|

市場調查報告書

商品編碼

1906889

可程式邏輯控制器(PLC):市場佔有率分析、產業趨勢與統計資料、成長預測(2026-2031)Programmable Logic Controller (PLC) - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

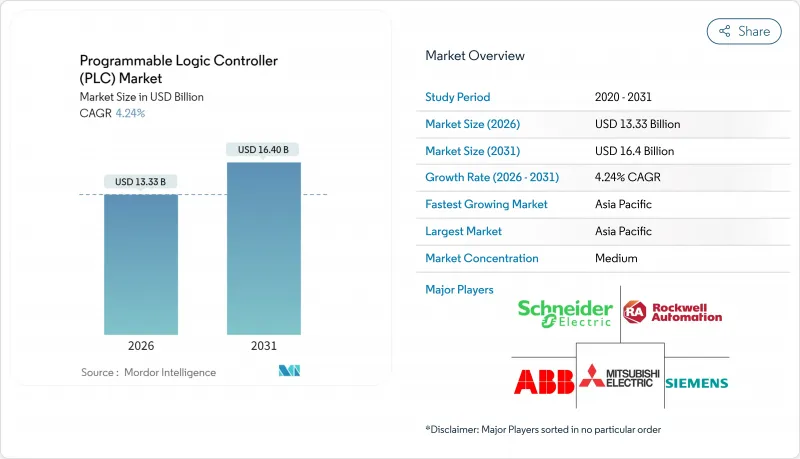

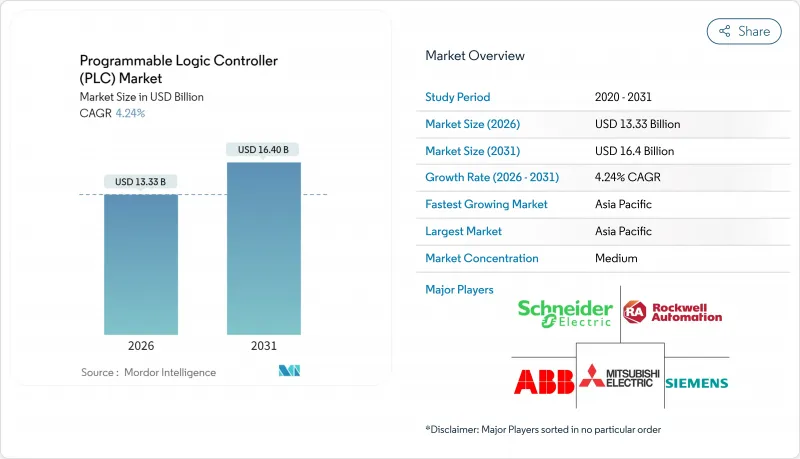

預計可程式邏輯控制器 (PLC) 市場將從 2025 年的 127.9 億美元成長到 2026 年的 133.3 億美元,並預計在 2031 年達到 164 億美元,2026 年至 2031 年的複合年成長率為 4.24%。

這種穩步擴張反映了工廠車間的持續現代化、網路安全驅動的回流趨勢以及從固定硬體向軟體定義自動化的逐步轉變。亞太地區在規模和發展勢頭方面均主導地位,中國和印度在補貼支持下擴大產能,推動了對緊湊型控制器平台的需求。儘管模組化架構在大型工廠中仍然至關重要,但隨著用戶尋求在標準工業用電腦上靈活部署,虛擬化解決方案的市場佔有率正在不斷成長。公用事業、車輛電氣化和電網邊緣計劃推動了近期採購,而預測性維護舉措則將收入來源拓展至服務領域。供應鏈中的雙重採購和不斷提高的網路安全要求推高了轉換成本,使得老牌企業即使在零件短缺緩解的情況下也能維持價格。

