|

市場調查報告書

商品編碼

1852177

複合材料:市場佔有率分析、行業趨勢、統計數據和成長預測(2025-2030 年)Composite Material - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

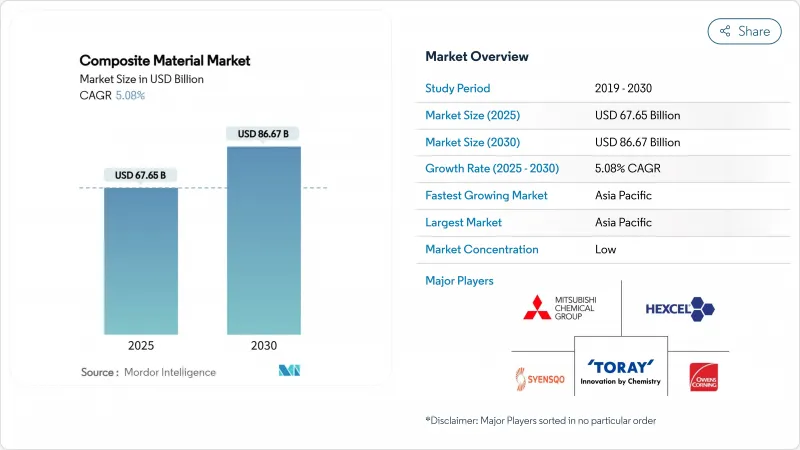

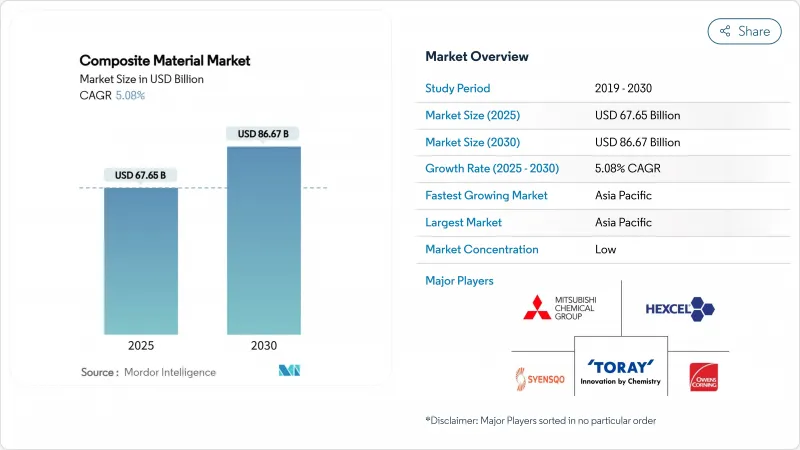

複合材料市場規模預計到 2025 年將達到 676.5 億美元,到 2030 年將達到 866.7 億美元,預測期(2025-2030 年)複合年成長率為 5.08%。

交通運輸、能源、基礎設施和電子產業對輕質高性能材料的強勁需求正在拓展其應用範圍,而持續的製程自動化則縮短了生產週期並減少了廢料。亞太地區預計在2024年將佔全球銷售額的45.12%,並將繼續保持銷售成長的中心地位,因為風力發電機的安裝、電氣化計畫和大型基礎設施計劃將推動區域消費。陶瓷基質技術的快速發展、聚合物基體材料對金屬的持續替代以及特種增強材料的供應基礎不斷完善,都增強了後進企業的競爭壁壘。然而,回收的限制仍為長期循環經濟目標蒙上陰影,如果報廢處理方案無法跟上安裝速度,則可能限制其應用。

