|

市場調查報告書

商品編碼

1851735

球閥:市場佔有率分析、產業趨勢、統計數據和成長預測(2025-2030 年)Ball Valve - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

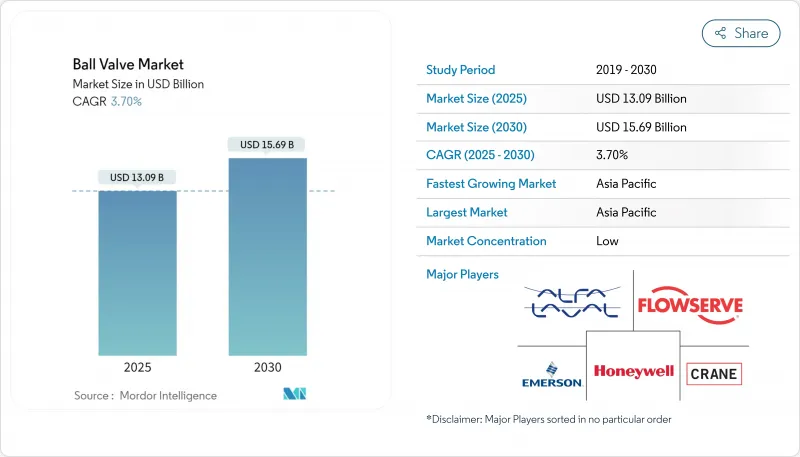

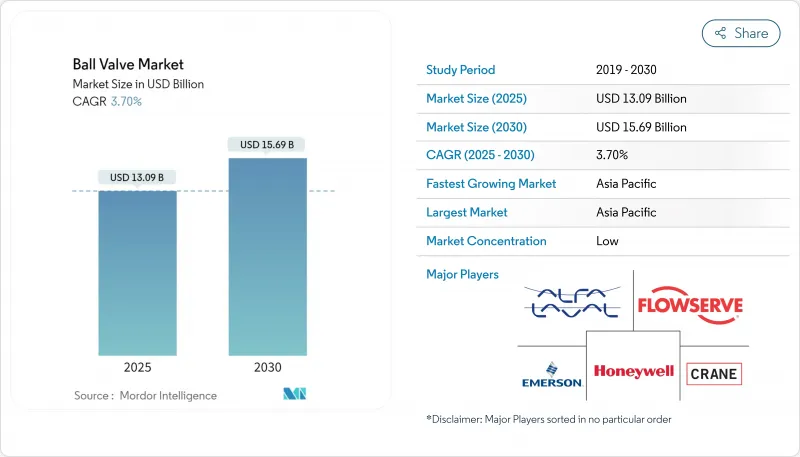

預計到 2025 年,球閥市場規模將達到 130.9 億美元,到 2030 年將達到 156.9 億美元,年複合成長率為 3.7%。

這項展望證實了需求驅動的穩定擴張,反映的是全球基礎設施升級的步伐,而非經濟繁榮週期所帶來的成長。液化天然氣(LNG)在亞洲的廣泛應用、碳氫化合物經濟體減少排放氣體的監管壓力以及水務部門數位化,都是推動閥門長期需求成長的關鍵因素。計劃業主優先考慮零件的完整性、安全合規性和低生命週期排放,因此更傾向於選擇高階球閥而非低成本替代品。同時,特種鍛件的供應鏈瓶頸和不銹鋼價格的波動限制了中型加工商(尤其是在亞洲)的近期利潤率。

全球球閥市場趨勢與洞察

新興亞太國家液化天然氣基礎設施擴張加速

亞洲各國政府將液化天然氣(LNG)視為加強能源安全和減少對煤炭依賴的直接解決方案。預計到2025年,全球LNG出口能力將成長18%,主要出口至亞洲進口終端,這將推動對-162 度C低溫球閥的需求。這些裝置必須確保在液化、運輸和再氣化過程中甲烷的密封性,因此,擁有深厚冶金專業知識和可靠低溫測試記錄的供應商更具優勢。像越南和菲律賓這樣依賴進口、缺乏管道網路的市場,正在部署浮體式儲存再氣化裝置(FSRG),這些裝置要求使用高階耳軸式低溫球閥。這項需求推高了平均售價,保護了主要供應商免受替代風險的影響,並增強了球閥市場的利潤成長。