全球可程式邏輯控制器 (PLC) 市場趨勢與洞察

加速製造業採用工業4.0

工廠正在數位化以提高生產效率,而PLC則作為連接機器和企業軟體的本地資料中心。德國聯邦經濟部的報告顯示,工業4.0的普及率將從2023年的65%躍升至2024年的78%,印證了控制器升級的強勁勢頭。中國和印度的補貼計畫進一步降低了中小生產商的自動化成本。同時,奧迪的虛擬PLC實施方案將試運行時間縮短了23%,提高了即時最佳化能力,並展現了向軟體控制的轉變。日益嚴格的ISO 9001可追溯性要求製造商用支援詳細資料記錄和無縫ERP整合的現代化控制器取代傳統硬體。在離散製造和流程製造業,對內建邊緣分析功能的PLC的需求不斷成長,這種PLC能夠在不影響網路安全通訊協定的前提下縮短回饋迴路。

透過工業物聯網和雲端整合實現預測性維護

邊緣運算PLC可在本地分析振動、溫度和功率指標,並將精煉後的資料傳送到雲端控制面板,從而實現全資產健康監控。Schneider Electric的EcoStruxure平台是混合模式的典範,它將本地邏輯與雲端演算法結合,實現持續最佳化。 5G連接數位雙胞胎軟體使分散式PLC節點能夠即時協作,幫助自主調整流程並減少計劃外停機時間。已實施預測性維護的公共產業和金屬加工廠報告稱,其整體設備效率(OEE)顯著提高,備件庫存減少,證明了其投資回報,儘管網路安全問題依然存在。

中小製造商的初始資本成本較高

計劃成本平均在1.5萬至5萬美元之間,對於許多小規模企業來說仍然是一大障礙,尤其是在考慮到整合、培訓和停機時間等因素時。有限的資金往往導致新手負責人為了規避風險而採取「一刀切」的方式,過度配置系統。融資方案和供應商租賃可以幫助減輕負擔,但無法徹底消除保守的投資文化。基於訂閱的虛擬PLC部署成本低廉,但由於服務尚不成熟,尤其是在網路連線不穩定的地區,其普及程度因地區而異。

細分市場分析

到2025年,模組化架構將佔據可程式邏輯控制器(PLC)市場41.56%的佔有率,這體現了其能夠隨著工廠升級而擴展I/O和運算能力。這種架構允許工程師在不更換堆高機的情況下添加運動控制、安全和人工智慧模組,從而支援汽車和消費性電子產業的混合型生產線。軟PLC目前仍是一個小眾市場,但隨著虛擬機器管理程式提供確定性效能以及供應商整合增強型內核,其複合年成長率(CAGR)正以7.22%的速度成長。

離散製造和流程製造業對具備邊緣分析功能的控制器(用於機器級異常檢測)的需求日益成長。緊湊型PLC在獨立機器領域仍然很受歡迎,而分散式PLC則被應用於大規模煉油廠和發電廠,在這些場所,容錯性和地理位置分散的節點至關重要。隨著基於TSN的OPC-UA技術的日趨成熟,使用者期望實現互通性,這將進一步降低硬體的同質化程度,並將差異化因素轉移到軟體工具鍊和支援生態系統上。

2025年,硬體和軟體將佔可程式邏輯控制器(PLC)市場規模的84.67%,而隨著用戶從資本支出(CapEx)模式轉向營運支出(OpEx)模式,業務收益將以7.76%的複合年成長率成長。工業物聯網(IIoT)連接各層整合複雜性的不斷增加,正在推動對廠商主導的諮詢和應用工程服務的需求。

預測性維護方案整合了遠端監控、韌體管理和人工智慧驅動的診斷功能,從而促成多年滾動合約的簽訂。供應商正在新興市場拓展培訓機構,以彌補技能差距並提升品牌知名度。基於雲端的支援入口網站降低了差旅成本,擴增實境指南縮短了現場維修週期,即使是以硬體更換為主的計劃,也因此增強了服務需求。