全球複合材料市場趨勢與洞察

電動化驅動的電動車對碳纖維的需求

電動車大約使用450磅塑膠和聚合物複合材料,比內燃機汽車平台增加了18%。碳纖維增強聚合物與鋁相比,可在不犧牲熱穩定性的前提下減輕30%的重量。採用玻璃纖維增強熱塑性塑膠模製的車身面板可實現具有成本競爭力的輕量化,而內裝中使用的天然纖維層壓板則進一步提升了永續性。汽車製造商正致力於開發融合碳纖維、玻璃纖維和生物增強材料的多材料架構,以最佳化車身剛度、碰撞安全性和生命週期排放。供應鏈正在積極應對,透過在北美、歐洲和東亞地區擴大運輸能力和合格的預浸料生產線,以避免在2026-2028年車型上市期間出現瓶頸。

在風力發電機葉片製造領域的應用不斷擴展

預計2024年全球風電裝置容量將成長17%,2025年將成長35%,推動累積裝置容量在2035年達到450吉瓦的里程碑。下一代離岸風力發電的功率將超過15兆瓦,需要長度超過110公尺的葉片,而這只能透複合材料積層法來實現。到本世紀末,葉片製造將每年消耗超過100萬噸的玻璃纖維和碳纖維增強材料,這將對玻璃纖維熔煉能力和高模量碳纖維的供應造成越來越大的壓力。雖然玻璃纖維增強塑膠在單位米成本方面仍然佔據主導地位,但選擇性碳纖維翼梁帽正變得越來越受歡迎,以限制葉尖撓度和葉片根部質量。歐洲正在試用具有根部焊接功能的熱塑性葉片,這有望實現一種無需在水泥窯中進行共處理的回收途徑。該行業關於葉片循環利用的新法規已使材料可追溯性和樹脂再製造成為原始設備製造商和加工商的當務之急。

複合材料高成本

碳纖維複合材料的單件交付成本通常是鋼材的五到十倍,這阻礙了其在對成本敏感的細分市場的滲透。航太預浸料需要高壓釜固化、嚴格的環境控制和廣泛的無損檢測,這些都會推高單位成本。汽車工程也面臨類似的障礙,儘管碳纖維具有優異的重量效益比,但其應用主要限於豪華車。由於纖維紡絲生產線和前驅工廠都是資本密集的,生產規模仍然是關鍵的限制因素。像美國國家可再生能源實驗室的熱成型製程這樣的突破性技術有望將可回收碳纖維片材的成本降低90%至95%,但商業性應用需要多年的認證宣傳活動。許多潛在的採用者可能會推遲大規模替代,直到原料價格下降或設計工程師發現系統層面的顯著成本節約。

細分市場分析

高分子複合材料(PMC)預計將佔2024年市場收入的56.21%,鞏固其作為兼顧性能和可製造性的理想選擇的地位。雖然熱固性環氧樹脂在航太、船舶和風力渦輪機葉片領域仍佔據主導地位,但可回收熱塑性塑膠在汽車和消費品領域的市場佔有率正在穩步下降。目前市售熱塑性單向帶材的寬度已超過1米,有利於電池托盤和片材結構的高通量壓模成型。同時,受航太推進系統和聚光型太陽光電接收器等應用的推動,陶瓷基質材料(CMC)預計將在2025年至2030年間以8.57%的複合年成長率成長。 CMC可承受1600°C以上的高溫,可取代鎳基高溫合金,降低冷卻需求,並提供無與倫比的熱效率。雖然投資成本較高,但一旦Quiver的生產穩定下來,其生命週期提案將透過減輕重量、降低消費量和減少維護成本來抵消初始投入。金屬複合材料的市場佔有率較小,憑藉其卓越的導熱性和耐磨性,在電子基板載體和刹車盤佔優勢。積層製造和五軸數控加工技術的進步正在拓展設計範圍,預示將在本世紀後半葉逐步滲透市場。

區域分析

亞太地區引領複合材料市場,2024年營收成長率達45.12%,預計到2030年將維持7.91%的年成長率,這主要得益於中國離岸風力發電裝置容量的擴張、印度地鐵網路的擴建以及東南亞電網基礎設施的升級改造。韓國曉星集團正將年產量提升至9,000噸,以滿足航太和氫氣罐的需求。日本的價值鏈則專注於高精度絲束拉伸和預浸料技術,以服務國內飛機機身專案和出口客戶。

