|

市場調查報告書

商品編碼

1851843

伺服馬達和驅動器:市場佔有率分析、行業趨勢、統計數據和成長預測(2025-2030 年)Servo Motors And Drives - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

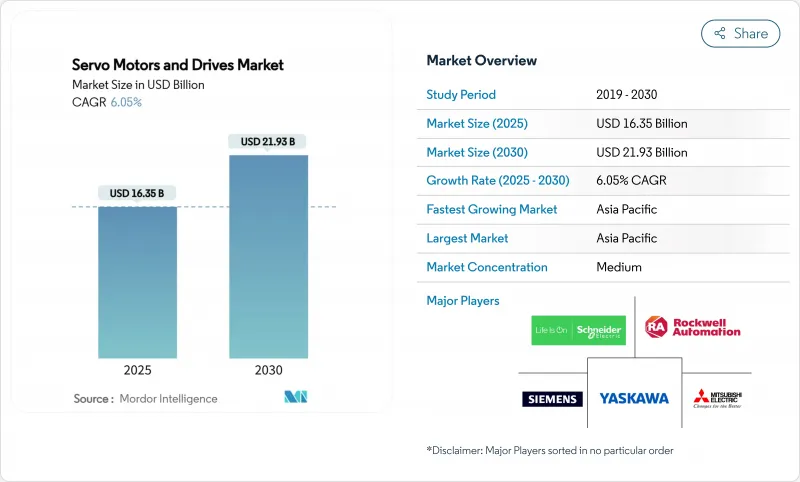

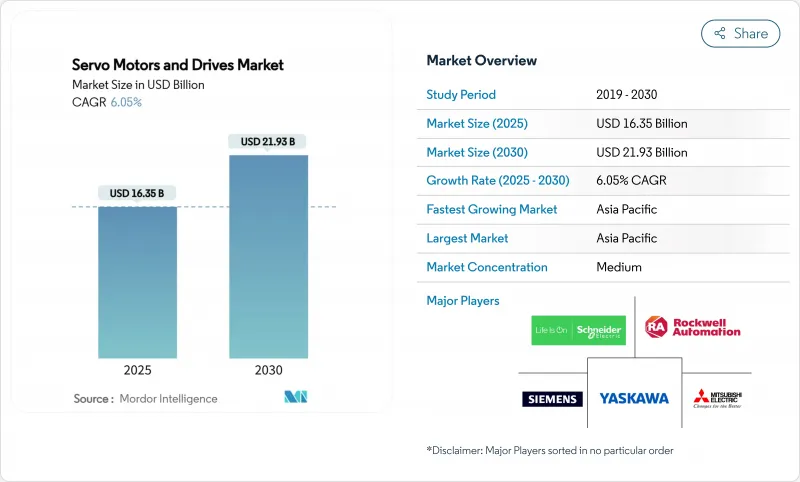

預計到 2025 年伺服馬達和驅動器市場規模將達到 163.5 億美元,到 2030 年將達到 219.3 億美元,在此期間的複合年成長率為 6.05%。

工廠升級到網路化運動系統,結合碳化矽功率電子裝置、數位雙胞胎模擬和協作機器人,推動了產業成長。半導體工廠和精密封裝生產線採用線性設計,消除了機械平移;汽車製造商投資於中壓高功率解決方案,用於電池和電力驅動橋的組裝。能源效率法規促使製造商用IE4級伺服封裝取代感應單元,而800V電動車架構的擴展則刺激了對高壓驅動器的需求。來自碳化矽專家和網路安全供應商日益激烈的競爭迫使傳統企業將機械技術與數位智慧結合。

全球伺服馬達和驅動器市場趨勢及洞察

工業自動化快速發展與智慧工廠的興起

2024年,一家德國汽車集團將其多軸機器人單元連接到數位雙胞胎平台,從而縮短了生產線切換時間並提高了生產效率。 Closure Systems International部署了FANUC伺服驅動生產線,將非計劃性停機時間降低至2.5%,並將整體資產效率提升至97.5%。支援EtherCAT的驅動器可在微秒同步運動,支援彈性製造,並為基於5G的機器協同鋪平了道路。

協作機器人和移動機器人的應用日益普及

協作機器人需要結構緊湊、安全可靠且內建扭力感測功能的致動器。安川馬達的C系列致動器符合ISO/TS 15066:2016力限制標準,並內建監控功能,可實現組裝上的人機直接互動。科爾摩根的高扭矩密度馬達為全球約一百萬個機器人關節提供動力,這表明伺服馬達和驅動器市場正朝著更輕、更容易使用的平台方向發展。

