|

市場調查報告書

商品編碼

1907262

再生PET-市場佔有率分析、產業趨勢與統計、成長預測(2026-2031年)Recyclate PET - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

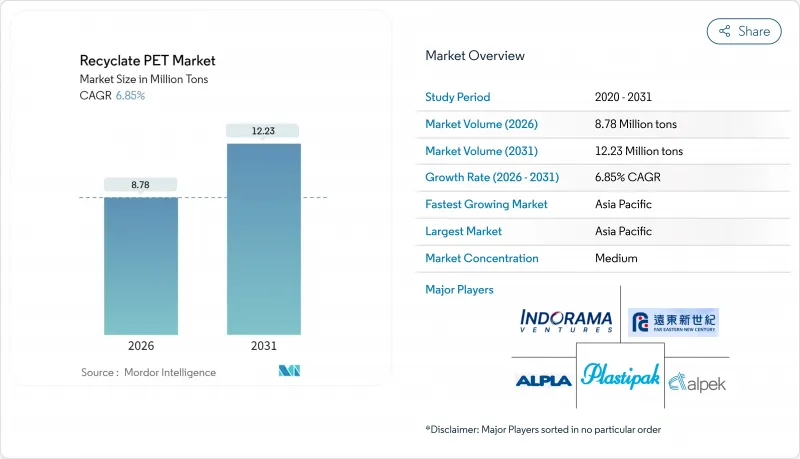

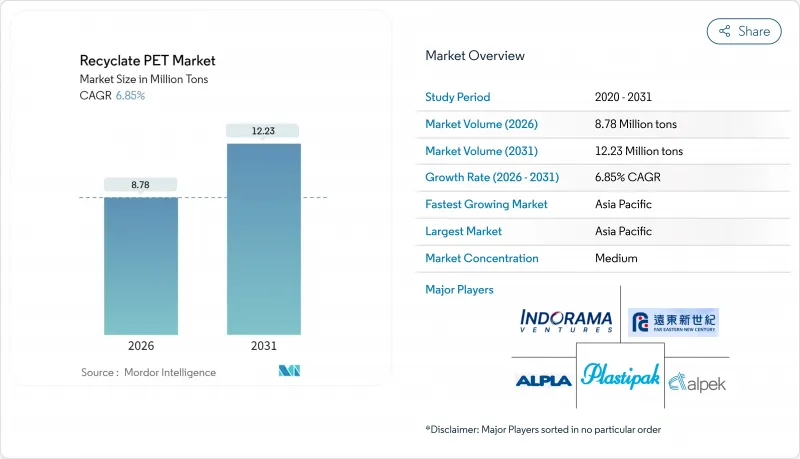

預計再生PET市場將從2025年的822萬噸成長到2026年的878萬噸,到2031年達到1,223萬噸,2026年至2031年的複合年成長率為6.85%。

監管要求、品牌所有者不斷提高的採購目標以及原生樹脂和再生樹脂成本的趨同,正在推動再生PET市場結構性需求的轉變。瓶到瓶循環利用在歐洲已成為一項法律要求,而美國12個州正在2024年至2025年初期間實施生產者延伸責任制(EPR)法律,以加強回收和再生材料含量的強制性要求。亞太地區的成長正在加速,這得益於中國2025年35%的再生材料含量強制性要求以及印度根據2024年《塑膠廢棄物管理修正規則》分階段實施EPR。酶解和溶劑解技術的進步使得利用以往降級回收的有色和不透明材料生產食品級產品成為可能,從而擴大了消費後資源的應用範圍。競爭格局正在改變。大型綜合石化公司正透過機械和化學加工能力來規避業務風險,而廢棄物管理公司則正在增加分類和清洗生產線,以獲取整個價值鏈的收益。