北美緊隨其後,這主要得益於永續航太交付、聯邦政府對可再生能源的投資以及休閒和海洋產業的復甦。美國能源局已累計2,000萬美元用於促進風力發電機複合材料的回收,顯示政策正朝著循環經濟的方向發展。加拿大各省正在資助先進材料叢集,將學術研究與開發和注塑成型試驗生產線相結合,旨在保護生物基熱塑性塑膠領域的國家智慧財產權。

歐洲先進的設計能力和嚴格的環境法規正在推動生物基樹脂和閉合迴路製程的快速普及。儘管供應鏈中斷和能源成本上漲導致2024年下半年產量下降,但歐盟仍維持全球22%的產量佔有率。維斯塔斯(Vestas)的圓形葉片和低排放氣體塔等舉措表明,歐盟氣候政策正引導原始設備製造商(OEM)將整體永續性。東歐國家憑藉其熟練的勞動力和毗鄰西方市場的地理優勢,正在吸引對拉絲廠和長絲復卷廠的投資。

南美洲和中東及非洲雖然整體規模較小,但由於基礎設施現代化和海水淡化計劃中複合材料解決方案的廣泛應用,這些地區的複合材料市場正呈現顯著成長。巴西的風能走廊、沙烏地阿拉伯的海水淡化輸水管以及南非的電動公車車身都是值得關注的需求區域。跨國公司的技術轉讓,加上本地增強材料(劍麻、黃麻)的供應,正在刺激本土創新,並逐步縮小與進口零件的成本差距。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 電動交通領域電氣化主導的碳纖維需求

- 風力發電機製造領域的應用不斷擴展

- 熱塑性複合材料在大規模生產車的應用日益廣泛

- 材料科學的技術進步

- 航太和國防工業中複合材料的使用日益增多

- 市場限制

- 複合材料高成本

- 回收的挑戰

- 自動化積層法工藝中技術純熟勞工短缺。

- 價值鏈分析

- 波特五力模型

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

第5章 市場規模與成長預測

- 透過基體材料

- 聚合物基複合材料(PMC)

- 熱固性樹脂

- 熱塑性樹脂

- 陶瓷/碳基複合材料(CMC)

- 其他基體(金屬基複合材料)

- 聚合物基複合材料(PMC)

- 透過增強纖維

- 玻璃纖維

- 碳纖維

- 醯胺纖維

- 其他纖維(天然纖維/生物纖維)

- 按最終用途行業分類

- 汽車與運輸

- 風力發電

- 航太/國防

- 管道和儲罐

- 建造

- 電氣和電子

- 運動與休閒

- 其他終端用戶產業(醫療保健、海運等)

- 按地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 泰國

- 馬來西亞

- 印尼

- 越南

- 亞太其他地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 俄羅斯

- 北歐國家

- 土耳其

- 其他歐洲地區

- 南美洲

- 巴西

- 阿根廷

- 哥倫比亞

- 其他南美洲國家

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 奈及利亞

- 卡達

- 埃及

- 阿拉伯聯合大公國

- 其他中東和非洲地區

- 亞太地區

第6章 競爭情勢

- 策略趨勢

- 市佔率(%)/排名分析

- 公司簡介

- 3M

- Arkema

- BASF

- CPIC BRASIL Fibras de Vidro Ltda

- DuPont

- Exel Composites

- Gurit Services AG

- Hexcel Corporation

- HS HYOSUNG ADVANCED MATERIALS

- Lanxess

- Mitsubishi Chemical Group Corporation.

- Nippon Graphite Fiber Co., Ltd.

- Owens Corning

- SGL Carbon

- Syensqo

- Teijin Limited

- Toray Industries Inc.