區域分析

亞太地區的製造業復甦將支撐規模和速度的提升,預計2025年將佔全球收入的35.10%,到2031年將維持6.12%的複合年成長率。中國疫情後的經濟獎勵策略正在補貼汽車和電子產業的控制器升級,而印度的產業走廊建設正在推動PLC的初步應用。日本的「品質4.0」舉措將使電子元件貼片機對奈秒確定性控制設備的需求保持旺盛。韓國的造船廠和半導體工廠正在指定使用冗餘PLC叢集,以確保關鍵任務的運作,從而支援高利潤訂單。

在歐洲,永續性計劃正推動以能源管理和循環經濟支持為中心的控制器採購。 2024 年歐盟《網路安全韌性法案》要求原始設備製造商 (OEM) 從設計階段就對安全性進行認證,從而推動了對具備加密通訊和內建異常檢測功能的產品的需求。德國汽車製造商已開始試驗軟體定義 PLC 沙箱,而法國和義大利則在航太複合材料線中自動部署故障安全邏輯。

北美用戶優先考慮安全的供應鏈和國產半導體元件的使用。 《基礎設施投資與就業法案》正在資助變電站維修,以引入用於負載平衡和故障隔離的現代化控制器。墨西哥近海產業的蓬勃發展正在擴大汽車線束的生產,這需要快速採用緊湊型PLC。加拿大的採礦和林業部門偏好具有更寬溫度範圍的堅固耐用設備。總體而言,區域買家在評估競標時優先考慮網路安全認證和國內維修支援。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 加速製造業採用工業4.0

- 中小企業對緊湊型自動化設備的需求日益成長

- 透過工業物聯網和雲端整合實現預測性維護

- 向軟體定義PLC工作站的過渡

- 採用開放式工業通訊協定(基於TSN的OPC-UA)

- 基於網路安全措施的強制國內採購

- 市場限制

- 中小製造商的初始資本成本較高

- 互聯PLC面臨的網路安全威脅日益增加

- 工業用電腦和軟PLC替代的風險

- 由於半導體供應不穩定,前置作業時間延長。

- 產業價值鏈分析

- 宏觀經濟因素的影響

- 監管環境

- 技術展望

- 波特五力分析

- 新進入者的威脅

- 供應商的議價能力

- 買方的議價能力

- 替代品的威脅

- 競爭對手之間的競爭

第5章 市場規模與成長預測

- 依產品類型

- 小型PLC

- 模組化PLC

- 分散式PLC

- 軟PLC

- 其他產品

- 按組件

- 硬體和軟體

- 服務

- 安裝與整合

- 培訓和支持

- 維護

- 按產品尺寸

- Nano PLC

- 微型PLC

- 小規模PLC

- 中型PLC

- 大型PLC

- 按最終用戶行業分類

- 車

- 食品/飲料

- 化工/石油化工

- 石油和天然氣

- 能源與公共產業

- 供水和污水處理

- 製藥

- 紙漿和造紙

- 金屬和採礦

- 其他

- 按地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地區

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 其他歐洲地區

- 亞太地區

- 中國

- 日本

- 印度

- 韓國

- 東南亞

- 亞太其他地區

- 中東和非洲

- 中東

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 土耳其

- 其他中東地區

- 非洲

- 南非

- 奈及利亞

- 其他非洲地區

- 中東

- 北美洲

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率分析

- 公司簡介

- Siemens AG

- Rockwell Automation Inc.

- Schneider Electric SE

- Mitsubishi Electric Corporation

- ABB Ltd.

- Omron Corporation

- Emerson Electric Co.

- Honeywell International Inc.

- Beckhoff Automation GmbH & Co. KG

- Delta Electronics Inc.

- Bosch Rexroth AG

- Panasonic Holdings Corporation

- Fuji Electric Co. Ltd.

- Hitachi Ltd.

- IDEC Corporation

- Keyence Corporation

- Toshiba Corporation

- General Electric Company

- Parker Hannifin Corporation

- Eaton Corporation plc

- Yokogawa Electric Corporation

- Inovance Technology Co. Ltd.

- Hollysys Automation Technologies Ltd.

