|

市場調查報告書

商品編碼

1907312

對二甲苯(PX):市佔率分析、產業趨勢與統計、成長預測(2026-2031)Paraxylene (PX) - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

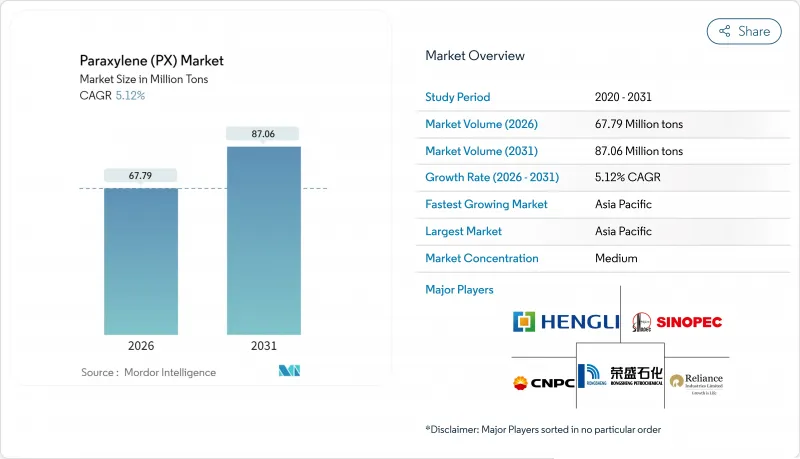

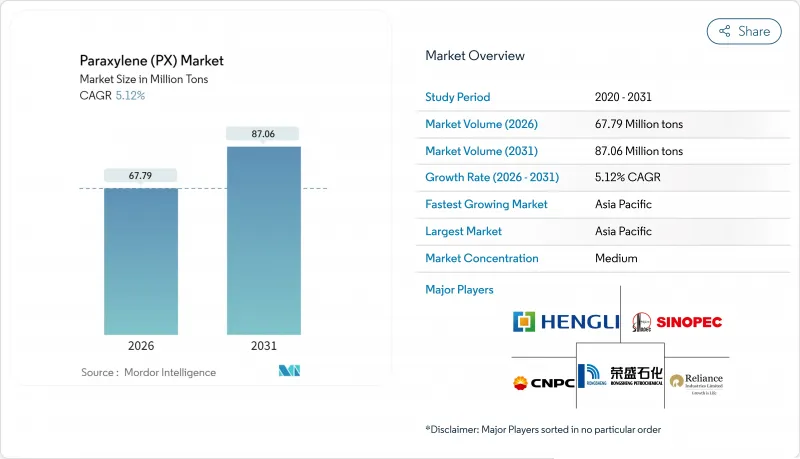

對二甲苯(PX)市場預計將從 2025 年的 6,448 萬噸成長到 2026 年的 6,779 萬噸,預計到 2031 年將達到 8,706 萬噸,2026 年至 2031 年的複合年成長率為 5.12%。

對二甲苯的穩定供應對全球聚酯產業至關重要,因為純對苯二甲酸(PTA)可直接轉化為聚對苯二甲酸乙二醇酯(PET),用於包裝和纖維生產。中國的綜合石化企業透過原油直接轉化為芳烴,享有成本優勢,此模式使得中國在2024年至2025年間新增對二甲苯產能超過1000萬噸。原料經濟性仍然至關重要,石腦油價格年減16.5%至每噸554.79美元,儘管供應過剩對現貨價格構成壓力,但仍有助於利潤率在2025年初回升。飲料和個人護理包裝、產業用紡織品以及全部區域可支配收入的成長支撐了需求的韌性。同時,生物基路線和化學回收利用對現有生產商而言既是風險也是機會。因此,競爭優勢取決於規模、整合、能源效率以及應對影響品牌籌資策略的永續性的能力。

全球對二甲苯(PX)市場趨勢及展望

PET包裝材料需求激增

品牌商在包裝飲料、家用液體和個人保健產品,正擴大用PET取代較重的材料,從而推動了對二甲苯(PTA)的需求。 PTA約佔瓶子樹脂重量的70%。信實工業(Reliance Industries)報告稱,2024會計年度全球PET回收量將成長13%,這主要得益於輕巧且完全可回收的瓶型,它們滿足了零售商對運輸效率和展示效果的需求。線上雜貨和直銷通路進一步推動了這一需求,因為PET在長途通路中不易破損的特性得到了充分體現。政府法規擴大採用強制性的最低再生材料含量要求,而非徹底禁止,這使得原生對二甲苯能夠滿足不斷成長的包裝需求,同時促進了回收基礎設施的發展。因此,擁有芳烴和PTA一體化裝置的煉油廠可以確保可預測的基本負載需求,即使在運輸燃料週期性低迷時期也能維持收入穩定。

