|

市場調查報告書

商品編碼

1906121

押出成型聚苯乙烯:市佔率分析、產業趨勢與統計、成長預測(2026-2031)Extruded Polystyrene - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

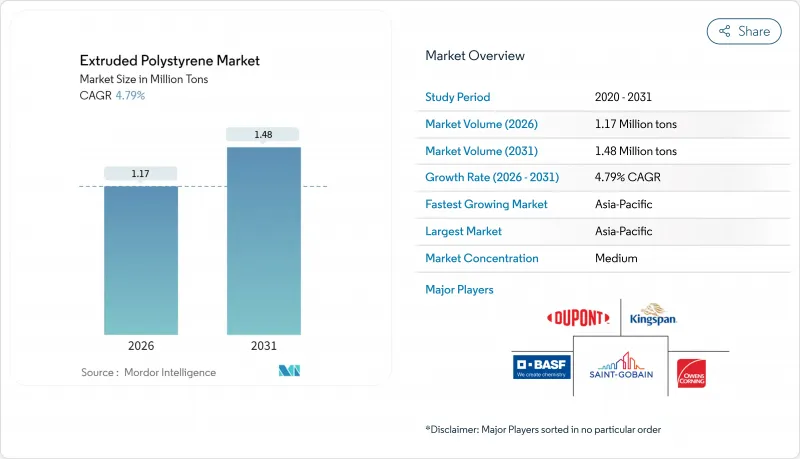

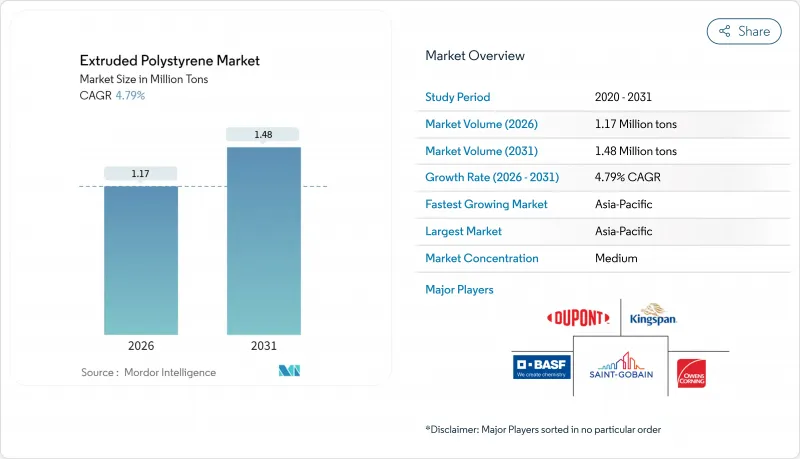

2025年押出成型聚苯乙烯市場價值為112萬噸,預計到2031年將達到148萬噸,高於2026年的117萬噸。

預計在預測期(2026-2031 年)內,複合年成長率將達到 4.79%。

這種成長主要得益於該材料的閉孔結構,與其它發泡體相比,它具有更優異的耐熱性和防潮性。銷售成長則受到全球建設活動加速、能源效率法規日益嚴格以及老舊建築維修需求不斷成長的推動。此外,該產品還具備許多優勢,例如可支撐屋頂安裝的抗壓強度和可減少長期能源損失的尺寸穩定性,這些特性也為其帶來了競爭優勢。而且,策略性地採用低全球暖化潛勢發泡有望增強長期需求的永續性,即使在氣候法規日益嚴格的背景下也是如此。

全球押出成型聚苯乙烯市場趨勢及洞察

節能建築的需求日益成長

政府和公共產業的獎勵提高了高性能(高R值)隔熱材料的投資回報率,促使建築師在牆體、屋頂和地基中更傾向於使用押出成型聚苯乙烯板。國際節能規範(IECC)對連續隔熱材料的要求推動了其在商業建築圍護結構中的應用,因為商業建築圍護結構必須最大限度地減少熱橋效應。業主將較高的初始成本與建築使用壽命期間可靠的暖氣、通風和空調(HVAC)系統所帶來的節能效益連結起來。優異的防水和抗水蒸氣擴散性能確保保溫材料即使在潮濕氣候下也能在安裝後保持其性能。 LEED v4等認證項目透過將整棟建築的能源性能與材料選擇掛鉤,支持了長期需求。隨著能源網路日益脫碳,隔熱材料仍然是一項關鍵的低成本節能措施,推動了大規模的維修。

