|

市場調查報告書

商品編碼

1906990

纖維水泥:市場佔有率分析、產業趨勢與統計、成長預測(2026-2031)Fiber Cement - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

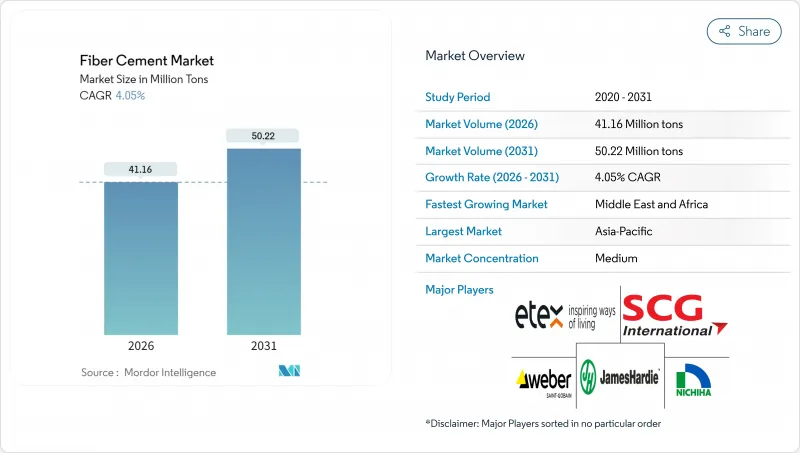

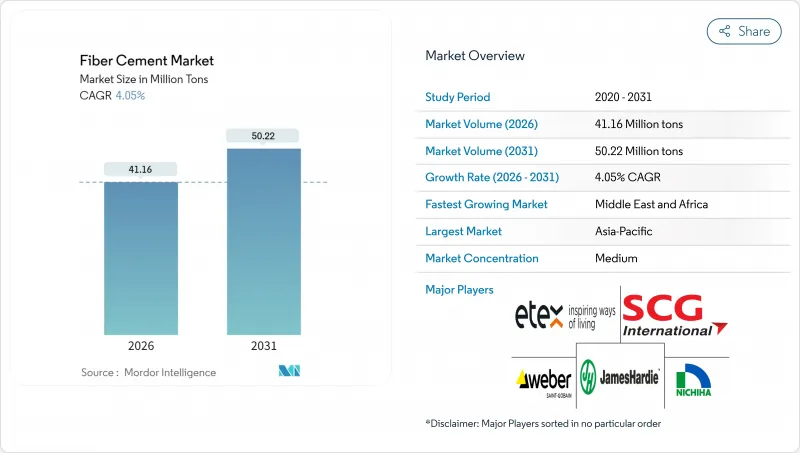

預計到 2026 年,纖維水泥市場規模將達到 4,116 萬噸,高於 2025 年的 3,956 萬噸,預計到 2031 年將達到 5,022 萬噸。

預計2026年至2031年年複合成長率(CAGR)為4.05%。

強勁的需求源自於纖維水泥的諸多優異特性,例如不可燃性(有助於滿足更嚴格的防火安全標準)、卓越的耐候性(可降低生命週期內的更換成本)以及設計柔軟性(可滿足從住宅翻新到大型商業開發等各種應用需求)。供應鏈合作夥伴也認可纖維水泥能夠彌合木質牆板和合成材料替代品之間的性能差距,即使在整體建築週期放緩的情況下,也能保持強勁的銷售成長。業主看重其長達40年的使用壽命,而保險公司則為不可燃外牆提供保費折扣,這進一步推動了易發野火地區的纖維水泥應用。在競爭方面,大型製造商正加速與建築商簽訂直接契約,以加強對分銷管道的控制,而中型企業則專注於合成纖維創新和碳負排放配方技術,以維持利潤率。

全球纖維水泥市場趨勢與洞察

亞太地區的快速都市化和住宅建設復甦

政府住宅政策和大型基礎設施項目正推動中國、印度和東南亞國協對纖維水泥市場產生穩定需求。預計2024年,中國的都市化將達到66.2%,每年新增城鎮居民1,400萬人。預計到2050年,印度的城鎮居民將達到4.16億。預計2024年印尼的建築許可數量將成長8.3%,而泰國的東部經濟走廊計畫預計將在2025年推動該產業成長4.2%。東協統一消防安全標準將纖維水泥列為不可燃外牆材料,進一步鞏固了其在該地區的應用。人口結構變化、保障性住宅政策和更嚴格的建築規範共同為纖維水泥市場未來多年的需求成長奠定了基礎。

