|

市場調查報告書

商品編碼

1905981

不織布:市場佔有率分析、產業趨勢與統計、成長預測(2026-2031)Non-woven Fabric - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

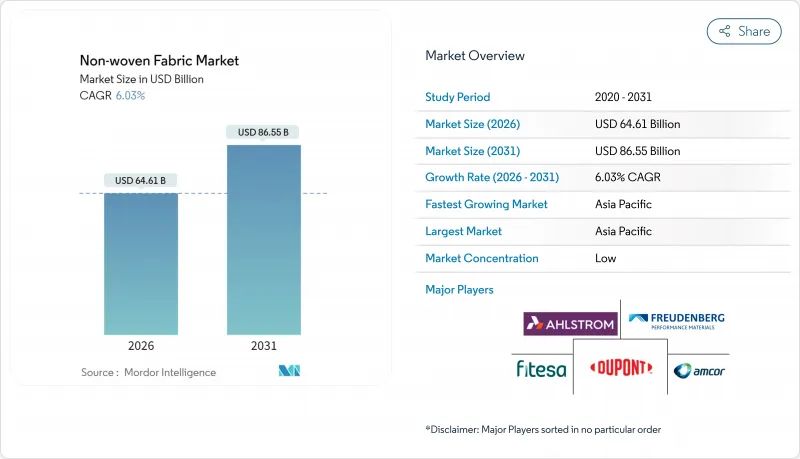

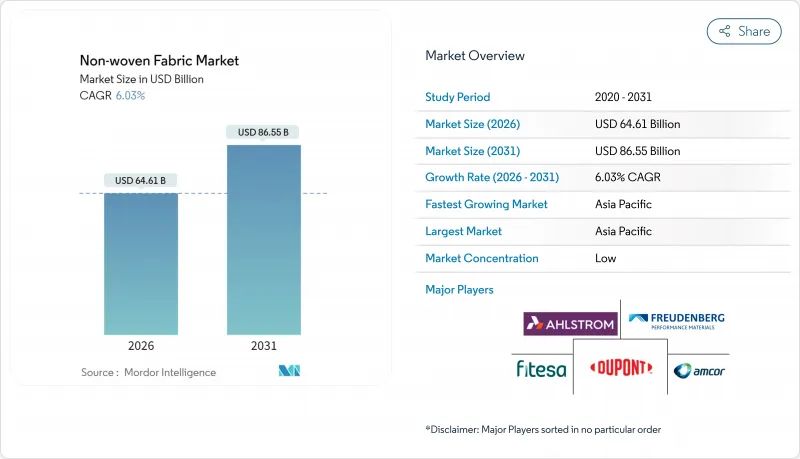

2025年,不織布市場價值為609.3億美元,預計到2031年將達到865.5億美元,而2026年為646.1億美元。

預測期(2026-2031 年)的複合年成長率預計為 6.03%。

醫療、建築和汽車行業的持續需求不斷推動紡粘生產線的投資,而靜電紡絲奈米纖維技術的進步則在創傷護理、過濾和固態電池隔膜等領域開闢了高階細分市場。儘管丙烯原料價格上漲,聚丙烯基產品仍比機織織物更具成本優勢,有助於加工商維持利潤。有關微塑膠洩漏和可回收包裝的監管趨勢正在重塑產品設計,使其朝著可生物分解或循環利用的方向發展,推動人造絲、Lyocell纖維和天然纖維混紡成為主流規格。

全球不織布市場趨勢與洞察

一次性衛生用品需求激增

亞太地區部分地區出生率的快速成長以及北美和歐洲人口老化的持續加劇,推動了輕質高吸水性不織布一次性尿布、成人失禁墊片和女性用衛生用品的銷量成長。採用可控蒸氣滲透膜和高吸水性芯材的智慧創傷護理基材正從試驗階段走向大規模生產,有助於改善傷口癒合並減少換藥次數。製造商正在採用結合紡粘層和熔噴層的結構,以最佳化液體處理性能,同時保持基材重量輕。這種結構使加工商能夠在不犧牲性能的前提下滿足價格要求。品牌所有者也傾向於使用無氯絨毛漿和生物基黏合劑,以滿足零售商的永續發展標準。預計到2020年代中期,這些趨勢將進一步推動不織布織佈在衛生用品領域的市場成長。

