|

市場調查報告書

商品編碼

1906077

脫模劑:市佔率分析、產業趨勢與統計、成長預測(2026-2031)Release Agents - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

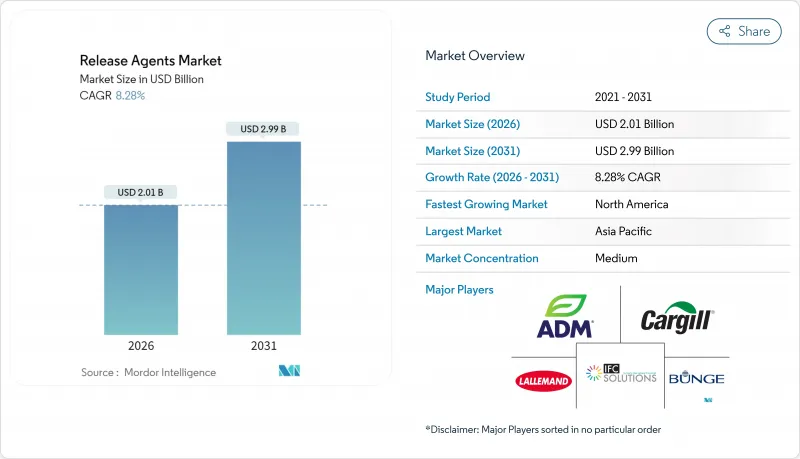

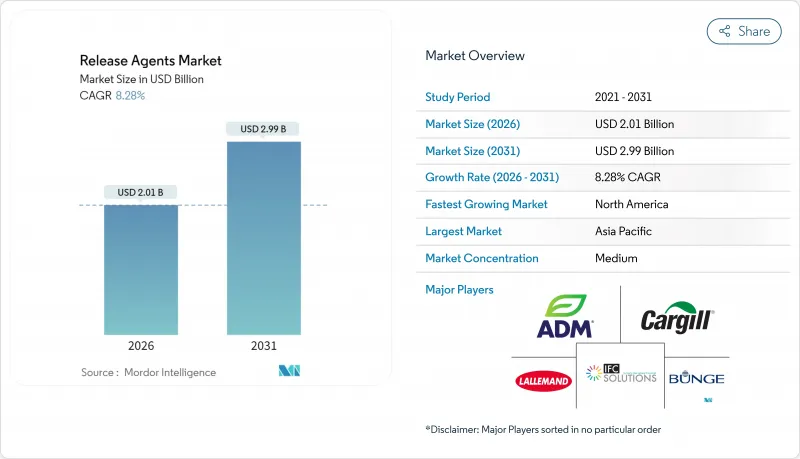

2025年,脫模劑市值為18.6億美元,預計2031年將達到29.9億美元,高於2026年的20.1億美元。

預計在預測期(2026-2031 年)內,複合年成長率將達到 8.28%。

這一成長反映了製造商在嚴格的食品接觸法規與自動化生產要求之間尋求平衡的努力。符合 NSF-H1 和歐盟 1935/2004 標準的組合藥物日益普及,以及低 VOC 水基噴塗系統的引入,凸顯了先進脫模劑在麵包房、肉類加工廠、糖果甜點生產線和冷凍甜點生產設施中的重要性。新興經濟體(尤其是亞太地區)的基礎設施投資推動了市場擴張,該地區乳製品、肉類和簡便食品業務的成長速度超過了當地在特種脫模技術方面的專業知識水平。各公司正致力於研發不含 PFAS 的配方、可生物分解的蠟酯和植物油,以在保持有效不黏性能的同時,滿足永續性目標和消費者對透明度的需求。此外,大宗商品價格波動和區域遷移測試要求正在推動供應商整合,凸顯了合規性和可靠的全球供應鏈的重要性。