與感應/步進馬達替代方案相比,初始成本較高

印度和東南亞的小型製造商正在比較高階伺服組件和變頻驅動感應馬達組件,通常會選擇後者。然而,《包裝世界》的一項研究發現,伺服在整個生命週期內節能省錢方面更具優勢,用電動致動器取代氣動致動器後,每年的營業成本可從7,320美元降至388.8美元。

細分市場分析

到2024年,交流伺服馬達將佔據伺服馬達和驅動器市場65.5%的佔有率,這主要得益於三相電網和成熟的生產線有利於旋轉式設計。線性伺服馬達將以9.8%的複合年成長率成長,並在半導體封裝、微影術和高速裝盒等領域佔優勢。德爾科的裝盒生產線透過取消旋轉式到線性式的轉換,實現了更高的生產效率。

線性模型的功能遠不止於簡單的定位。 Tolomatic伺服壓力機的效率比液壓壓力機高出80%,而液壓壓力機的效率僅為液壓壓力機的50%,因此吸引了那些需要衛生、無油運動的包裝公司。平台供應商也積極回應,推出了分散式驅動系統,例如羅克韋爾自動化公司的ArmorKinetix,該系統可將佈線量減少90%,安裝時間縮短30%。

低壓裝置佔市場佔有率的62.4%,但隨著工廠採用更高電壓架構以減小電纜尺寸和降低發熱量,1-35kV等級的市場佔有率每年成長7.2%。艾睿電子轉向碳化矽MOSFET,此元件可在高開關頻率下以低損耗運作。中壓驅動器為電動汽車馬達外殼中使用的100kW以上工具機提供支持,以滿足日益成長的扭矩需求。

西門子推出了超低電壓驅動單元 MICRO-DRIVE,專為需要 24-48V 安全電壓的自主移動機器人而設計。同時,800V 電動車產品線則採用中壓伺服,以縮小導線直徑並降低電阻損耗,從而在伺服電機和驅動器市場中佔據一席之地,並不斷擴大市場佔有率。

伺服馬達和驅動器市場報告按產品類型(馬達、驅動器)、電壓範圍(低壓≤1kV、中壓1kV-35kV、高壓>35kV)、功率用戶行業(汽車和電動汽車製造、石油和天然氣、醫療保健和醫療設備、包裝和標籤、其他)、功率等級(<1kW、終端機製造、石油和天然氣、醫療保健和醫療器材、包裝和標籤、其他)、功率等級(<1kW、終端1kW-5kW1kW-1kW。

區域分析

預計到2024年,亞太地區將佔據全球銷售額的46.3%,這主要得益於中國電子產品生產、日本的技術領先地位以及印度工廠的擴張。該地區保持最快的區域成長速度,年複合成長率達7.8%,這主要得益於東南亞國協鼓勵自動化以提升競爭力。中國在稀土供應方面的優勢降低了當地成本,但國際買家卻面臨出口限制的威脅。日本諧波驅動系統公司計劃透過加強在東京和長野的技術叢集,在2026會計年度實現900億日圓的淨銷售額。

在北美,為了提高供應鏈的韌性,製造業回流計畫增加。三菱電機在肯塔基州投資1.435億美元興建壓縮機工廠,反映了在地化生產和縮短前置作業時間的趨勢。日立收購Joliet Electric Motors公司,擴大了售後服務範圍,並提升了整個已安裝設備的生命週期價值。協作機器人在美國的應用有所成長,抵銷了重工業的疲軟。

歐洲重點關注脫碳數位雙胞胎分析。 IE4強制標準推動了德國和北歐地區的維修,網路安全問題促使CISA在ABB Drive Composer和Rockwell PowerFlex韌體中發現漏洞後展開審核。中壓驅動器在巴伐利亞和Piemonte的汽車產業叢集中得到廣泛應用,原始設備製造商(OEM)轉向800V電池生產線,儘管面臨宏觀經濟壓力,仍保持了中等個位數的成長。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 工業自動化和智慧工廠的快速部署

