|

市場調查報告書

商品編碼

1907288

印刷油墨:市場佔有率分析、產業趨勢與統計、成長預測(2026-2031)Printing Inks - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

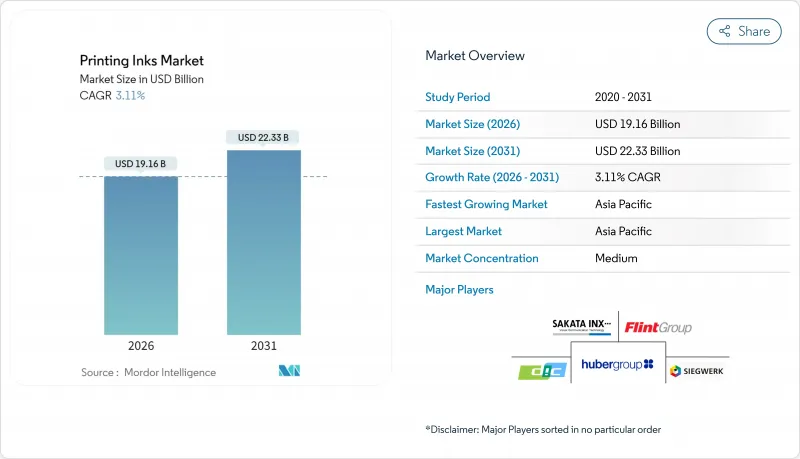

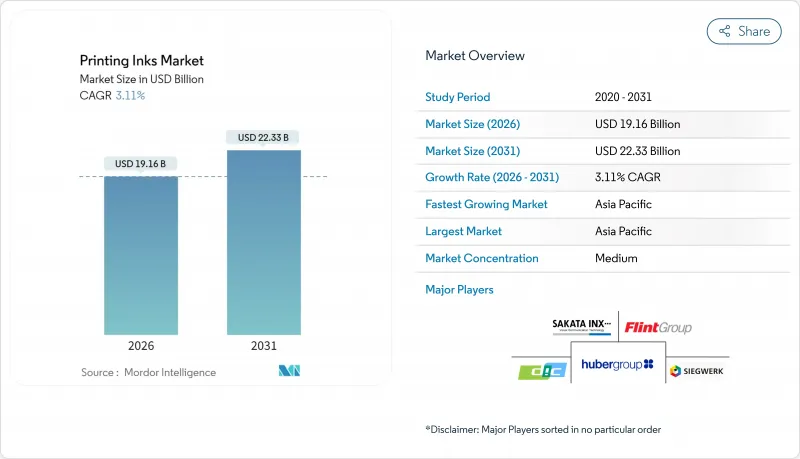

2025 年印刷油墨市場價值為 185.8 億美元,預計從 2026 年的 191.6 億美元成長到 2031 年的 223.3 億美元,在預測期(2026-2031 年)內複合年成長率為 3.11%。

包裝、數位化和永續性正在融合,共同塑造需求模式、資本投資和區域格局。包裝目前已佔印刷油墨市場55.94%的佔有率,並將持續維持成長最快的應用領域,到2030年複合年成長率將達到4.37%。油性油墨仍佔據市場主導地位,但隨著加工商追求即時固化和更低能耗,UV-LED油墨預計將以7.59%的複合年成長率成為成長最快的領域。因此,印刷油墨市場正在努力平衡傳統優勢與新興的綠色數位化能力。

全球印刷油墨市場趨勢與洞察

數位印刷產業的成長

數位印刷正在重塑印刷油墨市場,從利基概念發展成為主流生產平台。設備成本的持續下降和印字頭性能的提升,正促使加工商將中小批量生產轉向噴墨印刷,從而縮短交貨週期並降低庫存風險。油墨製造商積極回應,提供低黏度、高光學密度的顏料配方,即使在高噴射速度下也能保持色彩穩定性。受按需服裝和裝飾訂製需求的推動,數位織物印刷量正成長至每年近150億公尺。包裝加工商正在利用可變數據來實現季節性促銷和區域語言支持,將前置作業時間從數週縮短至數天。