全球脫模劑市場趨勢與洞察

不斷擴大的食品加工業

全球食品加工業的擴張,透過增加烘焙食品、糖果甜點、乳製品和加工肉品的產量,推動了脫模劑市場的成長。脫模劑對於在大生產過程中維持產品品質、減少廢棄物和確保生產線效率至關重要。英國麵包和烘焙食品製造業正是這一趨勢的典型代表,就公司數量而言,它是食品行業中最大的子部門。根據英國國家統計局 (ONS) 的數據,該子部門約有 2910 家公司,顯示對烘焙相關脫模劑的需求龐大。這一趨勢也正在蔓延至歐洲、北美和亞太地區,這些地區工業食品製造業的成長支撐了對脫模劑技術的需求。產業成長,加上消費者對預包裝和已調理食品需求的不斷成長,正在推動先進脫模劑配方的應用。製造商正在開發能夠滿足自動化生產系統、潔淨標示要求以及全球加工商所期望的永續性標準的解決方案。

優先選擇非氫化植物油

全球脫模劑市場正經歷轉型,非氫化植物油的日益普及是消費者健康意識增強和監管要求推動的結果。傳統上,氫化油因其穩定性和功能性而被廣泛用於脫模劑配方中。然而,研究顯示反式脂肪酸與心血管疾病、肥胖和代謝障礙等健康問題有關,這促使全球加強監管並重新設計產品。加拿大衛生署核准植物二醯甘油油取代部分氫化油(PHO),顯示監管機構對新型脂質技術的支持。這項核准可能會促使整個行業更廣泛地採用替代解決方案。目前,烘焙、糖果和加工肉品行業的食品製造商正在將非氫化油(例如芥花籽油、葵花籽油、大豆油和菜籽油)添加到其脫模劑產品中。這些替代品具有可靠的脫模性能和較長的保存期限等重要功能特性,同時符合潔淨標示的要求,避免了反式脂肪酸帶來的健康隱患。

原物料價格波動

商品價格波動對利潤率造成壓力,迫使企業在配方複雜性和成本競爭力之間尋求平衡。根據美國勞工統計局的數據,2020年至2024年間,食品加工應用領域的原料成本上漲了23.6%。這種通膨環境對特種脫模劑的影響尤其顯著,因為這類產品需要高品質的原料,而價格敏感度限制了其在成本敏感應用領域的市場滲透。供應鏈中斷加劇了價格波動的影響,為依賴特定原料等級和來源的脫模劑製造商帶來了採購挑戰。這種波動會影響直接材料成本、運輸成本和能源投入,導致利潤率面臨多重壓力,對於缺乏避險能力的中小型供應商而言,壓力尤其嚴重。期貨合約策略透過穩定價格和建立長期客戶關係提供競爭優勢,但規模較小的競爭對手在商品價格飆升期間會經歷週期性的利潤率壓縮。

細分市場分析

截至2025年,乳化劑佔了38.05%的市場佔有率,這表明它們在疏水性脫模劑和水性食品系統之間發揮著至關重要的橋樑作用。乳化劑在食品加工中的廣泛應用,特別是在單甘油酯、雙酸甘油酯、聚甘油酯和卵磷脂的配方中,確保了在各種生產條件下都能獲得穩定的效果。這些乳化劑對於維持產品穩定性、改善質地和提升加工食品的整體品質至關重要,使其成為食品產業不可或缺的一部分。此外,乳化劑對各種加工環境的適應性和對不同生產條件的耐受性進一步鞏固了其市場主導地位。

蠟和蠟酯是配方領域的熱門細分市場,預計到2031年將以高達8.84%的複合年成長率成長。這一快速成長主要得益於可生物分解配方和不含PFAS替代品的創新,這些創新兼顧了性能與環境合規性。日益成長的永續性意識和對環保解決方案的需求進一步加速了這些配方的應用。同時,受非氫化植物油監管建議的推動,植物油的需求持續旺盛。這與消費者對更健康、更天然成分日益成長的偏好不謀而合。抗氧化劑在脂質基釋放系統中發揮關鍵作用,它們能夠延長保存期限並抑制酸敗,從而確保產品在各種應用中的品質和更長的保存期限。此外,在這些系統中添加抗氧化劑不僅可以延長產品壽命,還有助於開發符合不斷變化的消費者和行業標準的高品質、穩定配方。

