|

市場調查報告書

商品編碼

1851630

粉末冶金:市場佔有率分析、產業趨勢、統計、成長預測(2025-2030)Powder Metallurgy - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

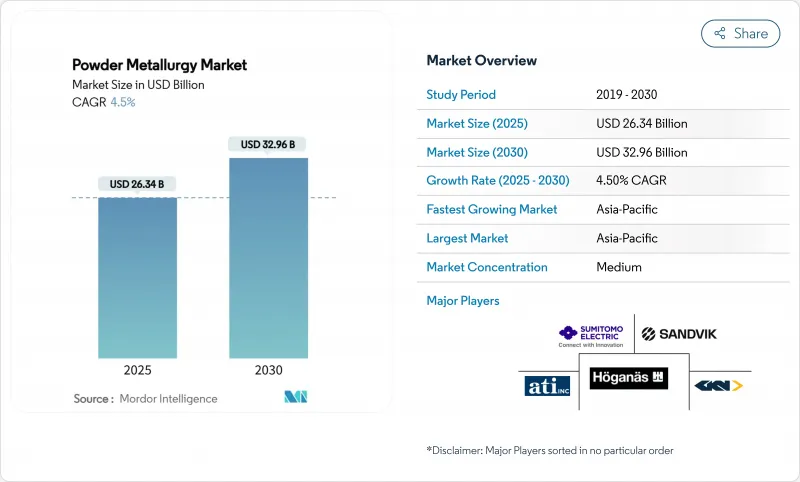

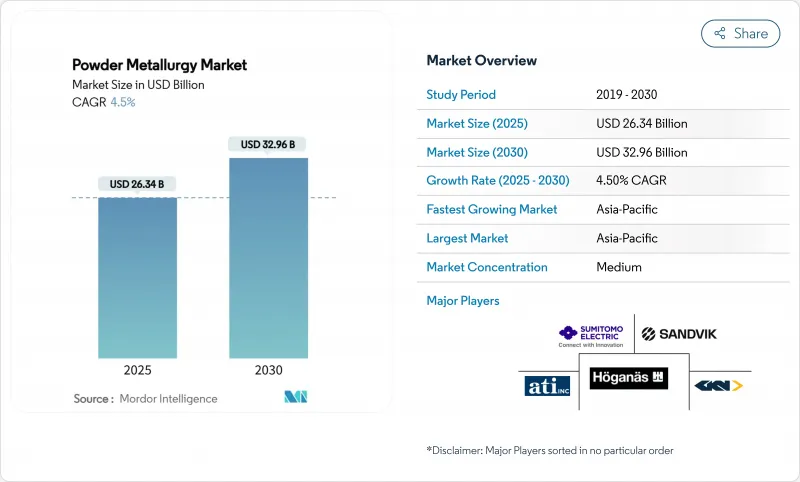

預計到 2025 年,粉末冶金市場規模將達到 263.4 億美元,到 2030 年將達到 329.6 億美元,預測期(2025-2030 年)複合年成長率為 4.5%。

推動成長的因素包括交通運輸電氣化、對複雜輕量化零件的需求,以及在醫療、航太和國防供應鏈中的穩定滲透。亞太地區佔最大佔有率,隨著各國政府加強該地區的材料生態系統,持續吸引新的產能。同時,北美和歐洲的製造商正將重心轉向高價值、小批量應用,以彌補傳統汽車生產成長放緩的影響。隨著積層製造程序削弱壓制燒結製程的主導地位,競爭日益激烈;特種合金供應商則瞄準電動車動力傳動系統、航太和整形外科的客戶,推出旨在提高效率和永續性的粉末材料。

