|

市場調查報告書

商品編碼

1851890

涼感布料:市場佔有率分析、產業趨勢、統計數據和成長預測(2025-2030 年)Cooling Fabrics - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

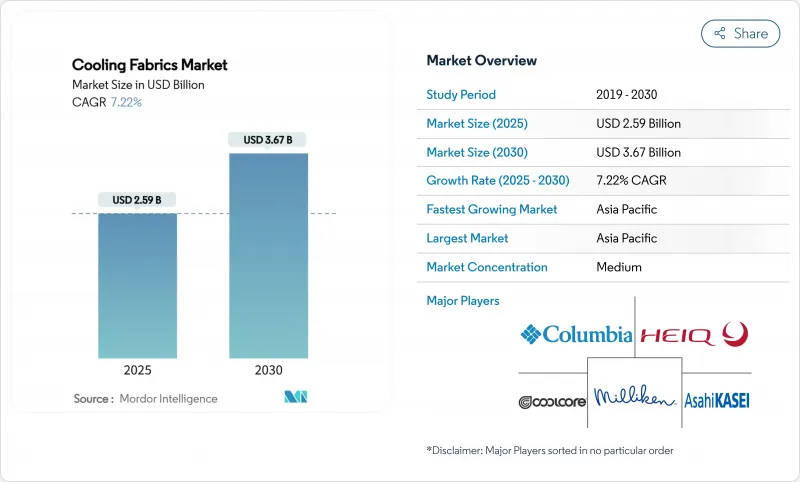

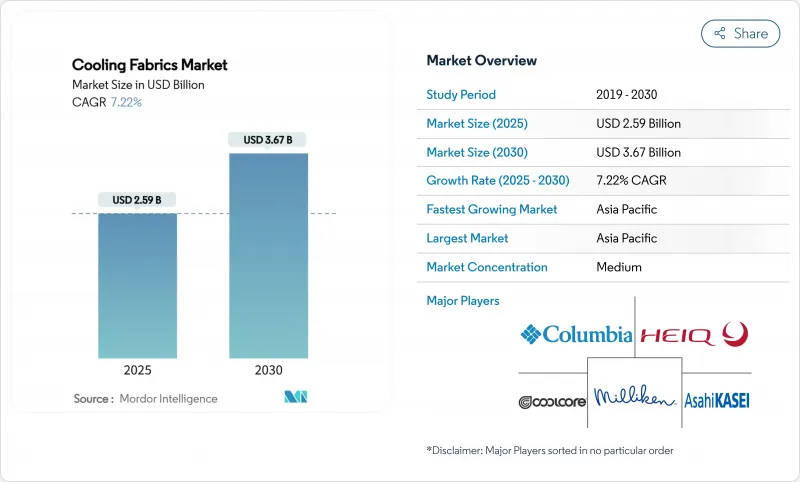

預計到 2025 年,涼感布料市場規模將達到 25.9 億美元,到 2030 年將達到 36.7 億美元,在預測期(2025-2030 年)內複合年成長率為 7.22%。

受日益加劇的城市熱島效應、運動和戶外生活方式的流行以及材料科學的快速發展等因素的推動,涼感布料市場預計將持續擴張。合成吸濕排汗纖維、被動釋放「超織物」和再生紗線的創新正在拓展產品功能,而永續性則加速了天然纖維的應用。製造商正從可進行塗層和混合整理而不影響其完整性的編織結構中獲得規模優勢,而軍方採購則刺激了高級產品在民用領域的普及。新興經濟體的價格敏感度和洗滌後性能下降仍然是不利因素,但各種應用領域的普及仍然能夠克服這些限制。

全球涼感布料市場趨勢與洞察

運動和休閒領域合成吸濕排汗和發熱纖維的快速成長

休閒休閒服和高性能運動服的基本需求。各大品牌紛紛採用 COOLMAX EcoMade、brrr° 等類似紗線,這些紗線注入了相變材料和微礦物,即使在大量出汗的情況下也能持續散熱。全球市場參與企業積極投身健身和戶外休閒,而合成纖維憑藉其可重複的吸濕排汗、彈性和機械耐久性,繼續佔據主導地位。技術紡織品的進步推動合成紗線在全球紡織品需求中佔比超過 19%,增強了規模經濟效益,從而支撐了涼感布料市場的發展。奈米混合填充材提高了導熱性,使人造合成纖維的性能超越了許多天然纖維。同時,回收聚對苯二甲酸乙二醇酯 (PET) 的使用穩定了成本,同時滿足了日益嚴格的環境設計法規要求。