區域分析

北美地區預計到2025年將佔據34.10%的市場佔有率,這得益於其先進的食品加工基礎設施和嚴格的法規環境進一步推動了先進脫模劑的應用,使北美成為市場主導。同時,亞太地區也呈現成長態勢,預計2031年將以9.10%的複合年成長率成長。這一快速成長主要歸功於食品加工產業的工業化程度不斷提高以及監管標準的不斷變化,這兩方面都推動了對專用脫模劑的需求。該地區不斷壯大的中產階級以及消費者對加工食品和包裝食品日益成長的需求,也促進了對高效脫模劑解決方案的需求。

歐洲擁有龐大的市場佔有率,並受歐盟法規1935/2004的監管。該法規對食品接觸材料提出了具體要求,並影響脫模劑的選擇。歐洲對環境保護的承諾推動了可生物分解和植物來源脫模劑的廣泛應用。憑藉著完善的法規結構和對永續性的重視,歐洲已成為推動脫模劑配方持續創新的關鍵市場。此外,該地區對研發的高度重視,推動了滿足監管要求和消費者需求的先進解決方案的開發,進一步鞏固了其在全球市場的地位。

隨著食品加工工業化程度的提高,南美洲和中東及非洲地區正崛起為極具潛力的市場。然而,由於法規結構和加工基礎設施成熟度的差異,市場發展速度並不均衡。儘管這些地區食品加工用脫模劑的使用量顯著增加,但成長速度高度依賴各國的產業成熟度和監管環境。在南美,需求成長主要得益於對食品加工設施現代化和食品安全標準提升的日益重視。同樣,在中東及非洲,食品加工業投資的增加和法規結構的逐步完善也為市場擴張創造了機會。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 不斷擴大的食品加工業

- 優先選擇非氫化植物油

- 根據 NSF-H1 和歐盟 1935/2004 標準進行食品安全推廣

- 脫模劑配方的技術進步

- 經濟實惠的植物來源符合法規要求

- 用於工業烘焙中溶劑揮發性有機化合物(VOC)減少的水性噴霧技術

- 市場限制

- 原物料價格波動

- 新興肉類加工叢集終端用戶意識不足

- 嚴格的監管標準

- 過敏原和“不含”產品限制

- 供應鏈分析

- 監理與技術展望

- 五力分析

- 新進入者的威脅

- 買方/消費者的議價能力

- 供應商的議價能力

- 替代品的威脅

- 激烈的競爭

第5章 市場規模與成長預測

- 按成分

- 乳化劑

- 抗氧化劑

- 植物油

- 蠟和蠟酯

- 其他

- 按形式

- 液體

- 固體的

- 透過使用

- 烘焙和糖果甜點

- 肉類及肉品

- 乳製品和冷凍甜點

- 其他用途

- 地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 北美其他地區

- 歐洲

- 德國

- 英國

- 法國

- 俄羅斯

- 西班牙

- 其他歐洲地區

- 亞太地區

- 印度

- 中國

- 日本

- 亞太其他地區

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 中東和非洲

- 阿拉伯聯合大公國

- 南非

- 其他中東和非洲地區

- 北美洲

第6章 競爭情勢

- 最活躍的公司

- 市場定位分析

- 公司簡介

- Archer Daniels Midland(ADM)

- Cargill Inc.

- AAK AB

- Palsgaard A/S

- Dow Inc.

- IFC Solutions

- Lallemand Inc.

- Bunge Ltd.

- Masterol Foods Pty Ltd.

- Mallet & Company

- The Bakels Group

- Bundy Baking Solutions

- Avatar Corporation

- Chem-Trend(Lubrizol)

- Kerry Group plc

- PPG Silicones

- Henkel AG

- JAX Inc.