嚴格的防火和隔音建築標準

加州2024年第24號法規修正案強制要求森林-城市交界區(WUI)的450萬棟建築使用A級覆材覆層。同樣,澳洲國家建築規範修正案也將對280萬套住宅施加類似的要求。 2024年國際建築規範(IBC)強化了多用戶住宅計劃的聲學性能標準,鼓勵採用能降低噪音傳播的高密度外牆覆層材料。北卡羅來納州的防火測試數據顯示,纖維水泥的燃點比木質牆板低73%,且無需額外加固即可降低18分貝的噪音。這些法規正使纖維水泥從一種高階選擇轉變為擴大區的強制性要求。

與乙烯基替代品相比,初始安裝成本比較

纖維水泥外牆的安裝成本為每平方英尺 8 至 12 美元,比乙烯基外牆貴 60% 至 100%。許多地區人手不足,加上需要使用專業的除塵工具,導致工時增加 25% 至 35%,進一步拉大了價格差距。關稅政策可能使進口材料成本再增加 6% 至 14%,這將進一步擴大首次住宅的價格差距,而首次購屋者在 2024 年佔購屋總數的 32%。成本壓力在多用戶住宅計劃中最為顯著,因為開發商通常在產生維護成本之前就出售房產,這抑制了他們對使用壽命長的外牆進行投資。

細分市場分析

到2025年,牆板將保持34.75%的市場佔有率,這反映了其在獨棟住宅和維修計劃中的長期應用,在這些項目中,木紋纖維水泥符合美學標準。老舊住宅存量的更換需求使銷售量免受新建設週期性波動的影響,而安裝人員的高度熟悉也增強了通路的穩定性。然而,由於中高層建築嚴格的消防法規以及預製建築系統的快速普及,預計到2031年,覆層的複合年成長率將超過牆板,達到4.52%。資料中心建設和大型計劃中對不可燃建築幕牆的頻繁採用,促使建築師擴大指定使用能夠承受極端溫度變化的厚纖維水泥覆層層板。屋頂、裝飾線條和裝飾組件的需求持續穩定成長,為製造商提供了利用現有塗裝設施進行交叉銷售的機會。這種不斷變化的應用組合為整個纖維水泥市場提供了均衡的成長要素。

覆層的擴展正在縮小其與牆板之間的歷史差距,並促使供應商拓展色彩範圍和表面紋理,以契合現代複合材料的美學概念。最新版《國際建築規範》(IBC)中的監管細則進一步強化了這一趨勢,確立了優先考慮不可燃外牆組件的性能要求。隨著開發商全面評估總成本和法規遵循性,纖維水泥在商業建築幕牆中日益普及,這為纖維水泥市場開闢了重要的成長途徑。

本纖維水泥市場報告按應用領域(牆板、覆層、模具及裝飾、屋頂及其他應用)、終端用戶行業(住宅、商業、工業及公共、基礎設施)和地區(亞太、北美、歐洲、南美、中東和非洲)進行細分。市場預測以噸為單位。

區域分析

亞太地區預計到2025年將佔全球纖維水泥市場總量的42.45%,主要得益於全部區域快速的都市化、扶持住宅政策以及嚴格的消防安全標準。中國每年新增1400萬城鎮居民,而印度大都市的擴張也帶動了強勁的建築許可需求。印尼的建築許可數量預計在2024年成長8.3%,而泰國東部經濟走廊超過1.7兆泰銖(約472億美元)的投資預計將推動2025年建築業成長4.2%。接近性纖維素原料產地和發達的水泥基礎設施帶來了成本優勢,吸引了纖維水泥市場各領域的產能投資。

北美市場成熟且穩定,受建築規範驅動的重建需求支撐著市場規模。美國西部地區大規模野火風險的增加,加速了房屋外牆維修向不可燃建築材料的轉變,而保險公司的激勵措施也激發了屋主的購買意願。在加拿大,強勁的維修市場抵消了多戶住宅開工量的放緩。同時,在墨西哥,新興中產階級推動了對中層住宅住宅耐用外牆覆層需求的成長。預製板材的持續創新以及與建築商的直接合作,繼續支撐著北美市場的需求,使該地區繼續保持其在纖維水泥行業全球戰略中的核心地位。