戶外和運動服飾品牌的全球擴張

跨國戶外品牌正將其獨特的降溫平台從野外探險領域拓展至日常都會服飾。哥倫比亞運動服飾公司的 Omni-Heat Infinity 和 Omni- 簾子技術就是這類跨界融合的典範。降溫材料能夠承受比周邊農村地區高出 8.9°C 的城市溫度,從而擴大了潛在市場需求。品牌利用亞太地區的製造群縮短了研發週期,降低了單位成本,並將高階降溫產品帶入了主流消費者的視野。結合 3D 列印結構和空氣動力學面板的迭代式產品發布,標誌著精英運動領域的經驗正被應用於休閒服飾,進一步擴大了涼感布料市場。跨半球的技術轉移也進一步加速了全球普及的應用。

高冷卻性紡織品生產成本高

被動式發光層需要二氧化鈦奈米顆粒、聚合物薄膜和奈米銀線,因此與普通服飾相比,其材料成本更高。專用塗層生產線需要資本投入,而嚴格的品管通訊協定則增加了勞動密集度。製程最佳化已將溢價降低至近10%,但低收入地區仍面臨高昂的價格,限制了產量。供應商必須改善連續輥塗製程並拓寬原料選擇範圍,才能達到大眾市場的價格分佈。儘管目前生產規模有所縮減,但隨著國防、專業運動和工業防護裝備(PPE)等高階類別吸收成本並允許研發費用攤銷,最終這種趨勢應該會惠及價值型市場。

細分市場分析

合成紗線能夠實現均勻的吸濕排汗和大規模拉伸,預計到2024年將佔據涼感布料市場61.19%的佔有率。憑藉眾多專利降溫技術,合成紗線仍是大規模生產運動服飾的成本效益之選。隨著監管機構和消費者對生物分解性的日益重視,天然纖維的複合年成長率將達到8.15%。目前,經奈米鑽石或幾丁聚醣微孔處理的棉花可實現2-3°C的降溫效果,而閉合迴路銅氨纖維紗線則將植物來源材料與工業可回收性結合。混紡結構結合了再生纖維素和微礦物合成纖維,以平衡觸感和性能。因此,投資者正在資助軋棉廠的升級改造和酵素預處理,以提高天然纖維的質量,這預示著天然纖維將在涼感布料市場中廣泛使用。

混紡紗線的進步表明,永續性目標和性能指標並非不可兼得。 Bemberg Cupro 實現了超過 99% 的溶劑回收率,同時又不影響散熱性能,充分展現了循環利用的概念。初步試驗表明,再生棉在耐熱性方面優於原生棉。隨著時尚集團宣布基於科學的碳排放目標,採購將轉向這些低影響選項,將環保偏好轉化為可衡量的需求。未來預測顯示,天然纖維冷卻系列產品將獲得更大的市場佔有率,而合成纖維仍將是注重吸濕排汗、快乾和彈性的服裝的核心材料。

到2024年,梭織布料將佔總收入的40.66%,複合年成長率(CAGR)為8.37%。這是因為梭織布料緊密控制的織造結構為奈米顆粒塗層、反光膜和相變印刷漿料提供了尺寸穩定的基材。目前織造廠的運作能已處於高位,最大限度地降低了增加冷卻設備所需的成本。針織布料憑藉其舒適的彈性和透氣性,在運動服領域佔據了穩固的地位,但其環狀結構需要更慢的機器運轉,並且可能會使多層塗層的製備變得複雜。不織布佈在一次性醫療和過濾領域的重要性日益凸顯,在這些領域,觸感懸垂性並非首要考慮因素。

