|

市場調查報告書

商品編碼

1906211

工業軸承:市場佔有率分析、產業趨勢與統計、成長預測(2026-2031)Industrial Bearings - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

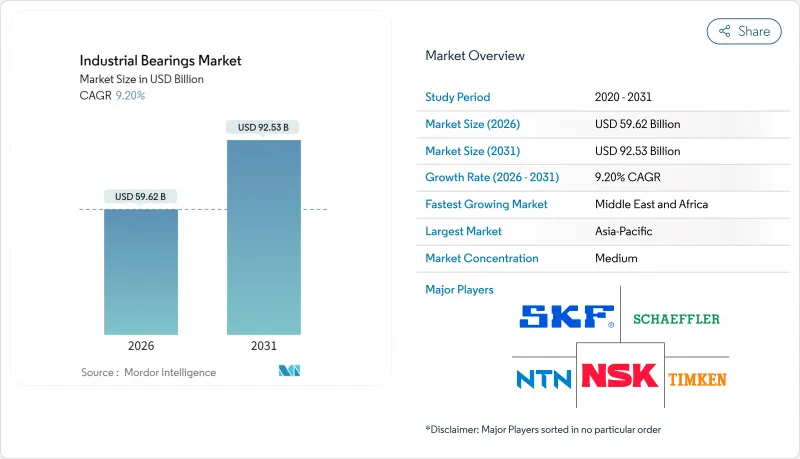

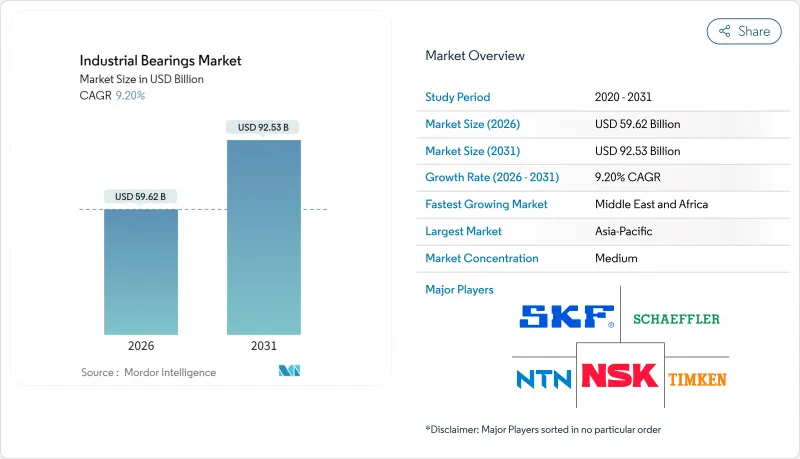

預計工業軸承市場將從 2025 年的 546 億美元成長到 2026 年的 596.2 億美元,到 2031 年將達到 925.3 億美元,2026 年至 2031 年的複合年成長率為 9.2%。

這一成長反映了交通運輸和工廠設備的電氣化程度不斷提高、自動化進程加速以及基礎設施升級對高性能機械部件的需求日益成長。配備感測器、微型電子元件和無線連接功能的智慧軸承正在將維護方式從被動式轉變為預測式,從而提高資產運轉率並減少非計畫性停機時間。製造商也積極研發輕量化材料和低摩擦設計,以提高電動車和工業機器人的能源效率。對風能、氫能和半導體計劃的持續資本投資進一步增加了對專用、高負載、高精度軸承的需求,這些軸承需在全球嚴苛、高速和潔淨的環境中運作。

全球工業軸承市場趨勢與洞察

汽車和電動車生產呈現復甦跡象

預計到2025年,全球輕型車產量將成長至8,960萬輛,其中電動車預計將佔總銷量的25%。電動車牽引馬達需要使用電絕緣軸承來減少雜訊電流造成的腐蝕。杜邦Vespel聚醯亞胺嵌件能夠承受高溫,且成本低於全陶瓷混合型軸承。能夠同時生產內燃機(ICE)和電動車軸承的雙產能生產線製造商,既可以維持其穩定的現有需求,又能抓住電動動力傳動系統領域不斷成長的需求。

智慧軸承在預測性維護中的快速普及

整合於外殼內的無線感測器組件可實現對振動、溫度和潤滑狀況的持續監測。舍弗勒的OPTIME生態系統體現了這項變革,它透過限制對旋轉設備的物理接觸,減少了人工檢查並提高了安全性。結合人工智慧分析,工廠報告稱,引入協作機器人後,組裝時間縮短了30%,品質提高了15%。向數據密集型產品的轉變不僅帶來了持續的業務收益,也提高了低成本假冒產品製造商的准入門檻。