全球粉末冶金市場趨勢與洞察

粉末冶金技術在輕量化電動動力傳動系統零件領域日益受到青睞

北美汽車製造商正在重新設計電動動力傳動系統,採用粉末冶金馬達鐵芯、齒輪和熱感板,以減少廢棄物並縮短加工週期。 GKN粉末冶金公司報告稱,2023年訂單中有72%為非驅動零件,凸顯了其向電氣化平台策略的轉型。供應商也在投資局部的電池級粉末。軟磁複合複合材料可將鐵芯損耗降低高達20%,直接提高電動驅動系統的設計效率。隨著汽車製造商追求動力總成減重,粉末冶金市場正在搶佔曾經由鑄造或鍛造材料主導的市場。鋼基電動驅動粉末的標準化進一步簡化了認證流程,並降低了二線供應商的進入門檻。

航太領域對近淨成形積層製造零件的需求激增

歐洲引擎和機身供應商正在增加粉末積層製造的消費量,以縮短前置作業時間並減少材料消耗。柯林斯太空公司安裝了兩台12雷射NXG XII 600設備,將渦輪零件的交付週期從52週縮短至8週。廢品率從50%降低到90%以上,提高了存貨周轉和碳排放強度,使粉末冶金工藝能夠與精密鑄造工藝相媲美。 SLM Solutions公司專門的適航性框架有助於協調程式參數和合金可追溯性,從而緩解認證瓶頸。隨著粉末冶金市場在飛行關鍵硬體領域佔據越來越重要的地位,歐洲服務機構正在擴大鎳基高溫合金的產能,並開始向用於下一代航空引擎的γ鈦粉末領域拓展業務。航太領域對近淨成形積層製造零件的需求激增。

高純度金屬粉末價格波動

中國於2025年初對鎢、碲、鉍、鉬和銦實施出口限制,導致現貨價格飆升,並給工具鋼、溫度控管和磁性粉末的分配帶來風險。各國政府已推出戰略蘊藏量立法予以應對,但新礦和提煉的計劃限制了短期緩解措施。買家正在延長合約期限並明確回收流程,但二次供應無法完全抵消地緣政治動盪的影響。在新的礦山產能運作或貿易政策穩定之前,粉末冶金市場將面臨短期利潤率壓力。由於替代品有限,高能耗的超細粉末尤其脆弱。

細分市場分析

2024年,鋼材粉末冶金市場佔有率佔比達79%,預計到2030年將以4.62%的複合年成長率成長。完善的壓制和燒結基礎設施使大批量生產商能夠實現密度超過7.4 g/cm³的產品,從而縮小了與鍛鋼在機械性能上的差距。同時,先進的燒結硬化配方使得齒輪和同步器輪轂能夠以接近最終形狀的精度製造,無需二次熱處理即可滿足電力驅動系統的扭矩負載需求。熱等靜壓也推動了市場成長,該技術能夠提高大型鋼製渦輪盤的密度,從而增強其在能源和船舶引擎領域的應用前景。

區域分析

預計到2024年,亞太地區將佔據全球粉末冶金市場佔有率的40%,並在2030年之前保持4.8%的最高區域複合年成長率,這主要得益於中國、日本和印度積極的產業政策、投資激勵措施以及積層製造設備的快速普及。在中國,3D列印鉭椎間融合器已獲得國家藥品監督管理局(NMPA)的批准,快速的監管發展正在加速該地區先進粉末的應用。

隨著電動車動力系統和航太粉末消耗量的調整,北美正在重新調整其市場地位。政府對關鍵礦物和惡劣環境材料研究的資助將優先用於國內鎢、鈮和稀土的開採,從而減少對政治敏感進口資源的依賴。

歐洲正透過永續性數位化不斷向前邁進。自2018年以來,Hoganas透過轉向生物基還原劑和再生能源,已將其碳排放減少了46%,使其粉末產品成為低碳供應鏈的核心。歐洲的航太巨頭對鎳和鈦合金的需求持續旺盛,而歐盟的國防計畫也推動了對耐火材料粉末的需求。東歐的鑄造廠正在採用混合燒結-黏結劑-噴射系統,並與西方機械製造商合作,擴大積層製造產能。總而言之,這些趨勢鞏固了歐洲作為更廣泛的粉末冶金市場技術中心的地位。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 北美電動車原始設備製造商加大對粉末冶金技術在輕量化電動動力傳動系統總成零件中的應用