快速的都市化和基礎設施擴張

亞太地區的城市人口每年持續成長數百萬,推動了高層住宅、大型交通樞紐和商業區的建設,這些都需要強大的圍護結構隔熱材料。中國和印度的基礎設施項目正在支撐區域消費,而東南亞的智慧城市計劃也日益吸引押出成型聚苯乙烯市場參與企業採用其設計。中產階級消費者對熱舒適性的需求促使建築規範制定者提高最低保溫性能值(R值)。印尼和菲律賓的公共住宅項目正在採用此前僅適用於豪華計劃的保溫標準。這些長期趨勢正在將押出成型聚苯乙烯市場拓展到正在經歷快速建設熱潮的區域性城市。

環保隔熱材料材料市佔率不斷擴大

基於生命週期影響的綠建築計劃正在指定使用木纖維板和再生纖維素隔熱材料。歐洲日益嚴格的塑膠廢棄物法規推動了對生物基解決方案的需求,並促使一些建築師放棄化石基泡沫材料。循環經濟政策鼓勵材料再利用,並優先選擇具有成熟可回收性的隔熱系統。這些變化目前主要集中在高階市場,但隨著生產規模的擴大,成本曲線正在改善。押出成型聚苯乙烯供應商正透過投資回收計畫和生物基發泡來提升其環保資質。

細分市場分析

預計到2025年,板材將佔押出成型聚苯乙烯市場佔有率的61.50%,這充分體現了其在屋頂、牆體和地基結構中的多功能性,在這些應用中,結構強度和可行走性至關重要。隨著建商越來越重視透過閉孔結構來提高抗壓性和防潮性,發泡聚苯乙烯板材的市場規模持續擴大。同時,受預製裝配工藝的推動,面板預計到2031年將以4.86%的複合年成長率成長,預製裝配組裝能夠簡化現場施工。

在周邊基礎和地下室防水領域,砌塊仍是一種小眾應用,因為這些領域對厚度的要求超過了傳統板材的極限。管材則用於機房和加工行業的隔熱材料,隨著低溫運輸的擴展,其應用前景也日益廣闊。目前,產品創新主要集中在邊緣輪廓設計上,以提高黏合力;同時,也致力於改進表面紋理,以增強多層屋頂系統的黏合性。

押出成型聚苯乙烯市場報告按產品類型(板材、面板、塊材、管材)、應用領域(屋頂隔熱、牆體隔熱材料、其他)、終端用戶行業(住宅、商業、基礎設施)和地區(亞太、北美、歐洲、南美、中東和非洲)進行細分。市場預測以噸為單位。

區域分析

預計到2025年,亞太地區將佔全球總量的44.20%,並在2031年之前以4.93%的複合年成長率成長,這主要得益於強勁的都市化、大規模計劃以及政府的住宅政策。中國的「一帶一路」計劃正在參與國帶動需求外溢效應,而印度的「智慧城市」計畫則納入了節能標準,提高了隔熱性能要求。

在北美,加拿大和美國的建築規範變更要求新建築必須提高屋頂和牆體的隔熱性能(R值)。公共工程部門擴大了建築外圍護結構改造的補貼計劃,從而推動了維修活動的增加。電子商務食品宅配的興起刺激了冷藏倉庫的建設,進而帶動了工業地產對冷藏產品的需求。該地區的押出成型聚苯乙烯市場正在經歷整合,這主要得益於那些能夠承受苯乙烯價格波動的垂直整合製造商。

儘管歐洲建築業成長放緩,但由於嚴格的能源性能法規和政府對大型維修計劃的資助,押出成型聚苯乙烯仍佔據相當大的市場佔有率。雖然其他隔熱材料的普及正在逐漸蠶食其市場佔有率,但由於其防水性能,擠塑聚苯乙烯在地下結構和反坡屋頂應用中仍然佔據主導地位。製造商經營符合當地回收規定的循環經濟回收計劃,這有助於其繼續成為永續性的建築商的首選材料。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 節能建築的需求日益成長

- 快速的都市化和基礎設施擴張

- 嚴格的建築規範要求隔熱材料

- 生技藥品和電商生鮮對低溫運輸倉庫的需求激增

- 異地模組化建築系統的興起

- 市場限制

- 環保隔熱材料材料市佔率不斷擴大

- 原物料(苯乙烯)價格波動

- 《基加利協議》下的氫氟碳化合物發泡法規

- 價值鏈分析

- 波特五力模型

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭對手之間的競爭

第5章 市場規模與成長預測

- 依產品類型

- 木板

- 控制板

- 堵塞

- 管段

- 透過使用

- 屋頂隔熱

- 牆體隔熱材料

- 其他(地板下、地下室、模腔、周圍區域)

- 按最終用戶行業分類

- 住宅

- 商業

- 基礎設施

- 按地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 亞太其他地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 其他歐洲地區

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地區

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 其他中東和非洲地區

- 亞太地區

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率(%)/排名分析

- 公司簡介

- Austrotherm

- BASF

- DuPont

- Emirates Extruded Polystyrene LLC

- JACKON Insulation GmbH

- Kingspan Group

- Knauf Insulation

- Owens Corning

- Polyfoam XPS

- Saint-Gobain

- Soprema Group

- Supreme Petrochem Ltd.

