|

市場調查報告書

商品編碼

1851834

機械安全:市場佔有率分析、行業趨勢、統計數據和成長預測(2025-2030 年)Machine Safety - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

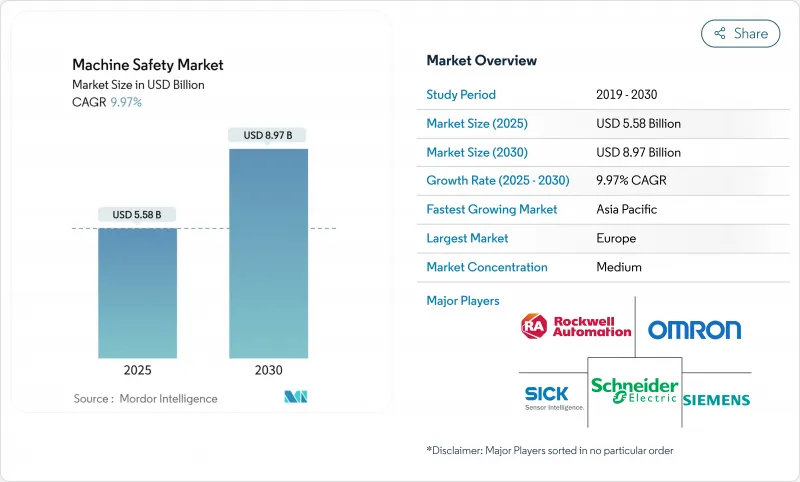

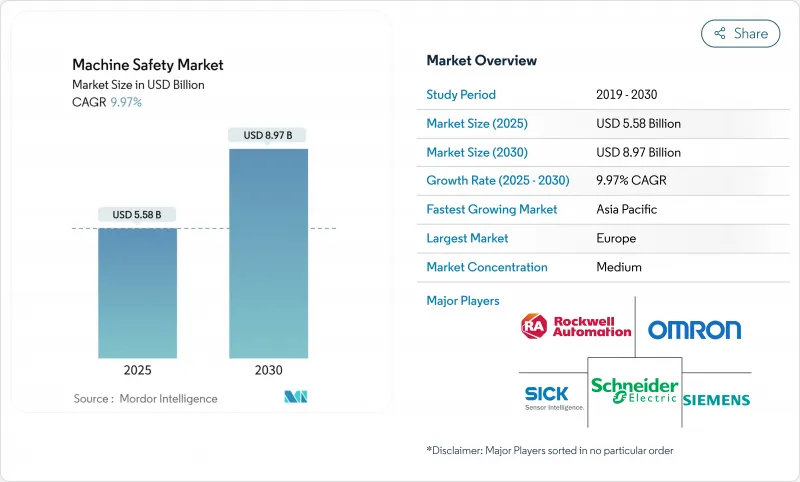

預計到 2025 年,機械安全市場規模將達到 55.8 億美元,到 2030 年將達到 89.7 億美元,年複合成長率為 9.97%。

日益成長的監管壓力、快速發展的工業自動化以及功能安全與網路安全的整合是推動這一成長的核心動力。歐洲即將實施的《機械法規2023/1230》正促使全球製造商採用性能等級e(Performance Level e)功能,並加強安全系統以抵禦數位威脅(ec.europa.eu)。同時,北美食品飲料製造商正在進行數位化維修,將工業4.0資料流與安全合規性結合(automate.org)。隨著終端用戶從硬線繼電器轉向軟體定義安全邏輯,能夠提供整合安全PLC、預測性維護分析和經認證的網路安全架構的供應商正在贏得市場佔有率。

全球機械安全市場趨勢與洞察

協作機器人在東亞電子組裝線的應用加速

中國、韓國和台灣的電子產品製造商正在用協作機器人取代孤立的工業機器人,這些機器人可以與操作人員共用工作空間。動態感應光柵和3D視覺防護區域僅在人員處於危險之中時才會停止協作機器人,從而將生產線整體生產率提高18%,並將可記錄事故減少27%。嵌入機器人控制器的AI安全邏輯能夠實現速度與距離監控,而非強制停止,進而進一步縮短生產週期。因此,為電子代工製造商提供認證安全掃描器、安全扭矩切斷驅動器和軟體可配置PLC的元件供應商的訂單量顯著成長。隨著電子組裝競相填補區域勞動力短缺並保持出口競爭力,預計未來三年協作機器人的應用浪潮將達到頂峰。