- 歐洲航太領域對近淨成形積層製造零件的需求激增

- 亞太地區精密醫療植入製造的快速局部化

- 國防現代化計畫促進了中東地區高性能耐火材料粉末的採用。

- 在電波和電磁波應用領域的應用日益廣泛

- 市場限制

- 由於關鍵礦物供應受限,高純度金屬粉末價格出現波動。

- 針對安全關鍵型航太零件的標準化和鑑定通訊協定有限

- 來自先進複雜鋁零件鑄造技術的競爭威脅

- 價值鏈分析

- 波特五力模型

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭對手之間的競爭

第5章 市場規模與成長預測

- 依材料類型

- 鐵

- 有色金屬

- 透過製造技術

- 壓制和燒結

- 金屬射出成型(MIM)

- 積層製造/粉末層熔融

- 等靜壓

- 透過使用

- 車

- 工業機械

- 電氣和電子

- 航太

- 其他用途

- 按地區

- 亞太地區

- 中國

- 日本

- 印度

- 韓國

- ASEAN

- 亞太其他地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 其他歐洲地區

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 埃及

- 其他中東和非洲地區

- 亞太地區

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率分析

- 公司簡介

- AMETEK Inc.

- ATI, Inc.

- CNPC POWDER

- CRS Holdings, LLC

- Elementum

- Elmet Technologies

- ERASTEEL

- Fine Sinter Co., Ltd.

- GKN Powder Metallurgy

- Hoganas AB

- Kymera International

- LIBERTY Steel Group

- Metalysis

- Miba AG

- Phoenix Sintered Metals, LLC

- Phoenix Sintered Metals, LLC

- Plansee Group Functions

- POSCO

- Powder Alloy Corporation(PAC)

- Resonac Holdings Corporation

- Rio Tinto

- Sandvik AB

- Sumitomo Electric Industries, Ltd.

第7章 市場機會與未來展望

The Powder Metallurgy Market size is estimated at USD 26.34 billion in 2025, and is expected to reach USD 32.96 billion by 2030, at a CAGR of 4.5% during the forecast period (2025-2030).

Expansion is supported by electrification of mobility, demand for complex lightweight parts, and steady penetration into medical, aerospace, and defense supply chains. Asia-Pacific commands the largest regional position and continues to attract new capacity as governments strengthen local materials ecosystems. Meanwhile, North American and European producers are pivoting toward high-value, low-volume applications to offset slower growth in conventional automotive volumes. Competitive intensity is rising as additive processes erode the dominance of press-and-sinter, and as specialty alloy suppliers target e-powertrain, aerospace, and orthopedic customers with powders engineered for higher efficiency and sustainability.

Global Powder Metallurgy Market Trends and Insights

Increasing Preference for Powder Metallurgy in Lightweight E-Powertrain Components

North American OEMs are re-engineering e-powertrains with powder-metallurgy motor cores, gears, and thermal plates that reduce waste and shorten machining cycles. GKN Powder Metallurgy reported that 72% of its 2023 order intake came from propulsion-agnostic parts, confirming a strategic shift toward electrified platforms. Suppliers are also investing in localized battery-grade powders; Soft-magnetic composites cut core losses by up to 20%, giving electric-drive designers a direct efficiency gain. As automakers pursue lighter drivetrains, the powder metallurgy market captures programs once dominated by cast or wrought materials. Standardization of steel-based e-drive powders further streamlines qualification cycles, lowering the entry barrier for second-tier suppliers.