全球再生PET市場趨勢與洞察

更嚴格的再生材料含量要求推動了結構性需求。

歐盟的《包裝和包裝廢棄物法規》為PET飲料瓶制定了具有約束力的再生材料含量標準:到2025年達到25%,到2030年達到30%,將自願承諾轉化為法律要求。美國目前有12個州已實施生產者延伸責任制(EPR)法律,強制規定最低再生材料含量,其中加州的SB54法案走在前列,規定到2030年再生材料含量目標為50%。中國國家發展和改革委員會宣布,自2025年1月起,再生材料含量必須達到35%,這將使原本出口的國內塑膠碎片重新分配到國內市場。印度修訂後的《塑膠廢棄物管理條例》要求品牌所有者收集和回收相當於其年塑膠使用量的塑膠,從而促進回收資產的貨幣化。總而言之,這些法規為再生PET市場的機械和化學加工能力提供了法律保障,並支持了相關資本投資。

品牌承諾確保長期忠誠度

包括可口可樂、百事可樂、聯合利華、雀巢和達能在內的全球飲料和消費品巨頭承諾,到2030年,其PET原料的25%至50%將來自回收材料。以目前的包裝量計算,預計將每年增加約200萬噸的需求。根據可口可樂2024年永續發展報告,該公司瓶子的再生材料含量為23%,並且與Indorama Ventures和Loop Industries簽訂的多年承購協議確保了食品級PET薄片的供應,直至2028年。百事可樂與Carbonlite的合資企業將於2026年開始在德克薩斯州每年供應6萬噸瓶對瓶再生樹脂,以確保供應穩定並降低現貨市場波動的風險。聯合利華已撥款10億磅用於永續包裝,並投入大量資金用於化學回收PET,以實現其品牌目標。這些具有約束力的協議提供了收入確定性,降低了新工廠的資金籌措風險,同時加快了再生PET市場的擴張計劃。

收集基礎設施不足限制了原料供應。

印度、印尼、奈及利亞和巴西的回收率在20%到40%之間,遠低於德國押金返還制度90%的回收率。非正規的廢棄物收集網路普遍存在,但由於缺乏收集和品管流程,導致包裝袋的污染率超過15%,不符合食品級標準。在印度尼西亞,都市區廢棄物覆蓋率僅40%,迫使回收商承擔額外的重新分類成本,並降低了機器的運轉率。在奈及利亞,新的生產者責任延伸制度尚未實施,導致押金制度基礎設施資金不足,原料轉用於出口。在巴西,由於缺乏逆向物流資源,到2024年,瓶子回收率將維持在25%,儘管包裝加工商的需求強勁,但國內供應仍有限。

細分市場分析

2025年,PET短纖維佔再生PET市場產量的41.20%。受服裝產業範圍3排放目標的推動,預計到2031年,該細分市場將以7.05%的複合年成長率成長。同期,再生PET短纖維市場規模預計將額外成長140萬噸,主要得益於H&M、Inditex和Nike等品牌的採購承諾。這些品牌已與遠東新世紀和江蘇中原簽署供應協議,確保在包裝嚴重短缺的情況下纖維供應穩定。機械回收商更傾向於使用短纖維,因為與瓶裝應用相比,短纖維對黏度的要求較低,並且允許混入一些低品質材料。

截至2025年, 寶特瓶(包括食品級和非食品級)佔總量的35.00%。由於歐洲和北美強制要求到2030年使用25-30%的再生材料,食品瓶樹脂的成長更為顯著,這推高了價格並促成了長期合約的簽訂。 PET片材和薄膜的需求主要來自醫藥和電子產品的熱成型包裝,這些產業優先考慮使用再生材料。 PET打包帶面臨原生聚丙烯的競爭,這給歐洲以外(有押金規定的市場)的利潤率帶來了壓力。其他特種產品類型,包括工程樹脂,也正經歷穩定成長,因為汽車製造商正在試行在非承重零件中使用再生PET。

本再生PET市場報告按產品類型(PET短纖維、PET打包帶、PET片材或薄膜、食品級寶特瓶、非食品級寶特瓶及其他產品類型)、應用領域(包裝、工業紗線、建材及其他應用)和地區(北美、南美、歐洲、亞太、中東和非洲)進行分析。市場預測以噸為單位。

