|

市場調查報告書

商品編碼

1906125

衝擊改質劑:市場佔有率分析、產業趨勢與統計、成長預測(2026-2031)Impact Modifier - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

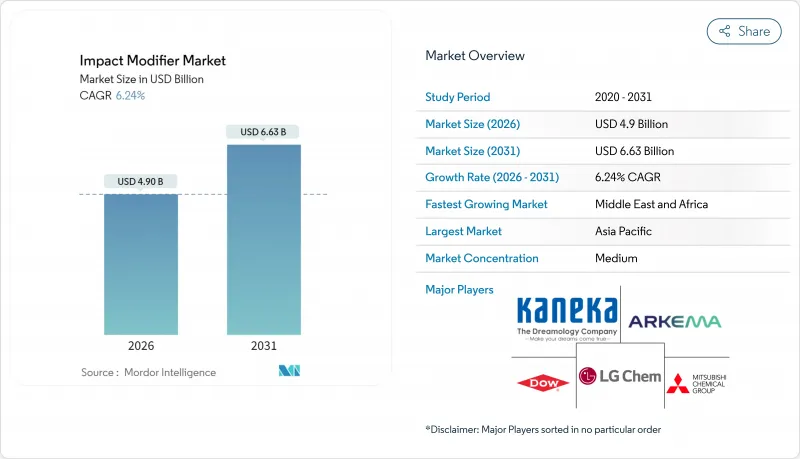

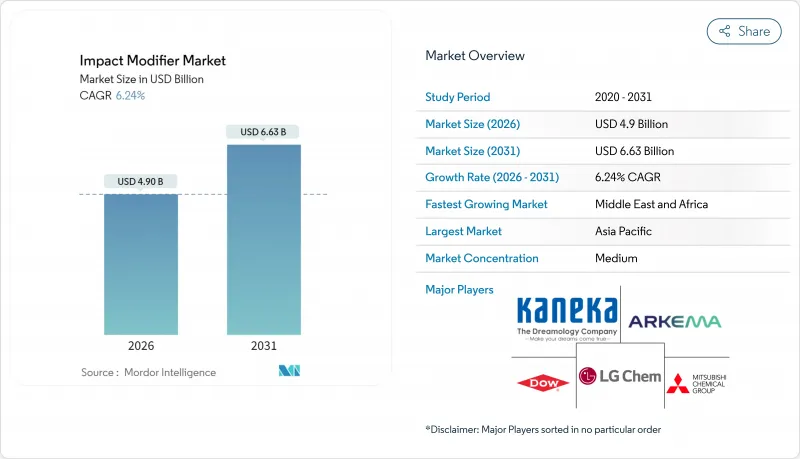

預計到 2026 年,衝擊改質劑市場價值將達到 49 億美元,從 2025 年的 46.1 億美元成長到 2031 年的 66.3 億美元。

預計2026年至2031年年複合成長率(CAGR)為6.24%。

聚合物的應用增強能力是推動成長的主要因素,它可用於製造輕量化汽車零件、抗衝擊建築材料和更薄的包裝薄膜。亞太地區的建築業蓬勃發展將支撐需求,預計到2024年,其市佔率將達到47.26%。同時,隨著汽車製造商積極實施輕量化策略,汽車應用預計將以6.45%的複合年成長率成長。丙烯腈-丁二烯-苯乙烯共聚物(ABS)仍將是最大的產品類型,到2024年將佔據33.48%的市場佔有率;而丙烯酸類抗衝擊改質劑(AIM)將以6.42%的複合年成長率成為成長最快的產品,主要用於需要耐候化合物的戶外應用。聚氯乙烯(PVC)將在管道和型材的強勁需求推動下,於2024年佔據主導地位,市場佔有率將達到42.67%;而隨著汽車製造商採用抗衝擊複合複合材料製造碰撞相關部件,工程塑膠的複合年成長率將達到6.63%。