嚴苛工況球閥在歐洲的氫能和碳捕集與封存(CCS)計劃中得到越來越廣泛的應用。

歐盟計畫在2030年生產1000萬噸可再生氫,這就要求管道和儲氫網路能夠承受超過700巴的壓力,同時避免氫致裂紋的產生。為了滿足這些機械性能要求,並應對碳捕獲與儲存(CCS)管線中超臨界二氧化碳的腐蝕挑戰,雙相不銹鋼和超級雙相不銹鋼正逐步進入主流生產領域。由於工廠業主在簽訂合約前要求提供可靠的安全證明文件,因此,那些能夠根據不斷發展的氫能標準對其材料進行認證的製造商將獲得先發優勢。這一趨勢鞏固了歐洲作為技術試驗場的地位,並擴大了高階球閥市場的佔有率。

由於全球鍛造能力受限,前置作業時間延長。

十年的供應商整合使得目前僅剩少數幾家能夠生產大直徑鎳合金坯料的開式模鍛廠。航太和能源產業的同步需求加劇了產能緊張,導致交貨週期從傳統的12-16週延長至24-32週。計劃業主現在要么增加緩衝庫存,要么在進度風險超過技術優勢時接受替代閥門類型。一些原始設備製造商(OEM)正在尋求垂直整合,但資金需求和資格確認時間限制使得緩解措施的實施要等到本世紀下半葉才能實現。

細分市場分析

預計到2024年,浮動球閥市場規模將達到27%的年均收入成長率。低溫球閥雖然市場定位小眾,但由於LNG接收站和氫氣出口樞紐對低至-162 度C的密封性能有較高要求,預計其複合年成長率將達到6.4%。終端用戶重視經氦質譜測試檢驗的零洩漏閥座和防爆閥桿。

目前已在海底試驗中得到現場驗證,積層製造的流道相比全焊接閥體可減輕重量並降低壓力損失;而軌道閥和升降桿閥可在節流操作下保持閥座壽命,避免傳統浮動閥在此類操作中受損。這些市場發展豐富了產品系列併拓展了功能範圍,使球閥在尋求蝶閥和旋塞閥替代方案的市場中保持競爭力。

碳鋼因其優異的強度成本比,在管道和工業設施領域具有優勢,預計2024年將佔球閥市場規模的32%。氫氣計劃目前更傾向使用抗脆性的超雙相不銹鋼和奧氏體不銹鋼閥體,推動合金需求以5.2%的複合年成長率成長。此外,雙相不銹鋼還具有更高的耐壓等級,有助於管道工程師縮短工期並降低資本支出。

不銹鋼價格的波動促使原始設備製造商 (OEM) 尋求符合 304L 和 316L 雙認證標準的鋼材,從而提高採購彈性。積層製造技術正在引入功能梯度材料,其中高鎳基體增強了座椅區域,而碳鋼則主導了外殼,從而最佳化了總成本。

區域分析

到2024年,亞洲將佔球閥市場收入的31%,這主要得益於中國工業的成長和東南亞液化天然氣進口終端的建設。各國政府所推行的清潔能源政策支持閥門的永續採購。印度的「印度製造」計畫促進了閥門的國內生產,但氫能試點計畫仍依賴進口重型閥門配件。日本和韓國優先發展用於特定化學製程的高性能合金,從而在區域貿易中保持技術優勢。

中東是成長最快的叢集,預計到2030年將以5.1%的複合年成長率成長,這主要得益於營運商對現有氣田進行低排放閥門維修,以及新建待開發區天然氣巨型生產線。光是卡達北部氣田的擴建就需要數千台低溫閥門裝置,而沙烏地阿美公司正在其天然氣收集網路中部署智慧致動器,以滿足甲烷排放強度目標。土耳其的天然氣過境運輸雄心也帶動了對大口徑管道閥門的訂單。