歐盟機械法規 2023/1230 要求自 2027 年起,新設備必須具備性能等級為 e 的安全特性。

該法規將於2027年1月20日生效,對關鍵功能引入了具有法律約束力的PL-e要求,並包含明確的網路安全條款,將駭客攻擊導致的故障歸類為安全隱患。因此,向歐盟供貨的機械製造商必須檢驗其安全相關的控制部件能夠承受隨機硬體故障和蓄意攻擊。這種雙重合規要求推動了對整合式安全控制器和經認證的安全遠端更新機制的需求。由於該法規無需各國自行轉換即可直接生效,供應商可以將單一架構擴展到所有27個成員國,從而簡化其產品開發流程。德國和義大利的原始設備製造商(OEM)為了避免最後時刻的重新設計,已經明顯感受到了包括風險評估、軟體修補程式管理和數位雙胞胎模擬在內的準備成本。

棕地遺留控制架構和安全網路的高度整合複雜性

許多 1980 年代的分散式控制系統使用專有總線,這些總線缺乏安全流量的確定性頻寬。這迫使整合商依賴通訊協定閘道器和影子控制器,導致計劃成本增加高達 65%,並延長試運行週期。連續流程工廠不願承受這種停機時間,因此傾向於採取最低限度的合規性措施,減緩了網路安全技術的普及。儘管供應商正在發布「即插即用」的遷移式橋接器和基於模擬的檢驗工具,但傳統硬體與現代功能安全標準之間的結構性不匹配問題可能會持續存在,直到控制系統進行重大改造。

細分市場分析

由於分立元件與棕地設備具有即插即用的兼容性,預計到2024年,它們仍將主導機械安全市場,市場佔有率將達到65%。然而,隨著PLC、驅動器和HMI等設備整合安全韌體,嵌入式元件預計將以11.8%的複合年成長率超越分立元件,從而減少控制櫃空間和佈線。汽車白車身設計就反映了這一趨勢。如今,單一控制器即可同時承載標準運動曲線和PL-e互鎖邏輯,無需重複配置處理器。在電子組裝,基於微控制器的安全協處理器能夠實現低於10毫秒的回應時間,滿足高速取放設備在機械安全市場的規模要求。如果供應商能夠使其組合控制晶片同時通過IEC 61508和ISO 26262認證,則有望贏得OEM設計訂單,因為它們的成本已接近分立繼電器。

在改裝領域,獨立式光柵和聯鎖裝置仍然很受歡迎,因為安裝人員可以在周末停機期間更換硬體,而無需重新檢驗基礎PLC代碼。然而,即使在改造領域,具有雙通道安全輸入的「切片式」I/O模組也越來越受歡迎,它允許機櫃在單一背板上同時容納標準線路和安全線路。一旦安全CPU獲得認證,即可在現場下載軟體更改,而無需重新連接實體繼電器,從而加快投資回報,尤其適用於季節性包裝作業。

到2024年,存在感應式安全感測器將佔總收入的30%,幾乎為所有安全系統提供支持,從彎折壓床到堆垛機,無所不包。光學和雷達感測器整合了靜音邏輯,能夠區分負載和人員,從而最大限度地減少輸送系統中的誤停。安全PLC是成長最快的細分市場,年複合成長率達12.5%,因為軟性製造需要可程式區域和快速邏輯重配置。從硬連線觸點到參數化功能塊的轉變,可將電氣圖減少高達60%,並支援數位雙胞胎在實施前檢驗變更。

最新的安全PLC還整合了安全啟動韌體和加密通訊,滿足歐盟機械法規對網路安全和功能安全的雙重要求。隨著OEM廠商向整合控制面板的遷移,安全PLC的機械安全市場規模進一步擴大。在整合控制面板中,單一CPU即可執行符合IEC 61131標準的各項任務以及SIL-3等級的診斷功能。組件供應商正在捆綁提供經過認證的安全扭力切割、安全限速和安全位置庫,從而縮短了機械製造商的應用開發時間。

區域分析

歐洲預計到2024年將佔據31%的市場佔有率,凸顯了其作為監管引領者和自動化先驅的地位。德國的汽車、化學和工具機製造商正在將連網安全系統整合到幾乎所有新生產線中,其中68%的設備已將診斷資料傳輸到中央控制面板。義大利的包裝OEM廠商正在向北美和南美出口符合PL-e標準的灌裝劑,進一步增強了歐洲的技術外溢效應。英國正在效仿歐盟標準以保障出口准入,而法國的航太工廠正在引入協作機器人防護裝置,以實現人機在機翼組裝單元中的協同工作。