Surge in Demand for Net-Shape Additive Metal Components in Aerospace

European engine and airframe suppliers amplify additive powder consumption to compress lead times and material usage. Collins Aerospace installed two twelve-laser NXG XII 600 machines that slash turbine component delivery from 52 to 8 weeks. Scrap reduction from 50% to over 90% improves inventory turns and carbon intensity, making powder routes competitive against precision casting. A dedicated airworthiness framework from SLM Solutions is helping harmonize process parameters and alloy traceability, easing certification bottlenecks. As the powder metallurgy market becomes entrenched in flight-critical hardware, European service bureaus are expanding nickel-superalloy capacity and diversifying into gamma-titanium powders for next-generation aero-engines.Surge in Demand for Net-Shape Additive Metal Components in Aerospace

Volatility in High-Purity Metal Powder Prices

China introduced export controls on tungsten, tellurium, bismuth, molybdenum, and indium in early 2025, triggering a sharp uptick in spot quotes and creating allocation risk for tool-steel, thermal-management, and magnet-grade powders. Governments are responding with strategic reserves legislation, but project timelines for new mines and refineries constrain short-term relief. Buyers are lengthening contracts and qualifying recycled streams, yet secondary supply cannot fully offset geopolitical disruptions. The powder metallurgy market faces near-term margin pressure until fresh extraction capacity comes online or trade policies stabilize. Energy-intensive ultra-fine powder grades remain particularly exposed because of their limited substitutability.

Other drivers and restraints analyzed in the detailed report include:

- Rapid Localization of Precision Medical Implants Manufacturing

- Defense Modernization Programs Stimulating Refractory Powder Adoption

- Limited Standardization and Qualification Protocols for Safety-Critical Aerospace Parts

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

The ferrous segment controlled 79% of the powder metallurgy market in 2024 and is projected to rise at 4.62% CAGR through 2030, driven by mature tooling, abundant scrap streams, and robust price-performance economics. Extensive press-and-sinter infrastructure allows high-volume producers to hit densities exceeding 7.4 g/cm3, closing mechanical-property gaps with wrought steels. In parallel, advanced sinter-hardening formulas enable near-net-shape gears and synchronizer hubs that meet e-drive torque loads without secondary heat treatment. Growth is reinforced by hot isostatic pressing that densifies large ferrous turbine disks, increasing appeal in energy and marine engines.

The Powder Metallurgy Market Report Segments the Industry by Material Type (Ferrous and Non-Ferrous), Manufacturing Technology (Press and Sinter, Metal Injection Molding (MIM), and More), Application (Automotive, Industrial Machinery, Electrical and Electronics, Aerospace, and Other Applications), and Geography (Asia-Pacific, North America, Europe, South America, and Middle East and Africa).

Geography Analysis

Asia-Pacific retained 40% of the global powder metallurgy market share in 2024 and is expected to post the highest 4.8% regional CAGR to 2030, backed by aggressive industrial policy, investment incentives, and fast adoption of additive equipment in China, Japan, and India. China's NMPA clearance for a 3-D-printed tantalum interspinal cage highlights rapid regulatory evolution that accelerates local advanced-powder uptake.

North America is recalibrating its position as EV drivetrains and aerospace rebalance powder consumption. Government funds for critical minerals and harsh-environment materials research prioritize domestic tungsten, niobium, and rare-earth extraction, reducing reliance on politically sensitive imports.

Europe advances through sustainability and digitalization. Hoganas has cut carbon dioxide emissions by 46% since 2018 by transitioning to bio-based reductants and renewable electricity, positioning its powders at the center of low-carbon supply chains. Continental aerospace primes maintain demand for nickel and titanium alloys, while EU defense initiatives raise refractory-powder needs. Eastern European foundries adopt hybrid sinter-binder-jet systems, collaborating with Western machine builders to expand additive capacity. Collectively, these trends reinforce Europe's role as a technology nucleus within the broader powder metallurgy market.

- AMETEK Inc.

- ATI, Inc.

- CNPC POWDER

- CRS Holdings, LLC

- Elementum

- Elmet Technologies

- ERASTEEL

- Fine Sinter Co., Ltd.

