|

市場調查報告書

商品編碼

1907325

乙丙橡膠(EPDM):市場佔有率分析、產業趨勢與統計、成長預測(2026-2031)Ethylene Propylene Diene Monomer (EPDM) - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

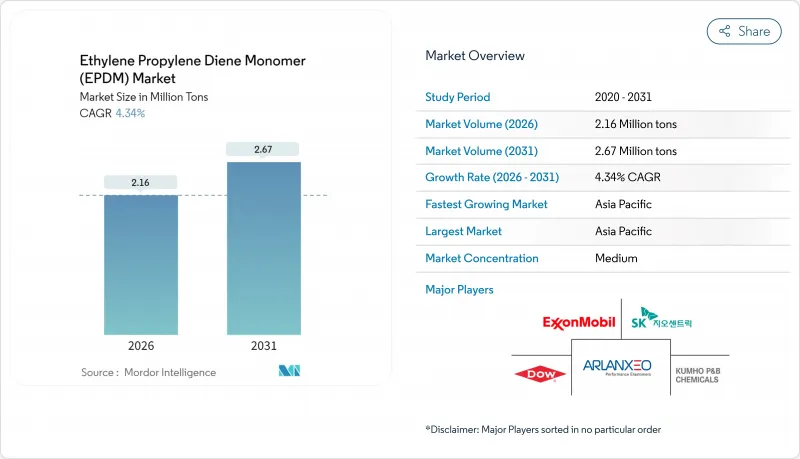

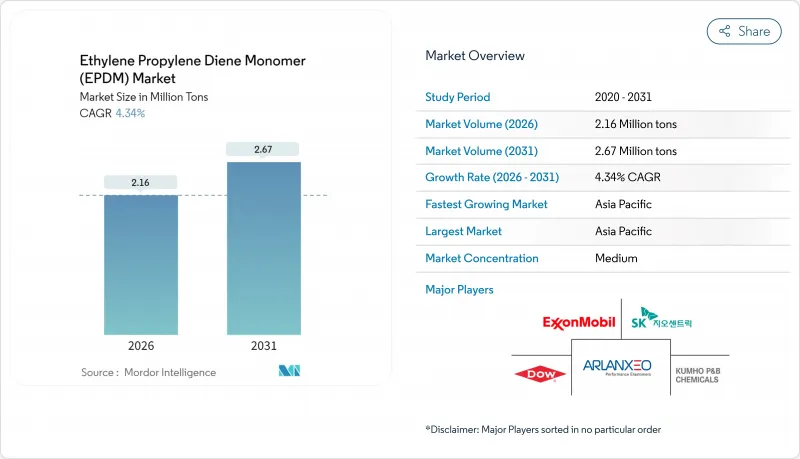

2025年乙丙橡膠(EPDM)市值207萬噸,預計2031年將達到267萬噸,高於2026年的216萬噸。

預測期(2026-2031 年)的複合年成長率預計為 4.34%。

電動車電池密封件、淨零排放屋頂膜以及氫燃料電池的早期應用等應用領域的需求成長勢頭強勁,這些應用領域都非常看重EPDM高達150°C的耐熱性和優異的耐臭氧性能。競爭優勢日益依賴生物基原料和先進催化劑,這些技術能夠在不犧牲聚合物性能的前提下降低碳足跡。區域供應的穩定性,尤其是在亞太地區,支撐了我們主導的銷售地位,並降低了成本波動的風險。儘管原料價格波動和熱塑性硫化橡膠(TPV)滲透率的不斷提高帶來了成本和替代壓力,但差異化的EPDM等級在對介電穩定性、耐化學性和使用壽命耐久性要求極高的高階應用領域仍然保持優勢。

