.

- Dupont Teijin Films

第7章 市場機會與未來展望

The packaging film market was valued at USD 108.63 billion in 2025 and estimated to grow from USD 113.53 billion in 2026 to reach USD 141.55 billion by 2031, at a CAGR of 4.51% during the forecast period (2026-2031).

Heightened demand for lightweight e-commerce shipping materials, stricter European recyclability rules, and rapid cold-chain expansion in emerging Asia-Pacific economies sustain steady momentum. Multilayer barrier innovations, antimicrobial masterbatches, and chemical-recycling feedstock agreements underpin premium growth niches, while strategic mergers accentuate scale advantages among the top global converters.

Global Packaging Film Market Trends and Insights

E-commerce Boom Driving Demand for Lightweight Shipping Films

Parcel-volume growth pushes brands to down-gauge shipping packs, trimming dimensional weight by up to 30% while preserving drop resistance. PAC Worldwide's Eco PAC jacket system automates mailer conversion and reduces labor at fulfillment centers, aligning cost efficiency with recyclability goals. Dual-seal courier bags support reverse-logistics programs that are integral to customer loyalty. Short-run graphics tap digital presses for thematic promotions that strengthen brand engagement and circumvent high plate charges. These factors collectively reinforce the packaging film market as a core beneficiary of global retail digitization.

EU Push for Mono-Material Recyclable Films

The Packaging and Packaging Waste Regulation obligates 30% recycled content in plastic food packs by 2030 and requires full recyclability, accelerating the shift toward polyolefin-only laminates. Mopack's certified structures with 80% rPE validate commercial readiness, while converters install de-inking and wash systems to secure compliance. Extended Producer Responsibility fees become a material cost lever that favors designs enabling closed-loop recovery. As compliance deadlines approach, the packaging film market adopts standardized design rules that harmonize performance with recyclability.

Plastic Bans/Taxes in North America and Europe

Single-use levies and PFAS prohibitions force rapid specification overhaul, stretching R&D budgets at mid-sized plants and lengthening customer qualification cycles. Fragmented policy rollouts complicate inventory planning as brands juggle differing regional cutoffs for legacy laminates.

Other drivers and restraints analyzed in the detailed report include:

- Cold-Chain Packaged Food Growth in Emerging Asia-Pacific

- Digital Printing Enabling Short-Run Personalised Packs

- Volatile Virgin-Resin Prices

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Polyethylene preserves 42.10% share of the packaging film market in 2025, riding its favorable price-performance profile and broad processability. High-density grades serve semi-rigid uses while LDPE and LLDPE underpin the bulk of blown-film applications. Bioplastics post a robust 7.75% CAGR through 2031 as policy signals and brand pledges intensify. The packaging film market size for bioplastic variants is projected to reach multi-billion USD territory by decade-end, provided feedstock scaling continues apace. Polypropylene's biaxially oriented formats compete on clarity and stiffness for premium confectionery. PET layers ensure dimensional stability in retort applications, often coupled with aluminum-oxide coatings for a high gas barrier. Chemical-recycling advances promise closed-loop PE that matches virgin properties, with titanosilicate catalysis now at pilot scale. Block-copolymerized PLA breakthroughs cut brittleness, offering an 80% bio-based alternative for fresh-produce pouches.

Polyethylene converters invest in metallocene catalysts that upgrade seal-through-contamination performance, an essential trait for high-speed form-fill-seal lines. The packaging film market thus balances cost efficiency against sustainability pulls, with incumbents safeguarding volume while specialty biopolymers address regulatory requirements and consumer preference shifts.

Multilayer constructions controlled 56.20% revenue in 2025 by optimizing mechanical, optical and barrier attributes through layer-specific functionality. Barrier stacks incorporating EVOH or AlOx layers are on course for 6.14% CAGR as pharma logistics and ready-meal sectors require longer shelf life. Monolayer films retain relevance where recovery streams demand simpler chemistries, notably for store drop-off recycling in North America.

Co-extruders add inline orientation units to produce machine-direction oriented PE laminates that satisfy recyclability while keeping puncture resistance. Nanoclay dispersions cut oxygen transmission by 60% at equivalent calipers, paving the way for further down-gauging. Layer-thickness scanners improve profile accuracy and minimize start-up scrap, delivering yield gains that feed directly into bottom-line improvement for participants within the packaging film market.

The Packaging Film Market Report is Segmented by Material Type (Polyethylene, Polypropylene, Polyester, and More), Film Structure (Monolayer, and More), Application (Food and Beverage, Pharmaceutical and Medical, Personal Care and Cosmetics, and More), End-Use Format (Bags and Pouches, Wraps and Lidding Films, Labels and Sleeves, and More ), and Geography. The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific sustained 37.00% share of the packaging film market in 2025, underpinned by abundant resin supply, competitive labor, and a vast consumer base. China's GB/T 31268-2024 rule on excessive packaging triggers demand for ultra-light pouches that meet parcel weight caps. Thailand and Indonesia implement harmonized food-contact controls that standardize test protocols and elevate local extrusion sophistication. Indian players such as JPFL Films add 60,000 tpa BOPP capacity to capture domestic and export opportunities. Japan and South Korea champion barrier-coating R&D, while Australia emphasizes post-consumer recycling content.

Europe faces transformative investment cycles to satisfy PPWR recyclability and recycled-content thresholds. Constantia Flexibles' acquisition of Aluflexpack consolidates foil competencies and bolsters Southeast-European footholds. Brands introduce QR-coded disposal instructions to guide consumers and to enhance collection purity. The UK and Germany pilot chemical-recycling drop-offs, driving rPE integration.