合金和能源價格波動對利潤率造成壓力。

鎳價飆升和能源附加費波動加劇了投入成本的波動,並侵蝕了毛利率,即便附加費已降至四年來的最低點。對華進口貨櫃附加費推高了運費,而美國鋼鐵關稅則限制了現貨採購選擇,並延長了鋼廠的前置作業時間。擁有多供應商合約和能源供應避險策略的公司,其業績優於單一供應商的競爭對手。

細分市場分析

到2025年,滾珠軸承將佔據工業軸承市場41.55%的佔有率,這主要歸功於其在汽車零件、工業馬達和家用電器等領域的廣泛應用。滾輪軸承仍然是礦山和施工機械的首選,因為這些領域承受著巨大的衝擊負荷。滑動軸承則用於腐蝕性海洋和化學應用。磁軸承是成長最快的細分市場,年複合成長率高達17.85%,其無油運轉消除了磨損,並實現了氫氣壓縮機和電動垂直起降飛行器(eVTOL)渦輪機的高速旋轉。 NSK面向城市空中運輸的燃氣渦輪機發電機解決方案已在航太領域初見成效(nsks.com)。 Upwing Energy的被動式磁徑向設計透過消除金屬間的直接接觸,延長了地下泵浦的使用壽命,展現了其跨產業的適用性。

對無摩擦系統日益成長的需求推動了磁性元件領域收入的快速成長,但材料成本和對先進控制電子設備的要求仍然限制了其在高階應用之外的廣泛部署。隨著原始設備製造商 (OEM) 將狀態監控感測器整合到磁性元件中,磁性元件能夠將電流、溫度和振動數據直接整合到設備控制迴路中,而同時掌握機械和電子技術的供應商則有望實現高利潤率。

截至2025年,合金鋼將佔據工業軸承市場67.10%的佔有率,這主要得益於其全球熔煉能力、良好的加工性能和優異的抗疲勞性能,且成本具有競爭力。陶瓷工業軸承市場雖然目前規模較小,但在電動車絕緣和高速主軸需求的推動下,預計到2031年將以13.85%的複合年成長率持續成長。研究表明,先進的金屬基複合材料靜壓軸承具有優異的導熱性能,既可實現輕量化應用,又能支援超精密加工。

混合鋼-陶瓷軸承設計將氮化矽滾動體與硬化鋼滾道相結合,兼顧成本和性能,在風力發電機需要關注電偶腐蝕問題。聚合物和複合材料保持架因其能夠耐受化學清洗且無需外部潤滑,在符合衛生標準的食品級泵浦和製藥攪拌機中也越來越受歡迎。

區域分析

亞太地區預計2025年將維持46.60%的工業軸承市場佔有率,這主要得益於中國大規模的OEM廠商群體和印度不斷發展的基礎設施。 SKF的在地化策略,包括擴大寧波工廠和建立研發中心,正在縮短前置作業時間並根據區域標準量身設計。日本在電子組裝和手術機器人所需的微型高精度軸承領域保持主導,而韓國和台灣則透過對半導體大型晶圓廠的投資擴大了需求。隨著企業利用具有成本競爭力的勞動力和新達成的區域貿易協定,東協地區的成長正在加速。

北美地區的經濟成長高於全球平均水平,這得益於1.4兆美元的資金回流以及公共部門的支持,例如《CHIPS法案》和《基礎設施法案》。儘管國內生產商正在擴張,但熟練工人的短缺延長了生產擴張的周期。目前,墨西哥的進口產品填補了供應缺口。在歐洲,永續性和高效機械是優先考慮的因素,但德國工業訂單的下降將限制短期生產。歐盟的政策正在推廣循環經濟軸承,SKF的雷射重塗層循環性能係列就是一個例證。

預計中東和非洲地區將以12.45%的複合年成長率成長,海灣國家正積極向石化、鋁和可再生能源領域多元化發展。阿拉伯聯合大公國自由區的經銷商是區域整合的樞紐,而沙烏地阿拉伯的本土化目標則為合資企業創造了機會。南美洲的需求主要局部採礦業主導,但貨幣波動和政治風險要求彈性價格設定和信貸條款。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 汽車和電動車(EV)生產正在復甦

- 智慧軸承在預測性維護中的快速普及

- 亞太和歐洲陸上風力發電機擴張

- 北美工業設備供應鏈回流

- 氫氣壓縮機用磁軸承和陶瓷軸承的利基需求(被低估了)