全球衝擊改質劑市場趨勢及洞察

包裝需求不斷成長

包裝加工商正在採用抗衝擊改質化合物,以實現更薄的壁厚,從而能夠承受電商配送中的跌落測試,滿足FDA食品接觸標準,同時減少樹脂用量。硬質包裝配方師正在添加改質劑以降低厚度,同時保持結構完整性,尤其適用於循環利用項目中的可重複使用容器。隨著品牌擁有者優先考慮與回收流程的兼容性,對兼具透明度和韌性的混合改質劑/相容劑系統的需求日益成長。材料供應商正在透過調整熔體流動性能來滿足高速薄膜生產線的需求。向單一材料形式的持續轉變進一步推動了對能夠在更薄的包裝中平衡剛度和抗衝擊性的改質劑的需求。

PVC管材和型材的需求不斷成長

亞太地區的基建計劃正在採用添加了改質劑的大口徑PVC管材,以增強其在安裝過程中的抗損傷能力和抗壓循環能力。颱風多發地區的建築規範規定使用抗衝擊改質PVC窗框型材,以承受風荷載和熱應力。隨著城市地下管網的擴展,承包商要求使用經久耐用、數十年不開裂的管道。 ASTM D1784和ISO 4422等標準規定了最低衝擊閾值,迫使複合材料生產商最佳化改質劑配方。海灣合作理事會(GCC)國家也採用了類似的規範,加速了PVC在中東地區計劃的應用。

原物料價格波動(苯乙烯、丙烯酸酯)

苯乙烯和丙烯酸酯單體價格波動擠壓了生產商的利潤空間,並透過促使現貨交易和短期合約的簽訂,為加工商帶來了不確定性。由於裂解裝置計劃外停產造成的供應中斷導致交付成本飆升,迫使複合材料生產商限制配額。買家正透過多源策略進行避險,但當原物料供應中斷波及整個供應鏈時,差異化策略難以實施。一些原始設備製造商 (OEM) 正在簽署代工加工協議以降低價格波動,但也因此承擔了更高的庫存風險。亞洲原料供應中心的能源成本波動進一步加劇了改質劑交付價格的不確定性。

細分市場分析

到2025年,ABS將維持32.92%的衝擊改質劑市場佔有率,主要用於家電機殼和汽車內裝。同時,AIM憑藉其卓越的抗紫外線性能,將應用於車身外板和窗框型材,推動市場以6.36%的複合年成長率成長。受AIM驅動的衝擊改質劑市場規模預計將穩定擴大,這主要得益於在惡劣氣候條件下對更耐用建築建築幕牆的需求。 ASA將服務於需要耐化學腐蝕的燃料接觸部件這一細分市場,而MBS則可用於製造兼具透明度和抗跌落性能的透明PVC包裝。 EPDM和CPE則適用於對阻燃性和彈性性能要求極高的領域。對於所有類型的材料而言,與回收材料的兼容性都是至關重要的採購因素,因為循環經濟的目標正日益實現。

AIM技術的持續應用也受到汽車造型設計嚴格要求的推動,這些要求需要使用能夠防止光亮表面出現應力泛白的材料。 ABS材料因其兼具剛性、耐熱性和色彩柔軟性,仍是儀表板和立柱區域的重要材料。從長遠來看,製造商正在探索將丙烯酸芯材與彈性體外殼材料結合的混合解決方案,以滿足更嚴格的碰撞能量吸收標準。隨著區域法規強制要求在新車和建築中使用再生聚烯樹脂,改質劑的化學性質及其與再生聚烯原料的相互作用已成為一項重要的研究主題。

區域分析

到2025年,亞太地區將以46.78%的市場佔有率主導全球市場,這主要得益於中國的大規模計劃規劃和印度不斷擴大的汽車生產。抗衝擊改質PVC管道系統是新型城市供水網路的主幹,而工程塑膠在亞太地區的汽車製造商中正被廣泛應用於儀表板、立柱和電池等領域。日本汽車製造商正在採用改質PP和PC/ABS共混物來減輕車身重量,同時又不影響側面碰撞性能。受益於供應鏈變化的東協製造商正在擴大家用電器的出口,這些家用電器依賴ABS改質劑來提升光澤度和韌性。