北美地區由於中游環節的更換義務,佔據了相當大的市場佔有率。頁岩氣集輸系統需要耐酸性氣體的高壓球閥。加拿大油砂管路需要硬質閥座以承受瀝青的磨損。隨著墨西哥能源市場的開放,其出口級管道進口了符合API 6D認證標準的閥門。氣候法規推動了ISO-15848-1認證產品的應用,並增加了有利於現有品牌的額外要求。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 加速亞太新興國家液化天然氣基礎設施的擴張

- 嚴苛工況球閥在歐洲氫能和碳捕集與封存計劃中得到更廣泛的應用

- 北美中游資產現代化改造指令推動了替換需求

- 斯堪的納維亞水務公司的快速數位化推動了智慧球閥的維修。

- FPSO部署激增推動巴西和西非地區低溫球閥的應用

- 中東地區加強對低排放(「無甲烷逸散」)閥門的監管

- 市場限制

- 由於全球鍛造能力受限,前置作業時間延長。

- 在高度磨蝕性的採礦應用中,金屬座閥需要高額的資本投入。

- 在緊湊型暖通空調系統中,塞閥和蝶閥越來越偏好。

- 不銹鋼價格波動侵蝕了亞洲二級製造商的利潤空間

- 價值/供應鏈分析

- 監理展望

- 技術展望

- 波特五力分析

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭對手之間的競爭

- 投資與資金籌措分析

第5章 市場規模與成長預測

- 按閥門類型

- 浮動球閥

- 耳軸式球閥

- 升桿/軌道球閥

- 頂部進入式球閥

- 全焊接球閥

- 低溫球閥

- 材料

- 碳鋼

- 防鏽的

- 鑄鐵/球墨鑄鐵

- 合金基體(雙相鋼、因科鎳合金、哈氏合金)

- 青銅和黃銅

- 其他材料

- 按閥門尺寸

- 最大 1 英吋(DN 25)

- 1"-6"

- 6 "-25"

- 25"-50"

- 50吋或以上

- 透過驅動

- 手動的

- 電

- 氣動

- 油壓

- 電液

- 按最終用戶行業分類

- 石油和天然氣

- 化工/石油化工

- 用水和污水

- 發電業務

- 採礦和金屬

- 飲食

- 製藥和生物技術

- 暖通空調和製冷

- 紙漿和造紙

- 其他行業

- 按地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 英國

- 德國

- 法國

- 義大利

- 其他歐洲地區

- 亞太地區

- 中國

- 日本

- 印度

- 韓國

- 亞太其他地區

- 中東

- 以色列

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 土耳其

- 其他中東地區

- 非洲

- 南非

- 埃及

- 其他非洲地區

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 北美洲

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率分析

- 公司簡介

- Emerson Electric Co.

- Flowserve Corporation

- Schlumberger(Cameron)

- IMI plc

- Kitz Corporation

- Crane Co.

- Baker Hughes(Valves and Process Solutions)

- Honeywell International Inc.

- Alfa Laval AB

- Curtiss-Wright Corporation

- SAMSON AG

- Velan Inc.

- CIRCOR International Inc.

- AVK Holding

- Mueller Water Products Inc.

- Neway Valve Co., Ltd.

- Bonney Forge Corp.

- Metso Corporation(Valmet)

- Hitachi Ltd.

- Valvitalia SpA

- Georg Fischer Ltd.

- Danfoss A/S

- Castel SRL

- Sanhua Holding Group

第7章 市場機會與未來展望

The Ball valve market reached USD 13.09 billion in 2025 and is forecast to advance at a 3.7% CAGR, lifting revenue to USD 15.69 billion by 2030.