水噴織布機能夠織造更細的丹尼織物,同時也能節省能源。多相織造技術可以調整孔隙幾何形狀,並有助於水蒸氣的傳輸。同時,針織機正採用數位化控制和更精細的針距,以減少表面平整度的差異。將靜電紡絲膜層疊在針織或梭織織物上,可以形成一層超薄的輻射層,從而創造出結合了兩種結構優勢的混合層壓材料。由於成本和多功能性優勢,梭織織物預計將繼續保持在涼感布料市場的領先地位,但由於消費者對拉伸的需求不斷成長,針織織物的市場佔有率預計將保持穩定,而不是下降。

區域分析

到2024年,亞太地區將佔全球銷售額的31.30%,到2030年將以7.86%的複合年成長率成長。這主要得益於中國在技術紡織品出口方面的規模優勢以及其在被動輻射研究領域的領先地位,該技術可使服裝溫度降低攝氏5度。政府補貼支持超織物試點工廠的建設,而越南、印尼和印度的下游服裝製造商則將這些紡織品整合到具有成本競爭力的裁剪縫紉生產線中。日本的材料科學生態系統正在改進用於紫外線反射的聚合物混合物,而韓國的電子產業則致力於研發可將體溫資料傳輸到行動裝置的智慧紡織品覆層。不斷壯大的中產階級人口面臨著潮濕的夏季,也推動了零售需求的成長。

北美受益於國防合約和戶外休閒文化。美國航空系統計畫加速了供應商的學習進程,並檢驗了耐用涼感布料的有效性。總部位於奧勒岡州和科羅拉多的戶外品牌每年夏季都會推出新品系列,穩步贏得消費者的青睞。加拿大極端的溫差促成了多季節疊穿概念的興起——一面涼爽,另一面保暖——從而延長了產品的使用壽命。墨西哥作為近岸縫紉基地的角色日益凸顯,為品牌在全球物流中斷的情況下提供了更大的靈活性。

歐洲的發展軌跡與環境政策息息相關。歐盟的生態設計法規優先考慮紡織品,鼓勵價值鏈可追溯性和回收。德國的Outlast等紡織廠正在使用美國太空總署(NASA)發明的相變材料(PCM)加工技術生產獲得生態認證的襯裡,而義大利的紡紗企業則在推廣對再生紗線進行低影響染色。英國研究理事會正在資助一個專注於奈米結構發光薄膜的大學-產業聯盟。該地區不斷上漲的能源成本正在推動被動式個人降溫設備的需求,儘管其價格昂貴,但仍促進了其在國內的普及。

南美洲和中東/非洲地區蘊藏著新的商機,加上快速的都市化和強烈的太陽輻射,使得這些地區受益匪淺。巴西運動服飾市場的蓬勃發展正推動相變聚酯纖維的在地採購,而海灣國家則正在測試用於在正午45攝氏度高溫下辛勤工作的建築工人的降溫工作服。儘管基礎設施匱乏和可支配收入有限制約了短期銷售成長,但持續的氣候暖化預示著長期成長的趨勢。為了克服關稅和物流的障礙,全球供應商正在探索與當地合作夥伴建立合資企業和技術許可機制,從而使涼感布料市場實現更廣泛的地理分佈。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 運動和休閒對吸濕排汗合成布料的需求激增

- 戶外和運動服飾品牌的全球擴張

- 一種突破性的被動輻射“超織物”,用於緩解城市熱島效應

- 為沙漠作戰採購抗高溫軍服。

- 永續性要求加速了再生冷卻纖維的採用

- 市場限制

- 高冷卻纖維的生產成本高

- 反覆洗滌導致性能劣化

- 高反射率發光織物的染色局限性

- 價值鏈分析

- 波特五力模型

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

第5章 市場規模與成長預測

- 依纖維類型

- 自然的

- 合成

- 按織物結構

- 織物

- 針織

- 不織布

- 透過使用

- 運動服

- 防護衣

- 服飾

- 其他用途(醫療/保健紡織品等)

- 按最終用戶行業分類

- 消費者

- 工業和製造業

- 國防與安全

- 衛生保健

- 汽車與運輸

- 按地區

- 亞太地區

- 中國

- 日本

- 印度

- 韓國

- 東南亞國協

- 亞太其他地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 俄羅斯

- 北歐國家

- 其他歐洲地區

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 其他中東和非洲地區

- 亞太地區

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率(%)/排名分析

- 公司簡介

- Ahlstrom

- Asahi Kasei Advance Corporation

- Balavigna Mills Pvt. Ltd.