由於石油化學原料產地接近性,改質劑生產成本降低,中東和非洲地區的複合年成長率達6.50%。沙烏地阿拉伯的一個計劃指定使用抗衝擊型材製作帷幕牆,以抵禦沙塵暴和強烈紫外線輻射。南非汽車組裝正在採用改質劑來減輕零件重量,同時滿足當地的碰撞安全法規。在北美,促進國內電池工廠建設的政策刺激了對改性聚醯胺屏蔽材料的需求,而聯邦基礎設施基金支持的新開工項目也推動了PVC導管的消費。在歐洲,嚴格的REACH法規加速了低VOC改質劑在地板材料和電纜管道中的應用。在南美,由AIM增強PVC製成的大直徑壓力管道正被用於多邊銀行資助的高速公路建設。同時,巴西汽車製造商正在試驗使用EPDM接枝改質劑製作引擎室管道,以適應高乙醇混合燃料。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 包裝需求不斷成長

- PVC管材和型材的需求不斷成長

- 亞太地區建築業主導樹脂需求成長

- 重點發展輕量化和安全型汽車

- 再生塑膠需要相容劑—IM混合物

- 市場限制

- 原物料價格波動(苯乙烯、丙烯酸酯樹脂)

- 更嚴格的VOC和PVC法規

- 高回收率樹脂流的處理挑戰

- 價值鏈分析

- 波特五力模型

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

第5章 市場規模及成長預測(金額)

- 按類型

- 丙烯腈丁二烯苯乙烯(ABS)

- 丙烯酸衝擊改質劑(AIM)

- 丙烯腈苯乙烯丙烯酸酯(ASA)

- 甲基丙烯酸丁二烯苯乙烯(MBS)

- 乙丙橡膠 (EPDM)

- 氯化聚乙烯(CPE)

- 其他類型

- 透過使用

- 聚氯乙烯(PVC)

- 尼龍

- 聚丁烯對苯二甲酸酯(PBT)

- 工程塑膠

- 其他用途

- 按最終用戶行業分類

- 包裝

- 建造

- 車

- 消費品

- 電氣和電子設備

- 其他終端用戶產業

- 按地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 東南亞國協

- 亞太其他地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 西班牙

- 義大利

- 俄羅斯

- 北歐國家

- 其他歐洲地區

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地區

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 其他中東和非洲地區

- 亞太地區

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率/排名分析

- 公司簡介

- Akdeniz Kimya

- Arkema

- BASF

- CLARIANT

- Dow

- Evonik Industries

- Formosa Plastics Corporation

- INEOS Styrolution Group GmbH

- Kaneka Corporation

- LANXESS

- LG Chem

- Mitsubishi Chemical Corporation

- Plastics Color Corporation

- Shandong Novista Chemicals Co.,Ltd.

- Shandong Ruifeng Chemical Cp.Ltd

- SI Group, Inc.

- SONGWON

- Sundow Polymers Co., Ltd.

- Wacker Chemie AG

第7章 市場機會與未來展望

Impact Modifier market size in 2026 is estimated at USD 4.9 billion, growing from 2025 value of USD 4.61 billion with 2031 projections showing USD 6.63 billion, growing at 6.24% CAGR over 2026-2031.

Growth rests on the material's ability to toughen polymers that enable lightweight automotive parts, resilient construction components and downgauged packaging films. Asia-Pacific's building boom anchors demand, accounting for a 47.26% volume share in 2024, while automotive applications increase at a 6.45% CAGR as vehicle makers pursue aggressive weight-reduction strategies. Acrylonitrile Butadiene Styrene (ABS) remains the largest product type with 33.48% share in 2024, but Acrylic Impact Modifiers (AIM) deliver the fastest 6.42% CAGR as outdoor applications require weatherable compounds. Polyvinyl Chloride (PVC) dominates usage with 42.67% share in 2024 on the strength of pipe and profile demand, whereas engineering plastics climb at 6.63% CAGR as automakers adopt impact-modified composites for crash-relevant parts.

Global Impact Modifier Market Trends and Insights

Growing Packaging Demand

Packaging converters deploy impact-modified compounds so thinner walls survive drop tests encountered in e-commerce distribution, meeting FDA food-contact requirements while reducing resin mass. Rigid packaging formulators add modifiers to downgrade thickness and keep structural integrity, especially in reusable containers targeted at closed-loop programs. Brand owners prioritize compatibility with recycled streams, spurring demand for hybrid modifier-compatibilizer systems that maintain clarity and toughness. Material suppliers respond by tailoring melt-flow characteristics that suit high-speed film lines. The ongoing shift toward mono-material formats intensifies the need for modifiers that balance stiffness and impact for downgauged packages.

