|

市場調查報告書

商品編碼

1906968

環氧塗料:市場佔有率分析、產業趨勢與統計、成長預測(2026-2031)Epoxy Coatings - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

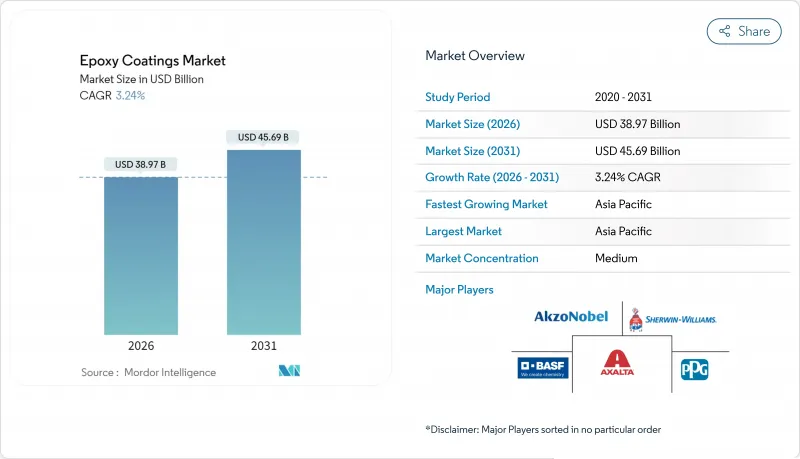

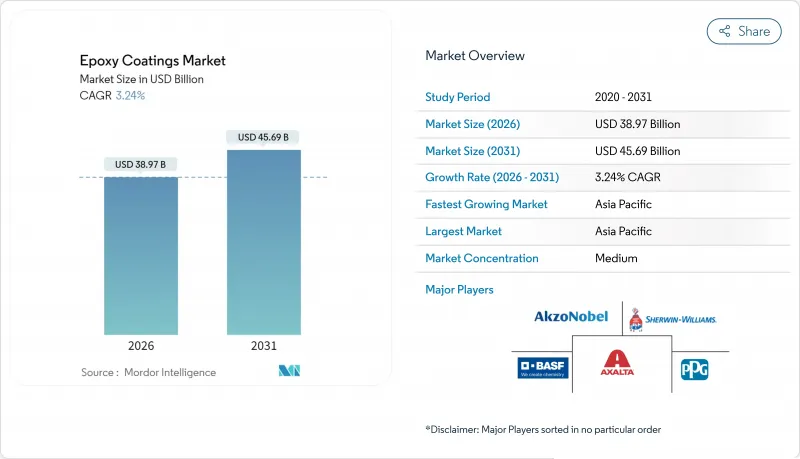

2025年環氧塗料市場價值為377.5億美元,預計到2031年將達到456.9億美元,而2026年為389.7億美元。

預計在預測期(2026-2031 年)內,複合年成長率將達到 3.24%。

這種溫和的成長速度反映出該行業日益成熟,需要在日益嚴格的排放法規和不斷擴大的終端用戶需求之間尋求平衡。製造商正在增加對永續化學技術的投資,特別是能夠減少揮發性有機化合物(VOC)的水基技術。建築、汽車和工業領域的客戶正在轉向使用這些低VOC產品,以滿足日益嚴格的空氣品質法規並提高職場安全。隨著供應商將業務重心轉向特殊應用和區域成長中心,最佳化產品組合(例如剝離大宗商品產品線並收購高性能資產)已成為一項關鍵的競爭策略。

全球環氧塗料市場趨勢與洞察

提高水性環氧樹脂在工業防護塗料中的滲透性。

為了滿足美國環保署 (EPA) 制定的每加侖 4.8 磅的嚴格揮發性有機化合物 (VOC)排放限值,工業設施正在加速向水性系統轉型。樹脂化學的進步使得水性環氧樹脂的延伸率和耐化學性能夠媲美以往只有溶劑型產品才能達到的水平。 2024 年的一項研究表明,使用環氧天然橡膠乳膠的塗料在不犧牲耐久性的前提下,延伸率提高了 370%。高固態配方在施工過程中幾乎不排放VOC,這有助於工廠達到空氣品質許可標準,並提高工人的安全保障。隨著監管合規期限的臨近,工廠維護計畫中向水性產品的轉變正逐漸成為結構性的市場變革,而不再只是短期趨勢。