包裝和標籤需求不斷成長

隨著都市化加快、家庭規模縮小以及電子商務物流的興起,全球對包裝產品的需求穩步成長,這主要得益於消費者習慣的改變。瓦楞紙箱、紙板套和軟包裝袋都需要耐用且食品安全的油墨,以承受運輸過程中的機械應力和潮濕環境。品牌靠著高清影像和觸感表面處理在琳瑯滿目的貨架上脫穎而出,從而提升了特殊塗料和金屬顏料的價值。包裝食品和個人保健產品在亞太和非洲部分新興經濟體中實現了兩位數的成長,推動了對水性柔版印刷和凹版印刷油墨的需求成長。標籤應用擴大整合資料密集型訊息,例如QR碼和防偽功能,這要求油墨具有精確的套準精度和優異的色彩穩定性。因此,即使在宏觀經濟放緩時期,包裝產業的需求仍持續成長,鞏固了其作為印刷油墨市場關鍵成長引擎的地位。

傳統商業印刷業的衰退

隨著廣告商將預算重新分配到數位管道,報紙和雜誌的發行量每季都在萎縮。 2024年1月,美國印刷和書寫紙的出貨量較去年同期下降了9%。這導致膠印油墨消費量減少,造成油墨調配產能過剩,並加劇了價格競爭。印刷商正在淘汰老舊印刷機,降低了售後市場對替代油墨的需求,也減少了維修服務收入。一些供應商正在透過改造調配設備來生產水性柔印系統,但鑑於商業印刷需求疲軟,投資回收期很長。這種長期放緩將使預測的複合年成長率降低0.4個百分點,但來自新興數位印刷和包裝領域的需求成長將部分抵消這一影響。

細分市場分析

由於油性油墨具有成本效益高、相容性廣等優點,預計到2025年,其收入將佔總收入的40.70%,但由於VOC(揮發性有機化合物)法規日益嚴格,其成長速度預計將會放緩。 UV-LED產品的複合年成長率將達到7.47%,反映出加工商對即時固化和節能的偏好。水性包裝在瓦楞紙箱和紙杯等產品中越來越普遍,尤其是在歐盟,由於食品接觸法規和回收要求更加嚴格,其需求量不斷成長。溶劑型系統將繼續用於需要極強附著力的特殊工業貼花,但生產正逐步轉向揮發性較低的替代品。

製造物流驅動消費者的購買行為。 UV-LED印表機的燈管壽命通常超過20,000小時,避免了長時間的維修停機。能量固化化學品由於減少了廢棄物並降低了能源成本,因此具有整體擁有成本優勢。同時,由於原料價格波動以及企業永續性報告標準中揭露要求的提高,人們對生物基油替代品的興趣日益濃厚。雖然生物溶劑供應鏈尚不成熟,但早期採用者已從植物來源成分中獲得了市場優勢。這些趨勢共同表明,印刷油墨市場正逐步但穩定地轉型為低VOC、快速固化平台。

印刷油墨市場報告按類型(溶劑型、水性、油性、UV、UV-LED、其他)、工藝(膠印、柔印、凹印、數位印刷、其他)、應用(包裝、商業印刷/出版、紡織品、其他應用)和地區(亞太地區、北美、歐洲、南美、中東/非洲)進行分析。

區域分析

到2025年,亞太地區將佔全球收入的40.10%,年複合成長率達3.96%,這反映了中國、印度和東南亞地區強大的製造業生態系統。隨著中產階級的壯大,國內消費不斷成長,推動了對包裝零食、個人護理用品和藥品的需求。當地加工商正在投資高速柔版印刷生產線,並對其維修,加裝紫外線LED燈,以節省能源並滿足出口客戶的審核。中國和印度政府正在支持電子產品和太陽能組件的供應鏈,間接刺激了對用於感測器和匯流排的導電油墨的需求。顏料和樹脂中間體等區域原料採購環境有利於價格競爭,並促進了印刷油墨的全球貿易流量。

歐洲擁有世界上最嚴格的環境法規,加速了水性油墨和能量固化油墨的轉型。德國在環保油墨領域的主導以及法國對礦物油的禁用,正促使區域供應商重新配製油墨並實施溶劑回收系統。在義大利和法國的奢侈品牌聚集區,對高階表面處理的追求推動了對金屬光澤、珠光和觸感清漆系統的需求。東歐的加工商正在安裝模組化柔印生產線,以服務跨洲零售集團,並且擴大指定使用與西歐買家相同的低遷移油墨。