- 機器人和協作機器人的普及,需要低摩擦微型軸承(被低估了)。

- 市場限制

- 合金和能源價格的波動給利潤率帶來了壓力。

- 汽車產業從內燃機(ICE)向電動車(EV)的轉變正在降低對引擎相關軸承的需求。

- 美國和歐盟基於智慧財產權(缺乏保障)對中國製造的軸承實施進口限制

- 積層製造的襯套可取代航太的小型滾輪軸承(報道不足)

- 價值/供應鏈分析

- 監管環境

- 技術展望

- 波特五力分析

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭對手之間的競爭

第5章 市場規模與成長預測

- 按軸承類型

- 滾珠軸承

- 滾輪軸承

- 滑動軸承

- 磁軸承

- 其他軸承

- 材料

- 合金鋼

- 陶瓷製品

- 聚合物/複合材料

- 混合

- 按最終用戶行業分類

- 車

- 航太

- 能源(風能、石油與天然氣、水力)

- 採礦和金屬

- 建築和重型設備

- 食品/飲料

- 物料輸送與物流

- 其他行業

- 透過使用

- 旋轉設備(馬達、幫浦)

- 直線運動系統

- 引擎、變速箱和傳動系統

- 底盤和輪轂

- 精密儀器和測量儀器

- 按銷售管道

- OEM

- 售後市場/MRO

- 按地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 英國

- 德國

- 法國

- 義大利

- 其他歐洲地區

- 亞太地區

- 中國

- 日本

- 印度

- 韓國

- 亞太其他地區

- 中東

- 以色列

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 土耳其

- 其他中東地區

- 非洲

- 南非

- 埃及

- 其他非洲地區

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 北美洲

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率分析

- 公司簡介

- AB SKF

- NSK Ltd.

- NTN Corporation

- The Timken Company

- JTEKT Corporation

- MinebeaMitsumi Inc.

- Regal Rexnord Corporation

- RBC Bearings Inc.

- THB Bearings Co., Ltd.

- HKT Bearings Ltd.

- Schaeffler AG

- Nachi-Fujikoshi Corp.

- CandU Group Co., Ltd.

- Federal-Mogul LLC(DRiV)

- THK Co., Ltd.

- SKF Motion Technologies

- Harbin HRB Bearing Group Co., Ltd.

- LYC Bearing Corporation

- KG International FZCO

- Others(validated)

第7章 市場機會與未來展望

The industrial bearings market is expected to grow from USD 54.6 billion in 2025 to USD 59.62 billion in 2026 and is forecast to reach USD 92.53 billion by 2031 at 9.2% CAGR over 2026-2031.

Growth reflects rising electrification across transport and factory equipment, accelerating automation adoption, and infrastructure upgrades that demand higher-performance mechanical components. Smart bearings equipped with sensors, miniaturised electronics and wireless connectivity shift maintenance from reactive to predictive, raising asset uptime and reducing unplanned downtime. Manufacturers also pursue lightweight materials and low-friction designs to improve energy efficiency in electric vehicles and industrial robots. Sustained capital expenditure in wind, hydrogen and semiconductor projects further increases demand for specialised, high-load and high-precision bearings that operate in harsher, faster and cleaner environments worldwide.

Global Industrial Bearings Market Trends and Insights

Rising Automotive & EV Production Rebound

Global light-vehicle output is forecast to edge up to 89.6 million units in 2025, with electric models accounting for 25% of sales. EV traction motors require electrically insulated bearings that mitigate stray-current erosion; DuPont's Vespel polyimide inserts lower cost versus full ceramic hybrids while tolerating high temperatures. Producers that build dual-capability lines for ICE and EV bearings benefit from steady legacy demand while capturing new e-powertrain volumes.

Rapid Adoption of Predictive-Maintenance-Ready Smart Bearings

Wireless sensor packages integrated into housings now monitor vibration, temperature and lubrication regimes continuously. Schaeffler's OPTIME ecosystem illustrates the shift, cutting manual inspection and raising safety by limiting physical access to rotating assets. When paired with AI analytics, factories report 30% assembly-time reduction and 15% quality gains from collaborative-robot deployments. The move to data-rich products creates recurring service revenue while raising qualification hurdles for low-cost imitators.

Volatile Alloy & Energy Prices Squeezing Margins

Nickel price spikes and energy-surcharge swings push input-cost volatility that erodes gross margins despite surcharges peaking at four-year lows. Container surcharges on inbound Chinese shipments inflate freight costs, while US steel tariffs limit spot options and lengthen mill lead times. Firms with multi-sourcing contracts and hedged energy supply outperform single-source competitors.