食品飲料工廠的工業地板材料升級改造

食品加工企業正用環氧樹脂地板材料取代生產區域的普通地板,這種地板能夠耐受強效消毒劑,並符合美國農業部 (USDA) 的檢驗標準。酚醛樹脂基環氧樹脂具有卓越的耐酸性,尤其適用於處理低 pH 值飲料的場所;而 100% 固含量配方無需溶劑揮發運作,從而減少停機時間。生命週期成本分析表明,環氧樹脂地板能夠降低維護成本並減少停機次數,這促使企業願意承擔較高的初始成本。隨著全球食品安全審核日益頻繁且嚴格,這一趨勢正在加速發展。

全球對溶劑型系統的VOC/HAP排放限制更加嚴格。

紐約州將工業維護塗料的揮發性有機化合物(VOC)含量限制在250克/公升,而加州則根據具體應用情況將限制放寬至100克/公升。中國的GB 30981-2020標準也為有害成分設定了類似的上限。違反這些規定可能導致罰款和市場准入壁壘,迫使配方商投資重新設計產品或退出該地區市場。在許多情況下,水性塗料和粉末塗料的替代品尚未能達到傳統產品的性能水平,導致一些專業細分市場出現短期供應缺口。

細分市場分析

2025年,水性化學品將佔總收入的41.80%,維持最高的複合年成長率(CAGR),達到4.32%。隨著原料供應商開發出室溫固化胺添加物和自交聯樹脂,其成本競爭力已提升。溶劑型塗料持續應用於船舶、石油天然氣和重型機械產業,在這些產業中,耐腐蝕性比VOC(揮發性有機化合物)法規更為重要。粉末塗料的市場佔有率正在成長,但仍處於少數地位,其在汽車輪轂、家用電器和金屬家具領域的應用日益增多。石墨烯增強型粉末塗料已被證明能夠使鹽霧試驗中的防腐蝕週期延長一倍。

一家水性塗料製造商正著力提升從生產到處置的永續性指標:生命週期評估中零熱點、減少工廠通風量、降低保險成本。採用可回收容器生產雙組分塗料,並儘可能減少塑膠用量,進一步降低了範圍 3排放,與客戶的淨零排放計劃相契合。一家粉末塗料供應商正致力於透過推廣低溫固化技術來實現脫碳,該技術不僅節省烘箱能源,還能在熱敏基材上進行塗裝。

環氧塗料報告按技術(水性、溶劑型、粉末塗料)、終端用戶產業(建築、汽車、交通運輸、工業及其他)和地區(亞太、北美、歐洲、南美、中東和非洲)進行細分。市場預測以美元以金額為準。

區域分析

到2025年,亞太地區將佔全球銷售額的46.43%,反映了該地區龐大的製造業基礎和持續的基礎設施建設。中國將佔該地區需求的一半以上,政府對溶劑的禁令加速了水性外牆塗料的轉型。印度的智慧城市計畫和印尼收費公路的擴建正在推動橋樑、機場和公共交通樞紐對環氧樹脂的需求。該地區環氧塗料市場預計將以3.63%的複合年成長率成長。擁有本土業務的供應商享有優惠關稅和快速交貨期,尤其是在印尼,該國對油漆進口徵收額外關稅。

北美憑藉著專為航太和電動汽車工廠設計的快速固化和複合材料相容系統,保持其技術領先地位。包括工廠車間、石油管線維修和海上平台在內的維修需求,即使宏觀經濟趨於平穩,也將維持穩定的基準消耗量。歐洲的需求成長主要受老舊基礎設施更新和日益嚴格的VOC法規的推動,加速了從溶劑型塗料轉向水性塗料的轉變。客戶願意為獲得環保標籤認證、證明其生命週期排放量低的塗料支付溢價。南美和中東/非洲地區的成長緩慢但不均衡。巴西的外國投資正在復甦,其中一項11.5億美元的收購案尤其引人注目,該收購案擴大了當地的分銷網路。儘管外匯波動和政治風險會影響計劃計劃,但承包商仍在繼續採用耐用襯裡,以延長惡劣環境下的資產使用壽命。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 增強水性環氧樹脂在工業防護塗料中的滲透性。

- 擴大亞太和非洲的建築業

- 食品飲料廠工業地面地板材料改造

- 用於高產能的快速固化紫外線/LED固化環氧樹脂技術

- 電動車電池外殼和馬達外殼需要耐化學腐蝕塗層。

- 市場限制

- 加強全球溶劑型系統VOC/HAP排放法規

- 雙酚A和環氧氯丙烷的價格波動會擾亂成本結構。

- 經認證的生物基環氧樹脂前驅物供應有限

- 價值鏈分析

- 波特五力模型

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭對手之間的競爭

第5章 市場規模與成長預測

- 透過技術

- 水溶液

- 溶劑型

- 粉狀

- 按最終用戶行業分類

- 建築/施工

- 車

- 運輸

- 產業

- 其他

- 按地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- ASEAN

- 亞太其他地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 北歐國家

- 俄羅斯

- 其他歐洲地區

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地區

- 中東和非洲

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 南非

- 其他中東和非洲地區

- 亞太地區

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率(%)/排名分析

- 公司簡介

- AkzoNobel NV

- Asian Paints

- Axalta Coating Systems LLC

- BASF

- Berger Paints India

- Diamond Vogel

- DuluxGroup Ltd

- Hempel A/S

- Jotun

- Kansai Paint Co., Ltd.