亞洲聚酯纖維的擴張

亞太地區仍然是世界紡織品生產基地,儘管對二甲苯價格波動,但聚酯纖維相對於棉花的成本優勢支撐著紡織品需求。中國計劃在2024年運作400多萬噸聚酯短纖維產能,印度也已核准一項基於績效的化學纖維激勵計劃,以促進國內服飾出口。汽車安全氣囊、輸送機和地工織物技術紡織品的需求取決於對二甲苯胺(PTA)的持續供應,因為這些產品需要穩定且高利潤的供應。位於賈姆訥格爾和大連的綜合產業群聚將對二甲苯、PTA和纖維紡絲集中在一處,降低了運輸成本,增強了區域競爭力。快時尚品牌正在加快訂貨週期,工廠優先選擇能夠確保PTA準時交付的供應商。這種能力在中國東部沿海省份的大型綜合產業叢集中最為容易取得。

加強對一次性塑膠製品的監管

歐盟的《一次性塑膠指令》將禁止某些外帶食品,並徵收生產者延伸責任費,這將增加使用原生PET的加工商的合規成本。加州的一項類似提案將強制要求到2028年,飲料瓶中必須含有25%的再生材料,這將迫使品牌所有者轉向鋁和紙基解決方案,以應對小眾產品。從營運層面來看,速食包裝對對二甲苯的需求可能會停滯不前,而無菌果汁和乳製品等阻隔性PET應用仍將受到性能要求的保護。這將導致成熟市場成長放緩,樹脂流向那些設定了切實可行的回收目標而非簡單使用限制的地區。

細分市場分析

到2025年,純對苯二甲酸將佔全球產量的94.35%,鞏固其作為對二甲苯主要用途的地位。江蘇、浙江和古吉拉突邦正在進行的對苯二甲酸(PTA)擴產預計將超過該領域芳烴的供應,到2031年將達到5.32%的複合年成長率。煉廠到化工環節一體化程度的提高,增強了運轉率的柔軟性,最大限度地減少了對二甲苯和PTA裝置之間的物流轉運,並確保了原料供應的穩定性。因此,該單體大型企劃的PTA年產能超過300萬噸,實現了規模經濟,從而降低了現貨市場對二甲苯溢價的價格波動。利用數位雙胞胎模型最佳化熱整合網路,可降低10-12%的能源成本並減少排放。這項優勢至關重要,因為歐洲出口客戶必須遵守範圍1的碳排放限制。

隨著授權生產商逐步淘汰酯交換生產線,對苯二甲酸二甲酯 (DMT) 的利基市場正在萎縮,其可變成本比直接採用對二甲苯 (PTA) 路線高出 15-20%。特種溶劑、塑化劑和除草劑中間體佔對二甲苯消耗量的剩餘 1-2%,呈現個位數的溫和成長,但不足以推動總需求。然而,它們在控制重整芳烴池中的異構體比例方面仍然發揮著重要作用,從而能夠制定最大化整個煉廠價值而非單一分子價值的生產計畫。雖然替代生物芳烴展現出一定的潛力,但其商業化產量仍微乎其微,這意味著在預測期內,傳統的對二甲苯 (PTA) 路線仍將繼續主導對二甲苯市場。

對二甲苯 (PX) 市場報告按應用(純對苯二甲酸、對苯二甲酸二甲酯及其他應用)、終端用戶行業(塑膠、紡織品及其他終端用戶行業)和地區(亞太地區、北美地區、歐洲地區、南美地區以及中東和非洲地區)進行細分。市場預測以公噸為單位。

區域分析

預計到2025年,亞太地區將以82.10%的市佔率主導對二甲苯市場,並在2031年之前維持5.48%的複合年成長率。這主要得益於中國、印度和東南亞地區下游聚酯產業生態系的不斷強化。中國的石化集中化策略將在2024年至2025年間促成五個新聯合裝置的投產,每個裝置都將運作對二甲苯、對苯二甲酸單酯(PTA)和聚合物生產單元。光是大宇山一家就將年產1180萬噸芳烴。印度正利用其位於賈姆訥格爾的年產140萬噸對二甲苯裝置以及不斷擴大的產業用紡織品出口激勵措施,提高區域自給率,並吸引外資進入其服裝製造群。日本和韓國仍在供應高品質對二甲苯,但隨著國內需求趨於平穩,兩國正被迫進行產能最佳化。