北美正經歷技術成熟與VOC(揮發性有機化合物)法規日益嚴格的雙重挑戰。美國環保署(EPA)的《有毒物質控制法案》(TSCA)評估迫使配方師檢驗原料的毒理學特性,並引入更安全的替代品。大型加工商正在部署預測性維護平台,INX International公司在其生產線上應用人工智慧分析技術後,產能運轉率提高了13%。墨西哥作為美國和加拿大包裝食品和個人保健產品的近岸外包中心,其市場佔有率不斷擴大,推動了該地區對油墨的需求。品牌商正在推廣可回收油墨,這些油墨不會阻礙紙張再製漿或聚烯回收,從而促進了整個包裝價值鏈的合作。該地區充分展現了自動化、永續性和日益嚴格的法規如何相互交織,共同塑造印刷油墨市場的未來。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 數位印刷產業的成長

- 包裝和標籤需求不斷成長

- 過渡到水性環保油墨

- 紫外線/能量固化技術的興起

- 功能性導電油墨在電子設備的應用

- 市場限制

- 傳統商業印刷業的衰退

- 嚴格的揮發性有機化合物 (VOC) 和廢棄物處理法規

- 硝化纖維素原料短缺

- 價值鏈分析

- 波特五力模型

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

第5章 市場規模與成長預測

- 按類型

- 溶劑型

- 水溶液

- 油膩的

- UV

- UV-LED

- 其他類型

- 透過流程

- 平版印刷

- 柔版印刷

- 凹版印刷

- 數位印刷

- 其他流程

- 透過使用

- 包裝

- 硬包裝

- 紙容器

- 瓦楞紙箱

- 硬質塑膠容器

- 金屬罐

- 其他硬質包裝

- 軟包裝

- 標籤

- 其他包裝

- 硬包裝

- 商業與出版

- 纖維

- 其他用途

- 包裝

- 按地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 澳洲和紐西蘭

- 東南亞國協

- 亞太其他地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 俄羅斯

- 西班牙

- 其他歐洲地區

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 其他中東和非洲地區

- 亞太地區

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率(%)/排名分析

- 公司簡介

- ALTANA

- Dainichiseika Color & Chemicals Mfg. Co., Ltd.

- DIC Corporation

- DuPont

- Epple Druckfarben AG

- Flint Group

- FUJIFILM Corporation

- hubergroup

- Nazdar

- Sakata INX Corporation

- Sanchez SA de CV

- SICPA HOLDING SA

- Siegwerk Druckfarben AG & Co. KGaA

- T&K TOKA Corporation

- Tokyo Printing Ink Mfg. Co., Ltd.

- Toyo Ink Co. Ltd(artience Co. Ltd)

- Wikoff Color Corporation

- Yip's Chemical Holdings Limited

- Zeller+Gmelin

第7章 市場機會與未來展望

The Printing Inks Market was valued at USD 18.58 billion in 2025 and estimated to grow from USD 19.16 billion in 2026 to reach USD 22.33 billion by 2031, at a CAGR of 3.11% during the forecast period (2026-2031).

Packaging, digitalization, and sustainability together shape demand patterns, capital investment, and regional shifts. Packaging already commands 55.94% of the printing inks market and remains the fastest-expanding application at 4.37% CAGR through 2030. Oil-based formulations keep a major share, but UV-LED inks post the highest 7.59% CAGR as converters pursue instant curing and lower energy use. The printing inks market, therefore, balances legacy strengths with emerging eco-friendly and digital capabilities.

Global Printing Inks Market Trends and Insights

Growth in Digital Printing Industry

Digital printing has moved from a niche concept to a mainstream production platform that reshapes the printing inks market. Continuous drops in equipment cost and head improvements allow converters to migrate short and medium runs toward inkjet, improving job turnaround and reducing inventory risk. Ink manufacturers respond with low-viscosity, high-optical-density pigment packages that maintain color consistency at high jetting speeds. Digital fabric printing already approaches 15 billion meters annually, stimulated by on-demand apparel and decor customization. Packaging converters exploit variable data to address seasonal promotions and localized languages, compressing lead times from weeks to days.

Expansion of Packaging and Labels Demand

Global demand for packaged goods expands steadily as rising urbanization, smaller household sizes, and e-commerce fulfillment change consumption habits. Corrugated boxes, paperboard sleeves, and flexible pouches all require durable, food-safe inks that withstand mechanical stress and logistics humidity. Brands rely on high-fidelity graphics and tactile finishes to stand out on crowded shelves, which boosts the value of specialty coatings and metallic pigments. Emerging economies in Asia-Pacific and parts of Africa see double-digit growth in packaged food and personal care, underpinning volume gains for water-based flexo and gravure inks. Label applications become more data-rich, integrating QR codes and anti-counterfeiting features that demand precise registration and robust color stability. The net result is sustained volume expansion even during macro-economic slowdowns, reinforcing packaging's role as the primary growth engine for the printing inks market.