- Synthos

- TECHNONICOL

- URSA

第7章 市場機會與未來展望

The Extruded Polystyrene Market was valued at 1.12 million tons in 2025 and estimated to grow from 1.17 million tons in 2026 to reach 1.48 million tons by 2031, at a CAGR of 4.79% during the forecast period (2026-2031).

This growth rests on the material's closed-cell structure, which delivers superior thermal resistance and moisture tolerance compared with alternative foams. Volume gains track the acceleration of global construction activity, the hardening of energy-efficiency mandates, and mounting renovation demand in mature building stocks. Competitive advantages also stem from the product's compressive strength, which supports rooftop equipment, and from its dimensional stability, which reduces long-term energy loss. Strategic focus on low-global-warming-potential blowing agents further reinforces long-range demand resilience under tightening climate regulations.

Global Extruded Polystyrene Market Trends and Insights

Growing Demand for Energy-Efficient Buildings

Government and utility incentives amplify the payback of high-R-value insulation, steering architects toward extruded polystyrene boards for walls, roofs, and foundations. Continuous insulation requirements in the International Energy Conservation Code elevate adoption in commercial envelopes where thermal bridging must be minimized. Building owners associate the material's higher upfront cost with reliable HVAC savings over building life. Resilience to bulk water and vapor diffusion protects installed R-value in humid climates. Certification schemes such as LEED v4 link whole-building energy performance to material selection, sustaining long-term demand. As energy grids decarbonize, insulation remains a primary low-cost efficiency measure, encouraging deeper retrofit scopes.

Rapid Urbanization and Infrastructure Expansion

Asia-Pacific's urban population adds millions of residents each year, driving high-rise housing, mass-transit stations, and commercial districts that specify robust envelope insulation. China's and India's infrastructure programs anchor regional consumption, while Southeast Asian smart-city projects multiply design wins for extruded polystyrene market participants. Middle-class consumer expectations for thermal comfort encourage code writers to raise minimum R-values. Public housing schemes in Indonesia and the Philippines adopt insulation guidelines that previously applied only to premium projects. These secular forces extend the extruded polystyrene market footprint into second-tier cities that are experiencing rapid construction booms.

Eco-Friendly Insulation Substitutes Gaining Share

Wood-fiber boards and recycled cellulose insulation win specifications in green building projects that benchmark lifecycle impacts. European regulatory pressure on plastic waste bolsters demand for bio-based solutions, nudging some architects away from fossil-derived foams. Circular-economy policies promote material reuse, which favors insulation systems with demonstrated recyclability. These shifts are still concentrated in premium segments, yet cost curves are improving as production scales. Extruded polystyrene suppliers counteract by investing in take-back programs and bio-sourced blowing agents to shore up environmental credentials.

Other drivers and restraints analyzed in the detailed report include:

- Stringent Building Codes Mandating Thermal Insulation

- Cold-Chain Warehousing Boom for Biologics and E-Grocery

- Kigali-Driven HFC Blowing-Agent Restrictions

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Boards accounted for 61.50% of the extruded polystyrene market share in 2025, underscoring their versatility across roofs, walls, and foundations, where structural integrity and walkability are critical. The extruded polystyrene market size tied to boards continues to rise as builders prioritize compressive strength and closed-cell moisture resistance in exposed conditions. Panels, meanwhile, are projected to register a 4.86% CAGR to 2031, benefiting from their suitability for prefabricated assemblies that streamline onsite labor.

Blocks remain a niche for perimeter foundations and below-grade waterproofing where thickness needs exceed conventional board limits. Pipe sections serve mechanical room and process-industry insulation, capturing emerging opportunities in cold-chain expansion. Product innovation now centers on edge profiles that promote tight interlocks and on surface textures that improve adhesion in multi-layer roof systems.