全球乙丙橡膠(EPDM)市場趨勢與洞察

零能耗建築對EPDM防水卷材的需求激增

EPDM防水卷材的使用壽命超過50年,與壽命較短的熱塑性材料相比,為開發商提供了更具成本效益的使用成本。白色配方能夠反射太陽輻射,有助於獲得LEED和BREEAM認證體系中的能源效率積分。歐洲獨立評估機構一致認為,EPDM的環境影響低於TPO和PVC等替代材料,使其成為氣候適應建築的首選。日益都市區熱島效應緩解法規推動了對反射性屋頂材料的需求,而該材料的化學惰性使其能夠用於建造雨水收集系統和綠色屋頂。此外,EPDM與太陽能光電裝置的兼容性進一步促進了其在維修和新建計劃中的應用,這些專案旨在提高能源和水資源利用效率。

電動車產量加速成長,推動了對密封件和墊圈的需求。

電動車電池需要能夠承受-55°C至+150°C溫度循環、在振動下保持彈性、並能耐受冷卻乙二醇基添加劑和阻燃劑的密封墊片。 EPDM的低壓縮永久變形可保護電池組的完整性並抑制水分滲入,從而直接滿足電池保固要求。介電性能在高壓車輛架構中至關重要,而EPDM在目前正在大規模生產的800V系統中提供了穩定的絕緣性能。亞太地區仍然是需求成長的中心,其中中國是主要的電池製造中心,而韓國則是大型密封件製造商的所在地。儘管汽車製造商正在嘗試使用熱塑性彈性體(TPV)來減輕重量並提高可回收性,但在引擎室等溫度和化學腐蝕環境超出TPV限制的條件下,EPDM仍然具有性能優勢。

與原油價格相關的原物料價格波動

由於煉油廠停產以及烯烴供需緊張,丙烯和乙烯價格高企,對三元乙丙橡膠(EPDM)的利潤率帶來壓力。煉油廠的合理化改造與新增聚丙烯產能導致2025年美國聚合物級丙烯現貨價格上漲。亞洲乙烯價格在過去幾個月中出現了兩位數的波動,這使得輪胎和墊片製造商的合約談判和庫存計劃變得更加複雜。雖然擁有自有裂解裝置的一體化EPDM供應商可以部分抵消這種風險,但非一體化製造商往往被迫承受利潤率下降,或者在對成本敏感的應用領域中,因替代材料的競爭而失去市場佔有率。

細分市場分析

到2025年,溶液聚合製程將佔據EPDM市場59.10%的佔有率,因為汽車製造商和屋頂防水卷材製造商願意為實現壓縮永久變形性能所需的嚴格分子量控制支付溢價。此製程能夠精確控制二烯的引入,使混煉商能夠靈活地調整固化速度和模量,以滿足電池墊片嚴苛的要求。近期觸媒技術的創新,例如AlranZeo公司的Keltan ACE鈦κ1-脒基絡合物,可在不改變下游混煉配方的情況下降低能耗和單位生產成本。

漿料/懸浮製程預計將以4.78%的複合年成長率成長,滿足軟管和電纜絕緣用通用等級材料的需求,因為反應器升級為更有效率的混合系統可減少溶劑用量。氣相工藝是一項小眾技術,但人們對用於特種壓縮密封件的超高分子量等級材料的興趣日益濃厚。

乙丙橡膠(EPDM)市場報告按生產流程(溶液聚合工藝、漿料/懸浮液聚合工藝、氣相聚合工藝)、應用領域(汽車、建築、製造及其他)和地區(亞太、北美、歐洲、南美、中東和非洲)進行細分。市場預測以噸為單位。

區域分析

預計到2025年,亞太地區將佔據EPDM市場56.05%的佔有率,這主要得益於中國電池式電動車的生產以及韓國錦湖聚合物化學公司22萬噸產能工廠的擴建。來自一體化裂解裝置和蒸汽裂解裝置的充足丙烯供應降低了原料風險和運輸成本,推動該地區以4.58%的複合年成長率成長。全球密封件供應商的本地化策略使電動車製造商能夠縮短前置作業時間,從而形成技術支援和集中需求的良性循環。