亞太地區是一個至關重要的成長區域,預計複合年成長率將達到11.6%。中國的電子組裝正競相滿足國內GB安全標準和出口所需的CE認證,促使他們對光柵和安全運動驅動器的需求激增。日本機器人製造商正在其機械手臂中整合雙通道扭力感測器,以實現ISO 13849合規性,並提高人機共用工作站的接受度。在印度,跨國製藥和汽車製造商正在新建待開發區安裝3類和4類系統,以提高當地安全意識並鼓勵供應商在地化。韓國晶片製造廠正在為超高純度化學品生產線採購SIL等級的閥組,這些閥組將功能安全性與低顆粒物結構相結合,以保護人員和晶圓的安全。

北美仍是技術領先者,但成長更為穩定。美國加工商正在升級安全措施以降低責任和保險成本,42%的食品加工廠計劃在2025年進行重大現代化改造。加拿大採礦業正在礦用卡車通道採用無線SIL-3緊急停機網路。拉丁美洲的普及程度不一。巴西汽車產業叢集正在適應歐盟和美國客戶的需求,但小型工廠的投資相對落後。中東和非洲地區在高風險能源領域發展最為迅速,正在煉油廠和LNG接收站部署整合式火災和氣體防護以及緊急停機系統。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 協作機器人在東亞電子組裝線的應用加速

- 歐盟機械法規 2023/1230 將要求自 2027 年起,新設備必須具備 e 級安全性能。

- 北美某食品飲料廠快速棕地數位化改造項目,引進安全I/O連結感測器

- 中東地區液化天然氣大型企劃的快速成長增加了對SIL-3級緊急停車系統的需求。

- 超過 OSHA TRIR基準值的工廠工傷保險費上漲,將促使美國小型企業尋求第四類安全解決方案。

- 歐洲包裝生產線從硬線繼電器轉向軟體可配置安全PLC,實現了靈活包裝。

- 市場限制

- 棕地安全網路與傳統控制架構的高度整合複雜性

- 受電動車需求波動影響,二級汽車供應商凍結資本預算

- 新興市場缺乏符合IEC 61508/62061標準的、具備功能安全軟體程式設計技能的人才。

- 東南亞中小企業對四類安全系統過度設計與投資報酬率不確定性的認知

- 價值/供應鏈分析

- 監理展望

- 技術展望

- 波特五力分析

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 競爭對手之間的競爭

- 替代品的威脅

- 投資分析

第5章 市場規模與成長預測

- 透過實施

- 各個部件

- 內建零件

- 改裝安全升級

- 按組件

- 存在檢測安全感測器

- 安全光柵

- 安全雷射掃描儀

- 緊急停止裝置

- 安全聯鎖切換

- 安全控制器/模組/繼電器

- 安全PLC

- 雙手控制和啟用開關

- 其他零件(墊子、邊緣、緩衝墊)

- 透過使用

- 物料輸送

- 機器人技術與協作機器人

- 包裝和托盤堆垛

- 切割、成型、加工

- 組裝和拾取放置

- 按最終用途行業分類

- 車

- 飲食

- 電子和半導體

- 石油和天然氣

- 醫藥和醫療保健

- 化學

- 金屬和採礦

- 航太/國防

- 包裝產業

- 其他行業

- 按地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 英國

- 德國

- 法國

- 義大利

- 其他歐洲地區

- 亞太地區

- 中國

- 日本

- 印度

- 韓國

- 亞太其他地區

- 中東

- 以色列

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 土耳其

- 其他中東地區

- 非洲

- 南非

- 埃及

- 其他非洲地區

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 北美洲

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率分析

- 公司簡介

- Rockwell Automation, Inc.

- Siemens AG

- Schneider Electric SE

- Omron Corporation

- Sick AG

- Pilz GmbH and Co. KG

- Mitsubishi Electric Corporation

- ABB Ltd.

- Honeywell International Inc.

- Keyence Corporation

- IDEC Corporation

- Banner Engineering Corp.

- Phoenix Contact GmbH and Co. KG

- Datalogic SpA

- Bihl+Wiedemann GmbH

- Euchner GmbH+Co. KG

- Leuze electronic GmbH+Co. KG

- Wenglor sensoric GmbH

- Rockford Systems LLC

- Fortress Safety

第7章 市場機會與未來展望

The machine safety market size at USD 5.58 billion in 2025 and is forecast to climb to USD 8.97 billion by 2030, advancing at a 9.97% CAGR.

