|

市場調查報告書

商品編碼

1851628

防彈複合材料:市場佔有率分析、行業趨勢、統計數據和成長預測(2025-2030 年)Ballistic Composites - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

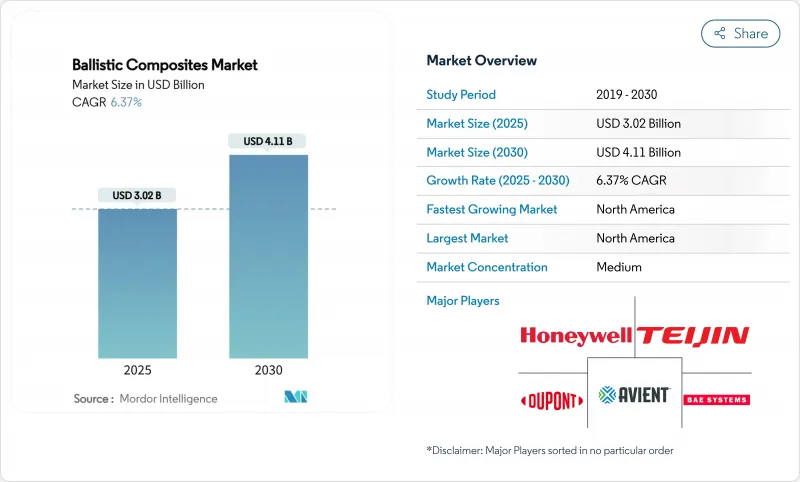

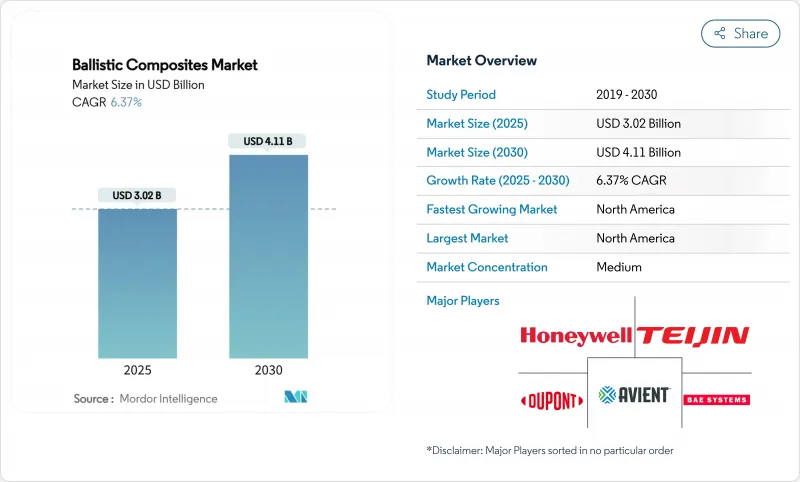

預計到 2025 年,彈道複合材料市場規模將達到 30.2 億美元,到 2030 年將達到 41.1 億美元,預測期(2025-2030 年)的複合年成長率為 6.37%。

國防現代化、自動駕駛車輛防護以及航太領域在不犧牲機組人員安全的前提下持續降低機身重量的努力,將推動市場穩定成長。需求成長將主要集中在輕質高強度層壓結構、混合纖維積層法的廣泛應用以及先進複合材料模具從航太供應鏈向裝甲生產線的轉移。醯胺纖維是目前大多數裝甲解決方案的增強材料,而聚合物基體則使製造商能夠在多次打擊性能和加工靈活性之間取得平衡。北美憑藉美國高預算的士兵現代化計劃以及依賴精密裝甲結構的下一代汽車平臺,保持領先地位。同時,隨著大規模步兵部隊個人防護工具採購的加速,亞太地區也日益受到重視。杜邦公司推出的克維拉EXO等新技術,其抗張強度比標準芳香聚醯胺高出30%,展現了彈道複合材料市場創新步伐的加快。