醫療個人防護裝備和創傷護理的快速應用

疫情期間,醫院供應鏈面臨供不應求,對具有認證阻隔性能的口罩、罩衣和手術鋪巾的庫存需求不斷成長。美國國家職業安全與健康研究所 (NIOSH) 的 2020-2030 年目標強調美國緊急生產能力,鼓勵投資於具有即時品質監控的高產量熔紡複合材料。基於聚醯亞胺和聚醚醚酮 (PEEK) 的靜電紡絲奈米纖維具有高耐熱性,適用於動力空氣淨化呼吸器和植入式醫療設備。含有銀奈米顆粒和生長因子的多功能傷口敷料在臨床前研究中顯示超過 99.99% 的細菌減少率和促進上皮化的作用。評估住院時間縮短情況的保險報銷制度改革將進一步推動對能夠降低感染風險和縮短癒合時間的高級不織布的需求。

PP和PET價格波動

煉油廠意外停產和新丙烯產能運作延遲導致供應緊張,預計2025年初南亞聚丙烯合約價格將上漲每噸10-20美元。同時,由於需繞道紅海運輸,運費附加費增加,導致交付主要加工中心的成本上升。 PET市場也呈現類似趨勢,由於價差為負,中國和歐洲生產商紛紛關閉老舊聚合物生產線。這些價格波動擠壓了與衛生用品品牌商簽訂固定價格供應合約的加工商的利潤空間,促使他們探索樹脂避險和材料替代策略。

細分市場分析

到2025年,紡粘不織布將佔不織布市場52.88%的佔有率,這反映了其高產能以及在衛生層壓材料、醫用罩衣和地工織物的卓越適用性。技術創新方面,引入了重量控制掃描器和封閉回路型空氣循環系統,以降低能耗。超柔軟面層和三層SMX複合材料也帶來了成長機遇,它們在不影響阻隔性能的前提下,顯著提升了織物般的觸感。

預計2031年,其他技術將以8.74%的複合年成長率成長,透過靜電紡絲、離心紡絲和高密度針刺平台等技術,不斷擴大其對不織布市場規模的貢獻。這些技術可生產奈米纖維網、梯度密度氈和3D蓬鬆氈。採用PAN/PS/PMMA共混物的靜電紡絲隔膜在150°C下可達到75.87%的孔隙率和低於3%的收縮率,這些特性對於高安全性電池組至關重要。熔噴製造商將駐極體充電與奈米顆粒摻雜相結合,可維持對0.3 μm氣溶膠97%以上的捕獲率,從而獲得空氣過濾和呼吸器領域的合約。

區域分析

預計到2025年,亞太地區將佔據不織布市場48.10%的佔有率,並在2031年之前以7.50%的複合年成長率成長。這主要得益於中國、印度和印尼等國加工商的擴張,以滿足日益成長的尿布和口罩需求。該地區的供應鏈將丙烯裂解裝置、纖維紡絲和最終產品組裝緊密整合,以最大限度地降低物流成本。中國正在增設專用針刺生產線,為國內電動車工廠生產隔音隔熱材料;而印度則在擴建水針工廠,以供應擦拭巾出口商。

北美正受惠於關鍵醫療防護裝備和電池防護工具等物資的恢復供應,例如金佰利公司斥資20億美元擴建位於俄亥俄州和南卡羅來納州的工廠,其中將包括一套由人工智慧驅動的物流系統。旭化成位於加拿大的薄膜工廠將於2027年開始為美國電動車生態系統供貨。勞動力短缺正在推動高度自動化紡粘生產線的應用,這為設備供應商創造了機會。

歐洲嚴格的監管政策正在推動可生物分解纖維和閉合迴路回收試點計畫的投資。弗羅伊登貝格收購海泰克斯公司,進一步鞏固了在塗層技術纖維領域的地位;蘭精公司擴大Lyocell纖維纖維產能,確保了生物基原料的長期供應。中東和非洲地區對本地生產的海岸防護和衛生用品的需求正在興起,而拉丁美洲則利用近岸外包模式,向北美衛生品牌供應價格具有競爭力的複合材料。