- WAGO Kontakttechnik GmbH & Co. KG

- B&R Industrial Automation GmbH

第7章 市場機會與未來展望

The Programmable Logic Controller Market is expected to grow from USD 12.79 billion in 2025 to USD 13.33 billion in 2026 and is forecast to reach USD 16.4 billion by 2031 at 4.24% CAGR over 2026-2031.

Steady expansion reflects ongoing modernization of factory floors, rising cybersecurity-driven reshoring, and the gradual shift from fixed hardware to software-defined automation. The Asia-Pacific region leads in both scale and momentum, as subsidy-backed capacity additions in China and India boost baseline demand for compact controllers. Modular architectures remain the cornerstone of large plants; yet, virtualized solutions are gaining market share as users seek flexible deployments on standard industrial PCs. Utilities, automotive electrification, and grid-edge projects anchor near-term purchases, while predictive-maintenance initiatives extend the revenue stream toward services. Supply-chain dual-sourcing and stronger cybersecurity mandates raise switching costs, allowing established brands to protect pricing even as component shortages ease.

Global Programmable Logic Controller (PLC) Market Trends and Insights

Accelerated Industry 4.0 Adoption in Manufacturing

Factories digitalize to boost productivity, and PLCs act as the local data hubs that connect machines with enterprise software. The German Federal Ministry for Economic Affairs reported a jump to 78% Industry 4.0 adoption in 2024, up from 65% in 2023, underscoring the momentum behind controller upgrades. Subsidies in China and India further lower the cost of automation for small producers, while Audi's virtual PLC rollout cut commissioning time by 23% and improved real-time optimization, validating the transition toward software-centric control. Rising ISO 9001 traceability requirements obligate manufacturers to replace legacy hardware with modern controllers that support granular data logging and seamless ERP integration. Across discrete and process industries, demand concentrates on PLCs with built-in edge analytics that shorten feedback loops without compromising cybersecurity protocols.

IIoT and Cloud Integration Enabling Predictive Maintenance

Edge-ready PLCs analyze vibration, temperature, and power metrics locally, sending only refined insights to cloud dashboards for fleetwide health monitoring. Schneider Electric's EcoStruxure platform exemplifies the hybrid model, fusing on-premise logic with cloud algorithms for continuous optimization. 5G connectivity and digital-twin software now coordinate distributed PLC nodes in real time, supporting autonomous process adjustments that curb unplanned downtime. Utilities and metals plants that deploy predictive maintenance report sharper OEE gains and lower spare-parts inventories, validating the investment case despite residual cybersecurity concerns.

High Up-Front Capital Cost for Small Manufacturers

Average project outlays of USD 15,000-50,000 still deter many micro-scale firms, especially when integration, training, and downtime are counted. Limited cash reserves often lead to over-specification because novice buyers adopt a one-size-fits-all mindset to mitigate perceived risk. Financing schemes and vendor leasing ease pressure, but cannot fully offset conservative investment cultures. Subscription-based virtual PLCs promise lower entry points, yet nascent offerings leave adoption uneven, particularly in regions where internet reliability lags.

Other drivers and restraints analyzed in the detailed report include:

- Growing Demand for Compact Automation Among SMEs

- Shift to Software-Defined PLC Workstations

- Escalating Cybersecurity Threats to Connected PLCs

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Modular configurations dominated with 41.56% programmable logic controller market share in 2025, reflecting their ability to expand I/O and compute power alongside plant upgrades. The architecture lets engineers add motion, safety, or AI cards without forklift replacements, supporting mixed-model lines in automotive and consumer electronics. Soft PLCs, though still niche, are advancing at a 7.22% CAGR as hypervisors deliver deterministic performance and vendors embed hardened kernels.

Across both discrete and process industries, demand centers on controllers that host edge analytics for anomaly detection at the machine level. Compact PLCs retain appeal for stand-alone machines, while distributed PLCs serve large refineries and power stations that favor fault-tolerant, geographically separated nodes. As OPC-UA over TSN matures, users expect seamless interoperability, further commoditizing hardware and shifting differentiation to software toolchains and support ecosystems.