North America leverages mature e-commerce networks and rolling policy clarity. PFAS withdrawal deadlines steer converters toward metallized BOPP and AlOx PET, while Canada capitalizes on feedstock cost advantages to remain a major exporter. Mexican facilities supply both domestic snack markets and southern U.S. value chains.

South America records the fastest 7.60% CAGR through 2031, propelled by agricultural exports that require high-barrier films. Investments by OPP FILM COLOMBIA and GDM Plasticos expand BOPP and CPP footprints, while regional funding bodies support eco-design labs. The momentum positions the region as the new growth frontier in the packaging film market.

Middle East and Africa post solid double-digit volume gains fostered by urban retail expansion. Saudi Arabia and the UAE introduce mandates for recyclable plastics that guide procurement choices, and South Africa's established converters serve the broader continent with cost-optimized offerings.

- Amcor plc

- Sealed Air Corporation

- Mondi plc

- Jindal Poly Films Ltd

- Cosmo Films Ltd

- Uflex Ltd

- Huhtamaki Oyj

- ProAmpac Holdings

- Novolex Holdings

- AEP Industries

- RKW SE

- Toray Plastics

- Coveris Holdings

- Sigma Plastics Group

- SRF Limited

- Klockner Pentaplast

- Taghleef Industries

- Polyplex Corporation

- Transcontinental Inc.

- Dupont Teijin Films

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 E-commerce boom driving demand for lightweight shipping films

- 4.2.2 EU push for mono-material recyclable films

- 4.2.3 Cold-chain packaged food growth in emerging Asia-Pacific

- 4.2.4 Digital printing enabling short-run personalised packs

- 4.2.5 Antimicrobial additive masterbatches for meat films

- 4.2.6 Chemical-recycling feedstock agreements for food-grade rPE

- 4.3 Market Restraints

- 4.3.1 Plastic bans / taxes in NA and Europe

- 4.3.2 Volatile virgin-resin prices

- 4.3.3 Barrier limits of bio-based films

- 4.3.4 Converter downtime from ultra-thin gauges

- 4.4 Industry Value Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Threat of New Entrants

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Bargaining Power of Suppliers

- 4.7.4 Threat of Substitutes

- 4.7.5 Intensity of Competitive Rivalry

- 4.8 Impact of Macroeconomic Factors on the Market

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Material Type

- 5.1.1 Polyethylene

- 5.1.1.1 High-Density Polyethylene (HDPE)

- 5.1.1.2 Low-Density Polyethylene (LDPE)

- 5.1.1.3 Linear Low-Density Polyethylene (LLDPE)

- 5.1.2 Polypropylene

- 5.1.3 Polyester (BOPET)

- 5.1.4 Bioplastics

- 5.1.5 Other Material Types

- 5.1.1 Polyethylene

- 5.2 By Film Structure

- 5.2.1 Monolayer

- 5.2.2 Multilayer (2-3 layers)

- 5.2.3 Barrier multilayer (More than 3 layers)

- 5.3 By Application

- 5.3.1 Food and Beverage

- 5.3.2 Pharmaceutical and Medical

- 5.3.3 Personal Care and Cosmetics

- 5.3.4 Consumer Durables and Electronics

- 5.3.5 Industrial and Institutional

- 5.3.6 Agriculture and Horticulture

- 5.3.7 Other Application

- 5.4 By End-Use Format

- 5.4.1 Bags and Pouches

- 5.4.2 Wraps and Lidding Films

- 5.4.3 Labels and Sleeves

- 5.4.4 Blister and Sachets

- 5.4.5 Shrink and Stretch Wrap

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 South America

- 5.5.2.1 Brazil

- 5.5.2.2 Argentina

- 5.5.2.3 Chile

- 5.5.2.4 Rest of South America

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Spain

- 5.5.3.6 Netherlands

- 5.5.3.7 Rest of Europe

- 5.5.4 Asia-Pacific

- 5.5.4.1 China

- 5.5.4.2 Japan

- 5.5.4.3 India

- 5.5.4.4 South Korea

- 5.5.4.5 Australia

- 5.5.4.6 Singapore

- 5.5.4.7 Malaysia

- 5.5.4.8 Rest of Asia-Pacific

- 5.5.5 Middle East and Africa

- 5.5.5.1 Middle East

- 5.5.5.1.1 Saudi Arabia

- 5.5.5.1.2 United Arab Emirates

- 5.5.5.1.3 Turkey

- 5.5.5.1.4 Rest of Middle East

- 5.5.5.2 Africa

- 5.5.5.2.1 South Africa

- 5.5.5.2.2 Nigeria

- 5.5.5.2.3 Egypt

- 5.5.5.2.4 Rest of Africa

- 5.5.5.1 Middle East

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Amcor plc

- 6.4.2 Sealed Air Corporation

- 6.4.3 Mondi plc

- 6.4.4 Jindal Poly Films Ltd

- 6.4.5 Cosmo Films Ltd

- 6.4.6 Uflex Ltd

- 6.4.7 Huhtamaki Oyj

- 6.4.8 ProAmpac Holdings

- 6.4.9 Novolex Holdings

- 6.4.10 AEP Industries

- 6.4.11 RKW SE

- 6.4.12 Toray Plastics

- 6.4.13 Coveris Holdings

- 6.4.14 Sigma Plastics Group

- 6.4.15 SRF Limited

- 6.4.16 Klockner Pentaplast

- 6.4.17 Taghleef Industries

- 6.4.18 Polyplex Corporation

- 6.4.19 Transcontinental Inc.

- 6.4.20 Dupont Teijin Films

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-Need Assessment