Other drivers and restraints analyzed in the detailed report include:

- Expansion of On-Shore Wind Turbines

- Re-shoring of Industrial Equipment Supply Chains

- Automotive ICE-to-EV Transition Reducing Engine-Related Bearing Volumes

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Ball bearings held 41.55% of the industrial bearings market in 2025 thanks to broad suitability for automotive accessories, industrial motors and consumer appliances. Roller bearings remain preferred in mining and construction machinery where shock loads dominate. Plain bearings serve corrosive marine and chemical duties. Magnetic bearings represent the fastest-growing niche at 17.85% CAGR as oil-free operation eliminates wear and enables higher rotational speeds in hydrogen compressors and eVTOL turbines. NSK's gas-turbine generator solution for urban air mobility highlights early aerospace traction nsk.com. Upwing Energy's passive magnetic radial design extends downhole pump life by removing metal-to-metal contact, illustrating cross-industry adoption potential.

Growing demand for friction-less systems underpins the magnetic segment's revenue leap, although material cost and sophisticated control-electronics requirements still limit widespread deployment beyond premium applications. As OEMs integrate condition-monitoring sensors, magnetic units can embed current, temperature and vibration data directly into equipment control loops, positioning suppliers that master both mechanics and electronics for higher margins.

Alloy steel comprised 67.10% of the industrial bearings market in 2025, benefiting from global melt capacity, machinability and fatigue resistance at competitive cost. The industrial bearings market size for ceramic products remains smaller but climbs at 13.85% CAGR through 2031 on the back of EV insulation needs and high-speed spindle requirements. Research shows advanced metal-matrix-composite hydrostatic bearings deliver superior thermal conductivity, supporting ultraprecision machining at reduced weight.

Hybrid steel-ceramic designs blend silicon-nitride rolling elements with hardened-steel races to balance cost and performance, accelerating uptake in wind-turbine generators where electrical corrosion is problematic. Polymer and composite cages gain share in food-grade pumps and pharmaceutical mixers because they endure chemical washdowns and eliminate external lubrication, complying with hygiene codes.

The Industrial Bearings Market Report is Segmented by Bearing Type (Ball Bearings, Roller Bearings, Plain Bearings, and More), Material (Alloy Steel, Ceramic, Polymer/Composite, Hybrid), End-User Industry (Automotive, Aerospace, Energy, and More), Application (Rotating Equipment, Linear Motion Systems, Engine/Transmission/Driveline, and More), Sales Channel, and Geography. The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific retained 46.60% industrial bearings market share in 2025, propelled by China's large-scale OEM base and India's infrastructure build-out. Localization strategies such as SKF's expanded Ningbo plant and R&D hub shorten lead times and customise designs for regional standards. Japan sustains leadership in miniaturised and high-accuracy bearings needed for electronics assembly and surgical robotics, while South Korea and Taiwan boost demand via semiconductor megafab investments. ASEAN growth accelerates as companies leverage cost-competitive labour and newly inked regional trade pacts.

North America grows above global average on the back of USD 1.4 trillion reshoring commitments and public-sector incentives like the CHIPS and Infrastructure acts. Domestic producers scale up, yet skill shortages lengthen ramp-up schedules; meantime, imports from Mexico fill interim supply gaps. Europe prioritises sustainability and high-efficiency machinery, but industrial order softness in Germany tempers near-term volume. EU policy pushes circular-economy bearings, evidenced by SKF's laser-reclad circular performance series.

The Middle East & Africa present 12.45% CAGR prospects as Gulf nations diversify into petrochemical, aluminium and renewable projects. Free-zone distributors in UAE serve as regional consolidation hubs, while localisation goals in Saudi Arabia open joint-venture opportunities. South America offers mining-driven pockets of demand, although currency volatility and political risk require flexible pricing and credit terms.

- AB SKF

- NSK Ltd.

- NTN Corporation

- The Timken Company

- JTEKT Corporation

- MinebeaMitsumi Inc.

- Regal Rexnord Corporation

- RBC Bearings Inc.

- THB Bearings Co., Ltd.

- HKT Bearings Ltd.

- Schaeffler AG

- Nachi-Fujikoshi Corp.

- CandU Group Co., Ltd.

- Federal-Mogul LLC (DRiV)

- THK Co., Ltd.

- SKF Motion Technologies

- Harbin HRB Bearing Group Co., Ltd.