Decline in Conventional Commercial Printing

Newspaper and magazine circulations shrink every quarter as advertisers reallocate budgets to digital channels. In January 2024, shipments of U.S. printing-writing paper fell 9% year on year. Offset ink consumption therefore declines, leaving surplus blending capacity and intensifying price competition. Print houses retire older presses, which trims aftermarket demand for replacement inks and dampens revenue for maintenance services. Some suppliers respond by refitting mixing facilities to produce water-based flexo systems, but pay-back periods stretch when demand for commercial print remains soft. The secular downturn subtracts 0.4 percentage points from the forecast CAGR, partially offset by new digital and packaging volumes.

Other drivers and restraints analyzed in the detailed report include:

- Shift Toward Water-Based Eco-Friendly Inks

- Emergence of UV/Energy-Curable Technologies

- Stringent VOC and Waste-Disposal Regulations

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Oil-based inks secured 40.70% of 2025 revenue due to cost efficiency and broad compatibility, yet their growth remains subdued under tightening VOC rules. UV-LED products post a 7.47% CAGR, reflecting converter preference for instant curing and energy savings. Water-based packages gain traction in corrugated cartons and paper cups, especially inside the European Union where food-contact and recyclability requirements grow stricter. Solvent systems persist in specialized industrial decals that need extreme adhesion, though volume gradually migrates toward less volatile alternatives.

Conversion logistics shape purchasing behavior. UV-LED presses avoid extended maintenance shut-downs because lamp life often exceeds 20,000 hours. Reduced scrap and lower energy bills tilt the total cost of ownership advantage toward energy-curable chemistries. In parallel, bio-based oil replacements gain interest as feedstock volatility and disclosure requirements under corporate sustainability reporting standards increase. Early adopters secure marketing premiums for plant-derived content, although supply chains for bio-solvents remain nascent. The combined trend signals a gradual, though definitive, reweighting of the printing inks market toward low-VOC, quick-cure platforms.

The Printing Inks Report is Segmented by Type (Solvent-Based, Water-Based, Oil-Based, UV, UV-LED, and Other Types), Process (Lithographic Printing, Flexographic Printing, Gravure Printing, Digital Printing, Other Processes), Application (Packaging, Commercial and Publication, Textiles, and Other Applications), and Geography (Asia-Pacific, North America, Europe, South America, and Middle-East and Africa).

Geography Analysis

Asia-Pacific holds 40.10% of global 2025 revenue and grows at 3.96% CAGR, reflecting robust manufacturing ecosystems in China, India, and Southeast Asia. Domestic consumption rises alongside expanding middle classes, boosting demand for packaged snacks, personal care, and pharmaceuticals. Local converters invest in high-speed flexo lines and adopt UV-LED retrofits to conserve energy and meet export customer audits. Governments in China and India support electronics and solar module supply chains, indirectly stimulating conductive ink opportunities for sensors and busbars. Regional raw material access, notably pigments and resin intermediates, supports competitive pricing that feeds into global trade flows of printing inks.

Europe enforces some of the most stringent environmental rules, accelerating migration to water-based and energy-curable platforms. Germany's leadership in eco-ink adoption and France's mineral-oil ban drive regional suppliers to overhaul formulations and invest in closed-loop solvent recovery. Luxury brand clusters in Italy and France pursue premium finishing, elevating the demand for metallic, pearlescent, and tactile varnish systems. Eastern European converters adopt modular flexo lines to serve cross-continent retail groups, often specifying the same low-migration inks required by Western buyers.

North America combines technological maturity with tight VOC oversight. The EPA's TSCA evaluations push formulators to validate raw-material toxicology and invest in safer alternatives. Major converters implement predictive maintenance platforms; INX International reported a 13% bump in asset availability after deploying AI analytics on production lines. Mexico gains share as a near-shoring hub for packaged food and personal care goods destined for the United States and Canada, lifting regional ink volumes. Brand owners push for recycling-ready inks that do not impair paper repulping or polyolefin reclamation, fostering collaboration across the packaging value chain. The region exemplifies how automation, sustainability, and regulatory stringency intersect to shape the future trajectory of the printing inks market.