隨著底特律汽車製造商加速推廣電動車,以及商業屋頂承包商指定使用EPDM進行節能維修,北美市場正在擴張。儘管國內裂解裝置面臨間歇性的丙烯供應限制,但頁岩氣經濟效益持續推動烯烴投資,並有望在中期內帶來更穩定的下游價格。聯邦政府對清潔能源建築的稅收優惠政策正在推動新倉庫屋頂的安裝,進一步促進了EPDM的消費。

在歐洲,由於嚴格的環境法規青睞具有成熟生命週期效益的材料,高價值應用佔據主導地位。循環經濟指令鼓勵企業安裝內部脫硫生產線,為區域混煉企業在再生EPDM混煉領域領先奠定了基礎。中東和非洲地區雖然規模較小,但正呈現出由基礎設施需求主導的復甦態勢,而南美洲的需求成長則依賴巴西的石化投資週期和鄰近地區的丙烯供應。在所有地區,高壓電力系統和氣候適應基礎設施的轉型都有利於EPDM的性能優勢,從而在原料價格波動的情況下維持全球消費。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 零能耗建築對EPDM屋頂防水卷材的需求激增

- 電動車產量加速成長,推動了對密封件和墊圈的需求。

- 強制部署5G基礎設施需要耐候電纜

- 氫燃料電池基礎設施需要耐高溫彈性體

- 透過促進循環經濟實現EPDM再生和脫硫

- 市場限制

- 原料價格因與原油價格掛鉤而波動

- 與熱塑性聚烯彈性體的競爭

- 深入探討石油衍生聚合物的碳排放強度

- 價值鏈分析

- 波特五力模型

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

第5章 市場規模與成長預測

- 透過製造程序

- 溶液聚合工藝

- 漿料/懸浮液工藝

- 氣相聚合工藝

- 透過使用

- 車

- 建築/施工

- 製造業

- 電氣和電子設備

- 其他用途

- 按地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 馬來西亞

- 泰國

- 印尼

- 越南

- 亞太其他地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 義大利

- 法國

- 俄羅斯

- 西班牙

- 土耳其

- 北歐國家

- 其他歐洲地區

- 南美洲

- 巴西

- 阿根廷

- 哥倫比亞

- 南美洲其他地區

- 中東和非洲

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 卡達

- 埃及

- 奈及利亞

- 南非

- 其他中東和非洲地區

- 亞太地區

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率(%)/排名分析

- 公司簡介

- ARLANXEO

- Carlisle Companies Inc.

- Dow

- ENEOS Materials Corporation

- Exxon Mobil Corporation

- Goodyear Rubber Company

- Kumho P&B Chemicals(Kumho Polychem)

- LANXESS

- Lion Elastomers

- Mitsui Chemicals Inc.

- SABIC

- SK geocentric Co., Ltd.

- Versalis SpA

- West American Rubber Company LLC

第7章 市場機會與未來展望

The Ethylene Propylene Diene Monomer Market was valued at 2.07 million tons in 2025 and estimated to grow from 2.16 million tons in 2026 to reach 2.67 million tons by 2031, at a CAGR of 4.34% during the forecast period (2026-2031).

Demand momentum is tied to electric-vehicle battery sealing, net-zero roofing membranes, and early hydrogen fuel cell adoption, all of which reward EPDM's thermal stability up to 150 °C and outstanding ozone resistance. Competitive positioning increasingly hinges on bio-based feedstocks and advanced catalysts that lower carbon footprints without compromising polymer properties. Regional supply security, particularly abundant propylene integration in Asia-Pacific, underpins volume leadership and buffers cost volatility risks. Feedstock price swings and rising thermoplastic vulcanizate (TPV) penetration pose cost and substitution pressures, yet differentiated EPDM grades continue to defend premium applications where dielectric stability, chemical resistance, and lifecycle durability are non-negotiable.