第7章 市場機會與未來展望

The Composite Material Market size is estimated at USD 67.65 billion in 2025, and is expected to reach USD 86.67 billion by 2030, at a CAGR of 5.08% during the forecast period (2025-2030).

Robust demand for lightweight, high-performance materials in transportation, energy, infrastructure and electronics is widening the application portfolio, while continuous process automation is lowering cycle times and defects. Asia-Pacific, holding 45.12% of global revenue in 2024, remains the epicenter of volume growth as wind-turbine expansion, electrification programs and large-scale infrastructure projects accelerate regional consumption. Rapid progress in ceramic matrix technologies, steady substitution of metals by polymer matrix grades and an improving supply base for specialty reinforcements are strengthening competitive barriers for late entrants. Recycling limitations, however, continue to cloud long-term circularity targets and could restrain adoption if end-of-life solutions do not keep pace with installation rates.

Global Composite Material Market Trends and Insights

Electrification-Driven Carbon-Fiber Demand in E-Mobility

Electric vehicles integrate roughly 450 lb of plastics and polymer composites-an 18% rise compared with internal-combustion platforms-because every 10% curb in curb weight typically stretches driving range by 6-8%. Battery enclosures have become a flagship application, where carbon-fiber reinforced polymers deliver a 30% mass cut versus aluminum without sacrificing thermal stability. Body panels molded from glass-fiber reinforced thermoplastics enable cost-competitive lightweighting, while natural-fiber laminates in interior trim broaden sustainability credentials. Automakers are converging on multi-material architectures that blend carbon, glass and bio reinforcements to optimise stiffness, crashworthiness and lifecycle emissions. Supply chains are responding by expanding tow capacity and qualified prepreg lines across North America, Europe and East Asia to avert bottlenecks during the 2026-2028 model-launch window.

Increasing Usage in the Manufacturing of Wind Turbine Blades

Global wind installations climbed 17% in 2024 and 35% in 2025, pushing cumulative capacity toward the 450 GW mark envisaged for 2035. Next-generation offshore machines now exceed 15 MW, requiring blades longer than 110 m that can only be realised with tailored composite lay-ups. More than 1 million t of glass and carbon reinforcements will be consumed annually for blade manufacture by the end of the decade, intensifying pressure on glass-fiber melt capacity and high-modulus carbon supply. While glass-fiber reinforced plastics continue to dominate on a cost-per-meter basis, selective carbon spar caps are proliferating to curb tip deflection and blade-root mass. Europe is piloting thermoplastic blades for weldable root joints, potentially enabling recycling routes that avoid co-processing in cement kilns. The sector's emerging blade-circularity regulations make material traceability and resin reformulation urgent priorities for OEMs and fabricators.

High Cost of Composite Materials

Carbon-fiber composites typically price at five-to-ten times steel on a delivered-part basis, deterring penetration into cost-sensitive segments. Aerospace-grade prepregs entail autoclave curing, tight environmental controls and extensive non-destructive testing, each inflating unit expense. Automotive programs confront similar hurdles, confining carbon-fiber usage largely to premium marques despite favorable weight-benefit ratios. Production scale remains a pivotal barrier, since fiber-spinning lines and precursor plants run capital-intensive. Breakthroughs such as National Renewable Energy Laboratory's thermoforming route promise 90-95% cost savings for recyclable carbon sheets, yet commercial deployment will require multi-year qualification campaigns. Until raw-material prices drop or design engineers capture superior system-level savings, many potential adopters may defer high-volume substitution.