- 協作機器人和移動機器人的應用日益普及

- 嚴格的全球和區域能源效率要求

- 促進汽車製造和電動車平台的電氣化

- 碳化矽功率模組可提高伺服驅動效率

- 基於數位雙胞胎的伺服系統預測性尺寸設計和最佳化

- 市場限制

- 與感應/步進馬達替代方案相比,初始成本較高

- 低成本步進馬達和變頻器控制的感應馬達的廣泛應用

- 高純度稀土元素永磁體的供應鏈風險

- 網路伺服驅動器中的網路漏洞會導致停機

- 關鍵法規結構評估

- 價值鏈分析

- 技術展望

- 波特五力模型

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭對手之間的競爭

- 關鍵相關人員影響評估

- 主要用例和案例研究

- 宏觀經濟因素對市場的影響

- 投資分析

第5章 市場區隔

- 依產品類型

- 引擎

- 交流伺服電機

- 直流無刷伺服電機

- 有刷直流伺服電機

- 直線伺服電機

- 駕駛

- 交流伺服驅動器

- 直流伺服驅動器

- 可調/多軸伺服驅動器

- 引擎

- 按電壓範圍

- 低電壓(1千伏特或以下)

- 中壓(1千伏-35千伏)

- 高壓(35千伏以上)

- 按最終用戶行業分類

- 汽車/電動車製造

- 石油和天然氣(上游、中游、下游)

- 醫療保健和醫療設備

- 包裝和標籤

- 半導體和電子學

- 化工/石油化工

- 飲食

- 其他行業(紡織、印刷等)

- 按額定輸出

- 1 kW

- 1 kW-5 kW

- 5 kW-15 kW

- 超過15千瓦

- 按地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲國家

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 俄羅斯

- 其他歐洲地區

- 亞太地區

- 中國

- 日本

- 韓國

- 印度

- ASEAN

- 亞太其他地區

- 中東和非洲

- 中東

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 土耳其

- 其他中東地區

- 非洲

- 南非

- 奈及利亞

- 其他非洲地區

- 北美洲

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率分析

- 公司簡介

- Yaskawa Electric Corporation

- Mitsubishi Electric Corporation

- Siemens AG

- Schneider Electric SE

- Rockwell Automation, Inc.

- ABB Ltd.

- Delta Electronics, Inc.

- FANUC Corporation

- Kollmorgen Corporation(Regal Rexnord Corporation)

- Bosch Rexroth AG

- Panasonic Holdings Corporation

- Nidec Corporation

- Omron Corporation

- Oriental Motor Co., Ltd.

- Lenze SE

- Parker-Hannifin Corporation

- Inovance Technology Co., Ltd.

- Moog Inc.

- WEG Equipamentos El-tricos SA

- Emerson Electric Co.

- AMETEK, Inc.

- TECO Electric & Machinery Co., Ltd.

- Nanotec Electronic GmbH & Co. KG

- SANYO DENKI Co., Ltd.

- Fuji Electric Co., Ltd.

第7章 市場機會與未來展望

The servo motors and drives market size stood at USD 16.35 billion in 2025 and was forecast to reach USD 21.93 billion by 2030, reflecting a 6.05% CAGR over the period.

Growth stemmed from factories upgrading to networked motion systems that combine silicon-carbide power electronics, digital twin simulation and collaborative robotics. Semiconductor plants and precision packaging lines adopted linear designs to eliminate mechanical conversions, while automotive producers invested in mid-voltage, high-power solutions for battery and e-axle assembly. Energy-efficiency legislation prompted manufacturers to replace induction units with IE4-class servo packages, and the expanding 800 V electric-vehicle architecture spurred demand for higher-voltage drives. Intensifying competition arrived from silicon-carbide specialists and cybersecurity vendors, pressuring traditional incumbents to blend mechanical expertise with digital intelligence.

Global Servo Motors And Drives Market Trends and Insights

Rapid industrial automation and smart-factory rollout

During 2024, automotive groups in Germany connected multi-axis robotic cells to digital-twin platforms, cutting line-change times and increasing throughput. Closure Systems International lifted overall equipment effectiveness to 97.5% after installing FANUC servo-driven lines that dropped unplanned downtime to 2.5%. EtherCAT-enabled drives synchronised motion within microseconds, supporting flexible manufacturing and paving the way for 5G-based machine coordination.

Rising adoption of collaborative and mobile robotics

Cobots require compact, safety-rated actuators with integrated torque sensing. Yaskawa's HC series met ISO/TS 15066:2016 force limits through embedded monitoring, allowing direct human interaction on assembly lines. High-torque-density motors supplied by Kollmorgen powered almost 1 million robotic joints worldwide, demonstrating the servo motors and drives market's shift toward lighter, user-friendly platforms.

High upfront cost vs. induction/stepper alternatives

Small manufacturers in India and Southeast Asia compared premium servo packages with variable-frequency-drive induction sets and frequently chose the latter. Yet studies by Packaging World showed lifetime energy and maintenance savings tilting favour back toward servos, with annual operating cost dropping from USD 7,320 to USD 388.8 when pneumatics were replaced by electric actuators.