其他福利:

- Excel格式的市場預測(ME)表

- 分析師支持(3個月)

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 一次性衛生用品需求激增

- 醫療個人防護工具和創傷護理的快速應用

- 基礎設施建設的擴張帶動了對地工織物的需求。

- 與梭織和針織布料相比,具有成本優勢

- 固體電動車電池隔膜

- 市場限制

- PP和PET價格波動

- 微塑膠/加強掩埋法規

- 與機織物相比,其拉伸強度和撕裂強度較差。

- 價值鏈分析

- 波特五力模型

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

第5章 市場規模與成長預測

- 透過技術

- 紡粘

- 濕法成網

- 空襲

- 其他技術

- 材料

- 聚酯纖維

- 聚丙烯

- 聚乙烯

- 人造絲(粘膠纖維)

- 其他

- 按最終用戶行業分類

- 建造

- 紡織品

- 衛生保健

- 車

- 其他終端用戶產業

- 按地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 馬來西亞

- 泰國

- 印尼

- 越南

- 亞太其他地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 土耳其

- 俄羅斯

- 北歐國家

- 其他歐洲地區

- 南美洲

- 巴西

- 阿根廷

- 哥倫比亞

- 其他南美洲

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 奈及利亞

- 埃及

- 卡達

- 阿拉伯聯合大公國

- 其他中東和非洲地區

- 亞太地區

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率(%)/排名分析

- 公司簡介

- Ahlstrom

- Amcor plc

- Asahi Kasei Advance Corporation

- Autotech Nonwovens Pvt Ltd

- Avgol Industries 1953 Ltd

- Cygnus Group

- DuPont

- Eximius Innovative Pvt. Ltd.

- Fibertex Nonwovens A/S

- Fitesa SA and Affiliates

- Freudenberg Performance Materials

- Hollingsworth & Vose

- Indorama Ventures Public Company Limited

- Johns Manville

- KCWW

- Lydall, Inc.

- Magnera

- Mitsui Chemicals, Inc.

- paramountnonwoven

- PFNonwovens Holding sro

- Toray Industries Inc.

- TWE GmbH & Co. KG

第7章 市場機會與未來展望

The Non-woven Fabric Market was valued at USD 60.93 billion in 2025 and estimated to grow from USD 64.61 billion in 2026 to reach USD 86.55 billion by 2031, at a CAGR of 6.03% during the forecast period (2026-2031).

Sustained demand from healthcare, construction, and automotive applications continues to accelerate investment in spun-bond manufacturing lines, while electrospun nanofiber breakthroughs open premium niches in wound care, filtration, and solid-state battery separators. Polypropylene-based grades preserve a cost edge over woven fabrics even as propylene feedstock prices rise, helping converters defend margins. Regulatory momentum around microplastic leakage and recyclable packaging is reshaping product design toward biodegradable or circular solutions, pushing rayon, lyocell, and natural-fiber blends into mainstream specifications.

Global Non-woven Fabric Market Trends and Insights

Exploding Demand for Disposable Hygiene Products

Soaring birth rates in parts of Asia-Pacific and steadily aging populations in North America and Europe are lifting unit sales of diapers, adult incontinence pads, and feminine hygiene articles that rely on lightweight, absorbent non-wovens. Smart wound-care substrates incorporating controlled vapor transmission films and super-absorbent cores are moving from pilot to high-volume production, improving healing environments and reducing dressing changes. Producers are pairing spun-bond and melt-blown layers to optimize fluid handling while keeping basis weight low, a configuration that helps converters meet price points without sacrificing performance. Brand owners also favor chlorine-free fluff pulps and bio-based binders to align with retailer sustainability scorecards. Together, these trends reinforce the non-woven fabric market trajectory in hygiene through mid-decade.