區域分析

預計到2025年,亞太地區將佔全球再生PET市場佔有率的42.85%,並在2031年之前維持8.05%的複合年成長率,展現出最快的區域成長動能。中國到2025年強制要求再生PET含量達到35%,促使出口產能轉向國內瓶裝業者,加劇了PET包的競爭,並推高了PET片的價格。印度的生產者責任延伸制度(EPR)於2024年正式認證了1200家回收企業,促進了非食品級PET轉化為食品級PET產能的研究。日本延長了《塑膠資源循環法》的適用期限,要求在2030年再生PET含量達到50%。這促使三得利和朝日製藥簽署了一項為期10年的承購協議。越南和印尼等東南亞市場已吸引多邊融資用於回收基礎設施建設,但由於源頭分類有限,PET套件的品質仍然不穩定。

歐洲已成為成熟的回收中心,其押金返還制度的回收率超過90%,確保了高品質材料的穩定供應。德國的押金返還制度在2024年實現了98%的瓶子回收率,支撐了62萬噸的機械處理能力。西班牙和義大利將分別於2025年和2026年實施押金返還制度,統一歐盟範圍內的再生材料含量要求,並鼓勵跨境投資。法國和荷蘭化學回收能力的擴建將新增15萬噸食品級高品質產品,使成長重心從機械處理轉向先進回收技術。

由於各州法規不盡相同,北美地區的進展並不均衡,但總體而言,進展穩步推進。加州、奧勒岡州州、緬因州、科羅拉多和新澤西州已頒布法律,要求飲料容器必須含有15%至50%的再生材料,這促成了百事可樂與CarbonLite、Indorama與Loop等合資企業的成立。加拿大的聯邦塑膠登記制度實現了全國範圍內的透明度,而墨西哥2024年的法律引入了寶特瓶的生產者延伸責任制(EPR),促使Alpec公司對其位於托盧卡的工廠進行維修,以生產食品級PET瓶。在美國,聯邦層級的不一致使得合規工作較為複雜,但也促使了區域中心的建立,這些中心透過集中式設施服務於多個州。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 更嚴格的再生材料含量要求(歐盟包裝廢棄物指令、塑膠包裝法規、美國州生產者延伸責任制)

- 品牌主導的2030年淨零排放與再生PET採購目標

- 在高含油量情境下,再生PET切片與原生PET的成本平衡

- 擴大解聚技術規模,生產食品級有色再生PET

- 人工智慧驅動的光學分選技術提高了草捆的純度和產量

- 市場限制

- 新興經濟體寶特瓶回收面臨的挑戰

- 原生PET供應過剩週期對再生PET利潤率帶來壓力

- 先進回收技術和食品級合規性的高昂資本投資成本

- 價值鏈分析

- 波特五力模型

- 新進入者的威脅

- 供應商的議價能力

- 買方的議價能力

- 替代品的威脅

- 競爭對手之間的競爭

第5章 市場規模與成長預測

- 依產品類型

- PET短纖維

- PET錶帶

- PET片材或薄膜

- 寶特瓶(食品用)

- 寶特瓶(非食品級)

- 其他產品類型

- 透過使用

- 包裝

- 工業紗線

- 建材

- 其他用途

- 按地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 南美洲

- 巴西

- 阿根廷

- 哥倫比亞

- 其他南美洲

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 北歐國家

- 土耳其

- 俄羅斯

- 其他歐洲地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 馬來西亞

- 泰國

- 印尼

- 越南

- 亞太其他地區

- 中東和非洲

- 沙烏地阿拉伯

- 卡達

- 阿拉伯聯合大公國

- 奈及利亞

- 埃及

- 南非

- 其他中東和非洲地區

- 北美洲

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率(%)/排名分析

- 公司簡介

- Alpek SAB de CV

- Alpla Group

- Biffa

- Evergreen

- Far Eastern New Century Corporation

- Ganesha Ecosphere Ltd.