- brrr°

- Cocona Labs

- Columbia Sportswear Company

- Coolcore

- Elevate Textiles, Inc.

- Everest Textile Co., Ltd.

- FORMOSA TAFFETA CO., LTD.

- HeiQ Materials AG

- LunaMicro AB

- Milliken & Company

- NAN YA PLASTICS CORPORATION

- NILIT

- Outlast Technologies GmbH

第7章 市場機會與未來展望

The Cooling Fabrics Market size is estimated at USD 2.59 Billion in 2025, and is expected to reach USD 3.67 Billion by 2030, at a CAGR of 7.22% during the forecast period (2025-2030).

Heightened urban heat island effects, widespread athletic and outdoor lifestyles, and rapid material-science breakthroughs position the cooling fabrics market for sustained expansion. Synthetic moisture-wicking fibers, passive radiative "metafabrics," and recycled yarn innovations are widening product capabilities while sustainability mandates accelerate natural-fiber adoption. Manufacturers gain scale advantages from woven constructions that accept coatings and hybrid finishes without compromising integrity, and military procurement is stimulating premium product diffusion into civilian segments. Price sensitivity in emerging economies and performance fade after laundering remain headwinds, yet diversified application uptake continues to outweigh these constraints.

Global Cooling Fabrics Market Trends and Insights

Surge in Synthetic Moisture-wicking Fibers for Sports and Athleisure

Athleisure and performance sportswear now treat dynamic cooling as a baseline expectation. Brands integrate COOLMAX EcoMade, brrr° and comparable yarns that embed phase-change materials or micro-minerals, providing continuous heat draw-down even under heavy perspiration . Market penetration benefits from global participation in fitness and outdoor recreation, and synthetic fibers retain dominance because they deliver repeatable moisture transport, stretch and mechanical durability. Technical-textile advances lift synthetic yarns' share of global fiber demand above 19%, reinforcing scale economies that underpin the cooling fabrics market. With nanohybrid fillers improving thermal conductivity, engineered synthetics outperform many natural alternatives. In parallel, recycled Polyethylene Terephthalate (PET) streams keep cost bases stable while satisfying tightening eco-design rules.

Expansion of Outdoor and Performance Apparel Brands Globally

Multinational outdoor labels channel proprietary cooling platforms into both back-country and everyday urban lines. Columbia Sportswear's Omni-Heat Infinity and Omni-Shade technologies exemplify such crossover. Heat-mitigating fabrics combat city temperatures that can sit 8.9°C higher than surrounding rural zones, broadening addressable demand. As brands leverage Asia-Pacific manufacturing clusters, they shorten development cycles and lower per-unit costs, making premium cooling attainable for mainstream consumers. Iterative launches that combine 3D-printed structures with aerodynamic panels demonstrate a migration of elite-sport learnings to lifestyle garments, thus enlarging the cooling fabrics market. Technology transfer across hemispheres further accelerates global uptake.

High Production Cost of Advanced Cooling Textiles

Passive-radiative layers call for titanium dioxide nanoparticles, polymer membranes and silver nanowires that elevate bill-of-materials costs relative to commodity apparel. Specialized coating lines introduce capital outlays, while stringent quality-control protocols add labor intensity. Although process optimization has trimmed the premium to almost 10%, sticker shock persists in lower-income regions, slowing volume. Suppliers must refine continuous-roll deposition and broaden raw-material options to reach mass-price points. Scaling pauses notwithstanding, premium categories such as defense, professional sports and industrial Personal Protective Equipment (PPE) absorb the cost, allowing research and development (R&D) amortization that should eventually spill into value segments.