PVC Pipe and Profile Boom

Asia-Pacific infrastructure projects favor large-diameter PVC pipes where modifiers raise resistance to installation damage and pressure cycling. Building codes in typhoon-prone regions specify impact-modified PVC window profiles to withstand wind loads and thermal stress. As cities expand underground utility grids, contractors require rugged conduits that last decades without cracking. Standards such as ASTM D1784 and ISO 4422 dictate minimum impact thresholds, pushing compounders to optimize modifier loading. GCC countries replicate these specifications, accelerating penetration into Middle Eastern water projects.

Raw-Material Price Volatility (Styrene, Acrylates)

Styrene and acrylate monomer swings compress producer margins, prompting spot-pricing and shorter contracts that unsettle converters. Supply interruptions tied to unplanned cracker outages can lift delivered costs sharply, forcing compounders to ration allocations. Buyers hedge through multi-source strategies, yet differentiation remains difficult when feedstock disruptions cascade through the chain. Some OEMs lock in tolling deals to cushion volatility but accept higher inventory risk. Volatile energy costs in Asia's feedstock centers compound unpredictability in delivered modifier prices.

Other drivers and restraints analyzed in the detailed report include:

- Construction-Led Resin Uptake in Asia-Pacific

- Automotive Lightweighting and Safety Focus

- Tightening VOC and PVC Regulations

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

ABS retained 32.92% of impact modifier market share in 2025, anchoring appliance housings and interior automotive trim. AIM, however, leads growth with a 6.36% CAGR as its superior UV durability supports exterior body panels and window profiles. The impact modifier market size attributable to AIM is projected to expand steadily as building facades demand longer service life under harsh climates. ASA serves niche fuel-contact parts needing chemical resistance, while MBS enables clear PVC packaging that combines transparency with drop-test integrity. EPDM and CPE round out the suite where flame-retardant or elastomeric performance is paramount. Across all types, recyclate compatibility becomes a decisive purchase factor as manufacturers align with circular-economy targets.

Continued AIM uptake also reflects tight automotive styling gaps that require materials to keep glossy surfaces free from stress-whitening. ABS remains indispensable in dashboard and pillar areas thanks to its balance of rigidity, heat resistance and coloring flexibility. Long-term, producers anticipate hybrid solutions blending acrylic cores with elastomeric shells to satisfy stricter crash-energy dissipation metrics. The interplay between modifier chemistry and recycled polyolefin streams is a research priority because regional mandates now require post-consumer resin thresholds in new cars and buildings.

The Impact Modifier Market Report is Segmented by Type (Acrylonitrile Butadiene Styrene, Acrylic Impact Modifiers, Acrylonitrile Styrene Acrylate, and More), Application (Polyvinyl Chloride, Nylon, Polybutylene Terephthalate, and More), End-User Industry (Packaging, Construction, Automotive, and More), and Geography (Asia-Pacific, North America, Europe, and More). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific's commanding 46.78% share in 2025 stems from China's megaproject pipeline and India's swelling auto output. Impact-modified PVC pipe systems form the backbone of new municipal water grids, and engineering plastics capture dashboard, pillar, and battery applications across regional OEM plants. Japanese automakers deploy modified PP and PC/ABS blends to cut vehicle weight without compromising side-impact scores. ASEAN manufacturers-benefiting from shifts in supply chains-expand appliance exports that rely on ABS modifiers for gloss and toughness.

The Middle East & Africa enjoys a 6.50% CAGR as petrochemical feedstock proximity lowers modifier production cost. Saudi Arabia's giga-projects specify impact-resistant profiles for curtain walls that withstand sandstorms and high UV exposure. South Africa's auto assemblers adopt modifiers to meet local crash regulations while reducing part weight. North America's policy push for domestic battery plants stimulates demand for modified polyamide shields, and construction starts supported by federal infrastructure funds lift PVC conduit consumption. Europe's stringent REACH rules spur the rollout of low-VOC modifiers in flooring and cable ducts. South America's highways, financed by multilateral banks, absorb large-diameter pressure pipes made from AIM-enhanced PVC; meanwhile Brazilian automakers trial EPDM-grafted modifiers in under-hood ducts to handle ethanol-rich fuel blends.