Heightened regulatory pressure, rapid industrial automation and the growing convergence of functional-safety with cybersecurity are the core forces behind this growth. Europe's upcoming Machinery Regulation 2023/1230 is compelling manufacturers worldwide to embed Performance Level e functions and to harden safety systems against digital threats ec.europa.eu. Asia-Pacific's expanding electronics and automotive bases are accelerating demand for adaptive safeguarding, while North American food and beverage processors are pursuing digital retrofits that combine Industry 4.0 data flows with safety compliance automate.org. Vendors that can offer integrated safety PLCs, predictive-maintenance analytics and certified cyber-secure architectures are capturing share as end-users transition from hard-wired relays to software-defined safety logic.

Global Machine Safety Market Trends and Insights

Accelerated Adoption of Collaborative Robots in Electronics Assembly Lines across East Asia

Electronics producers in China, South Korea and Taiwan are replacing isolated industrial robots with collaborative units that share workspaces with operators. Dynamic presence-sensing light curtains and 3D vision guard zones now stop cobots only when a person is at risk, lifting overall line productivity by 18% while cutting recordable incidents by 27%. AI-powered safety logic embedded in the robot controller enables speed-and-separation monitoring rather than hard stops, which further shortens cycle times. Component vendors supplying certified safety scanners, safe torque off drives and software-configurable PLCs are therefore experiencing outsized order growth from contract electronics manufacturers. The wave of cobot deployment is expected to peak over the next three years as electronics assemblers race to offset regional labor shortages and maintain export competitiveness.

EU Machinery Regulation 2023/1230 Mandating Performance Level e Safety Functions in New Equipment from 2027

The regulation, entering force on 20 January 2027, introduces legally binding PL-e requirements for critical functions and embeds explicit cybersecurity clauses that classify hacking-induced malfunction as a safety hazard. Machine builders supplying the EU must therefore validate that safety-related control parts withstand both random hardware faults and intentional attacks. This dual compliance need is fueling demand for integrated safety-security controllers and certified secure remote-update mechanisms. Because the rule applies directly without national transposition, suppliers can scale one architecture across all 27 member states, streamlining product-development pipelines. Preparatory spending on risk assessments, software patch management and digital-twin simulation is already evident among German and Italian OEMs looking to avoid last-minute redesigns.

High Integration Complexity of Safety Networks with Legacy Control Architecture in Brownfield Sites

Many 1980s-era distributed-control systems use proprietary buses lacking deterministic bandwidth for safety traffic. Integrators therefore resort to protocol gateways and shadow controllers, inflating project costs by up to 65% and extending commissioning windows. Continuous-process plants resist such downtime, opting for minimum-compliance fixes that slow the adoption of networked safety. Although vendors are releasing "plug-in" migration bridges and simulation-based validation tools, the structural mismatch between legacy hardware and modern functional-safety standards will persist until large-scale control-system overhauls occur.

Other drivers and restraints analyzed in the detailed report include:

- Rapid Brownfield Digital Retrofit Programs in North-American Food & Beverage Plants Incorporating Safety I/O-Link Sensors

- Surge in LNG Megaprojects in the Middle East Elevating Demand for SIL-3 Rated Emergency Shutdown Systems

- Capital Budget Freezes in Automotive Tier-2 Suppliers Amid EV Demand Volatility

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Individual components continued to dominate in 2024 with a 65% machine safety market share due to their plug-and-play compatibility with brownfield equipment. However, embedded components are forecast to outpace at an 11.8% CAGR as PLCs, drives and HMIs ship with integrated safety firmware, trimming cabinet space and wiring. Automotive body-in-white lines illustrate the trend: a single controller now hosts both standard motion profiles and PL-e interlock logic, eliminating duplicate processors. In electronics assembly, microcontroller-based safety co-processors handle reaction times below 10 ms, satisfying the machine safety market size requirement for high-speed pick-and-place equipment. Suppliers that certify combo-control chips under both IEC 61508 and ISO 26262 are positioned to capture OEM design wins as cost parity with discrete relays approaches.

The retrofit arena still favors discrete light curtains and interlocks because installers can swap hardware during weekend shutdowns without revalidating the base PLC code. Yet even here, "slice" I/O modules with dual-channel safety inputs are edging in, allowing cabinets to host standard and safety wiring on one backplane. Regulatory harmonization across Europe and the Americas is also tilting investment toward embedded solutions; once a safety CPU is certified, software changes can be field-downloaded rather than rewiring physical relays, delivering faster ROI especially in seasonal packaging operations.