- Indorama Ventures Public Company Limited

- Jiangsu Zhongyuan Industrial Group Co. Ltd

- Loop Industries Inc.

- Phoenix Technologies

- Plastipak Holdings Inc.

- PolyQuest Inc.

- Reliance Industries Ltd

- SUEZ

- Veolia

- Verdeco Recycling Inc.

- Visy

第7章 市場機會與未來展望

The recyclate PET market is expected to grow from 8.22 million tons in 2025 to 8.78 million tons in 2026 and is forecast to reach 12.23 million tons by 2031 at 6.85% CAGR over 2026-2031.

Regulatory mandates, rising brand-owner procurement targets, and cost convergence between virgin and recycled resin are jointly propelling structural demand shifts in the recyclate PET market. In Europe, bottle-to-bottle circularity is now embedded in law, while 12 U.S. states adopted Extended Producer Responsibility (EPR) statutes between 2024 and early 2025, reinforcing collection and recycled-content obligations. Asia-Pacific growth is accelerating on the back of China's 35% recycled-content mandate for 2025 and India's staged EPR roll-out under the 2024 Plastic Waste Management Amendment Rules. Parallel advances in enzymatic and solvent-based depolymerization enable food-grade output from formerly downcycled colored and opaque feedstock, thereby widening the addressable pool of post-consumer materials. Competitive dynamics are shifting as integrated petrochemical majors hedge their operations with both mechanical and chemical capacity, while waste-management operators add sorting and washing lines to capture margins across the value chain.

Global Recyclate PET Market Trends and Insights

Stricter Recycled-Content Mandates Drive Structural Demand

The European Union's Packaging and Packaging Waste Regulation sets binding recycled-content thresholds of 25% in 2025 and 30% in 2030 for PET beverage bottles, effectively turning voluntary pledges into legal requirements. Twelve U.S. states now enforce EPR statutes that impose minimum recycled content, with California's SB 54 leading the way, which increases to 50% by 2030. China's National Development and Reform Commission issued a 35% recycled-content mandate effective January 2025, redirecting domestic flake that formerly entered export channels. India's amended Plastic Waste Management Rules require brand owners to match their annual plastic footprints with equivalent collection and recycling efforts, thereby monetizing their collection assets. Collectively, these mandates create a legally guaranteed offtake, underpinning capital deployment in both mechanical and chemical capacity across the recyclate PET market.

Brand Commitments Anchor Long-Term Offtake

Global beverage and consumer-goods majors, including Coca-Cola, PepsiCo, Unilever, Nestle, and Danone, have pledged to source 25-50% of their PET from recycled materials by 2030, resulting in approximately 2 million tons of incremental demand annually at current packaging volumes. Coca-Cola's 2024 sustainability report shows 23% recycled content in its bottles and details multi-year offtake with Indorama Ventures and Loop Industries to secure food-grade flake through 2028. PepsiCo's joint venture with CarbonLite will deliver 60,000 tons per year of bottle-to-bottle resin in Texas starting in 2026, securing supply and mitigating spot-market volatility. Unilever earmarked GBP 1 billion for sustainable packaging, with a sizable allocation for chemical-recycled PET to meet branding goals. These binding contracts provide revenue certainty, derisking new plant financing, and accelerating expansion plans across the recyclate PET market.

Collection Infrastructure Gaps Constrain Feedstock

Collection rates in India, Indonesia, Nigeria, and Brazil range from 20% to 40%, far below the 90% achieved in German deposit-return systems. Informal waste-picker networks dominate, yet they lack aggregation and quality control processes, resulting in bales with more than 15% contamination that fail to meet food-grade standards. Indonesia's municipal waste coverage spans only 40% of urban zones, forcing recyclers to spend more on re-sorting and thus curbing machine utilization. Nigeria's nascent EPR scheme remains unenforced, leaving deposit infrastructure unfunded and feedstock redirected to export. Brazil's under-resourced reverse logistics collected only 25% of bottles in 2024, limiting local supply despite strong demand from packaging converters.