- Akdeniz Kimya

- Arkema

- BASF

- CLARIANT

- Dow

- Evonik Industries

- Formosa Plastics Corporation

- INEOS Styrolution Group GmbH

- Kaneka Corporation

- LANXESS

- LG Chem

- Mitsubishi Chemical Corporation

- Plastics Color Corporation

- Shandong Novista Chemicals Co.,Ltd.

- Shandong Ruifeng Chemical Cp.Ltd

- SI Group, Inc.

- SONGWON

- Sundow Polymers Co., Ltd.

- Wacker Chemie AG

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Growing packaging demand

- 4.2.2 PVC pipe and profile boom

- 4.2.3 Construction-led resin uptake in Asi-Pacific

- 4.2.4 Automotive lightweighting and safety focus

- 4.2.5 Recycled-content plastics need compatibilizer-IM hybrids

- 4.3 Market Restraints

- 4.3.1 Raw-material price volatility (styrene, acrylates)

- 4.3.2 Tightening VOC and PVC regulations

- 4.3.3 Processing issues with high-recycle resin streams

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitute Products

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts (Value )

- 5.1 By Type

- 5.1.1 Acrylonitrile Butadiene Styrene (ABS)

- 5.1.2 Acrylic Impact Modifiers (AIM)

- 5.1.3 Acrylonitrile Styrene Acrylate (ASA)

- 5.1.4 Methacrylate-Butadiene- Styrene (MBS)

- 5.1.5 Ethylene Propylene Diene Monomer (EPDM)

- 5.1.6 Chlorinated Polyethylene (CPE)

- 5.1.7 Other Types

- 5.2 By Application

- 5.2.1 Polyvinyl Chloride (PVC)

- 5.2.2 Nylon

- 5.2.3 Polybutylene Terephthalate (PBT)

- 5.2.4 Engineering Plastics

- 5.2.5 Other Applications

- 5.3 By End-user Industry

- 5.3.1 Packaging

- 5.3.2 Construction

- 5.3.3 Automotive

- 5.3.4 Consumer Goods

- 5.3.5 Electrical and Electronics

- 5.3.6 Other End-user Industries

- 5.4 By Geography

- 5.4.1 Asia-Pacific

- 5.4.1.1 China

- 5.4.1.2 India

- 5.4.1.3 Japan

- 5.4.1.4 South Korea

- 5.4.1.5 ASEAN Countries

- 5.4.1.6 Rest of Asia-Pacific

- 5.4.2 North America

- 5.4.2.1 United States

- 5.4.2.2 Canada

- 5.4.2.3 Mexico

- 5.4.3 Europe

- 5.4.3.1 Germany

- 5.4.3.2 United Kingdom

- 5.4.3.3 France

- 5.4.3.4 Spain

- 5.4.3.5 Italy

- 5.4.3.6 Russia

- 5.4.3.7 NORDIC Countries

- 5.4.3.8 Rest of Europe

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Rest of South America

- 5.4.5 Middle-East and Africa

- 5.4.5.1 Saudi Arabia

- 5.4.5.2 South Africa

- 5.4.5.3 Rest of Middle-East and Africa

- 5.4.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share**/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Akdeniz Kimya

- 6.4.2 Arkema

- 6.4.3 BASF

- 6.4.4 CLARIANT

- 6.4.5 Dow

- 6.4.6 Evonik Industries

- 6.4.7 Formosa Plastics Corporation

- 6.4.8 INEOS Styrolution Group GmbH

- 6.4.9 Kaneka Corporation

- 6.4.10 LANXESS

- 6.4.11 LG Chem

- 6.4.12 Mitsubishi Chemical Corporation

- 6.4.13 Plastics Color Corporation

- 6.4.14 Shandong Novista Chemicals Co.,Ltd.

- 6.4.15 Shandong Ruifeng Chemical Cp.Ltd

- 6.4.16 SI Group, Inc.

- 6.4.17 SONGWON

- 6.4.18 Sundow Polymers Co., Ltd.

- 6.4.19 Wacker Chemie AG

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-Need Assessment