- ROCOL(ITW)

- Vegalene(R)/PLZ Corp.

第7章 市場機會與未來展望

The release agents market was valued at USD 1.86 billion in 2025 and estimated to grow from USD 2.01 billion in 2026 to reach USD 2.99 billion by 2031, at a CAGR of 8.28% during the forecast period (2026-2031).

This growth reflects manufacturers' efforts to balance strict food-contact regulations with automated production requirements. The increased use of NSF-H1 and EU 1935/2004-compliant formulations, combined with the implementation of low-VOC water-based spray systems, highlights the importance of advanced release agents in bakeries, meat processing plants, confectionery production lines, and frozen-dessert facilities. The market expansion is supported by infrastructure investments in emerging economies, particularly in Asia-Pacific region, where the growth of dairy, meat, and convenience food operations exceeds local expertise in specialized release technologies. Companies are focusing on PFAS-free formulations, biodegradable wax esters, and plant-based oils to meet sustainability goals and consumer transparency demands while maintaining effective anti-stick properties. Additionally, fluctuating commodity prices and regional migration testing requirements are driving supplier consolidation, emphasizing the importance of regulatory compliance and reliable global supply chains.

Global Release Agents Market Trends and Insights

Expanding food processing industry

The global food processing industry's expansion drives the release agents market growth through increased production of bakery, confectionery, dairy, and processed meat products. Release agents are essential for maintaining product quality, minimizing waste, and ensuring production line efficiency in high-volume processing operations. The United Kingdom's bread and bakery manufacturing sector exemplifies this trend, representing the food industry's largest subsector by number of companies. The Office for National Statistics (UK) reports approximately 2,910 enterprises operating in this subsector, demonstrating substantial bakery-related demand for release agents. This pattern extends across Europe, North America, and Asia-Pacific, where industrial food manufacturing growth sustains the demand for release technologies. The combination of industry growth and increasing consumer demand for packaged and ready-to-eat foods drives the adoption of advanced release agent formulations. Manufacturers are developing solutions that align with automated production systems, clean-label requirements, and sustainability standards required by global processors.

Preference for non-hydrogenated vegetable oils

The global release agents market is transforming due to the increasing adoption of non-hydrogenated vegetable oils, influenced by growing consumer health consciousness and regulatory requirements. While hydrogenated oils were previously common in release agent formulations due to their stability and functionality, research linking trans fats to health issues such as cardiovascular disease, obesity, and metabolic disorders has led to global regulatory restrictions and product reformulations. Health Canada's endorsement of vegetable diacylglycerol oil as an alternative to partially hydrogenated oils (PHOs) demonstrates regulatory support for new lipid technologies. This approval may increase the adoption of alternative solutions across the industry. Food manufacturers in the bakery, confectionery, and processed meat industries are now implementing non-hydrogenated oils, including canola, sunflower, soybean, and rapeseed oils, in their release agent products. These alternatives provide essential functional properties such as reliable release performance and longer shelf life while supporting clean-label initiatives without the health concerns linked to trans fats.

Raw-material price volatility

Commodity price fluctuations create margin pressure, forcing strategic decisions between formulation complexity and cost competitiveness. Food processing ingredient costs increased by 23.6% between 2020-2024, according to Bureau of Labor Statistics data. The inflationary environment significantly affects specialty release agents that require premium raw materials, as price sensitivity restricts their market penetration in cost-conscious applications. Supply chain disruptions intensify volatility effects, creating procurement challenges for release agent manufacturers who depend on specific raw material grades or sources. The volatility impacts direct material costs, transportation, and energy inputs, creating compound margin pressure that particularly affects smaller suppliers without hedging capabilities. Forward contracting strategies provide competitive advantages by enabling price stability and supporting long-term customer relationships, while smaller competitors experience periodic margin compression during commodity price spikes.