Other drivers and restraints analyzed in the detailed report include:

- Growing Adoption of Thermoplastic Composites in Mass-Production Automotive

- Increasing Use of Composites in the Aerospace and Defense Industry

- Challenges in Recycling Composite Materials

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Polymer matrix composites (PMCs) delivered 56.21% of 2024 revenue, reinforcing the composites market as the preferred option for balanced performance and manufacturability. Thermoset epoxies remain mainstream in aerospace, marine and wind blades, yet recyclable thermoplastics are steadily eroding share in automotive and consumer goods. Commercial thermoplastic UD-tape lines now exceed 1 m wide, favouring high-throughput press forming for battery trays and seat structures. In parallel, the composites market size attributable to ceramic matrix composites is projected to post an 8.57% CAGR between 2025 and 2030, propelled by aerospace propulsion and concentrated solar-power receivers. CMCs withstand more than 1 600 °C, replacing nickel super-alloys and slashing cooling demands, thereby unlocking unrivalled thermal efficiencies. Investment outlays are significant, but once quiver production stabilises, their life-cycle value proposition offsets initial premiums through weight savings, fuel burn reductions and lower maintenance. Metal matrix composites occupy a smaller niche that thrives on extraordinary thermal conductivity and wear resistance for electronic substrate carriers and brake rotors. Additive-manufacturing pathways and five-axis CNC finishing are broadening design envelopes, hinting at incremental penetration in the latter half of the decade.

The Composites Market Report Segments the Industry by Matrix Material (Polymer Matrix Composites (PMC), Ceramic/Carbon Matrix Composites (CMCs), Other Matrices), Reinforcement Fiber (Glass Fiber, Carbon Fiber, and More), End-Use Industry (Automotive and Transportation, Wind Energy, and More), and Geography (Asia-Pacific, North America, Europe, and More). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific anchors the composites market with 45.12% revenue in 2024 and is projected to grow at 7.91% through 2030 as China escalates offshore wind installations, India expands metro rail networks and Southeast Asia upgrades grid infrastructure. The regional composites market size also benefits from escalating carbon-fiber capacity; South Korea's Hyosung is lifting annual output to 9 000 t to meet aerospace and hydrogen-tank demand. Japan's value chain focuses on high-precision tow spreading and prepreg technologies, serving both domestic air-frame programs and export customers.

North America trails closely, propelled by sustained aerospace deliveries, federal investments in renewable energy and a resurgent recreational-marine segment. The United States Department of Energy earmarked USD 20 million to advance wind-turbine composite recycling, signalling policy momentum toward circularity. Canadian provinces sponsor advanced-materials clusters that couple academic R&D with injection over-molding pilot lines, aiming to retain domestic IP around bio-based thermoplastics.

Europe commands sophisticated design capabilities and stringent environmental regulations that foster rapid adoption of bio-resins and closed-loop processes. Although supply-chain disruptions and energy-cost spikes trimmed production in late-2024, the bloc maintains a 22% share of global volumes. Initiatives such as Vestas's circular blades and low-emission towers illustrate how EU climate policy is steering OEM priorities toward holistic sustainability. Eastern European nations, leveraging skilled labor and proximity to Western markets, are courting investment in pultrusion and filament-winding plants.

South America and the Middle East & Africa, while collectively smaller, are registering outsized percentage gains as infrastructure modernization and desalination projects specify composite solutions. Brazilian wind corridors, Saudi desalination brine lines and South African electric-bus bodies are notable demand pockets. Technology transfer from multinational players, combined with local reinforcement supply (sisal, jute), is catalysing indigenous innovation and gradually narrowing cost gaps with imported parts.

- 3M

- Arkema

- BASF

- CPIC BRASIL Fibras de Vidro Ltda

- DuPont

- Exel Composites

- Gurit Services AG

- Hexcel Corporation

- HS HYOSUNG ADVANCED MATERIALS

- Lanxess

- Mitsubishi Chemical Group Corporation.

- Nippon Graphite Fiber Co., Ltd.