Other drivers and restraints analyzed in the detailed report include:

- Cost Parity Emerges in High-Oil Scenarios

- Depolymerization Unlocks Food-Grade Colored Feedstock

- Virgin-PET Oversupply Cycles Compress Margins

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

PET staple fiber accounted for 41.20% of the 2025 volume in the recyclate PET market. The segment is expected to grow at a 7.05% CAGR through 2031, driven by apparel-sector Scope 3 reduction goals. The recyclate PET market size for staple fiber is forecast to expand by an additional 1.4 million tons over the period, underpinned by sourcing commitments from H&M, Inditex, and Nike. These brands have locked supply contracts with Far Eastern New Century and Jiangsu Zhongyuan, ensuring fiber offtake in a tightening bale environment. Mechanical recyclers prefer staple fiber because the viscosity requirements are less stringent than those in bottle applications, allowing the inclusion of lower-grade feedstock.

PET bottles, encompassing both food-grade and non-food-grade formats, accounted for 35.00% of the volume in 2025. Food-grade bottle resin is expanding faster because European and North American laws mandate 25-30% recycled content by 2030, driving premium pricing and long-term contracts. PET sheets or films demand is driven by thermoformed packaging for pharmaceuticals and electronics that value recycled content. PET straps witness pricing competition from virgin polypropylene, which constrains margins outside deposit-driven European markets. Other specialty product types, including engineering resins, are growing steadily as automakers test recycled PET in non-load-bearing parts.

The Recyclate PET Market Report is Segmented by Product Type (PET Staple Fiber, PET Straps, PET Sheets or Films, PET Bottles Food Grade, PET Bottles Non-Food Grade, and Other Product Types), Application (Packaging, Industrial Yarn, Building Materials, and Other Applications), and Geography (North America, South America, Europe, Asia-Pacific, and Middle-East and Africa). The Market Forecasts are Provided in Terms of Volume (Tons).

Geography Analysis

Asia-Pacific contributed 42.85% of 2025 volume and is forecast to post an 8.05% CAGR to 2031, the fastest regional trajectory for the recyclate PET market. China's 35% recycled-content rule, effective 2025, has redirected export-oriented capacity toward domestic bottlers, tightening bale competition and lifting flake pricing. India's EPR program formalized 1,200 recycler certificates in 2024, catalyzing capacity upgrades from sub-food to food grade. Japan extended its Plastic Resource Circulation Act, stipulating 50% recycled content by 2030, prompting Suntory and Asahi to sign decade-long offtake agreements. Southeast Asian markets such as Vietnam and Indonesia attract multilateral financing for collection infrastructure, yet bale quality remains inconsistent due to limited source segregation.

Europe remains an established hub with deposit-return systems that deliver >90% collection, ensuring a steady supply of high-quality feedstock. Germany's Pfandsystem recovered 98% of bottles in 2024, feeding 620,000 tons of mechanical capacity. Spain and Italy will adopt deposit-return in 2025 and 2026, respectively, harmonizing recycled-content requirements across the bloc and encouraging cross-border investments. Chemical-recycling build-outs in France and the Netherlands add 150,000 tons of premium food-grade output, shifting incremental growth toward advanced recycling rather than mechanical throughput.

North America is fragmented but advancing due to state-level mandates. California, Oregon, Maine, Colorado, and New Jersey now legislate 15-50% recycled content in beverage containers, compelling joint ventures like PepsiCo-CarbonLite and Indorama-Loop. Canada's federal Plastics Registry brings national transparency, while Mexico's 2024 law introduces EPR for PET bottles, spurring Alpek to retrofit its Toluca plant for food-grade production. Federal-level inconsistency in the United States creates compliance complexity, yet also incentivizes regional hubs that service multiple states from centralized facilities.

- Alpek S.A.B. de C.V.

- Alpla Group

- Biffa

- Evergreen

- Far Eastern New Century Corporation

- Ganesha Ecosphere Ltd.

