|

市場調查報告書

商品編碼

1907272

氣霧罐:市場佔有率分析、產業趨勢與統計、成長預測(2026-2031)Aerosol Cans - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

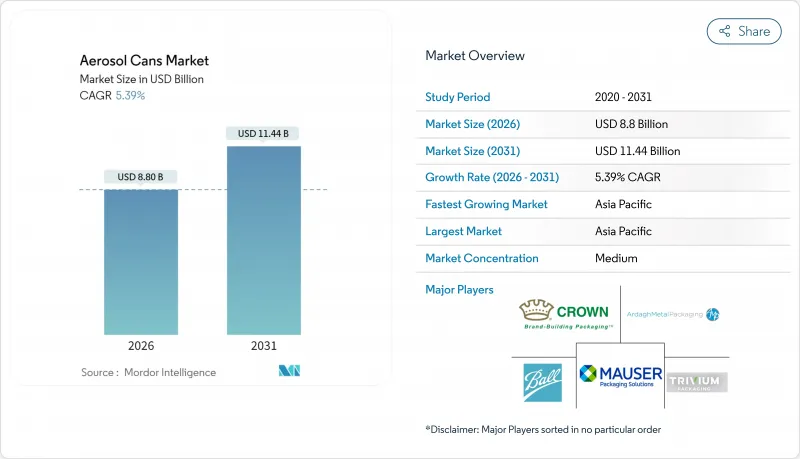

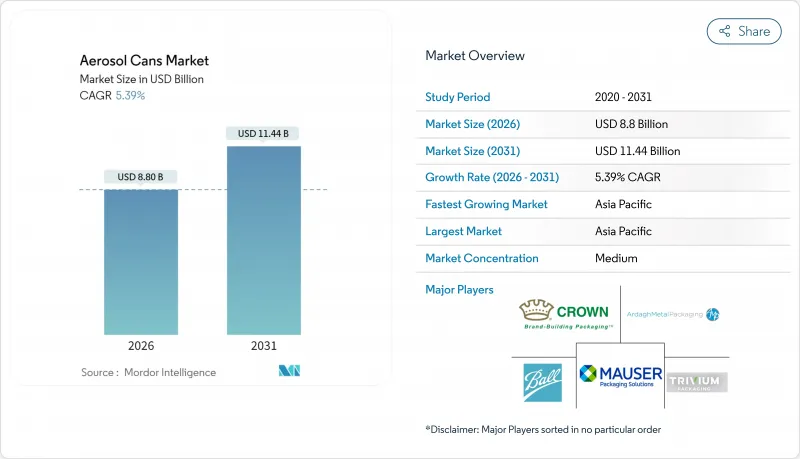

預計到 2026 年,氣霧罐市場規模將達到 88 億美元,高於 2025 年的 83.5 億美元。預計到 2031 年,該市場規模將達到 114.4 億美元,2026 年至 2031 年的複合年成長率為 5.39%。

包裝產業的持續成長得益於其向可再生材料的轉型、監管政策與循環經濟目標的契合,以及鋁製包裝在滿足更嚴格的揮發性有機化合物 (VOC) 排放限制方面的卓越表現。電子商務的蓬勃發展進一步推動了這一趨勢,品牌商們正尋求能夠承受複雜物流網路考驗的防漏、可直接上架的包裝形式。低全球暖化潛勢 (GWP) 推進劑和單一材料罐體設計的創新,正在增強市場領導的競爭優勢。然而,原料成本的波動以及可重複填充概念的快速普及,正在限制短期內的利潤率。

全球氣霧罐市場趨勢與洞察

可回收性和與循環經濟的兼容性

鋁的無限可回收性使其成為品牌所有者在生產者延伸責任制(EPR)計劃下記錄產品生命週期末期性能的關鍵材料。波爾公司的ReAl合金在保持強度的同時,將罐體的碳足跡減少了50%,從而增強了現有全球回收基礎設施的閉合迴路效益——目前,全球75%的鋁製品仍在循環利用。這一良好記錄為波爾公司與面臨氣候變遷報告要求和塑膠減量目標的大型消費品公司簽訂長期供應協議提供了有力支持。