- LYC Bearing Corporation

- KG International FZCO

- Others (validated)

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Rising automotive and EV production rebound

- 4.2.2 Rapid adoption of predictive-maintenance?ready smart bearings

- 4.2.3 Expansion of on-shore wind turbines in APAC and Europe

- 4.2.4 Re-shoring of industrial equipment supply chains in North America

- 4.2.5 Niche demand for magnetic and ceramic bearings in hydrogen compressors (under-reported)

- 4.2.6 Surge in robotics and cobots requiring low-friction miniature bearings (under-reported)

- 4.3 Market Restraints

- 4.3.1 Volatile alloy and energy prices squeezing margins

- 4.3.2 Automotive ICE-to-EV transition reducing engine-related bearing volumes

- 4.3.3 IP-driven import restrictions on Chinese bearings in U.S. and EU (under-reported)

- 4.3.4 Additive-manufactured bushings replacing small roller bearings in aerospace (under-reported)

- 4.4 Value / Supply-Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Threat of New Entrants

- 4.7.4 Threat of Substitutes

- 4.7.5 Intensity of Competitive Rivalry

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Bearing Type

- 5.1.1 Ball Bearings

- 5.1.2 Roller Bearings

- 5.1.3 Plain Bearings

- 5.1.4 Magnetic Bearings

- 5.1.5 Other Bearings

- 5.2 By Material

- 5.2.1 Alloy Steel

- 5.2.2 Ceramic

- 5.2.3 Polymer / Composite

- 5.2.4 Hybrid

- 5.3 By End-user Industry

- 5.3.1 Automotive

- 5.3.2 Aerospace

- 5.3.3 Energy (Wind, Oil and Gas, Hydro)

- 5.3.4 Mining and Metals

- 5.3.5 Construction and Heavy Equipment

- 5.3.6 Food and Beverage

- 5.3.7 Material Handling and Logistics

- 5.3.8 Other Industries

- 5.4 By Application

- 5.4.1 Rotating Equipment (Motors, Pumps)

- 5.4.2 Linear Motion Systems

- 5.4.3 Engine, Transmission and Driveline

- 5.4.4 Chassis and Wheel Hubs

- 5.4.5 Precision and Instrumentation

- 5.5 By Sales Channel

- 5.5.1 OEM

- 5.5.2 Aftermarket / MRO

- 5.6 By Geography

- 5.6.1 North America

- 5.6.1.1 United States

- 5.6.1.2 Canada

- 5.6.1.3 Mexico

- 5.6.2 Europe

- 5.6.2.1 United Kingdom

- 5.6.2.2 Germany

- 5.6.2.3 France

- 5.6.2.4 Italy

- 5.6.2.5 Rest of Europe

- 5.6.3 Asia-Pacific

- 5.6.3.1 China

- 5.6.3.2 Japan

- 5.6.3.3 India

- 5.6.3.4 South Korea

- 5.6.3.5 Rest of Asia-Pacific

- 5.6.4 Middle East

- 5.6.4.1 Israel

- 5.6.4.2 Saudi Arabia

- 5.6.4.3 United Arab Emirates

- 5.6.4.4 Turkey

- 5.6.4.5 Rest of Middle East

- 5.6.5 Africa

- 5.6.5.1 South Africa

- 5.6.5.2 Egypt

- 5.6.5.3 Rest of Africa

- 5.6.6 South America

- 5.6.6.1 Brazil

- 5.6.6.2 Argentina

- 5.6.6.3 Rest of South America

- 5.6.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level Overview, Core Segments, Financials, Strategic Information, Market Rank/Share, Products and Services, Recent Developments)

- 6.4.1 AB SKF

- 6.4.2 NSK Ltd.

- 6.4.3 NTN Corporation

- 6.4.4 The Timken Company

- 6.4.5 JTEKT Corporation

- 6.4.6 MinebeaMitsumi Inc.

- 6.4.7 Regal Rexnord Corporation

- 6.4.8 RBC Bearings Inc.

- 6.4.9 THB Bearings Co., Ltd.

- 6.4.10 HKT Bearings Ltd.

- 6.4.11 Schaeffler AG

- 6.4.12 Nachi-Fujikoshi Corp.

- 6.4.13 CandU Group Co., Ltd.

- 6.4.14 Federal-Mogul LLC (DRiV)

- 6.4.15 THK Co., Ltd.

- 6.4.16 SKF Motion Technologies

- 6.4.17 Harbin HRB Bearing Group Co., Ltd.

- 6.4.18 LYC Bearing Corporation

- 6.4.19 KG International FZCO

- 6.4.20 Others (validated)

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-need Assessment