The outlook confirms a steady, demand-backed expansion that mirrors the pace of global infrastructure upgrades rather than boom-cycle growth. Widespread liquefied natural gas (LNG) build-outs in Asia, regulatory pressure to cut fugitive emissions in hydrocarbon economies, and accelerated digitalization of water utilities are the principal forces reinforcing long-term valve demand. Project owners are prioritizing component integrity, safety compliance, and low lifetime emissions, which amplifies preference for premium ball valves over lower-cost substitutes. At the same time, supply-chain bottlenecks in specialty forgings and volatile stainless-steel prices are tempering near-term profit margins, especially for mid-tier Asian fabricators.

Global Ball Valve Market Trends and Insights

Accelerated LNG Infrastructure Expansion in Emerging Asia Pacific

Asian governments view LNG as an immediate route to strengthen energy security and cut coal reliance. An 18% rise in global LNG export capacity in 2025, mainly aimed at Asian import terminals, magnifies demand for cryogenic ball valves rated to -162 °C. These units must guarantee methane-tight sealing throughout liquefaction, transport, and regasification duty, which favors vendors with deep metallurgical expertise and validated low-temperature testing records. Import-dependent markets such as Vietnam and the Philippines, lacking pipeline grids, are rolling out floating storage and regasification units that specify premium trunnion-mounted cryogenic valves. This requirement lifts average selling prices and insulates leading suppliers from substitution risk, reinforcing profitable growth for the Ball valve market.

Rising Adoption of Severe-Service Ball Valves in Hydrogen & CCS Projects across Europe

The EU's plan to generate 10 million t of renewable hydrogen by 2030 requires pipelines and storage networks that can withstand pressures above 700 bar while avoiding hydrogen-induced cracking. Duplex and super-duplex alloys are moving into mainstream production to meet these mechanical demands and the corrosion challenges of supercritical CO2 in carbon capture and storage (CCS) lines. Manufacturers that certify materials under evolving hydrogen standards enjoy a first-mover advantage, because plant owners seek proven safety documentation before awarding contracts. This trend cements Europe's role as a technology test bed and enlarges the premium tier of the Ball valve market.

Prolonged Lead-Times due to Global Forging Capacity Constraints

A decade of supplier consolidation has left only a handful of open-die forges capable of producing large-diameter, nickel-alloy blanks. Simultaneous demand from aerospace and energy increases capacity strain, with delivery cycles stretching to 24-32 weeks versus the historical 12-16 week window. Project owners now embed buffer inventories or accept alternate valve styles if schedule risk outweighs technical benefit. Some OEMs pursue vertical integration, but capital needs and qualification timelines delay relief until late decade.

Other drivers and restraints analyzed in the detailed report include:

- North American Mid-stream Asset Modernization Mandates Driving Replacement Demand

- Rapid Digitalization of Water Utilities Spurs Smart Ball Valve Retrofit in Nordics

- High Capital Outlay for Metal-Seated Valves in Abrasive Mining Applications

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

The Ball valve market size for floating designs logged 27% revenue in 2024, driven by their adaptability across refinery, water, and general-purpose services. Cryogenic ball valves, though niche, are rising at a 6.4% CAGR as LNG terminals and hydrogen export hubs demand guaranteed sealing down to -162 °C. End users emphasize zero-leakage seats and blow-out-proof stems validated by helium mass-spectrometer testing, a standard that raises entry barriers and sustains premium price realization.

Additive-manufactured flow paths, now field-proven in subsea pilots, reduce weight and pressure drop in fully welded bodies. Meanwhile, orbit and rising-stem variants preserve seat life where throttling duty would damage conventional floating valves. Together, these developments diversify product portfolios and extend the functional scope, preserving relevance of ball valves even in markets exploring butterfly or plug alternatives.

Carbon steel held 32% share of the Ball valve market size in 2024 thanks to its favorable strength-to-cost ratio across pipelines and industrial utilities. Hydrogen projects now favor alloy-based bodies with super-duplex or austenitic grades to resist embrittlement, raising alloy demand at a 5.2% CAGR. Duplex grades also unlock higher allowable pressure ratings, enabling pipeline engineers to downsize schedules and shave capex.