Hardware and software together held 84.67% of the programmable logic controller market size in 2025, yet service revenue is expanding at 7.76% CAGR as users pivot from CapEx to OpEx models. Integration complexity climbs with each layer of IIoT connectivity, elevating demand for vendor-led consulting and application engineering.

Predictive maintenance packages bundle remote monitoring, firmware management, and AI-driven diagnostics, creating sticky multi-year contracts. Vendors also ramp training academies in emerging economies to close the skills gap and lock in brand familiarity. Cloud-hosted support portals lower travel costs, while augmented-reality guides shorten onsite repair cycles, reinforcing service pull even in hardware-centric replacement projects.

PLC Market Report is Segmented by Product Type (Compact PLC, Modular PLC, Distributed PLC, Soft PLC, Other Products), Component (Hardware and Software, Services), Product Size (Nano PLC, Micro PLC, Small PLC, Medium PLC, Large PLC), End-User Industry (Automotive, Food and Beverage, Chemical and Petrochemical, and More), and Geography. The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific's manufacturing resurgence underpins both scale and speed, with 35.10% revenue in 2025 and 6.12% CAGR to 2031. China's post-pandemic stimulus subsidized controller upgrades in automotive and electronics, while India's industrial corridor builds encourage first-time PLC rollouts. Japan's Quality-4.0 initiatives keep demand high for deterministic, nano-second-level controllers used in electronics placement machines. South Korean shipyards and fabs specify redundant PLC clusters for mission-critical uptime, anchoring high-margin orders.

Europe's sustainability push frames controller purchases around energy management and circular-economy compliance. The EU Cyber Resilience Act of 2024 obliges OEMs to certify security-by-design, boosting demand for products with encrypted communications and built-in anomaly detection. German automakers pilot software-defined PLC sandboxes, while France and Italy automate aerospace composites lines with fail-safe logic.

North American users prioritize secure supply chains and domestic semiconductor content. The Infrastructure Investment and Jobs Act funds substation refurbishments that incorporate modern controllers for load-balancing and fault isolation. Mexico's nearshore boom ramps automotive harness production, requiring swift deployment of compact PLCs. Canada's mining and lumber sectors favor rugged gear with extended temperature ratings. Overall, regional buyers weigh cybersecurity credentials and on-shore repair support heavily in tender scoring.

- Siemens AG

- Rockwell Automation Inc.

- Schneider Electric SE

- Mitsubishi Electric Corporation

- ABB Ltd.

- Omron Corporation

- Emerson Electric Co.

- Honeywell International Inc.

- Beckhoff Automation GmbH & Co. KG

- Delta Electronics Inc.

- Bosch Rexroth AG

- Panasonic Holdings Corporation

- Fuji Electric Co. Ltd.

- Hitachi Ltd.

- IDEC Corporation

- Keyence Corporation

- Toshiba Corporation

- General Electric Company

- Parker Hannifin Corporation

- Eaton Corporation plc

- Yokogawa Electric Corporation

- Inovance Technology Co. Ltd.

- Hollysys Automation Technologies Ltd.

- WAGO Kontakttechnik GmbH & Co. KG

- B&R Industrial Automation GmbH

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Accelerated Industry-4.0 adoption in manufacturing

- 4.2.2 Growing demand for compact automation among SMEs

- 4.2.3 IIoT and cloud integration enabling predictive maintenance

- 4.2.4 Shift to software-defined PLC workstations

- 4.2.5 Adoption of open industrial protocols (OPC-UA over TSN)