北美市場規模雖小,卻在全球市場佔有重要的戰略地位。由於混合二甲苯原料與汽油混合後辛烷值較高,因此在燃料需求高峰期,北美地區單獨生產對二甲苯的利潤率低於亞洲。然而,先進的連續燃燒重整(CCR)維修和豐富的頁岩冷凝油供應確保了原料來源的多樣性。到2031年,北美對二甲苯市場規模預計將擴大至447萬噸。這項成長將主要得益於那些位置消費品品牌、致力於縮短物流鏈的特種PET和生物基對二甲苯(bio-PX)先導工廠。化學回收材料的政策支持將進一步促進原料來源多元化,但在預測期內,其對原生對二甲苯的絕對替代效應將十分有限。

能源和監管成本的上漲給歐洲帶來了挑戰,導致從中東和亞洲的進口量增加。天然氣價格持續高企推高了蒸氣裂解裝置的公用成本,降低了本地對甲苯(PX)的競爭力。然而,一次性塑膠法規正推動需求轉向完全可回收的聚對苯二甲酸乙二醇酯(PET),從而維持了採用閉合迴路的對甲苯(PTA)工廠的基本負載需求。中東正透過將過剩的石腦油和重整油轉化為芳烴,並專注於與亞洲主要聚酯公司簽訂出口契約,來收緊全球供應平衡。南美洲的需求主要由巴西飲料產業驅動,造成了結構性的對甲苯(PX)虧損,這種逆差透過與美國墨西哥灣沿岸和阿拉伯灣地區的出口商簽訂長期供應協議來彌補。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- PET包裝材料需求激增

- 亞洲聚酯纖維的擴張

- 輕巧、可回收的飲料瓶推動了PX的需求。

- 高產率CCR和PRT芳烴裝置的商業化。

- 生物基對二甲苯商業規模先導工廠(非化石燃料)

- 市場限制

- 加強對一次性塑膠製品的監管

- 原油價格波動主導原物料價格波動

- 用新型化學回收取代原生PX

- 價值鏈分析

- 波特五力模型

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭對手之間的競爭

第5章 市場規模與成長預測

- 透過使用

- 純對苯二甲酸(PTA)

- 對苯二甲酸二甲酯(DMT)

- 其他用途

- 按最終用戶行業分類

- 塑膠

- 紡織品

- 其他終端用戶產業

- 按地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 泰國

- 印尼

- 馬來西亞

- 越南

- 亞太其他地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 俄羅斯

- 其他歐洲地區

- 南美洲

- 巴西

- 阿根廷

- 哥倫比亞

- 南美洲其他地區

- 中東和非洲

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 卡達

- 奈及利亞

- 埃及

- 南非

- 其他中東和非洲地區

- 亞太地區

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率(%)/排名分析

- 公司簡介

- China Petrochemical Corporation

- CNPC

- Eneos Corporation

- Exxon Mobil Corporation

- FCFC

- GS Caltex Corporation

- Hengli Petrochemical Co., Ltd.

- Idemitsu Kosan Co.,Ltd.

- Ineos

- LOTTE CHEMICAL CORPORATION

- PTT Global Chemical Public Company Limited

- Reliance Industries Limited

- Rongsheng Petrochemical Co., Ltd.

- S-oil Corporation

- TotalEnergies

第7章 市場機會與未來展望

The Paraxylene Market is expected to grow from 64.48 Million tons in 2025 to 67.79 Million tons in 2026 and is forecast to reach 87.06 Million tons by 2031 at 5.12% CAGR over 2026-2031.

A secure supply of para-xylene underpins the global polyester chain because purified terephthalic acid (PTA) converts directly into polyethylene terephthalate (PET) for packaging and fiber. Integrated oil-to-chemicals complexes in China hold cost advantages by processing crude directly into aromatics, an approach that added more than 10 million tons of new para-xylene capacity during 2024-2025. Feedstock economics remain pivotal; a 16.5% year-over-year decrease in naphtha pricing to USD 554.79 per ton restored margins in early 2025 even as oversupply pressured spot values. Demand resilience comes from beverage and personal-care packaging, technical textiles and rising disposable incomes across Asia-Pacific, while bio-based routes and chemical recycling offer both risk and opportunity for incumbent producers. Competitive positioning, therefore, rests on scale, integration, energy efficiency, and the ability to navigate sustainability mandates that influence brand procurement strategies.