Presence-sensing safety sensors accounted for 30% of revenue in 2024, underpinning virtually every safeguarding scheme from press brakes to palletizers. Optical and radar variants now incorporate muting logic that differentiates payload from personnel, minimizing nuisance stops in conveyor systems. Safety PLCs represent the fastest-growing sub-segment at 12.5% CAGR because flexible manufacturing demands programmable zones and high-speed logic reconfiguration. The transition from hard-wired contacts to parameterized function blocks reduces electrical drawings by up to 60% and enables digital twins that validate changes before deployment.

Modern safety PLCs also embed secure-boot firmware and encrypted communications, satisfying the dual requirement of cybersecurity and functional safety posed by the EU Machinery Regulation. The machine safety market size for safety PLCs is further lifted by the migration of OEMs to unified control panels where one CPU executes both standard IEC 61131 tasks and SIL-3 diagnostics. Component suppliers are bundling pre-certified libraries for safe torque off, safe limited speed and safe position, shortening application development time for machine builders.

The Machine Safety Market Report is Segmented by Implementation (Individual Components, Embedded Components, and More), Component (Presence-Sensing Safety Sensors, Safety Light Curtains, Safety Laser Scanners, and More), Application (Material Handling, Robotics & Collaborative Robots, and More), End User (Automotive, Food & Beverage, and More), and Geography. The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Europe's 31% share in 2024 underscores its role as regulatory pacesetter and automation pioneer. German automotive, chemical and machine-tool builders integrate networked safety backbones on virtually every new line, and 68% of installations already stream diagnostic data to central dashboards. Italian packaging OEMs export PL-e compliant fillers to North and South America, amplifying Europe's technology spillover. The United Kingdom mirrors EU norms to protect export access, while French aerospace plants deploy collaborative-robot guarding to co-locate humans and robots in wing-assembly cells.

Asia-Pacific, projected to post an 11.6% CAGR, is the pivotal growth arena. China's electronics assemblers rush to meet both domestic GB safety codes and CE marking for export, driving volume orders of light curtains and safe-motion drives. Japan's robotics makers embed dual-channel torque sensors in arms, enabling built-in ISO 13849 compliance and boosting acceptance of humans and robots in shared workstations. India sees multinational pharma and automotive OEMs installing Category 3 and 4 systems at new greenfield sites, lifting local awareness and triggering supplier localization. South Korean chip fabs procure SIL-rated valve-manifolds for ultrapure chemical lines, combining functional-safety with low-particulate construction to safeguard both personnel and wafers.

North America remains a technology leader, yet growth is steadier. US processors upgrade safety to mitigate liability and insurance costs, with 42% of food plants planning major modernizations in 2025. Canada's mining sector adopts wireless SIL-3 emergency-stop networks for haul-truck corridors. Latin American adoption is uneven: Brazil's automotive clusters align with EU and US customer mandates, whereas smaller factories delay investments. The Middle East & Africa region expands fastest in high-risk energy sectors, installing integrated fire-and-gas plus ESD systems at refineries and LNG terminals.

- Rockwell Automation, Inc.

- Siemens AG

- Schneider Electric SE

- Omron Corporation

- Sick AG

- Pilz GmbH and Co. KG

- Mitsubishi Electric Corporation

- ABB Ltd.

- Honeywell International Inc.

- Keyence Corporation

- IDEC Corporation

- Banner Engineering Corp.

- Phoenix Contact GmbH and Co. KG

- Datalogic S.p.A.

- Bihl + Wiedemann GmbH

- Euchner GmbH + Co. KG

- Leuze electronic GmbH + Co. KG

- Wenglor sensoric GmbH

- Rockford Systems LLC

- Fortress Safety

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Accelerated Adoption of Collaborative Robots in Electronics Assembly Lines across East Asia

- 4.2.2 EU Machinery Regulation 2023/1230 Mandating Performance Level e Safety Functions in New Equipment from 2027

- 4.2.3 Rapid Brownfield Digital Retrofit Programs in North American Food and Beverage Plants Incorporating Safety I/O-Link Sensors

- 4.2.4 Surge in LNG Megaprojects in Middle East Elevating Demand for SIL-3 Rated Emergency Shutdown Systems

- 4.2.5 Rising Insurance Premium Penalties for Plant Injuries Above OSHA TRIR Thresholds Pushing US SMEs toward Category 4 Safety Solutions