Other drivers and restraints analyzed in the detailed report include:

- Food safety push for NSF-H1 and EU 1935/2004-compliant release agents

- Technological advancements in release agent formulations

- Stringent regulatory standards

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

In 2025, emulsifiers command a 38.05% share of the market, underscoring their pivotal role in bridging the gap between hydrophobic release agents and water-based food systems. Their widespread use in food processing, particularly with formulations like mono- and diglycerides, polyglycerol esters, and lecithin, ensures consistent results across diverse manufacturing conditions. These emulsifiers are critical in maintaining product stability, improving texture, and enhancing the overall quality of processed foods, making them indispensable in the industry. Additionally, their ability to adapt to various processing environments and withstand different manufacturing conditions further solidifies their dominance in the market.

Wax and wax esters are the composition segment to watch, boasting an impressive 8.84% CAGR through 2031. This surge is largely fueled by innovations in biodegradable formulations and PFAS-free alternatives, striking a balance between environmental compliance and performance. The growing emphasis on sustainability and the need for eco-friendly solutions have further accelerated the adoption of these compositions. Meanwhile, vegetable oils enjoy sustained demand, bolstered by regulatory endorsements for non-hydrogenated options, which align with the increasing consumer preference for healthier and more natural ingredients. Antioxidants play a crucial role, enhancing shelf life and curbing rancidity in lipid-based release systems, thereby ensuring product integrity and extending usability in various applications. Furthermore, the integration of antioxidants into these systems not only improves product longevity but also supports the development of high-quality, stable formulations that meet evolving consumer and industry standards.

The Release Agents Market Report Segments the Industry by Composition (Emulsifiers, Antioxidants, Vegetable Oils, Wax and Wax Esters, Others), by Form (Liquid, Solid), by Application (Bakery and Confectionery, Meat and Meat Products, More), and Geography (North America, Europe, Asia-Pacific, South America, Middle East and Africa). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

In 2025, North America commands a 34.10% share of the market, bolstered by its sophisticated food processing infrastructure and stringent regulations that demand top-tier release agent formulations. Years of advancement in industrial food processing have equipped the region with robust supply chains and deep technical expertise, ensuring the consistent application of release agent performance standards. The region's regulatory environment, which emphasizes food safety and quality, further drives the adoption of advanced release agents, making North America a dominant player in the market. Meanwhile, the Asia-Pacific region is on a growth trajectory, boasting a 9.10% CAGR through 2031. This surge is largely due to heightened industrialization in food processing and shifting regulatory standards, both of which amplify the demand for specialized release agents. The region's expanding middle-class population and increasing consumer demand for processed and packaged foods also contribute to the growing need for efficient release agent solutions.

Europe, with its significant market presence, is guided by EU Regulation 1935/2004. This regulation delineates specific requirements for food contact materials, influencing the selection of release agents. Europe's dedication to environmental stewardship has spurred the rise of biodegradable and plant-based release agents. Coupled with a robust regulatory framework and a sustainability focus, Europe stands out as a pivotal market, driving continuous innovation in release agent formulations. Additionally, the region's strong emphasis on research and development fosters the creation of advanced solutions that align with both regulatory and consumer demands, further solidifying its position in the global market.

As food processing industrialization gains momentum, South America and the Middle East, and Africa emerge as promising markets. Yet, the pace of market development is uneven, shaped by the nuances of regulatory frameworks and the maturity of processing infrastructure. While there's a noticeable uptick in the adoption of release agents for food processing in these regions, the speed of this growth is heavily influenced by each country's industrial maturity and regulatory landscape. In South America, the growing focus on modernizing food processing facilities and improving food safety standards is driving demand. Similarly, in the Middle East and Africa, increasing investments in food processing industries and the gradual establishment of regulatory frameworks are creating opportunities for market expansion.

- Archer Daniels Midland (ADM)

- Cargill Inc.

- AAK AB

- Palsgaard A/S

- Dow Inc.

- IFC Solutions

- Lallemand Inc.