Rapid Adoption in Medical PPE and Wound-Care

Hospital supply chains that experienced shortages during the pandemic have expanded stocking requirements for masks, gowns, and drapes with certified barrier performance. NIOSH targets for 2020-2030 emphasize domestic surge capacity, prompting investment in high-output spun-melt composites equipped with real-time quality monitoring. Electrospun nanofibers based on polyimide or PEEK deliver elevated heat resistance, allowing their use in powered air-purifying respirators and implantable devices. Multifunctional wound dressings integrating silver nanoparticles or growth factors show more than 99.99% bacterial reduction and faster epithelialization in pre-clinical trials. Reimbursement reforms that reward shorter hospital stays further support demand for advanced non-wovens that cut infection risk and healing time.

PP and PET Price Volatility

Unplanned refinery outages and delayed new propylene capacities have tightened supply, lifting polypropylene contract prices in South Asia by USD 10-20 per ton in early 2025. At the same time, freight surcharges tied to Red Sea rerouting inflate delivered costs into key converting hubs. PET markets mirror the pattern as producers in China and Europe shut older polymer lines amid negative spreads. Such swings compress margins for converters locked into fixed-price supply contracts with hygiene brand owners, prompting them to explore resin hedging or material substitution strategies.

Other drivers and restraints analyzed in the detailed report include:

- Infrastructure Boom Driving Geotextile Uptake

- Cost Advantage Over Woven and Knitted Fabrics

- Microplastic and Landfill Regulations Tightening

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

The spun-bond segment accounted for 52.88% of the non-woven fabric market in 2025, reflecting its high throughput and proven suitability for hygiene laminates, medical gowns, and geotextiles. Generational upgrades now integrate weight-control scanners and closed-loop air recirculation to curb energy use. Growth opportunities emerge in ultra-soft topsheets and 3-layer SMX-based composites that enhance cloth-like feel without sacrificing barrier integrity.

Other technologies are set to expand at an 8.74% CAGR to 2031, lifting their contribution to the non-woven fabric market size through electrospinning, centrifugal spinning, and intense needling platforms that deliver nanofiber webs, gradient density mats, and 3D lofted felts. Electrospun separators using PAN/PS/PMMA blends achieve 75.87% porosity and less than 3% shrinkage at 150 °C, features valued in high-safety battery packs. Melt-blown producers combine electret charging with nanoparticle doping to maintain more than 97% capture of 0.3 µm aerosols, securing air-filtration and respirator contracts.

The Non-Woven Fabric Market Report is Segmented by Technology (Spun-Bond, Wet Laid, Dry Laid, and Other Technologies), Material (Polyester, Polypropylene, Polyethylene, Rayon (Viscose), and Others), End-User Industry (Construction, Textiles, Healthcare, and More), and Geography (Asia-Pacific, North America, Europe, South America, and Middle-East and Africa). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific commanded 48.10% of non-woven fabric market share in 2025 and is on course for a 7.50% CAGR to 2031 as converters expand in China, India, and Indonesia to serve growing diaper and mask consumption. Regional supply chains integrate propylene crackers, fiber spinning, and end-product assembly within close proximity, minimizing logistics cost. Chinese lines add needlepunch capacity dedicated to acoustic and thermal insulation for domestic EV factories, while Indian producers scale spun-lace installations to supply wipes exporters.

North America benefits from reshoring of critical medical-PPE and battery-separator supply, supported by Kimberly-Clark's USD 2 billion expansion across Ohio and South Carolina facilities that feature AI-enabled logistics. Canada's forthcoming separator plant from Asahi Kasei will feed the U.S. EV ecosystem beginning in 2027. Tight labor markets push the adoption of high-automation spun-bond lines, creating opportunities for equipment vendors.

Europe's stringent regulations spur investment in biodegradable fibers and closed-loop recycling pilots. Freudenberg's acquisition of Heytex deepens exposure to coated technical textiles, while Lenzing's lyocell upgrades secure long-term supply of bio-based inputs. Middle East and Africa show emerging demand linked to coastal protection and sanitary product localization, whereas Latin America leverages nearshoring to supply North American hygiene brands with competitively priced composites.

- Ahlstrom

- Amcor plc

- Asahi Kasei Advance Corporation

- Autotech Nonwovens Pvt Ltd

- Avgol Industries 1953 Ltd

- Cygnus Group

- DuPont

- Eximius Innovative Pvt. Ltd.