- 4.2.6 Shift from Hard-wired Relays to Software-Configurable Safety PLCs Enabling Flexible Packaging Lines in Europe

- 4.3 Market Restraints

- 4.3.1 High Integration Complexity of Safety Networks with Legacy Control Architecture in Brownfield Sites

- 4.3.2 Capital Budget Freezes in Automotive Tier-2 Suppliers Amid EV Demand Volatility

- 4.3.3 Limited Skilled Workforce to Program Functional-Safety Software per IEC 61508/62061 in Emerging Markets

- 4.3.4 Perception of Over-Engineering and ROI Uncertainty for Category-4 Safety Systems among Southeast-Asian SMEs

- 4.4 Value / Supply-Chain Analysis

- 4.5 Regulatory Outlook

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Threat of New Entrants

- 4.7.4 Intensity of Competitive Rivalry

- 4.7.5 Threat of Substitutes

- 4.8 Investment Analysis

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Implementation

- 5.1.1 Individual Components

- 5.1.2 Embedded Components

- 5.1.3 Retrofit Safety Upgrades

- 5.2 By Component

- 5.2.1 Presence-Sensing Safety Sensors

- 5.2.2 Safety Light Curtains

- 5.2.3 Safety Laser Scanners

- 5.2.4 Emergency Stop Devices

- 5.2.5 Safety Interlock Switches

- 5.2.6 Safety Controllers / Modules / Relays

- 5.2.7 Safety PLCs

- 5.2.8 Two-Hand Controls and Enabling Switches

- 5.2.9 Other Components (Mats, Edges, Bumpers)

- 5.3 By Application

- 5.3.1 Material Handling

- 5.3.2 Robotics and Collaborative Robots

- 5.3.3 Packaging and Palletizing

- 5.3.4 Cutting, Forming and Machining

- 5.3.5 Assembly and Pick-and-Place

- 5.4 By End-Use Industry

- 5.4.1 Automotive

- 5.4.2 Food and Beverage

- 5.4.3 Electronics and Semiconductor

- 5.4.4 Oil and Gas

- 5.4.5 Pharmaceuticals and Healthcare

- 5.4.6 Chemicals

- 5.4.7 Metals and Mining

- 5.4.8 Aerospace and Defense

- 5.4.9 Packaging Industry

- 5.4.10 Other Industries

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 Europe

- 5.5.2.1 United Kingdom

- 5.5.2.2 Germany

- 5.5.2.3 France

- 5.5.2.4 Italy

- 5.5.2.5 Rest of Europe

- 5.5.3 Asia-Pacific

- 5.5.3.1 China

- 5.5.3.2 Japan

- 5.5.3.3 India

- 5.5.3.4 South Korea

- 5.5.3.5 Rest of Asia-Pacific

- 5.5.4 Middle East

- 5.5.4.1 Israel

- 5.5.4.2 Saudi Arabia

- 5.5.4.3 United Arab Emirates

- 5.5.4.4 Turkey

- 5.5.4.5 Rest of Middle East

- 5.5.5 Africa

- 5.5.5.1 South Africa

- 5.5.5.2 Egypt

- 5.5.5.3 Rest of Africa

- 5.5.6 South America

- 5.5.6.1 Brazil

- 5.5.6.2 Argentina

- 5.5.6.3 Rest of South America

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global-level Overview, Market-level Overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share, Products and Services, and Recent Developments)

- 6.4.1 Rockwell Automation, Inc.

- 6.4.2 Siemens AG

- 6.4.3 Schneider Electric SE

- 6.4.4 Omron Corporation

- 6.4.5 Sick AG

- 6.4.6 Pilz GmbH and Co. KG

- 6.4.7 Mitsubishi Electric Corporation

- 6.4.8 ABB Ltd.

- 6.4.9 Honeywell International Inc.

- 6.4.10 Keyence Corporation

- 6.4.11 IDEC Corporation

- 6.4.12 Banner Engineering Corp.

- 6.4.13 Phoenix Contact GmbH and Co. KG

- 6.4.14 Datalogic S.p.A.

- 6.4.15 Bihl + Wiedemann GmbH

- 6.4.16 Euchner GmbH + Co. KG

- 6.4.17 Leuze electronic GmbH + Co. KG

- 6.4.18 Wenglor sensoric GmbH

- 6.4.19 Rockford Systems LLC

- 6.4.20 Fortress Safety

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-Need Assessment