預計到2031年,中東和非洲地區將實現4.38%的年複合成長率,成為該地區成長最快的區域。沙烏地阿拉伯的「2030願景」大型企劃(包括NEOM和The Line)將創造超過5000億美元的建築價值,所有這些項目都必須符合嚴格的外牆性能標準。阿拉伯聯合大公國和卡達的基礎建設也持續推進,高層建築的消防法規鼓勵使用不可燃覆層。沿岸地區極端的氣候條件推動了對耐候材料的需求,提高了纖維水泥的吸引力。雖然當地產能有限可能會限制短期供應,但先前宣布的合資企業和工廠擴建計劃旨在解決這一前景廣闊的纖維水泥市場領域的瓶頸問題。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場促進因素

- 亞太地區的快速都市化和住宅建設復甦

- 嚴格的防火和隔音建築標準

- 與木質和乙烯基牆板相比,生命週期成本優勢

- 在中高層建築採用板式預製建築幕牆

- 利用纖維素奈米纖維的碳負排放水泥配方技術

- 市場限制

- 與乙烯基替代品相比,初始安裝成本較高

- 可供選擇的替代方案,例如工程木牆板

- 全球紙漿價格波動導致纖維採購面臨風險

- 價值鏈分析

- 監管環境

- 波特五力模型

- 新進入者的威脅

- 買方的議價能力

- 供應商的議價能力

- 替代品的威脅

- 競爭對手之間的競爭

- 終端用戶產業趨勢

第5章 市場規模與成長預測

- 透過使用

- 牆板

- 覆層

- 塑形和修剪

- 屋頂材料

- 其他用途

- 按最終用戶行業分類

- 住宅

- 商業的

- 工業和公共設施

- 基礎設施

- 按地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 東南亞國協

- 亞太其他地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 俄羅斯

- 北歐國家

- 其他歐洲地區

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地區

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 其他中東和非洲地區

- 亞太地區

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率(%)/排名分析

- 公司簡介

- Allura

- American Fiber Cement.

- CSR Limited

- ElEMENTIA MATERIALS, SAB DE CV

- Eterno Ivica Srl

- Etex Group

- Everest

- HIL Limited

- James Hardie Building Products Inc.

- KMEW Co., Ltd.

- Mahaphant Fibre-Cement(South Asia)Pvt. Ltd

- Maxitile Inc.

- NICHIHA

- Ramco Industries Limited

- Renaatus Group

- Saint-Gobain(Weber & Eternit)

- SCG International Corporation

- SHERA Public Company Limited

- Swisspearl Group AG

第7章 市場機會與未來展望

第8章:執行長面臨的關鍵策略挑戰

Fiber Cement Market size in 2026 is estimated at 41.16 Million tons, growing from 2025 value of 39.56 Million tons with 2031 projections showing 50.22 Million tons, growing at 4.05% CAGR over 2026-2031.

Robust demand stems from the material's non-combustible nature that eases compliance with stricter fire codes, its superior weather resistance that lowers life-cycle replacement outlays, and design flexibility that satisfies both single-family renovators and large-scale commercial developers. Supply chain partners also recognize fiber cement's ability to bridge the performance gap between wood siding and synthetic substitutes, a factor that underpins resilient volume growth even when broader construction cycles moderate. Building owners favor the product's four-decade service life, while insurers reward non-combustible facades with lower premiums, reinforcing adoption intent in wildfire-prone regions. On the competitive front, leading manufacturers accelerate direct builder agreements that tighten channel control, whereas mid-tier players focus on synthetic fiber innovation and carbon-negative formulations to defend margins.

Global Fiber Cement Market Trends and Insights

Rapid Urbanization and Residential Construction Rebound in Asia-Pacific

Government housing mandates and mega-infrastructure programs stimulate steady fiber cement market demand across China, India, and ASEAN nations. China posted a 66.2% urbanization rate in 2024, adding 14 million urban residents each year, while India is expected to integrate 416 million city dwellers by 2050. Construction permit issuances in Indonesia rose 8.3% during 2024 and Thailand forecasts 4.2% sector growth in 2025 under the Eastern Economic Corridor framework. Harmonized ASEAN fire-safety standards that classify fiber cement as a non-combustible facade option further solidify regional usage. The confluence of demographic shifts, pro-housing policies, and stricter codes secures a multi-year demand runway for the fiber cement market.