Other drivers and restraints analyzed in the detailed report include:

- Breakthrough Passive Radiative "Metafabrics" for Urban Heat Mitigation

- Military Procurement of Heat-stress Uniforms for Desert Operations

- Performance Degradation After Repeated Laundering Cycles

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Synthetic yarns retained 61.19% of cooling fabrics market share in 2024 by delivering uniform moisture transport and stretch at scale. They underpin many patented cooling chemistries that remain cost-optimal for high-volume sportswear. Natural fibers, though, are on an 8.15% CAGR path as regulators and consumers prize biodegradability. Cotton modified with nanodiamonds or chitosan micro-porosity now attains 2-3°C temperature drops, while closed-loop cupro yarns marry plant-based feedstocks with industrial recyclability. Blended constructions pair regenerated cellulose with micro-mineral synthetics, balancing feel and function. Investors therefore finance gin upgrades and enzymatic pre-treatments that elevate natural fiber quality, pointing to broader acceptance within the cooling fabrics market.

Hybrid yarn advances demonstrate that sustainability targets and performance metrics need not be mutually exclusive. Bemberg cupro showcases solvent recovery rates exceeding 99%, illustrating circularity without sacrificing heat-dissipation capacity. Recycled cotton streams also outperform virgin cotton on thermal resistance in pilot trials. As fashion groups publish science-based carbon goals, procurement pivots toward these lower-impact options, translating eco-preference into measurable demand. Over the forecast horizon, natural-fiber cooling lines will likely take incremental share, though synthetics will remain central to rapid-wicking and stretch-critical apparel tiers.

Woven fabrics supplied 40.66% of 2024 revenue and are growing at an 8.37% CAGR because their tightly-controlled interlacings provide dimensionally stable substrates for nanoparticle coatings, reflective films and phase-change print pastes. Weaving plants already operate at high throughput, minimizing incremental cost to add cooling capability. Knits retain strong footholds in activewear thanks to comfort stretch and breathability, yet their looped structure demands slower machinery and can complicate multilayer coatings. Non-wovens gain relevance in disposable medical or filtration niches where tactile drape is secondary.

Process innovation continues to lift woven productivity, with water-jet looms delivering finer deniers while conserving energy. Multi-phase weaves adjust pore geometry, aiding moisture vapor transport. At the same time, knitting equipment adopts digital control and finer gauges, narrowing the gap in surface regularity. Electrospun membranes layered onto knits or wovens add ultra-thin emissive skins, creating hybrid laminates that fuse each construction's strengths. Cost and versatility advantages suggest woven textiles will retain top billing in the cooling fabrics market, but rising consumer appetite for stretch will keep knitted shares steady rather than declining.

The Cooling Fabrics Market Report is Segmented by Fiber Type (Natural and Synthetic), Fabric Construction (Woven, Knitted, and Non-Woven), Application (Sportswear, Protective Wear, and More), End-User Industry (Consumer, Industrial and Manufacturing, Healthcare, and More), and Geography (Asia-Pacific, North America, Europe, South America, and Middle East and Africa). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific held 31.30% of global revenue in 2024 and is moving at a 7.86% CAGR through 2030, anchored by China's scale in technical-textile exports and its leadership in passive-radiative research that delivers 5°C garment cooling. Government grants support pilot plants for metafabric yardage, while downstream apparel makers in Vietnam, Indonesia, and India integrate these textiles into cost-competitive cut-and-sew lines. Japan's material-science ecosystem refines polymer blends for Ultraviolet (UV) reflection, and South Korea's electronics sector pursues smart-textile overlays that feed body-temperature data to mobile devices. Rising middle-class populations confronting humid summers amplify retail pull.

North America benefits from defense contracts and an outdoor recreation culture. US Naval Air Systems programs accelerate supplier learning curves and validate ruggedized cooling fabrics. Outdoor labels headquartered in Oregon and Colorado roll new collections each summer, driving steady consumer uptake. Canada's severe temperature swings prompt multi-season layering concepts that embed cooling on one face and insulation on the other, stretching product utility. Mexico expands role as a near-shore sewing destination, giving brands flexibility amid global logistics disruptions.

Europe's trajectory intertwines with environmental policy. The European Union (EU) Ecodesign regulation prioritizes textiles, compelling value-chain traceability and recyclate usage. German mills like Outlast adapt NASA-born Phase Change Material (PCM) treatments into eco-certified linings, while Italian spinners push low-impact dyeing of recycled yarns. The United Kingdom (UK) research councils fund university-industry consortia focused on nanostructured emissive films. Higher energy costs in the region reinforce demand for passive personal cooling, stimulating domestic uptake despite premium pricing.