Global Ethylene Propylene Diene Monomer (EPDM) Market Trends and Insights

Surging Demand for EPDM Roofing Membranes in Net-Zero Buildings

EPDM membranes deliver service lives exceeding 50 years, giving developers a favorable cost-in-use equation against shorter-lived thermoplastics. White-colored formulations reflect solar radiation, helping projects achieve energy-efficiency credits under LEED and BREEAM schemes. Independent European reviews consistently rank EPDM's environmental impact lower than TPO or PVC alternatives, strengthening specification preference in climate-resilient construction. Growing urban heat-island mitigation codes increase demand for reflective roofs, while the material's chemical inertness supports rainwater harvesting and green-roof assemblies. Compatibility with photovoltaic mounting systems further raises adoption prospects in retrofits and new builds that seek combined energy and water performance benefits.

Accelerated EV Production Boosting Seals and Gaskets Demand

Electric-vehicle batteries require gaskets that withstand thermal cycling between -55 °C and +150 °C, remain elastic under vibration, and endure exposure to coolant glycols and fire-retardant additives. EPDM's low compression set protects pack integrity and limits moisture ingress, directly supporting battery warranty targets. Higher-voltage vehicle architectures make dielectric performance critical, and EPDM offers stable insulation in the 800-V systems now moving to mass production. Asia-Pacific remains the epicenter of demand growth due to China's dominant cell manufacturing base and Korea's high-capacity seal producers. Automakers are trialing TPVs to cut weight and aid recyclability, but EPDM still holds the performance edge in under-hood environments where temperatures and chemical exposure exceed TPV limits.

Volatile Crude-Oil-Linked Feedstock Prices

Propylene and ethylene price spikes driven by refinery shutdowns and tight olefin balances erode EPDM profit margins. U.S. polymer-grade propylene spot prices climbed in 2025 on the heels of refinery rationalizations and new polypropylene capacity additions. Asian ethylene values have displayed double-digit percentage swings within months, complicating contract negotiations and inventory planning for tire and gasket producers. Integrated EPDM suppliers with captive crackers partially offset the risk, but merchant producers often absorb margin compression or cede share to substitute materials in cost-sensitive applications.

Other drivers and restraints analyzed in the detailed report include:

- Mandatory 5G Infrastructure Roll-outs Requiring Weather-Resistant Cables

- Hydrogen Fuel-Cell Infrastructure Needs High-Temperature Elastomers

- Competition from Thermoplastic Polyolefin Elastomers

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Solution polymerization delivered 59.10% of the EPDM market size in 2025 as automakers and roof-membrane fabricators paid premiums for tight molecular-weight control essential to compression-set performance. The process allows precise diene incorporation, giving compounders latitude to tailor cure speed and elasticity for demanding battery gasket profiles. Recent catalyst breakthroughs, such as ARLANXEO's Keltan ACE titanium κ1-amidinate complex, reduce energy consumption, trimming unit production costs without altering downstream compounding recipes.

Slurry/suspension routes, projected to climb at a 4.78% CAGR, are capturing commodity grades for hose and cable insulation as operators retrofit reactors with higher-efficiency agitation systems that cut solvent use. Gas-phase technology remains niche but draws interest for ultra-high molecular-weight grades used in specialty compression seals.

The Ethylene Propylene Diene Monomer (EPDM) Report is Segmented by Manufacturing Process (Solution Polymerization Process, Slurry/Suspension Process, and Gas-Phase Polymerization Process), Application (Automotive, Building and Construction, Manufacturing, and More), and Geography (Asia-Pacific, North America, Europe, South America, and Middle-East and Africa). The Market Forecasts are Provided in Terms of Volume (Tons).

Geography Analysis

Asia-Pacific represented 56.05% of the EPDM market size in 2025, buoyed by Chinese battery-electric vehicle production and Korean capacity expansions such as Kumho Polychem's 220,000-ton site. Regional growth at 4.58% CAGR is supported by ample propylene supply from integrated crackers and steam-cracking complexes, reducing feedstock risk and freight cost. Localization strategies by global seal suppliers shorten lead times for EV manufacturers, creating a virtuous cycle of technical support and demand concentration.