- Koster Bauchemie AG

- Nippon Paint Holdings Co., Ltd.

- Pidilite Industries Limited

- PPG Industries, Inc.

- RPM International Inc.

- Sika AG

- The Euclid Chemical Company

- The Sherwin-Williams Company

- Tikkurila

第7章 市場機會與未來展望

The Epoxy Coatings Market was valued at USD 37.75 billion in 2025 and estimated to grow from USD 38.97 billion in 2026 to reach USD 45.69 billion by 2031, at a CAGR of 3.24% during the forecast period (2026-2031).

The measured pace mirrors a mature sector that is balancing tougher emission rules with widening end-use demands. Manufacturers are channeling investment toward sustainable chemistries, particularly waterborne technologies that curb volatile organic compounds. Construction, automotive, and industrial customers are pivoting toward these low-VOC offerings to comply with tightening air-quality mandates and to improve workplace safety. Portfolio optimization, such as divestitures of commodity lines and acquisitions of high-performance assets, has become the dominant competitive tactic as suppliers reposition around specialty applications and regional growth hotspots.

Global Epoxy Coatings Market Trends and Insights

Waterborne Epoxy Penetration Rising in Industrial Protective Coatings

Industrial facilities are accelerating the shift toward waterborne systems to meet strict volatile organic compound caps, such as the U.S. Environmental Protection Agency limit of 4.8 pounds per gallon. Advances in resin chemistry now allow waterborne epoxies to match the elongation and chemical resistance once exclusive to solvent-based products. A 2024 study using epoxidized natural-rubber latex recorded a 370% gain in elongation without sacrificing durability. High-solids versions emit virtually no VOCs during application, helping plants satisfy air-quality permits and improve worker safety profiles. As compliance deadlines tighten, the conversion of factory maintenance programs to waterborne offerings is becoming a structural market shift rather than a short-term trend.

Industrial Flooring Upgrades in Food and Beverage Plants

Food processors are resurfacing production areas with epoxy floors that withstand aggressive sanitizers and meet USDA inspections. Novolac chemistries offer exceptional acid resistance for facilities that handle beverages with low pH, while 100% solids formulations shorten turnaround times because they cure without solvent evaporation. Operators are willing to pay higher upfront costs once lifecycle models reveal lower maintenance spending and fewer shutdowns. The trend gains momentum as global food-safety audits grow in frequency and rigor.

Stringent Global VOC/HAP Emission Limits on Solvent-Based Systems

New York limits industrial maintenance coatings to 250 g/L VOC, while California allows as little as 100 g/L depending on use. China's GB 30981-2020 standard sets parallel caps on harmful constituents. Non-compliance triggers fines and market access barriers, forcing formulators to invest in re-engineering or face regional exit. In many cases, waterborne or powder alternatives cannot yet duplicate the performance of legacy products, leaving short-term supply gaps in specialty niches.

Other drivers and restraints analyzed in the detailed report include:

- Rapid-Cure UV/LED-Curable Epoxy Technologies Enabling Higher Throughput

- EV Battery Casings and Motor Housings Need Chemically-Resistant Coats

- BPA and Epichlorohydrin Price Volatility Disrupting Cost Structures

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Water-based chemistries contributed 41.80% of 2025 revenue and hold the top growth slot at 4.32% CAGR. Cost competitiveness has improved as raw-material suppliers develop amine adducts and self-crosslinking resins that cure under ambient conditions. Solvent-borne grades continue in marine, oil-and-gas, and heavy-equipment segments where extreme corrosion resistance overrides VOC concerns. Powder coatings account for a rising but still minority share; adoption is pacing automotive wheels, home appliances, and metal furniture. Graphene-reinforced powders have proven to double corrosion-protection cycle time in salt-spray testing.

Waterborne suppliers emphasize cradle-to-grave sustainability metrics: zero-hot-spot life-cycle assessments, reduced plant ventilation needs, and lower insurance premiums. Production of two-component packs in minimal-plastic, returnable containers further cuts scope-3 emissions, aligning with customer net-zero roadmaps. Powder-coating vendors target decarbonization by promoting low-temperature cure chemistries that save furnace energy and enable coating of heat-sensitive substrates.