- Bunge Ltd.

- Masterol Foods Pty Ltd.

- Mallet & Company

- The Bakels Group

- Bundy Baking Solutions

- Avatar Corporation

- Chem-Trend (Lubrizol)

- Kerry Group plc

- PPG Silicones

- Henkel AG

- JAX Inc.

- ROCOL (ITW)

- Vegalene(R) / PLZ Corp.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and market definition

- 1.2 Scope of the study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Expanding food processing industry

- 4.2.2 Preference for non-hydrogenated vegetable oils

- 4.2.3 Food safety push for NSF-H1 and EU 1935/2004-compliant release agents

- 4.2.4 Technological advancements in release agent formulations

- 4.2.5 Cost-effective plant-based formulations are gaining regulatory tailwinds

- 4.2.6 Water-based spray technologies cutting solvent VOCs in industrial bakeries

- 4.3 Market Restraints

- 4.3.1 Raw-material price volatility

- 4.3.2 Low end-user awareness in emerging meat-processing clusters

- 4.3.3 Stringent Regulatory Standards

- 4.3.4 Allergen and "free-from" limitations

- 4.4 Supply-Chain Analysis

- 4.5 Regulatory and Technological Outlook

- 4.6 Porters Five Force Analysis

- 4.6.1 Threat of New Entrants

- 4.6.2 Bargaining Power of Buyers/Consumers

- 4.6.3 Bargaining Power of Suppliers

- 4.6.4 Threat of Substitute Products

- 4.6.5 Intensity of Competitive Rivalry Source

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Composition

- 5.1.1 Emulsifiers

- 5.1.2 Antioxidants

- 5.1.3 Vegetable Oils

- 5.1.4 Wax and Wax Esters

- 5.1.5 Others

- 5.2 By Form

- 5.2.1 Liquid

- 5.2.2 Solid

- 5.3 By Application

- 5.3.1 Bakery and Confectionery

- 5.3.2 Meat and Meat Products

- 5.3.3 Dairy and Frozen Desserts

- 5.3.4 Other Applications

- 5.4 Geography

- 5.4.1 North America

- 5.4.1.1 United States

- 5.4.1.2 Canada

- 5.4.1.3 Mexico

- 5.4.1.4 Rest of North America

- 5.4.2 Europe

- 5.4.2.1 Germany

- 5.4.2.2 United Kingdom

- 5.4.2.3 France

- 5.4.2.4 Russia

- 5.4.2.5 Spain

- 5.4.2.6 Rest of Europe

- 5.4.3 Asia-Pacific

- 5.4.3.1 India

- 5.4.3.2 China

- 5.4.3.3 Japan

- 5.4.3.4 Rest of Asia-Pacific

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Rest of South America

- 5.4.5 Middle East and Africa

- 5.4.5.1 United Arab Emirates

- 5.4.5.2 South Africa

- 5.4.5.3 Rest of Middle East and Africa

- 5.4.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Most Active Companies

- 6.2 Market Positioning Analysis

- 6.3 Company Profiles

- 6.3.1 Archer Daniels Midland (ADM)

- 6.3.2 Cargill Inc.

- 6.3.3 AAK AB

- 6.3.4 Palsgaard A/S

- 6.3.5 Dow Inc.

- 6.3.6 IFC Solutions

- 6.3.7 Lallemand Inc.

- 6.3.8 Bunge Ltd.

- 6.3.9 Masterol Foods Pty Ltd.

- 6.3.10 Mallet & Company

- 6.3.11 The Bakels Group

- 6.3.12 Bundy Baking Solutions

- 6.3.13 Avatar Corporation

- 6.3.14 Chem-Trend (Lubrizol)

- 6.3.15 Kerry Group plc

- 6.3.16 PPG Silicones

- 6.3.17 Henkel AG

- 6.3.18 JAX Inc.

- 6.3.19 ROCOL (ITW)

- 6.3.20 Vegalene(R) / PLZ Corp.