Global Paraxylene (PX) Market Trends and Insights

Surging Demand for PET Packaging

Brand owners that package beverages, home-care liquids and personal-care products continue to substitute heavier materials with PET, propelling para-xylene demand because PTA constitutes nearly 70% of bottle resin weight. Reliance Industries reported a 13% in global PET off-take during fiscal 2024, driven by lightweight and fully recyclable bottle formats that satisfy retailer requirements for transport efficiency and shelf appeal. Online grocery and direct-to-consumer channels magnify these volumes because PET resists breakage throughout longer distribution chains. Government regulations increasingly specify minimum recycled content rather than outright bans, allowing virgin para-xylene to keep pace with packaging growth while stimulating collection infrastructure. Consequently, refineries with integrated aromatics and PTA assets secure predictable baseload demand, smoothing earnings even when transportation fuels see cyclical downturns.

Polyester-Fiber Expansion in Asia

Asia-Pacific remains the textile workbench of the world, and polyester's cost advantage over cotton sustains fiber demand despite para-xylene price volatility. China commissioned more than 4 million tons of new polyester staple capacity in 2024, while India approved performance-linked incentive schemes covering man-made fibers to stimulate domestic garment exports. Technical textile off-take in automotive airbags, conveyor belts, and geotextiles adds steadier, higher-margin volumes that rely on consistent PTA supply. Integrated complexes in Jamnagar and Dalian reduce transport costs by colocating para-xylene, PTA, and fiber spinning, thereby boosting regional competitiveness. Fast-fashion brands accelerate order cycles, meaning mills favor suppliers that guarantee just-in-time PTA deliveries, a capability most feasible inside large integrated clusters across Eastern China's coastal provinces.

Single-Use-Plastic Legislation Tightening

The European Union's Single-Use Plastics Directive bans selected takeaway items and imposes extended-producer-responsibility fees that raise compliance costs for converters using virgin PET. Similar proposals in California mandate 25% recycled content in beverage bottles by 2028, prompting brand owners to diversify into aluminum or paper-based solutions for niche SKUs. Operationally, para-xylene demand could stall in quick-service packaging, though high-barrier PET applications such as aseptic juice or dairy remain protected by performance requirements. The net effect reduces growth in mature markets while redirecting resin flows toward regions with pragmatic recyclability targets rather than outright volume caps.

Other drivers and restraints analyzed in the detailed report include:

- Lightweight, Recyclable Beverage Bottles Push PX

- High-Yield CCR and PRT Aromatics Units Commercializing

- Crude-Oil-Led Feedstock Price Volatility

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Purified terephthalic acid retained 94.35% of global volume in 2025, cementing its status as the core outlet for the para-xylene market. The scale of PTA expansions underway in Jiangsu, Zhejiang, and Gujarat means the segment will outpace overall aromatics supply, generating a 5.32% CAGR to 2031. Ongoing refinery-to-chemicals integration raises operating-rate flexibility, minimizing logistics transfers between para-xylene and PTA units and locking in feedstock security. As a result, PTA capacity at single-site mega-projects now exceeds 3 million tons per year, enabling economies that blunt price swings in spot PX premiums. Digital-twin models optimize heat-integration networks within these complexes, shaving 10-12 % from energy costs and shrinking emissions-an advantage when compliance with Scope 1 carbon limits affects European export customers.

The dimethyl terephthalate niche shrinks as licensees retire transesterification lines, citing 15-20 % higher variable costs than direct PTA routes. Specialty solvents, plasticizers, and herbicide intermediates account for the residual 1-2 % of para-xylene consumption and exhibit mid-single-digit growth, insufficient to sway aggregate demand. Nevertheless, they remain important for balancing isomer ratios inside reformer aromatics pools, ensuring that production planning maximizes overall refinery value rather than a single molecule. While substitute bio-aromatics appear promising, commercial tonnage remains minimal, indicating that conventional PTA will continue to shape the para-xylene market during the outlook period.

The Paraxylene (PX) Market Report is Segmented by Application (Purified Terephthalic Acid, Dimethyl Terephthalate, and Other Applications), End-User Industry (Plastics, Textile, and Other End-User Industries), and Geography (Asia-Pacific, North America, Europe, South America, and Middle East and Africa). The Market Forecasts are Provided in Terms of Volume (Tons).

Geography Analysis

Asia-Pacific dominated the para-xylene market with an 82.10% share in 2025 and is forecast to maintain a 5.48% CAGR to 2031 as China, India, and Southeast Asia reinforce downstream polyester ecosystems. China's centralized oil-to-chemicals strategy placed five new complexes online in 2024-2025, each with integrated para-xylene, PTA, and polymer units; Dayushan alone yields 11.8 million tons of aromatics annually. India leverages Jamnagar's 1.4 million-ton PX train and the nation's expanding technical-textile export incentives, enhancing regional self-sufficiency and attracting foreign investment in apparel manufacturing clusters. Japan and South Korea continue to supply premium specification PX grades, although capacity rationalizations loom as domestic demand plateaus.