The Extruded Polystyrene Report is Segmented by Product Type (Boards, Panels, Blocks, and Pipe Sections), Application (Roof Insulation, Wall Insulation, and Others), End-User Industry (Residential, Commercial, and Infrastructure), and Geography (Asia-Pacific, North America, Europe, South America, and Middle-East and Africa, ). The Market Forecasts are Provided in Terms of Volume (Tons).

Geography Analysis

Asia-Pacific held 44.20% of global volume in 2025, and the region is projected to log a 4.93% CAGR through 2031 on the back of robust urbanization, infrastructure megaprojects, and government housing programs. China's Belt and Road Initiative generates spill-over demand in participating nations, while India's Smart Cities Mission embeds energy-efficiency standards that elevate insulation specifications.

North America is buoyed with code updates in Canada and the United States mandating higher R-values for roofs and walls in new builds. Renovation activity picks up as utilities expand rebate programs targeting envelope improvements. Cold-storage construction accelerates due to strong e-grocery adoption, reinforcing product pull-through in industrial real estate. The extruded polystyrene market in this region remains consolidated around vertically integrated producers able to navigate styrene price swings.

Europe maintains a sizable base despite slower construction volume growth, supported by strict energy-performance legislation and public funding for deep-renovation projects. Adoption of alternative insulation materials exerts gradual share pressure; however, extruded polystyrene still dominates below-grade and inverted-roof applications because of its water-resistance profile. Manufacturers operate circular-economy take-back programs to align with regional recycling mandates, which helps preserve specification preference among sustainability-conscious builders.

- Austrotherm

- BASF

- DuPont

- Emirates Extruded Polystyrene L.L.C.

- JACKON Insulation GmbH

- Kingspan Group

- Knauf Insulation

- Owens Corning

- Polyfoam XPS

- Saint-Gobain

- Soprema Group

- Supreme Petrochem Ltd.

- Synthos

- TECHNONICOL

- URSA

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Growing demand for energy-efficient buildings

- 4.2.2 Rapid urbanization and infrastructure expansion

- 4.2.3 Stringent building codes mandating thermal insulation

- 4.2.4 Cold-chain warehousing boom for biologics and e-grocery

- 4.2.5 Uptake of off-site modular construction systems

- 4.3 Market Restraints

- 4.3.1 Eco-friendly insulation substitutes gaining share

- 4.3.2 Raw-material (styrene) price volatility

- 4.3.3 Kigali-driven HFC blowing-agent restrictions

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitute Products

- 4.5.5 Competitive Rivalry

5 Market Size and Growth Forecasts (Volume)

- 5.1 By Product Type

- 5.1.1 Boards

- 5.1.2 Panels

- 5.1.3 Blocks

- 5.1.4 Pipe Sections

- 5.2 By Application

- 5.2.1 Roof Insulation

- 5.2.2 Wall Insulation

- 5.2.3 Others (Floor, Basement, Cavity and Perimeter)

- 5.3 By End-user Industry

- 5.3.1 Residential

- 5.3.2 Commercial

- 5.3.3 Infrastruture

- 5.4 By Geography

- 5.4.1 Asia-Pacific

- 5.4.1.1 China

- 5.4.1.2 India

- 5.4.1.3 Japan

- 5.4.1.4 South Korea

- 5.4.1.5 Rest of Asia-Pacific

- 5.4.2 North America

- 5.4.2.1 United States

- 5.4.2.2 Canada

- 5.4.2.3 Mexico

- 5.4.3 Europe

- 5.4.3.1 Germany

- 5.4.3.2 United Kingdom

- 5.4.3.3 France

- 5.4.3.4 Italy

- 5.4.3.5 Rest of Europe

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Rest of South America

- 5.4.5 Middle-East and Africa

- 5.4.5.1 Saudi Arabia

- 5.4.5.2 South Africa

- 5.4.5.3 Rest of Middle-East and Africa

- 5.4.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share (%)/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Austrotherm

- 6.4.2 BASF

- 6.4.3 DuPont

- 6.4.4 Emirates Extruded Polystyrene L.L.C.

- 6.4.5 JACKON Insulation GmbH

- 6.4.6 Kingspan Group

- 6.4.7 Knauf Insulation

- 6.4.8 Owens Corning

- 6.4.9 Polyfoam XPS

- 6.4.10 Saint-Gobain

- 6.4.11 Soprema Group

- 6.4.12 Supreme Petrochem Ltd.

- 6.4.13 Synthos

- 6.4.14 TECHNONICOL

- 6.4.15 URSA

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-need Assessment

- 7.2 Innovations in Extruded Polystyrene Manufacturing