個人護理和化妝品行業的需求快速成長

高階個人保健產品線正擴大採用拉絲金屬外觀和特殊閥門,以提升用戶體驗並實現更高的定價。 Ball and Meadow 計劃於 2025 年推出的可填充式「Meadow Kapsul」噴霧罐,展現了高階護膚和護髮品牌如何透過採用時尚的鋁製氣霧罐,以永續性和設計脫穎而出。電子商務正在加速這一趨勢,因為金屬容器在最後一公里配送過程中更耐磕碰和洩漏,並且兼容 360 度全景攝影,便於進行數位促銷。

嚴格的揮發性有機化合物和廢棄物處理法規

美國環保署(EPA)的修正案將於2025年7月生效,該修正案強制規定了產品加權反應性限值,並要求替換高反應性溶劑。歐洲的氟化氣體法規也即將生效,這進一步增加了合規難度,迫使中小型製造商將研發外包或退出受影響的生產線。處置法規要求按照既定通訊協定對廢舊罐體進行排氣和壓縮,這增加了處理成本,並催生了對專業回收解決方案的需求,例如Republic Services的專用設施。

細分市場分析

到2025年,鋁將佔據84.72%的市場佔有率,這表明其基礎設施完善,且符合大多數回收法規的要求。這一主導地位有助於實現經濟高效的閉合迴路供應,並與歐盟已實施的生產者延伸責任制相契合。氣霧槽市場正受惠於ReAl合金的進步,在不影響抗凹陷性的前提下,厚度和重量減少了15%,降低了碳排放指標,同時維持了單位經濟效益。

塑膠氣霧劑正以每年 8.18% 的速度成長,滿足了品牌對完全透明、抗衝擊性和與酸性配方相容性的需求。 Plastipak 的無金屬「SprayPET 革命」證明,隨著樹脂製造商採用先進的隔離層,聚合物可以滿足壓力閾值,並與主流 PET 回收基礎設施保持相容。在個人保健產品和食品噴霧應用領域,塑膠正日益普及,因為這些應用領域關注金屬味和冷衝擊問題。儘管發展勢頭強勁,但由於單一材料法規和金屬價格波動,鋁仍然是氣霧劑罐市場策略的核心組成部分。

到 2025 年,採用單次衝擊擠壓製程的一體式單體生產線將佔總產量的 64.58%,該生產線可最大限度地減少焊接並簡化品管。均勻壁厚結構因其抗跌落測試性能和高內壓性能而聞名,這對於髮膠噴霧和汽車煞車清潔劑等易燃推進劑產品至關重要。

同時,兩片式易拉罐正以7.05%的複合年成長率快速成長,這主要得益於伺服控制成型技術提升了側縫強度,以及採用混合金屬厚度材料減少了材料用量。品牌商看重兩片式易拉罐能夠生產出高挑纖細的罐身,以及能夠無變形地包裹圓柱形罐體的高清光刻技術。為了滿足季節性產品上市帶來的快速設計變更需求,製造商正在投資研發模組化模具,以便在一體式和兩片式生產之間切換,從而適應不斷變化的市場偏好。

區域分析

2025年,亞太地區將佔全球消費量的39.62%,年複合成長率達7.86%,主要得益於中國作為主要消費和生產中心的雙重地位。都市化和可支配收入的成長推動了個人護理氣霧劑產品的普及,而地方政府推行的回收政策與鋁的閉合迴路優勢相輔相成。日本品牌商正積極推廣單一材料設計,而印度美容產業的快速發展也促使當地填充劑生產商擴大生產規模。

歐洲在技術和法規方面繼續保持領先地位。對氯氟烴(CFC)和揮發性有機化合物(VOC)排放的限制正在加速向綠色推進劑的轉型,使擁有合規產品系列的現有企業獲得優勢。德國和英國在輕量化罐體研發方面主導,而東歐工廠正在擴大低成本灌裝產能,以滿足跨區域的快速消費品(FMCG)合約需求。市場成長傾向於高級產品和永續產品,傳統品類的飽和限制了其擴張。

北美市場持續保持著創新主導的穩定需求。美國環保署(EPA)的反應性法規要求對配方進行重新設計,而充足的研發資金則使當地生產商能夠維持產品系列的柔軟性。美國在非處方醫療產品和DIY塗料氣霧劑領域處於主導,墨西哥作為近岸製造地的地位日益增強。加拿大消費者對低氣味家用噴霧的興趣日益濃厚,推動了水性推進劑的普及。這些趨勢共同推動成熟且盈利的區域市場保持著持續的溫和個位數成長。

其他福利:

- Excel格式的市場預測(ME)表

- 分析師支持(3個月)