Stainless-steel price volatility pushes OEMs to qualify dual-certified grades that meet both 304L and 316L requirements, streamlining procurement flexibility. Additive manufacturing introduces functionally graded materials where high-nickel matrices reinforce seat zones, while carbon-steel dominates outer shells, optimizing total cost.

The Ball Valve Market Report is Segmented by Valve Type (Floating, Trunnion-Mounted, Rising-Stem, Top-Entry, Fully-Welded, Cryogenic), Material (Carbon Steel, Stainless Steel, Cast Iron, and More), Valve Size (Up To 1", 1"-6", 6"-25", and More), Actuation (Manual, Electric, Pneumatic, and More), End-User (Oil & Gas, Chemicals, Water, and More), and Geography. The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia accounted for 31% of Ball valve market revenue in 2024, propelled by Chinese industrial growth and Southeast Asian LNG import terminals. Government policies that mandate cleaner energy mix underpin sustained valve procurement. India's "Make in India" scheme fosters domestic valve production yet still relies on imported severe-service trims for hydrogen pilots. Japan and South Korea prioritize high-performance alloys for niche chemical processes, maintaining a technology premium in regional trade.

The Middle East is the fastest-growing cluster, projecting 5.1% CAGR to 2030 as operators retrofit low-emission valves in legacy fields and build green-field LNG mega-trains. Qatar's North Field expansion alone calls for thousands of cryogenic units, while Saudi Aramco deploys smart actuators across gas gathering networks to satisfy methane-intensity goals. Turkey's transit ambitions also translate into large-bore pipeline valve orders.

North America retains sizable share owing to mid-stream replacement mandates. Shale-gas gathering systems need high-pressure ball valves resistant to acid gases. Canadian oil sands lines demand hard-faced seats to manage bitumen abrasion. Mexico, opening its energy market, imports API 6D-certified valves for export-class pipelines. Climate regulation stimulates adoption of ISO-15848-1 certified products, adding incremental requirements that favor established brands.

- Emerson Electric Co.

- Flowserve Corporation

- Schlumberger (Cameron)

- IMI plc

- Kitz Corporation

- Crane Co.

- Baker Hughes (Valves and Process Solutions)

- Honeywell International Inc.

- Alfa Laval AB

- Curtiss-Wright Corporation

- SAMSON AG

- Velan Inc.

- CIRCOR International Inc.

- AVK Holding

- Mueller Water Products Inc.

- Neway Valve Co., Ltd.

- Bonney Forge Corp.

- Metso Corporation (Valmet)

- Hitachi Ltd.

- Valvitalia S.p.A.

- Georg Fischer Ltd.

- Danfoss A/S

- Castel SRL

- Sanhua Holding Group

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Accelerated LNG Infrastructure Expansion in Emerging Asia Pacific

- 4.2.2 Rising Adoption of Severe-Service Ball Valves in Hydrogen and CCS Projects across Europe

- 4.2.3 North American Mid-stream Asset Modernization Mandates Driving Replacement Demand

- 4.2.4 Rapid Digitalization of Water Utilities Spurs Smart Ball Valve Retrofit in Nordics

- 4.2.5 Surge in FPSO Deployments Boosting Cryogenic Ball Valve Uptake in Brazil and West Africa

- 4.2.6 Regulatory Push for Low-Emission ("Fugitive-Methane-Free") Valves in the Middle East

- 4.3 Market Restraints

- 4.3.1 Prolonged Lead-Times due to Global Forging Capacity Constraints

- 4.3.2 High Capital Outlay for Metal-Seated Valves in Abrasive Mining Applications

- 4.3.3 Increasing Preference for Plug and Butterfly Valves in Compact HVAC Systems

- 4.3.4 Volatile Stainless-Steel Prices Eroding Margins for Tier-2 Asian Manufacturers