North America retains a smaller but strategically important slice of global volume. Mixed-xylene streams fetch a strong octane value in gasoline blending, pushing stand-alone PX margins below those in Asia during high-fuel-demand seasons. Nevertheless, advanced CCR revamps and abundant shale condensate maintain feedstock diversity. The para-xylene market size in North America could edge toward 4.47 million tons by 2031, with incremental growth tied to specialty PET and bio-PX pilots located close to consumer brands that value shorter logistics chains. Policy support for chemically recycled content further diversifies sourcing, though absolute displacement of virgin PX remains modest through the forecast horizon.

Europe confronts steeper energy and regulatory costs, driving imports from the Middle East and Asia. Persistent natural-gas premiums elevate steam-cracker utility expenses, eroding local PX competitiveness. Nonetheless, single-use-plastic rules tilt demand toward fully recyclable PET, preserving baseload offtake for PTA plants that adopt closed-loop recycling schemes. The Middle East tightens global supply equations by channeling surplus naphtha and reformate into aromatics, focusing on export contracts with Asia's polyester majors. South America's demand centers on Brazil's beverages sector, leading to structural PX trade deficits addressed through long-term supply contracts with U.S. Gulf Coast and Arabian Gulf exporters.

- China Petrochemical Corporation

- CNPC

- Eneos Corporation

- Exxon Mobil Corporation

- FCFC

- GS Caltex Corporation

- Hengli Petrochemical Co., Ltd.

- Idemitsu Kosan Co.,Ltd.

- Ineos

- LOTTE CHEMICAL CORPORATION

- PTT Global Chemical Public Company Limited

- Reliance Industries Limited

- Rongsheng Petrochemical Co., Ltd.

- S-oil Corporation

- TotalEnergies

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Surging Demand for PET Packaging

- 4.2.2 Polyester-fiber Expansion in Asia

- 4.2.3 Lightweight, Recyclable Beverage Bottles Push PX

- 4.2.4 High-yield CCR and PRT Aromatics Units Commercialising

- 4.2.5 Bio-based PX Commercial Scale Pilots (non-fossil)

- 4.3 Market Restraints

- 4.3.1 Single-use-plastic Legislation Tightening

- 4.3.2 Crude-oil Led Feedstock Price Volatility

- 4.3.3 Emerging Chemical Recycling Displacing Virgin PX

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Competitive Rivalry

5 Market Size and Growth Forecasts (Volume)

- 5.1 By Application

- 5.1.1 Purified Terephthalic Acid (PTA)

- 5.1.2 Dimethyl Terephthalate (DMT)

- 5.1.3 Other Applications

- 5.2 By End-user Industry

- 5.2.1 Plastics

- 5.2.2 Textile

- 5.2.3 Other End-user Industries

- 5.3 By Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 South Korea

- 5.3.1.5 Thailand

- 5.3.1.6 Indonesia

- 5.3.1.7 Malaysia

- 5.3.1.8 Vietnam

- 5.3.1.9 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 France

- 5.3.3.4 Italy

- 5.3.3.5 Spain

- 5.3.3.6 Russia

- 5.3.3.7 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Colombia

- 5.3.4.4 Rest of South America

- 5.3.5 Middle East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 United Arab Emirates

- 5.3.5.3 Qatar

- 5.3.5.4 Nigeria

- 5.3.5.5 Egypt

- 5.3.5.6 South Africa

- 5.3.5.7 Rest of Middle East and Africa

- 5.3.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share (%)/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share, Products and Services, Recent Developments)

- 6.4.1 China Petrochemical Corporation

- 6.4.2 CNPC

- 6.4.3 Eneos Corporation

- 6.4.4 Exxon Mobil Corporation

- 6.4.5 FCFC

- 6.4.6 GS Caltex Corporation

- 6.4.7 Hengli Petrochemical Co., Ltd.

- 6.4.8 Idemitsu Kosan Co.,Ltd.

- 6.4.9 Ineos

- 6.4.10 LOTTE CHEMICAL CORPORATION

- 6.4.11 PTT Global Chemical Public Company Limited

- 6.4.12 Reliance Industries Limited

- 6.4.13 Rongsheng Petrochemical Co., Ltd.

- 6.4.14 S-oil Corporation

- 6.4.15 TotalEnergies

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-Need Assessment