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 可回收性和循環經濟相容性

- 個人護理和化妝品需求激增

- 向低揮發性有機化合物/綠色推進劑過渡

- 電子商務中「貨架上的即時銷售」的差異化

- 推動單一材料包裝法規

- 營養保健品/非處方氣霧劑的興起

- 市場限制

- 嚴格的揮發性有機化合物和廢棄物處理法規

- 鋁和鋼價格波動

- 可重複填充產品和濃縮液的興起

- 消費者對氣霧劑產品的環保意識

- 供應鏈分析

- 監管環境

- 技術展望

- 波特五力分析

- 買方的議價能力

- 供應商的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭對手之間的競爭

- 生命週期與碳足跡分析

第5章 市場規模與成長預測

- 依材料類型

- 鋁

- 鋼

- 鍍錫

- 塑膠

- 其他材料類型

- 按罐的類型

- 一體化(單體式)

- 兩件套

- 三件套

- 按推進劑類型

- 壓縮氣體

- 液化氣

- 碳氫化合物

- DME

- 其他液化氣體

- 閥門式袋

- 按容量(毫升)

- 不足100

- 101-300

- 301-500

- 超過500

- 按最終用戶行業分類

- 個人護理和化妝品

- 家居用品

- 汽車和工業

- 醫療/製藥

- 食品/飲料

- 油漆和清漆

- 其他終端用戶產業

- 按地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 俄羅斯

- 其他歐洲地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 澳洲和紐西蘭

- 亞太其他地區

- 中東和非洲

- 中東

- 阿拉伯聯合大公國

- 沙烏地阿拉伯

- 土耳其

- 其他中東地區

- 非洲

- 南非

- 奈及利亞

- 埃及

- 其他非洲地區

- 中東

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 北美洲

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率分析

- 公司簡介

- Ball Corporation

- Crown Holdings Inc.

- Ardagh Metal Packaging SA

- Trivium Packaging

- Mauser Packaging Solutions

- Toyo Seikan Co. Ltd

- CCL Container

- Colep Packaging Portugal SA

- CPMC Holdings Limited

- Nampak Ltd

- Graham Packaging Company

- SGD Pharma

- Silgan Holdings

- DS Containers

- Montebello Packaging

- Tubex GmbH

- Grupo Zapata(Exal)

- Hindustan Tin Works

- Thai Beverage Can

- Bharat Containers

第7章 市場機會與未來展望

Aerosol cans market size in 2026 is estimated at USD 8.8 billion, growing from 2025 value of USD 8.35 billion with 2031 projections showing USD 11.44 billion, growing at 5.39% CAGR over 2026-2031.

Sustained growth is shaped by the packaging sector's pivot toward recyclable materials, regulatory alignment with circular-economy targets, and the proven ability of aluminum containers to meet stricter volatile-organic-compound (VOC) limits. E-commerce expansion adds momentum as brands seek leak-proof, shelf-ready pack formats that withstand complex fulfillment networks. Innovation in low-GWP propellants and mono-material can designs is strengthening the competitive differentiation of market leaders. At the same time, raw-material cost volatility and fast-rising refillable concepts temper near-term margins.

Global Aerosol Cans Market Trends and Insights

Recyclability and circular-economy alignment

Aluminum's infinite recyclability has turned it into a decisive material for brand owners that must document end-of-life performance under extended producer responsibility schemes. Ball Corporation's ReAl alloy cuts the can body's carbon footprint by 50% while maintaining strength, reinforcing the closed-loop advantages of an existing global recycling infrastructure where 75% of aluminum ever produced remains in active circulation. Such credentials underpin long-term supply contracts with consumer-goods majors that face climate-reporting requirements and plastic-reduction targets.

Surging demand from personal-care and cosmetics

Premium personal-care lines increasingly specify brushed-metal aesthetics and specialized valves that elevate user experience and enable higher pricing. Ball and Meadow's 2025 launch of refillable MEADOW KAPSUL cartridges illustrates how luxury skin- and hair-care brands turn to elegant aluminum aerosols to differentiate on sustainability and design. E-commerce accelerates this trend because metallic containers resist dents and leakage during last-mile delivery while offering 360-degree imaging for digital merchandising.