- Fibertex Nonwovens A/S

- Fitesa SA and Affiliates

- Freudenberg Performance Materials

- Hollingsworth & Vose

- Indorama Ventures Public Company Limited

- Johns Manville

- KCWW

- Lydall, Inc.

- Magnera

- Mitsui Chemicals, Inc.

- paramountnonwoven

- PFNonwovens Holding s.r.o.

- Toray Industries Inc.

- TWE GmbH & Co. KG

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Exploding demand for disposable hygiene products

- 4.2.2 Rapid adoption in medical PPE and wound-care

- 4.2.3 Infrastructure boom driving geotextile uptake

- 4.2.4 Cost-advantage over woven and knitted fabrics

- 4.2.5 Solid-state EV battery separators

- 4.3 Market Restraints

- 4.3.1 PP and PET price volatility

- 4.3.2 Micro-plastic / landfill regulations tightening

- 4.3.3 Inferior tensile and tear strength vs woven fabric

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts (Value)

- 5.1 By Technology

- 5.1.1 Spun-bond

- 5.1.2 Wet Laid

- 5.1.3 Dry Laid

- 5.1.4 Other Technologies

- 5.2 By Material

- 5.2.1 Polyester

- 5.2.2 Polypropylene

- 5.2.3 Polyethylene

- 5.2.4 Rayon (Viscose)

- 5.2.5 Others

- 5.3 By End-user Industry

- 5.3.1 Construction

- 5.3.2 Textiles

- 5.3.3 Healthcare

- 5.3.4 Automotive

- 5.3.5 Other End-user Industries

- 5.4 By Geography

- 5.4.1 Asia-Pacific

- 5.4.1.1 China

- 5.4.1.2 India

- 5.4.1.3 Japan

- 5.4.1.4 South Korea

- 5.4.1.5 Malaysia

- 5.4.1.6 Thailand

- 5.4.1.7 Indonesia

- 5.4.1.8 Vietnam

- 5.4.1.9 Rest of Asia-Pacific

- 5.4.2 North America

- 5.4.2.1 United States

- 5.4.2.2 Canada

- 5.4.2.3 Mexico

- 5.4.3 Europe

- 5.4.3.1 Germany

- 5.4.3.2 United Kingdom

- 5.4.3.3 France

- 5.4.3.4 Italy

- 5.4.3.5 Spain

- 5.4.3.6 Turkey

- 5.4.3.7 Russia

- 5.4.3.8 Nordic Countries

- 5.4.3.9 Rest of Europe

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Colombia

- 5.4.4.4 Rest of South America

- 5.4.5 Middle-East and Africa

- 5.4.5.1 Saudi Arabia

- 5.4.5.2 South Africa

- 5.4.5.3 Nigeria

- 5.4.5.4 Egypt

- 5.4.5.5 Qatar

- 5.4.5.6 United Arab Emirates

- 5.4.5.7 Rest of Middle-East and Africa

- 5.4.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share (%)/Ranking Analysis

- 6.4 Company Profiles {(includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)}

- 6.4.1 Ahlstrom

- 6.4.2 Amcor plc

- 6.4.3 Asahi Kasei Advance Corporation

- 6.4.4 Autotech Nonwovens Pvt Ltd

- 6.4.5 Avgol Industries 1953 Ltd

- 6.4.6 Cygnus Group

- 6.4.7 DuPont

- 6.4.8 Eximius Innovative Pvt. Ltd.

- 6.4.9 Fibertex Nonwovens A/S

- 6.4.10 Fitesa SA and Affiliates

- 6.4.11 Freudenberg Performance Materials

- 6.4.12 Hollingsworth & Vose

- 6.4.13 Indorama Ventures Public Company Limited

- 6.4.14 Johns Manville

- 6.4.15 KCWW

- 6.4.16 Lydall, Inc.

- 6.4.17 Magnera

- 6.4.18 Mitsui Chemicals, Inc.

- 6.4.19 paramountnonwoven

- 6.4.20 PFNonwovens Holding s.r.o.

- 6.4.21 Toray Industries Inc.

- 6.4.22 TWE GmbH & Co. KG

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-need Assessment