The Epoxy Coatings Report is Segmented by Technology (Water-Based, Solvent-Based, and Powder-Based), End-User Industry (Building and Construction, Automotive, Transportation, Industrial, and Others), and Geography (Asia-Pacific, North America, Europe, South America, and Middle-East and Africa). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific accounted for 46.43% of global sales in 2025, reflecting its broad manufacturing base and relentless infrastructure build-out. China represents more than half of regional demand and is intensifying its transition to waterborne exterior wall coatings under municipal solvent bans. India's Smart Cities Mission and Indonesia's toll-road expansions funnel epoxy orders into bridges, airports, and mass-transit depots. The epoxy coatings market is forecast to grow by a 3.63% CAGR in the region. Local suppliers with in-country hubs enjoy tariff advantages and faster delivery times, especially in Indonesia, where paint imports face incremental duties.

North America remains a technology leader through rapid-cure and composite-compatible systems designed for aerospace and electric-vehicle plants. Retrofit demand, such as factory floors, oil-pipeline refurbishment, and offshore platforms, maintains a steady baseline consumption even in flat macro cycles. European demand is driven by the renovation of aged infrastructure and progressive VOC legislation that accelerates solvent-to-water conversions. Customers are willing to pay premiums for coatings certified under Ecolabel frameworks that validate low life-cycle emissions. South America, the Middle East, and Africa offer incremental but uneven growth. Brazil is experiencing renewed foreign investment, exemplified by a USD 1.15 billion acquisition that broadens local distribution reach. Currency swings and political risk temper project pipelines, yet contractors continue to specify durable linings to extend asset life under harsh environmental conditions.

- AkzoNobel N.V.

- Asian Paints

- Axalta Coating Systems LLC

- BASF

- Berger Paints India

- Diamond Vogel

- DuluxGroup Ltd

- Hempel A/S

- Jotun

- Kansai Paint Co., Ltd.

- Koster Bauchemie AG

- Nippon Paint Holdings Co., Ltd.

- Pidilite Industries Limited

- PPG Industries, Inc.

- RPM International Inc.

- Sika AG

- The Euclid Chemical Company

- The Sherwin-Williams Company

- Tikkurila

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Waterborne Epoxy Penetration Rising in Industrial Protective Coatings

- 4.2.2 Construction Sector Expansion in APAC and Africa

- 4.2.3 Industrial Flooring Upgrades in Food and Beverage Plants

- 4.2.4 Rapid-Cure UV/LED-Curable Epoxy Technologies Enabling Higher Throughput

- 4.2.5 EV Battery Casings and Motor Housings Need Chemically Resistant Coats

- 4.3 Market Restraints

- 4.3.1 Stringent Global VOC/HAP Emission Limits on Solvent-Based Systems

- 4.3.2 BPA and Epichlorohydrin Price Volatility Disrupting Cost Structures

- 4.3.3 Limited Supply of Certified Bio-Based Epoxy Precursors

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Competitive Rivalry

5 Market Size and Growth Forecasts (Value)

- 5.1 By Technology

- 5.1.1 Water-based

- 5.1.2 Solvent-based

- 5.1.3 Powder-based

- 5.2 By End-user Industry

- 5.2.1 Building and Construction

- 5.2.2 Automotive

- 5.2.3 Transportation

- 5.2.4 Industrial

- 5.2.5 Others

- 5.3 By Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 South Korea

- 5.3.1.5 ASEAN

- 5.3.1.6 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 France

- 5.3.3.4 Italy

- 5.3.3.5 NORDIC

- 5.3.3.6 Russia

- 5.3.3.7 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Rest of South America

- 5.3.5 Middle-East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 United Arab Emirates

- 5.3.5.3 South Africa

- 5.3.5.4 Rest of Middle-East and Africa

- 5.3.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share (%)/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 AkzoNobel N.V.

- 6.4.2 Asian Paints

- 6.4.3 Axalta Coating Systems LLC

- 6.4.4 BASF

- 6.4.5 Berger Paints India

- 6.4.6 Diamond Vogel

- 6.4.7 DuluxGroup Ltd

- 6.4.8 Hempel A/S

- 6.4.9 Jotun

- 6.4.10 Kansai Paint Co., Ltd.

- 6.4.11 Koster Bauchemie AG

- 6.4.12 Nippon Paint Holdings Co., Ltd.

- 6.4.13 Pidilite Industries Limited

- 6.4.14 PPG Industries, Inc.

- 6.4.15 RPM International Inc.

- 6.4.16 Sika AG

- 6.4.17 The Euclid Chemical Company

- 6.4.18 The Sherwin-Williams Company

- 6.4.19 Tikkurila

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-Need Assessment