- Owens Corning

- SGL Carbon

- Syensqo

- Teijin Limited

- Toray Industries Inc.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Electrification-Driven Carbon-Fiber Demand in E-Mobility

- 4.2.2 Increasing Usage in the Manufacturing of Wind Turbine

- 4.2.3 Growing Adoption of Thermoplastic Composites in Mass-Production Automotive

- 4.2.4 Technological Advancement in the Field of Material Science

- 4.2.5 Increasing Use of Composites in the Aerospace and Defense Industry

- 4.3 Market Restraints

- 4.3.1 High Cost of Composite Material

- 4.3.2 Challenges in Recycling of these Materials

- 4.3.3 Skilled-Labour Gap in Automated Lay-up Processes

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts (Value)

- 5.1 By Matrix Material

- 5.1.1 Polymer Matrix Composites (PMC)

- 5.1.1.1 Thermoset Resins

- 5.1.1.2 Thermoplastic Resins

- 5.1.2 Ceramic/Carbon Matrix Composites (CMCs)

- 5.1.3 Other Matrices (Metal Matrix Composites)

- 5.1.1 Polymer Matrix Composites (PMC)

- 5.2 By Reinforcement Fiber

- 5.2.1 Glass Fiber

- 5.2.2 Carbon Fiber

- 5.2.3 Aramid Fiber

- 5.2.4 Other Fibers (Natural/Bio Fiber)

- 5.3 By End-use Industry

- 5.3.1 Automotive and Transportation

- 5.3.2 Wind Energy

- 5.3.3 Aerospace and Defense

- 5.3.4 Pipes and Tanks

- 5.3.5 Construction

- 5.3.6 Electrical and Electronics

- 5.3.7 Sports and Recreation

- 5.3.8 Other End user Industries (Healthcare, Marine, etc.)

- 5.4 By Geography

- 5.4.1 Asia-Pacific

- 5.4.1.1 China

- 5.4.1.2 India

- 5.4.1.3 Japan

- 5.4.1.4 South Korea

- 5.4.1.5 Thailand

- 5.4.1.6 Malaysia

- 5.4.1.7 Indonesia

- 5.4.1.8 Vietnam

- 5.4.1.9 Rest of Asia-Pacific

- 5.4.2 North America

- 5.4.2.1 United States

- 5.4.2.2 Canada

- 5.4.2.3 Mexico

- 5.4.3 Europe

- 5.4.3.1 Germany

- 5.4.3.2 United Kingdom

- 5.4.3.3 France

- 5.4.3.4 Italy

- 5.4.3.5 Spain

- 5.4.3.6 Russia

- 5.4.3.7 NORDIC Countries

- 5.4.3.8 Turkey

- 5.4.3.9 Rest of Europe

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Colombia

- 5.4.4.4 Rest of South America

- 5.4.5 Middle East and Africa

- 5.4.5.1 Saudi Arabia

- 5.4.5.2 South Africa

- 5.4.5.3 Nigeria

- 5.4.5.4 Qatar

- 5.4.5.5 Egypt

- 5.4.5.6 United Arab Emirates

- 5.4.5.7 Rest of Middle-East and Africa

- 5.4.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Strategic Moves

- 6.2 Market Share (%)/Ranking Analysis

- 6.3 Company Profiles {(includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, Recent Developments)}

- 6.3.1 3M

- 6.3.2 Arkema

- 6.3.3 BASF

- 6.3.4 CPIC BRASIL Fibras de Vidro Ltda

- 6.3.5 DuPont

- 6.3.6 Exel Composites

- 6.3.7 Gurit Services AG

- 6.3.8 Hexcel Corporation

- 6.3.9 HS HYOSUNG ADVANCED MATERIALS

- 6.3.10 Lanxess

- 6.3.11 Mitsubishi Chemical Group Corporation.

- 6.3.12 Nippon Graphite Fiber Co., Ltd.

- 6.3.13 Owens Corning

- 6.3.14 SGL Carbon

- 6.3.15 Syensqo

- 6.3.16 Teijin Limited

- 6.3.17 Toray Industries Inc.

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-Need Assessment