Other drivers and restraints analyzed in the detailed report include:

- Stringent global and regional energy-efficiency mandates

- Electrification push in automotive manufacturing and EV platforms

- Supply-chain risk for high-grade rare-earth permanent magnets

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

AC units kept 65.5% of the servo motors and drives market in 2024 because three-phase grids and mature manufacturing lines favoured rotary designs. Linear variants captured semiconductor packaging, lithography and high-speed cartooning, expanding at 9.8% CAGR. Delkor's cartoning lines achieved higher throughputs by eliminating rotary-to-linear conversions.

Linear models extended beyond simple positioning. Tolomatic servo presses delivered 80% efficiency versus 50% for hydraulics, attracting packaging firms that needed hygienic, oil-free motion. Platform suppliers responded with distributed drives such as Rockwell Automation's ArmorKinetix, cutting cabling 90% and installation time 30%.

Low-voltage installations held 62.4% share but the 1-35 kV class grew 7.2% annually as plants adopted higher-voltage architectures to reduce cable size and heat. Arrow Electronics highlighted silicon-carbide MOSFETs running at higher switching frequencies with lower losses. Medium-voltage drives supported 100 kW-plus machine tools used for EV motor housings, matching growing torque demands.

Siemens introduced MICRO-DRIVE extra-low-voltage units for autonomous mobile robots that need safe 24-48 V levels. Conversely, 800 V EV lines deployed mid-voltage servos to shrink conductor diameters and lower resistive loss, holding a niche but rising share in the servo motors and drives market.

The Servo Motors and Drives Market Report is Segmented by Product Type (Motor, and Drive), Voltage Range (Low Voltage <=1kV, Medium Voltage 1kV-35kV, and High Voltage >35kV), End-User Industry (Automotive and EV Manufacturing, Oil and Gas, Healthcare and Medical Devices, Packaging and Labelling, and More), Power Rating (<=1kW, 1kW-5kW, 5kW-15kW, and >15kW), and Geography.

Geography Analysis

Asia-Pacific captured 46.3% of global revenue in 2024 on the back of Chinese electronics production, Japanese technology leadership and India's factory expansions. Regional growth remained the fastest at 7.8% CAGR as ASEAN nations incentivised automation to raise competitiveness. China's dominance in rare-earth supply lowered local costs but exposed foreign buyers to export controls. Japan's Harmonic Drive Systems aimed for JPY 90 billion net sales by FY 2026, reinforcing the technology cluster in Tokyo and Nagano.

North America increased its reshoring programmes to improve supply resilience. Mitsubishi Electric's USD 143.5 million compressor plant in Kentucky illustrated the trend toward localised production and shorter lead times. Hitachi's purchase of Joliet Electric Motors broadened aftermarket services, supporting lifecycle value across installed fleets. Rising collaborative-robot utilisation in the United States offset softness in heavy industry.

Europe focused on decarbonisation and digital-twin analytics. IE4 mandates spurred retrofits in Germany and the Nordics, while cybersecurity concerns prompted audits after CISA flagged vulnerabilities in ABB Drive Composer and Rockwell PowerFlex firmware. Medium-voltage drives penetrated automotive clusters in Bavaria and Piedmont as OEMs migrated to 800 V battery lines, sustaining mid-single-digit growth despite macroeconomic pressures.

- Yaskawa Electric Corporation

- Mitsubishi Electric Corporation

- Siemens AG

- Schneider Electric SE

- Rockwell Automation, Inc.

- ABB Ltd.

- Delta Electronics, Inc.

- FANUC Corporation

- Kollmorgen Corporation (Regal Rexnord Corporation)

- Bosch Rexroth AG

- Panasonic Holdings Corporation

- Nidec Corporation

- Omron Corporation

- Oriental Motor Co., Ltd.

- Lenze SE

- Parker-Hannifin Corporation

- Inovance Technology Co., Ltd.

- Moog Inc.

- WEG Equipamentos El-tricos S.A.

- Emerson Electric Co.

- AMETEK, Inc.

- TECO Electric & Machinery Co., Ltd.

- Nanotec Electronic GmbH & Co. KG

- SANYO DENKI Co., Ltd.