North America's market is growing as Detroit automakers accelerate EV roll-outs and commercial roofing contractors specify EPDM for retrofit energy-efficiency upgrades. Domestic crackers face intermittent propylene tightness, but shale-gas economics continue to encourage olefin investment that promises more stable downstream pricing over the medium term. Federal tax incentives for clean-energy buildings are catalyzing new warehouse roof installations, further underpinning EPDM consumption.

Europe commands a premium application share driven by stringent environmental regulations that favor materials with demonstrated lifecycle benefits. Circular-economy directives encourage in-house devulcanization lines, giving regional compounders a head start in recycled-content EPDM blends. The Middle East and Africa, though smaller, show infrastructure-driven demand recovery, while South America's uptake hinges on petrochemical investment cycles in Brazil and nearby propylene supply. Across all regions, the shift toward higher-voltage power systems and climate-resilient infrastructure favors EPDM's performance attributes, sustaining worldwide consumption even amid feedstock volatility.

- ARLANXEO

- Carlisle Companies Inc.

- Dow

- ENEOS Materials Corporation

- Exxon Mobil Corporation

- Goodyear Rubber Company

- Kumho P&B Chemicals (Kumho Polychem)

- LANXESS

- Lion Elastomers

- Mitsui Chemicals Inc.

- SABIC

- SK geocentric Co., Ltd.

- Versalis S.p.A

- West American Rubber Company LLC

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Surging Demand for EPDM Roofing Membranes in Net-Zero Buildings

- 4.2.2 Accelerated EV Production Boosting Seals and Gaskets Demand

- 4.2.3 Mandatory 5G Infrastructure Rollouts Requiring Weather-Resistant Cables

- 4.2.4 Hydrogen Fuel-Cell Infrastructure Needs High-Temperature Elastomers

- 4.2.5 Circular-Economy Push for EPDM Reclaim and Devulcanization

- 4.3 Market Restraints

- 4.3.1 Volatile Crude-Oil-Linked Feedstock Prices

- 4.3.2 Competition from Thermoplastic Polyolefin Elastomers

- 4.3.3 Carbon-Intensity Scrutiny of Petro-Based Polymers

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts (Volume)

- 5.1 By Manufacturing Process

- 5.1.1 Solution Polymerization Process

- 5.1.2 Slurry/Suspension Process

- 5.1.3 Gas-phase Polymerization Process

- 5.2 By Application

- 5.2.1 Automotive

- 5.2.2 Building and Construction

- 5.2.3 Manufacturing

- 5.2.4 Electrical and Electronics

- 5.2.5 Other Applications

- 5.3 By Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 South Korea

- 5.3.1.5 Malaysia

- 5.3.1.6 Thailand

- 5.3.1.7 Indonesia

- 5.3.1.8 Vietnam

- 5.3.1.9 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 Italy

- 5.3.3.4 France

- 5.3.3.5 Russia

- 5.3.3.6 Spain

- 5.3.3.7 Turkey

- 5.3.3.8 NORDIC Countries

- 5.3.3.9 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Colombia

- 5.3.4.4 Rest of South America

- 5.3.5 Middle-East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 United Arab Emirates

- 5.3.5.3 Qatar

- 5.3.5.4 Egypt

- 5.3.5.5 Nigeria

- 5.3.5.6 South Africa

- 5.3.5.7 Rest of Middle-East and Africa

- 5.3.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share (%)/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 ARLANXEO

- 6.4.2 Carlisle Companies Inc.

- 6.4.3 Dow

- 6.4.4 ENEOS Materials Corporation

- 6.4.5 Exxon Mobil Corporation

- 6.4.6 Goodyear Rubber Company

- 6.4.7 Kumho P&B Chemicals (Kumho Polychem)

- 6.4.8 LANXESS

- 6.4.9 Lion Elastomers

- 6.4.10 Mitsui Chemicals Inc.

- 6.4.11 SABIC

- 6.4.12 SK geocentric Co., Ltd.

- 6.4.13 Versalis S.p.A

- 6.4.14 West American Rubber Company LLC

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-Need Assessment