Stringent VOC and disposal regulations

EPA amendments effective July 2025 enforce product-weighted reactivity ceilings that oblige formulators to swap high-reactivity solvents or face penalties. Parallel F-gas restrictions in Europe intensify compliance complexity, pushing smaller firms to outsource R&D or exit affected lines.Disposal rules now require spent cans to be vented and baled under documented protocols that elevate processing costs, yet also spur specialized recycling solutions such as Republic Services' dedicated facilities.

Other drivers and restraints analyzed in the detailed report include:

- Transition to low-VOC/green propellants

- E-commerce "shelf-ready" differentiation

- Volatility in aluminum and steel prices

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Aluminum captured 84.72% of the 2025 volume, underscoring its entrenched infrastructure and acceptance under most recycling codes. This leadership supports cost-efficient closed-loop supply and aligns with extended-producer-responsibility statutes already active in the EU. The aerosol cans market benefits from ReAl alloy advances that trim gauge weight by 15% without compromising dent resistance, keeping unit economics competitive while lowering carbon metrics.

Plastic aerosols, growing 8.18% annually, address brand requirements for full transparency, shatter resistance, and compatibility with acidic formulas. Plastipak's metal-free SprayPET Revolution validates that polymers can meet pressure thresholds and remain compatible with mainstream PET recycling infrastructures as resin suppliers roll out advanced barrier layers, plastics secure footholds in personal-care and food spray applications where metal taste or cold shock are concerns. Even with this momentum, mono-material legislation and metal price volatility keep aluminum at the core of the aerosol cans market strategy.

One-piece monobloc lines own 64.58% of 2025 unit output thanks to single-stroke impact-extrusion that minimizes weld seams and simplifies quality control. The configuration's uniform wall thickness supports a reputation for drop-test resilience and elevated internal pressures, essential for flammable propellants in hair-spray or automotive brake-cleaner SKUs.

Two-piece cans, posting a 7.05% CAGR, gain traction as servo-controlled body-maker technology enhances side-seam strength and allows hybrid metal gauges that lower material use. Brand owners appreciate the ability to produce tall, slim profiles and high-definition lithography that wraps around the cylindrical body without distortion. With demand for fast design turnarounds in seasonal product drops, manufacturers invest in modular tooling that switches between monobloc and two-piece runs, hedging against market preference shifts.

The Aerosol Cans Market Report is Segmented by Material Type (Aluminium, Steel, Tinplate, and More ), Can Type (One-Piece (Monobloc), Two-Piece, Three-Piece), Propellant Type (Compressed Gas, Bag-On-Valve, and More), Capacity (ml) (Less Than 100, 101-300, and More), End-User Industry (Personal Care and Cosmetics, and More), and Geography (North America, Europe, and More). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific composed 39.62% of 2025 consumption and is rising at an 7.86% CAGR, anchored by China's dual role as leading consumer and production hub. Urbanization and disposable-income growth support wider adoption of personal-care aerosols, while regional authorities impose recycling mandates that dovetail with aluminum's closed-loop advantages. Japanese brand owners advance mono-material designs, and India's accelerating beauty segment amplifies volumes for local fillers.

Europe remains a technology and regulation frontrunner. F-gas and VOC ceilings prompt swift migration to green propellants, rewarding incumbents with compliant product portfolios.Germany and the United Kingdom lead in lightweight-can R&D, while Eastern European plants extend low-cost filling capacity to pan-regional FMCG contracts. Market growth leans toward premium and sustainable offerings as volume saturation limits expansion in traditional categories.

North America demonstrates steady, innovation-driven demand. EPA reactivity rules compel formula redesigns, yet robust R&D funding helps local converters maintain portfolio agility. The United States leads in OTC healthcare and DIY paint aerosols, while Mexico strengthens as a near-shore manufacturing base. Canadian consumers show elevated interest in low-odor household sprays, bolstering adoption of water-based propellants. Together these trends sustain mid-single-digit growth across a maturing yet profitable regional landscape.

- Ball Corporation

- Crown Holdings Inc.