South America and the Middle East & Africa present emerging opportunities tied to rapid urbanization and intense solar exposure. Brazil's athletic-wear boom spurs local sourcing of phase-change infused polyester, and Gulf states test cooling uniforms for construction crews working in 45°C midday heat. Infrastructure gaps and limited disposable income temper near-term volumes, yet sustained climate warming suggests long-run growth. Global suppliers eye joint ventures and technology-licensing to local partners to overcome tariff and logistics hurdles, ensuring the cooling fabrics market achieves broader geographic balance.

- Ahlstrom

- Asahi Kasei Advance Corporation

- Balavigna Mills Pvt. Ltd.

- brrr°

- Cocona Labs

- Columbia Sportswear Company

- Coolcore

- Elevate Textiles, Inc.

- Everest Textile Co., Ltd.

- FORMOSA TAFFETA CO., LTD.

- HeiQ Materials AG

- LunaMicro AB

- Milliken & Company

- NAN YA PLASTICS CORPORATION

- NILIT

- Outlast Technologies GmbH

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Surge in Synthetic Moisture-wicking Fibers for Sports and Athleisure

- 4.2.2 Expansion of Outdoor and Performance Apparel Brands Globally

- 4.2.3 Breakthrough Passive Radiative "Metafabrics" for Urban Heat Mitigation

- 4.2.4 Military Procurement of Heat-stress Uniforms for Desert Operations

- 4.2.5 Sustainability Mandates Accelerating Recycled Cooling Fibers Adoption

- 4.3 Market Restraints

- 4.3.1 High Production Cost of Advanced Cooling Textiles

- 4.3.2 Performance Degradation After Repeated Laundering Cycles

- 4.3.3 Dye-uptake Limitations on High-reflectance Radiative Fabrics

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts (Value)

- 5.1 By Fiber Type

- 5.1.1 Natural

- 5.1.2 Synthetic

- 5.2 By Fabric Construction

- 5.2.1 Woven

- 5.2.2 Knitted

- 5.2.3 Non-woven

- 5.3 By Application

- 5.3.1 Sportswear

- 5.3.2 Protective Wear

- 5.3.3 Apparels

- 5.3.4 Other Applications (Medical and Healthcare Textiles, etc.)

- 5.4 By End-user Industry

- 5.4.1 Consumer

- 5.4.2 Industrial and Manufacturing

- 5.4.3 Defense and Security

- 5.4.4 Healthcare

- 5.4.5 Automotive and Transportation

- 5.5 By Geography

- 5.5.1 Asia-Pacific

- 5.5.1.1 China

- 5.5.1.2 Japan

- 5.5.1.3 India

- 5.5.1.4 South Korea

- 5.5.1.5 ASEAN Countries

- 5.5.1.6 Rest of Asia-Pacific

- 5.5.2 North America

- 5.5.2.1 United States

- 5.5.2.2 Canada

- 5.5.2.3 Mexico

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Spain

- 5.5.3.6 Russia

- 5.5.3.7 NORDIC Countries

- 5.5.3.8 Rest of Europe

- 5.5.4 South America

- 5.5.4.1 Brazil

- 5.5.4.2 Argentina

- 5.5.4.3 Rest of South America

- 5.5.5 Middle East and Africa

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 South Africa

- 5.5.5.3 Rest of Middle East and Africa

- 5.5.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share(%)/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Ahlstrom

- 6.4.2 Asahi Kasei Advance Corporation

- 6.4.3 Balavigna Mills Pvt. Ltd.

- 6.4.4 brrr°

- 6.4.5 Cocona Labs

- 6.4.6 Columbia Sportswear Company

- 6.4.7 Coolcore

- 6.4.8 Elevate Textiles, Inc.

- 6.4.9 Everest Textile Co., Ltd.

- 6.4.10 FORMOSA TAFFETA CO., LTD.

- 6.4.11 HeiQ Materials AG

- 6.4.12 LunaMicro AB

- 6.4.13 Milliken & Company

- 6.4.14 NAN YA PLASTICS CORPORATION

- 6.4.15 NILIT

- 6.4.16 Outlast Technologies GmbH

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-need Assessment

- 7.2 Cooling Fabric with Chalk-based Coating