- ALTANA

- Dainichiseika Color & Chemicals Mfg. Co., Ltd.

- DIC Corporation

- DuPont

- Epple Druckfarben AG

- Flint Group

- FUJIFILM Corporation

- hubergroup

- Nazdar

- Sakata INX Corporation

- Sanchez SA de CV

- SICPA HOLDING SA

- Siegwerk Druckfarben AG & Co. KGaA

- T&K TOKA Corporation

- Tokyo Printing Ink Mfg. Co., Ltd.

- Toyo Ink Co. Ltd (artience Co. Ltd)

- Wikoff Color Corporation

- Yip's Chemical Holdings Limited

- Zeller+Gmelin

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Growth in Digital Printing Industry

- 4.2.2 Expansion of Packaging and Labels Demand

- 4.2.3 Shift Toward Water-Based, Eco-Friendly Inks

- 4.2.4 Emergence of UV/Energy-Curable Technologies

- 4.2.5 Adoption of Functional Conductive Inks for Electronics

- 4.3 Market Restraints

- 4.3.1 Decline in Conventional Commercial Printing

- 4.3.2 Stringent VOC and Waste-Disposal Regulations

- 4.3.3 Nitrocellulose Raw-Material Shortages

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts (Value)

- 5.1 By Type

- 5.1.1 Solvent-Based

- 5.1.2 Water-Based

- 5.1.3 Oil-Based

- 5.1.4 UV

- 5.1.5 UV-LED

- 5.1.6 Other Types

- 5.2 By Process

- 5.2.1 Lithographic Printing

- 5.2.2 Flexographic Printing

- 5.2.3 Gravure Printing

- 5.2.4 Digital Printing

- 5.2.5 Other Processes

- 5.3 By Application

- 5.3.1 Packaging

- 5.3.1.1 Rigid Packaging

- 5.3.1.1.1 Paperboard Containers

- 5.3.1.1.2 Corrugated Boxes

- 5.3.1.1.3 Rigid Plastic Containers

- 5.3.1.1.4 Metal Cans

- 5.3.1.1.5 Other Rigid Packaging

- 5.3.1.2 Flexible Packaging

- 5.3.1.3 Labels

- 5.3.1.4 Other Packaging

- 5.3.1.1 Rigid Packaging

- 5.3.2 Commercial and Publication

- 5.3.3 Textiles

- 5.3.4 Other Applications

- 5.3.1 Packaging

- 5.4 By Geography

- 5.4.1 Asia-Pacific

- 5.4.1.1 China

- 5.4.1.2 India

- 5.4.1.3 Japan

- 5.4.1.4 South Korea

- 5.4.1.5 Australia and New Zealand

- 5.4.1.6 ASEAN Countries

- 5.4.1.7 Rest of Asia-Pacific

- 5.4.2 North America

- 5.4.2.1 United States

- 5.4.2.2 Canada

- 5.4.2.3 Mexico

- 5.4.3 Europe

- 5.4.3.1 Germany

- 5.4.3.2 United Kingdom

- 5.4.3.3 France

- 5.4.3.4 Italy

- 5.4.3.5 Russia

- 5.4.3.6 Spain

- 5.4.3.7 Rest of Europe

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Rest of South America

- 5.4.5 Middle-East and Africa

- 5.4.5.1 Saudi Arabia

- 5.4.5.2 South Africa

- 5.4.5.3 Rest of Middle-East and Africa

- 5.4.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share (%)/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 ALTANA

- 6.4.2 Dainichiseika Color & Chemicals Mfg. Co., Ltd.

- 6.4.3 DIC Corporation

- 6.4.4 DuPont

- 6.4.5 Epple Druckfarben AG

- 6.4.6 Flint Group

- 6.4.7 FUJIFILM Corporation

- 6.4.8 hubergroup

- 6.4.9 Nazdar

- 6.4.10 Sakata INX Corporation

- 6.4.11 Sanchez SA de CV

- 6.4.12 SICPA HOLDING SA

- 6.4.13 Siegwerk Druckfarben AG & Co. KGaA

- 6.4.14 T&K TOKA Corporation

- 6.4.15 Tokyo Printing Ink Mfg. Co., Ltd.

- 6.4.16 Toyo Ink Co. Ltd (artience Co. Ltd)

- 6.4.17 Wikoff Color Corporation

- 6.4.18 Yip's Chemical Holdings Limited

- 6.4.19 Zeller+Gmelin

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-need Assessment