- 4.2.6 Cybersecurity-driven domestic sourcing mandates

- 4.3 Market Restraints

- 4.3.1 High up-front capital cost for small manufacturers

- 4.3.2 Escalating cybersecurity threats to connected PLCs

- 4.3.3 Substitution risk from industrial PCs and soft-PLCs

- 4.3.4 Semiconductor supply volatility inflating lead times

- 4.4 Industry Value Chain Analysis

- 4.5 Impact of Macroeconomic Factors

- 4.6 Regulatory Landscape

- 4.7 Technological Outlook

- 4.8 Porter's Five Forces Analysis

- 4.8.1 Threat of New Entrants

- 4.8.2 Bargaining Power of Suppliers

- 4.8.3 Bargaining Power of Buyers

- 4.8.4 Threat of Substitutes

- 4.8.5 Competitive Rivalry

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Product Type

- 5.1.1 Compact PLC

- 5.1.2 Modular PLC

- 5.1.3 Distributed PLC

- 5.1.4 Soft PLC

- 5.1.5 Other Products

- 5.2 By Component

- 5.2.1 Hardware and Software

- 5.2.2 Services

- 5.2.2.1 Installation and Integration

- 5.2.2.2 Training and Support

- 5.2.2.3 Maintenance

- 5.3 By Product Size

- 5.3.1 Nano PLC

- 5.3.2 Micro PLC

- 5.3.3 Small PLC

- 5.3.4 Medium PLC

- 5.3.5 Large PLC

- 5.4 By End-user Industry

- 5.4.1 Automotive

- 5.4.2 Food and Beverage

- 5.4.3 Chemical and Petrochemical

- 5.4.4 Oil and Gas

- 5.4.5 Energy and Utilities

- 5.4.6 Water and Wastewater Treatment

- 5.4.7 Pharmaceutical

- 5.4.8 Pulp and Paper

- 5.4.9 Metals and Mining

- 5.4.10 Others

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 South America

- 5.5.2.1 Brazil

- 5.5.2.2 Argentina

- 5.5.2.3 Rest of South America

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Spain

- 5.5.3.6 Rest of Europe

- 5.5.4 Asia-Pacific

- 5.5.4.1 China

- 5.5.4.2 Japan

- 5.5.4.3 India

- 5.5.4.4 South Korea

- 5.5.4.5 South-East Asia

- 5.5.4.6 Rest of Asia-Pacific

- 5.5.5 Middle East and Africa

- 5.5.5.1 Middle East

- 5.5.5.1.1 Saudi Arabia

- 5.5.5.1.2 United Arab Emirates

- 5.5.5.1.3 Turkey

- 5.5.5.1.4 Rest of Middle East

- 5.5.5.2 Africa

- 5.5.5.2.1 South Africa

- 5.5.5.2.2 Nigeria

- 5.5.5.2.3 Rest of Africa

- 5.5.5.1 Middle East

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level overview, Market level overview, Core segments, Financials as available, Strategic information, Market rank/share for key companies, Products and Services, and Recent developments)

- 6.4.1 Siemens AG

- 6.4.2 Rockwell Automation Inc.

- 6.4.3 Schneider Electric SE

- 6.4.4 Mitsubishi Electric Corporation

- 6.4.5 ABB Ltd.

- 6.4.6 Omron Corporation

- 6.4.7 Emerson Electric Co.

- 6.4.8 Honeywell International Inc.

- 6.4.9 Beckhoff Automation GmbH & Co. KG

- 6.4.10 Delta Electronics Inc.

- 6.4.11 Bosch Rexroth AG

- 6.4.12 Panasonic Holdings Corporation

- 6.4.13 Fuji Electric Co. Ltd.

- 6.4.14 Hitachi Ltd.

- 6.4.15 IDEC Corporation

- 6.4.16 Keyence Corporation

- 6.4.17 Toshiba Corporation

- 6.4.18 General Electric Company

- 6.4.19 Parker Hannifin Corporation

- 6.4.20 Eaton Corporation plc

- 6.4.21 Yokogawa Electric Corporation

- 6.4.22 Inovance Technology Co. Ltd.

- 6.4.23 Hollysys Automation Technologies Ltd.

- 6.4.24 WAGO Kontakttechnik GmbH & Co. KG

- 6.4.25 B&R Industrial Automation GmbH

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-need Assessment