- 4.4 Value / Supply-Chain Analysis

- 4.5 Regulatory Outlook

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Threat of New Entrants

- 4.7.4 Threat of Substitutes

- 4.7.5 Intensity of Competitive Rivalry

- 4.8 Investment and Funding Analysis

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Valve Type

- 5.1.1 Floating Ball Valves

- 5.1.2 Trunnion-Mounted Ball Valves

- 5.1.3 Rising-Stem / Orbit Ball Valves

- 5.1.4 Top-Entry Ball Valves

- 5.1.5 Fully-Welded Ball Valves

- 5.1.6 Cryogenic Ball Valves

- 5.2 By Material

- 5.2.1 Carbon Steel

- 5.2.2 Stainless Steel

- 5.2.3 Cast Iron / Ductile Iron

- 5.2.4 Alloy-Based (Duplex, Inconel, Hastelloy)

- 5.2.5 Bronze and Brass

- 5.2.6 Other Materials

- 5.3 By Valve Size

- 5.3.1 Up to 1" (DN 25)

- 5.3.2 1" - 6"

- 5.3.3 6 " - 25"

- 5.3.4 25" - 50"

- 5.3.5 Above 50"

- 5.4 By Actuation

- 5.4.1 Manual

- 5.4.2 Electric

- 5.4.3 Pneumatic

- 5.4.4 Hydraulic

- 5.4.5 Electro-Hydraulic

- 5.5 By End-User Industry

- 5.5.1 Oil and Gas

- 5.5.2 Chemicals and Petrochemicals

- 5.5.3 Water and Wastewater

- 5.5.4 Power Generation

- 5.5.5 Mining and Metals

- 5.5.6 Food and Beverage

- 5.5.7 Pharmaceuticals and Biotechnology

- 5.5.8 HVAC and Refrigeration

- 5.5.9 Pulp and Paper

- 5.5.10 Other Industries

- 5.6 By Geography

- 5.6.1 North America

- 5.6.1.1 United States

- 5.6.1.2 Canada

- 5.6.1.3 Mexico

- 5.6.2 Europe

- 5.6.2.1 United Kingdom

- 5.6.2.2 Germany

- 5.6.2.3 France

- 5.6.2.4 Italy

- 5.6.2.5 Rest of Europe

- 5.6.3 Asia-Pacific

- 5.6.3.1 China

- 5.6.3.2 Japan

- 5.6.3.3 India

- 5.6.3.4 South Korea

- 5.6.3.5 Rest of Asia-Pacific

- 5.6.4 Middle East

- 5.6.4.1 Israel

- 5.6.4.2 Saudi Arabia

- 5.6.4.3 United Arab Emirates

- 5.6.4.4 Turkey

- 5.6.4.5 Rest of Middle East

- 5.6.5 Africa

- 5.6.5.1 South Africa

- 5.6.5.2 Egypt

- 5.6.5.3 Rest of Africa

- 5.6.6 South America

- 5.6.6.1 Brazil

- 5.6.6.2 Argentina

- 5.6.6.3 Rest of South America

- 5.6.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Emerson Electric Co.

- 6.4.2 Flowserve Corporation

- 6.4.3 Schlumberger (Cameron)

- 6.4.4 IMI plc

- 6.4.5 Kitz Corporation

- 6.4.6 Crane Co.

- 6.4.7 Baker Hughes (Valves and Process Solutions)

- 6.4.8 Honeywell International Inc.

- 6.4.9 Alfa Laval AB

- 6.4.10 Curtiss-Wright Corporation

- 6.4.11 SAMSON AG

- 6.4.12 Velan Inc.

- 6.4.13 CIRCOR International Inc.

- 6.4.14 AVK Holding

- 6.4.15 Mueller Water Products Inc.

- 6.4.16 Neway Valve Co., Ltd.

- 6.4.17 Bonney Forge Corp.

- 6.4.18 Metso Corporation (Valmet)

- 6.4.19 Hitachi Ltd.

- 6.4.20 Valvitalia S.p.A.

- 6.4.21 Georg Fischer Ltd.

- 6.4.22 Danfoss A/S

- 6.4.23 Castel SRL

- 6.4.24 Sanhua Holding Group

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-Space and Unmet-Need Assessment