- Fuji Electric Co., Ltd.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Rapid industrial automation and smart-factory rollout

- 4.2.2 Rising adoption of collaborative and mobile robotics

- 4.2.3 Stringent global and regional energy-efficiency mandates

- 4.2.4 Electrification push in automotive manufacturing and EV platforms

- 4.2.5 Silicon-carbide power modules boosting servo-drive efficiency

- 4.2.6 Digital-twin-enabled predictive sizing and optimisation of servo systems

- 4.3 Market Restraints

- 4.3.1 High upfront cost vs. induction/stepper alternatives

- 4.3.2 Proliferation of low-cost stepper and VFD-controlled induction motors

- 4.3.3 Supply-chain risk for high-grade rare-earth permanent magnets

- 4.3.4 Cyber-vulnerabilities in networked servo drives causing downtime

- 4.4 Evaluation of Critical Regulatory Framework

- 4.5 Value Chain Analysis

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Threat of New Entrants

- 4.7.4 Threat of Substitutes

- 4.7.5 Competitive Rivalry

- 4.8 Impact Assessment of Key Stakeholders

- 4.9 Key Use Cases and Case Studies

- 4.10 Impact on Macroeconomic Factors of the Market

- 4.11 Investment Analysis

5 MARKET SEGMENTATION

- 5.1 By Product Type

- 5.1.1 Motor

- 5.1.1.1 AC Servo Motor

- 5.1.1.2 DC Brushless Servo Motor

- 5.1.1.3 Brushed DC Servo Motor

- 5.1.1.4 Linear Servo Motor

- 5.1.2 Drive

- 5.1.2.1 AC Servo Drive

- 5.1.2.2 DC Servo Drive

- 5.1.2.3 Adjustable / Multi-axis Servo Drive

- 5.1.1 Motor

- 5.2 By Voltage Range

- 5.2.1 Low Voltage (<=1 kV)

- 5.2.2 Medium Voltage (1 kV-35 kV)

- 5.2.3 High Voltage (>35 kV)

- 5.3 By End-user Industry

- 5.3.1 Automotive and EV Manufacturing

- 5.3.2 Oil and Gas (Up-, Mid-, Down-stream)

- 5.3.3 Healthcare and Medical Devices

- 5.3.4 Packaging and Labelling

- 5.3.5 Semiconductor and Electronics

- 5.3.6 Chemicals and Petrochemicals

- 5.3.7 Food and Beverage

- 5.3.8 Other Industries (Textile, Printing, etc.)

- 5.4 By Power Rating

- 5.4.1 ?1 kW

- 5.4.2 1 kW-5 kW

- 5.4.3 5 kW-15 kW

- 5.4.4 >15 kW

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 South America

- 5.5.2.1 Brazil

- 5.5.2.2 Argentina

- 5.5.2.3 Rest of South America

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Russia

- 5.5.3.6 Rest of Europe

- 5.5.4 Asia-Pacific

- 5.5.4.1 China

- 5.5.4.2 Japan

- 5.5.4.3 South Korea

- 5.5.4.4 India

- 5.5.4.5 ASEAN

- 5.5.4.6 Rest of Asia-Pacific

- 5.5.5 Middle East and Africa

- 5.5.5.1 Middle East

- 5.5.5.1.1 Saudi Arabia

- 5.5.5.1.2 United Arab Emirates

- 5.5.5.1.3 Turkey

- 5.5.5.1.4 Rest of Middle East

- 5.5.5.2 Africa

- 5.5.5.2.1 South Africa

- 5.5.5.2.2 Nigeria

- 5.5.5.2.3 Rest of Africa

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles {(includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)}

- 6.4.1 Yaskawa Electric Corporation

- 6.4.2 Mitsubishi Electric Corporation

- 6.4.3 Siemens AG

- 6.4.4 Schneider Electric SE

- 6.4.5 Rockwell Automation, Inc.

- 6.4.6 ABB Ltd.

- 6.4.7 Delta Electronics, Inc.

- 6.4.8 FANUC Corporation

- 6.4.9 Kollmorgen Corporation (Regal Rexnord Corporation)

- 6.4.10 Bosch Rexroth AG

- 6.4.11 Panasonic Holdings Corporation

- 6.4.12 Nidec Corporation

- 6.4.13 Omron Corporation

- 6.4.14 Oriental Motor Co., Ltd.

- 6.4.15 Lenze SE

- 6.4.16 Parker-Hannifin Corporation

- 6.4.17 Inovance Technology Co., Ltd.

- 6.4.18 Moog Inc.

- 6.4.19 WEG Equipamentos El-tricos S.A.

- 6.4.20 Emerson Electric Co.

- 6.4.21 AMETEK, Inc.

- 6.4.22 TECO Electric & Machinery Co., Ltd.

- 6.4.23 Nanotec Electronic GmbH & Co. KG

- 6.4.24 SANYO DENKI Co., Ltd.

- 6.4.25 Fuji Electric Co., Ltd.

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-Need Assessment