- GKN Powder Metallurgy

- Hoganas AB

- Kymera International

- LIBERTY Steel Group

- Metalysis

- Miba AG

- Phoenix Sintered Metals, LLC

- Phoenix Sintered Metals, LLC

- Plansee Group Functions

- POSCO

- Powder Alloy Corporation (PAC)

- Resonac Holdings Corporation

- Rio Tinto

- Sandvik AB

- Sumitomo Electric Industries, Ltd.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Increasing Preference for Powder Metallurgy in Lightweight E-Powertrain Components among EV OEMs in North America

- 4.2.2 Surge in Demand for Net-Shape Additive Metal Components in Aerospace across Europe

- 4.2.3 Rapid Localization of Precision Medical Implants Manufacturing in Asia-Pacific

- 4.2.4 Defense Modernization Programs Stimulating Adoption of High-Performance Refractory Powders in Middle East

- 4.2.5 Growing Implementation in Electrical and Electromagnetic Applications

- 4.3 Market Restraints

- 4.3.1 Volatility in High-Purity Metal Powder Prices Due to Critical Mineral Supply Constraints

- 4.3.2 Limited Standardization and Qualification Protocols for Safety-Critical Aerospace Parts

- 4.3.3 Competitive Threat from Advanced Casting of Complex Aluminum Components

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitute Products

- 4.5.5 Intensity of Competitive Rivalry

5 Market Size and Growth Forecasts (Value )

- 5.1 By Material Type

- 5.1.1 Ferrous

- 5.1.2 Non-Ferrous

- 5.2 By Manufacturing Technology

- 5.2.1 Press and Sinter

- 5.2.2 Metal Injection Molding (MIM)

- 5.2.3 Additive Manufacturing / Powder Bed Fusion

- 5.2.4 Isostatic Pressing

- 5.3 By Application

- 5.3.1 Automotive

- 5.3.2 Industrial Machinery

- 5.3.3 Electrical and Electronics

- 5.3.4 Aerospace

- 5.3.5 Other Applications

- 5.4 By Geography

- 5.4.1 Asia-Pacific

- 5.4.1.1 China

- 5.4.1.2 Japan

- 5.4.1.3 India

- 5.4.1.4 South Korea

- 5.4.1.5 ASEAN

- 5.4.1.6 Rest of Asia-Pacific

- 5.4.2 North America

- 5.4.2.1 United States

- 5.4.2.2 Canada

- 5.4.2.3 Mexico

- 5.4.3 Europe

- 5.4.3.1 Germany

- 5.4.3.2 United Kingdom

- 5.4.3.3 France

- 5.4.3.4 Italy

- 5.4.3.5 Spain

- 5.4.3.6 Rest of Europe

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Rest of South America

- 5.4.5 Middle-East and Africa

- 5.4.5.1 Saudi Arabia

- 5.4.5.2 South Africa

- 5.4.5.3 Egypt

- 5.4.5.4 Rest of Middle-East and Africa

- 5.4.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles {(includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)}

- 6.4.1 AMETEK Inc.

- 6.4.2 ATI, Inc.

- 6.4.3 CNPC POWDER

- 6.4.4 CRS Holdings, LLC

- 6.4.5 Elementum

- 6.4.6 Elmet Technologies

- 6.4.7 ERASTEEL

- 6.4.8 Fine Sinter Co., Ltd.

- 6.4.9 GKN Powder Metallurgy

- 6.4.10 Hoganas AB

- 6.4.11 Kymera International

- 6.4.12 LIBERTY Steel Group

- 6.4.13 Metalysis

- 6.4.14 Miba AG

- 6.4.15 Phoenix Sintered Metals, LLC

- 6.4.16 Phoenix Sintered Metals, LLC

- 6.4.17 Plansee Group Functions

- 6.4.18 POSCO

- 6.4.19 Powder Alloy Corporation (PAC)

- 6.4.20 Resonac Holdings Corporation

- 6.4.21 Rio Tinto

- 6.4.22 Sandvik AB

- 6.4.23 Sumitomo Electric Industries, Ltd.

7 Market Opportunities and Future Outlook

- 7.1 White-Space and Unmet-Need Assessment

- 7.2 Increasing Adoption of Powder Metallurgy Techniques in Medical Sector