- Indorama Ventures Public Company Limited

- Jiangsu Zhongyuan Industrial Group Co. Ltd

- Loop Industries Inc.

- Phoenix Technologies

- Plastipak Holdings Inc.

- PolyQuest Inc.

- Reliance Industries Ltd

- SUEZ

- Veolia

- Verdeco Recycling Inc.

- Visy

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Stricter recycled-content mandates (EU SUPD, PPWR, US state EPR)

- 4.2.2 Brand-led 2030 net-zero and recycled PET procurement targets

- 4.2.3 Cost parity of rPET chips vs. virgin PET in high-oil scenarios

- 4.2.4 Scale-up of depolymerisation unlocking food-grade coloured rPET

- 4.2.5 AI-enabled optical sorting boosting bale purity and yield

- 4.3 Market Restraints

- 4.3.1 PET bottle collection gaps in emerging economies

- 4.3.2 Virgin-PET oversupply cycles depressing rPET margins

- 4.3.3 High CAPEX for advanced recycling and food-grade compliance

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Threat of New Entrants

- 4.5.2 Bargaining Power of Suppliers

- 4.5.3 Bargaining Power of Buyers

- 4.5.4 Threat of Substitutes

- 4.5.5 Competitive Rivalry

5 Market Size and Growth Forecasts (Volume)

- 5.1 By Product Type

- 5.1.1 PET Staple Fiber

- 5.1.2 PET Straps

- 5.1.3 PET Sheets or Films

- 5.1.4 PET Bottles (Food Grade)

- 5.1.5 PET Bottles (Non-food Grade)

- 5.1.6 Other Product Types

- 5.2 By Application

- 5.2.1 Packaging

- 5.2.2 Industrial Yarn

- 5.2.3 Building Materials

- 5.2.4 Other Applications

- 5.3 By Geography

- 5.3.1 North America

- 5.3.1.1 United States

- 5.3.1.2 Canada

- 5.3.1.3 Mexico

- 5.3.2 South America

- 5.3.2.1 Brazil

- 5.3.2.2 Argentina

- 5.3.2.3 Colombia

- 5.3.2.4 Rest of South America

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 France

- 5.3.3.4 Italy

- 5.3.3.5 Spain

- 5.3.3.6 NORDIC Countries

- 5.3.3.7 Turkey

- 5.3.3.8 Russia

- 5.3.3.9 Rest of Europe

- 5.3.4 Asia-Pacific

- 5.3.4.1 China

- 5.3.4.2 India

- 5.3.4.3 Japan

- 5.3.4.4 South Korea

- 5.3.4.5 Malaysia

- 5.3.4.6 Thailand

- 5.3.4.7 Indonesia

- 5.3.4.8 Vietnam

- 5.3.4.9 Rest of Asia-Pacific

- 5.3.5 Middle-East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 Qatar

- 5.3.5.3 United Arab Emirates

- 5.3.5.4 Nigeria

- 5.3.5.5 Egypt

- 5.3.5.6 South Africa

- 5.3.5.7 Rest of Middle-East and Africa

- 5.3.1 North America

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share (%)/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Alpek S.A.B. de C.V.

- 6.4.2 Alpla Group

- 6.4.3 Biffa

- 6.4.4 Evergreen

- 6.4.5 Far Eastern New Century Corporation

- 6.4.6 Ganesha Ecosphere Ltd.

- 6.4.7 Indorama Ventures Public Company Limited

- 6.4.8 Jiangsu Zhongyuan Industrial Group Co. Ltd

- 6.4.9 Loop Industries Inc.

- 6.4.10 Phoenix Technologies

- 6.4.11 Plastipak Holdings Inc.

- 6.4.12 PolyQuest Inc.

- 6.4.13 Reliance Industries Ltd

- 6.4.14 SUEZ

- 6.4.15 Veolia

- 6.4.16 Verdeco Recycling Inc.

- 6.4.17 Visy

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-Need Assessment