- Ardagh Metal Packaging SA

- Trivium Packaging

- Mauser Packaging Solutions

- Toyo Seikan Co. Ltd

- CCL Container

- Colep Packaging Portugal SA

- CPMC Holdings Limited

- Nampak Ltd

- Graham Packaging Company

- SGD Pharma

- Silgan Holdings

- DS Containers

- Montebello Packaging

- Tubex GmbH

- Grupo Zapata (Exal)

- Hindustan Tin Works

- Thai Beverage Can

- Bharat Containers

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Recyclability and circular?economy alignment

- 4.2.2 Surging demand from personal-care and cosmetics

- 4.2.3 Transition to low-VOC/green propellants

- 4.2.4 e-commerce "shelf-ready" differentiation

- 4.2.5 Regulatory push for mono-material packaging

- 4.2.6 Emergence of nutraceutical/OTC aerosol formats

- 4.3 Market Restraints

- 4.3.1 Stringent VOC and disposal regulations

- 4.3.2 Volatility in aluminium and steel prices

- 4.3.3 Rise of refillable and concentrated formats

- 4.3.4 Consumer eco-perception of aerosols

- 4.4 Supply-Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Bargaining Power of Buyers

- 4.7.2 Bargaining Power of Suppliers

- 4.7.3 Threat of New Entrants

- 4.7.4 Threat of Substitutes

- 4.7.5 Competitive Rivalry

- 4.8 Lifecycle and Carbon-Footprint Analysis

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Material Type

- 5.1.1 Aluminium

- 5.1.2 Steel

- 5.1.3 Tinplate

- 5.1.4 Plastic

- 5.1.5 Other Material Type

- 5.2 By Can Type

- 5.2.1 One-piece (Monobloc)

- 5.2.2 Two-piece

- 5.2.3 Three-piece

- 5.3 By Propellant Type

- 5.3.1 Compressed Gas

- 5.3.2 Liquefied Gas

- 5.3.2.1 Hydrocarbon

- 5.3.2.2 DME

- 5.3.2.3 Other Liquefied Gas

- 5.3.3 Bag-on-Valve

- 5.4 By Capacity (ml)

- 5.4.1 Less than 100

- 5.4.2 101-300

- 5.4.3 301-500

- 5.4.4 More than 500

- 5.5 By End-User Industry

- 5.5.1 Personal Care and Cosmetics

- 5.5.2 Household Care

- 5.5.3 Automotive and Industrial

- 5.5.4 Healthcare and Pharmaceutical

- 5.5.5 Food and Beverage

- 5.5.6 Paints and Varnishes

- 5.5.7 Other End-User Industry

- 5.6 By Geography

- 5.6.1 North America

- 5.6.1.1 United States

- 5.6.1.2 Canada

- 5.6.1.3 Mexico

- 5.6.2 Europe

- 5.6.2.1 Germany

- 5.6.2.2 United Kingdom

- 5.6.2.3 France

- 5.6.2.4 Italy

- 5.6.2.5 Spain

- 5.6.2.6 Russia

- 5.6.2.7 Rest of Europe

- 5.6.3 Asia-Pacific

- 5.6.3.1 China

- 5.6.3.2 India

- 5.6.3.3 Japan

- 5.6.3.4 South Korea

- 5.6.3.5 Australia and New Zealand

- 5.6.3.6 Rest of Asia-Pacific

- 5.6.4 Middle East and Africa

- 5.6.4.1 Middle East

- 5.6.4.1.1 United Arab Emirates

- 5.6.4.1.2 Saudi Arabia

- 5.6.4.1.3 Turkey

- 5.6.4.1.4 Rest of Middle East

- 5.6.4.2 Africa

- 5.6.4.2.1 South Africa

- 5.6.4.2.2 Nigeria

- 5.6.4.2.3 Egypt

- 5.6.4.2.4 Rest of Africa

- 5.6.4.1 Middle East

- 5.6.5 South America

- 5.6.5.1 Brazil

- 5.6.5.2 Argentina

- 5.6.5.3 Rest of South America

- 5.6.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Ball Corporation

- 6.4.2 Crown Holdings Inc.

- 6.4.3 Ardagh Metal Packaging SA

- 6.4.4 Trivium Packaging

- 6.4.5 Mauser Packaging Solutions

- 6.4.6 Toyo Seikan Co. Ltd

- 6.4.7 CCL Container

- 6.4.8 Colep Packaging Portugal SA

- 6.4.9 CPMC Holdings Limited

- 6.4.10 Nampak Ltd

- 6.4.11 Graham Packaging Company

- 6.4.12 SGD Pharma

- 6.4.13 Silgan Holdings

- 6.4.14 DS Containers

- 6.4.15 Montebello Packaging

- 6.4.16 Tubex GmbH

- 6.4.17 Grupo Zapata (Exal)

- 6.4.18 Hindustan Tin Works

- 6.4.19 Thai Beverage Can

- 6.4.20 Bharat Containers

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-need Assessment