Stringent Fire and Acoustic-Performance Building Codes

California's 2024 update to Title 24 now requires Class A exteriors in Wildland-Urban Interface zones covering 4.5 million structures, while Australia's National Construction Code revision applies comparable mandates to 2.8 million dwellings. The 2024 International Building Code tightens acoustic performance benchmarks for multifamily projects, driving adoption of dense facades that limit sound transfer. North Carolina fire-test data show fiber cement exhibits 73% lower ignition probability than wood siding and achieves an 18-decibel noise reduction without extra layers. These regulations elevate fiber cement from premium option to compliance necessity across an expanding set of jurisdictions.

High Initial Installation Cost Versus Vinyl Alternatives

Fiber cement requires USD 8-12 per square foot installed, a 60-100% price premium over vinyl. Labor scarcity in many regions inflates the gap because installers need specialized dust-management tools that add 25-35% to man-hours. Tariff scenarios could raise imported input costs another 6-14%, widening the delta for first-time homebuyers who already represent 32% of 2024 purchases. Cost headwinds are most acute in multifamily projects where developers monetize properties before maintenance bills accrue, reducing willingness to pay for longer-life facades.

Other drivers and restraints analyzed in the detailed report include:

- Lifecycle Cost Advantage Over Wood and Vinyl Siding

- Adoption of Panelized Prefab Facades in Mid-Rise Buildings

- Availability of Substitutes Such as Engineered Wood Siding

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Siding retained 34.75% of 2025 volume, reflecting long-standing use in detached housing and renovation projects where fiber cement's wood-like grain patterns satisfy aesthetic norms. Replacement demand from an aging housing stock cushions volume against cyclical new-build fluctuations, and wide installer familiarity fortifies channel stability. Cladding, however, is set to outpace siding with a 4.52% CAGR through 2031, propelled by stringent fire codes for mid-rise and high-rise structures and the rapid embrace of panelized construction systems. Data center builds and infrastructure megaprojects frequently select non-combustible facades, prompting architects to specify thicker fiber cement cladding panels that withstand extreme temperature swings. Roofing, moulding, and trimming components continue to deliver steady supplemental demand, offering manufacturers cross-selling opportunities that leverage existing color-coating assets. Collectively, this evolving application mix underpins balanced growth drivers across the fiber cement market.

The expansion of cladding narrows the historical gap with siding and encourages suppliers to broaden color palettes and surface textures compatible with contemporary mixed-material aesthetics. Regulatory clarity within the latest International Building Code strengthens this trajectory by codifying performance requirements that favor non-combustible exterior wall assemblies. As developers evaluate total cost and regulatory compliance holistically, fiber cement's rising profile in commercial facades becomes a pivotal growth avenue within the fiber cement market.

The Fiber Cement Market Report is Segmented by Application (Siding, Cladding, Moulding and Trimming, Roofing and Other Applications), End-User Sector (Residential, Commercial, Industrial and Institutional, and Infrastructure), and Geography (Asia-Pacific, North America, Europe, South America, and Middle East and Africa). The Market Forecasts are Provided in Terms of Volume (Tons).

Geography Analysis

Asia-Pacific commanded 42.45% of 2025 volume thanks to rapid urbanization, supportive housing policies, and region-wide adoption of stricter fire-safety codes. China continues to add 14 million urban residents annually, and India's metro expansions underpin robust permit pipelines. Indonesia's building permits rose 8.3% in 2024, while Thailand projects 4.2% construction growth for 2025 under Eastern Economic Corridor investments exceeding THB 1.7 trillion (USD 47.2 billion). Proximity to cellulose feedstock and developed cement infrastructure yields cost advantages that attract capacity investments throughout the fiber cement market.

North America represents a mature but stable arena where code-driven replacement activity sustains volume. Extensive wildfire exposure in the western United States accelerates siding upgrades to non-combustible alternatives, and insurance incentives bolster homeowner interest. In Canada, a resilient renovation segment offsets moderation in multifamily starts, while Mexico's emerging middle class drives incremental demand for durable facades in mid-rise housing. Continued innovation in prefabricated panels and direct builder contracting further supports North American volume, keeping the region central to global strategy within the fiber cement industry.

Middle East and Africa is set to achieve the fastest regional CAGR of 4.38% through 2031. Saudi Arabia's Vision 2030 megaprojects, including NEOM and The Line, add more than USD 500 billion of construction value, all subject to stringent facade performance criteria. The UAE and Qatar continue infrastructure build-outs, and fire-safety regulations in high-rise clusters favor non-combustible cladding. Climatic extremes in the Gulf place a premium on weather-resistant materials, amplifying fiber cement's appeal. Limited local production capacity may constrain near-term supply, yet joint ventures and plant expansions already announced are aimed at mitigating bottlenecks in this promising slice of the fiber cement market.

- Allura

- American Fiber Cement.

- CSR Limited

- ElEMENTIA MATERIALS, SAB DE CV

- Eterno Ivica S.r.l.

- Etex Group

- Everest

- HIL Limited

- James Hardie Building Products Inc.

- KMEW Co., Ltd.

- Mahaphant Fibre-Cement (South Asia) Pvt. Ltd

- Maxitile Inc.

- NICHIHA

- Ramco Industries Limited

- Renaatus Group

- Saint-Gobain (Weber & Eternit)

- SCG International Corporation

- SHERA Public Company Limited

- Swisspearl Group AG

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Drivers

- 4.1.1 Rapid Urbanisation and Residential Construction Rebound in Asia-Pacific

- 4.1.2 Stringent Fire and Acoustic-Performance Building Codes

- 4.1.3 Lifecycle Cost Advantage Over Wood and Vinyl Siding

- 4.1.4 Adoption of Panelised Prefab Facades in Mid-Rise Buildings

- 4.1.5 Carbon-Negative Cement Formulations Using Cellulose Nanofibers

- 4.2 Market Restraints

- 4.2.1 High Initial Installation Cost Versus Vinyl Alternatives

- 4.2.2 Availability of Substitutes Such as Engineered Wood Siding

- 4.2.3 Fibre-Sourcing Risk Amid Global Pulp-Price Volatility

- 4.3 Value Chain Analysis

- 4.4 Regulatory Landscape

- 4.5 Porter's Five Forces

- 4.5.1 Threat of New Entrants

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Bargaining Power of Suppliers

- 4.5.4 Threat of Substitutes

- 4.5.5 Competitive Rivalry

- 4.6 End Use Sector Trends

5 Market Size and Growth Forecasts (Volume)

- 5.1 By Application

- 5.1.1 Siding

- 5.1.2 Cladding

- 5.1.3 Moulding and Trimming

- 5.1.4 Roofing

- 5.1.5 Other Applications

- 5.2 By End-User Sector

- 5.2.1 Residential

- 5.2.2 Commercial

- 5.2.3 Industrial and Institutional

- 5.2.4 Infrastructure

- 5.3 By Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 South Korea

- 5.3.1.5 ASEAN Countries

- 5.3.1.6 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 France

- 5.3.3.4 Italy

- 5.3.3.5 Russia

- 5.3.3.6 NORDIC Countries

- 5.3.3.7 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Rest of South America

- 5.3.5 Middle East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 South Africa

- 5.3.5.3 Rest of Middle East and Africa

- 5.3.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share (%)/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Allura

- 6.4.2 American Fiber Cement.

- 6.4.3 CSR Limited

- 6.4.4 ElEMENTIA MATERIALS, SAB DE CV

- 6.4.5 Eterno Ivica S.r.l.

- 6.4.6 Etex Group

- 6.4.7 Everest

- 6.4.8 HIL Limited

- 6.4.9 James Hardie Building Products Inc.

- 6.4.10 KMEW Co., Ltd.

- 6.4.11 Mahaphant Fibre-Cement (South Asia) Pvt. Ltd

- 6.4.12 Maxitile Inc.

- 6.4.13 NICHIHA

- 6.4.14 Ramco Industries Limited

- 6.4.15 Renaatus Group

- 6.4.16 Saint-Gobain (Weber & Eternit)

- 6.4.17 SCG International Corporation

- 6.4.18 SHERA Public Company Limited

- 6.4.19 Swisspearl Group AG

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-need Assessment