全球彈道複合材料市場趨勢與洞察

增加全球國防費用

主要國家不斷成長的國防支出正從根本上改變防彈複合材料的需求模式,採購重點轉向防護重量比更高的先進材料。美國的地面X車輛技術專案便是這一趨勢的典型例證,該專案旨在透過創新的複合裝甲系統而非傳統的鋼板,在保持生存能力的同時,將重量減輕50%。這項戰略轉變反映出軍事規劃者認知到,未來的作戰效能將取決於機動性和靈活性,而非被動裝甲的厚度。在亞洲國防市場,類似的現代化進程也在進行中,例如印度等國正在將先進的防彈頭盔納入標準步兵裝備,MKU有限公司已於2025年向印度陸軍交付了Kavro Doma 360頭盔。採購轉向複合材料將帶來持續的需求成長,超越了傳統的周期性國防費用模式。

推動航太和國防平台減重

航太和國防製造商正積極推行輕量化策略,將抗彈複合材料定位為提升下一代平台性能的關鍵因素。碳纖維複合材料在飛彈應用中已展現出比鋁合金輕40-50%的減重效果,從而延長了射程並負載容量,直接轉化為戰術性優勢。這一趨勢也延伸至低溫高超音速系統。 2025年, 座艙罩 Aerospace公司贏得了美國一份價值280萬美元的契約,為其提供可重複使用的隔熱瓦,以承受再入大氣層時的彈道衝擊。隔熱和彈道性能要求的交叉融合為抗彈複合材料市場開闢了新的成長點。

高昂的加工和認證成本

防彈複合材料產業面臨許多挑戰,複雜的加工要求和繁瑣的認證通訊協定顯著增加了製造成本和市場進入門檻。將於2024年生效的NIJ 0101.07標準引入了更嚴格的防彈衣測試方法,要求製造商投資先進的測試設備並延長認證週期。諸如STANAG 4569之類的軍用標準進一步增加了複雜性,其多角度、多速度的射擊測試方法只有少數實驗室能夠提供。對可控氣氛熱壓、纖維張力鑽機和電腦控制的鋪展成型生產線的投資推高了准入門檻,使防彈複合材料市場的現有企業佔據優勢。

細分市場分析

預計到2024年,醯胺纖維將佔彈道複合材料市場43.69%的佔有率,複合年成長率達6.40%。最新的克維拉EXO纖維在保持阻燃性的同時,抗張強度提高了30%,從而能夠製造更薄的裝甲板,並提升士兵的機動性。超高分子量聚乙烯(UHMWPE)正在縮小與芳綸纖維的差距,吸引那些優先考慮輕量化和防潮性能的客戶。對於經常暴露在高溫環境下的車輛裝甲而言,S玻璃纖維仍然佔據主導地位。隨著研究機構展現出動態強度超過14 GPa的奈米碳管紗線,市場競爭日益激烈。

芳香聚醯胺供應商正透過改進表面處理技術來增強基體黏合力,並與織物製造商合作,以實現多軸積層法,從而應對多重衝擊場景,以此鞏固自身市場地位。超高分子量聚乙烯(UHMWPE)製造商正在亞洲擴大產能,以穩定前置作業時間和降低成本。混合醯胺纖維、UHMWPE和碳纖維的複合材料層壓板兼具拉伸強度、抗分層性和耐熱性。生物基纖維舉措雖然仍處於小眾市場,但正吸引著注重永續性目標的國防機構,並為彈道複合材料市場的長期多元化發展指明了方向。

區域分析

北美將在2024年以43.16%的市佔率引領彈道複合材料市場,預計到2030年將以6.51%的複合年成長率成長。未來遠程突擊飛機專案正在為貝爾V-280「英勇」飛機配備Entegris複合材料裝甲,這清楚地表明了市場對該產品持續的需求。強大的聯邦國防預算、穩健的供應鏈以及大學支持的測試基礎設施,都為該地區的領先地位提供了支撐。

亞太地區是北美以外成長最快的地區。中國、印度、日本和韓國都在投資研發更輕的個人防護裝備和國產車裝甲。印度的輕型戰車計畫指定使用複合材料附加套件來減輕車輛重量,這反映出其正在逐步拋棄全鋼車體設計。韓國正在將纖維金屬層壓板整合到其K2「黑豹」坦克中,以提高其防雷性能而不減輕重量。

在歐洲,由於安全情勢日益嚴峻,國防預算受到限制。國際裝甲集團等製造商正在保加利亞擴建車輛工廠,以縮短北約合約的前置作業時間。德國已開始測試配備主動防護系統和模組化複合裙板的豹2 ARC 3.0坦克。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 增加全球國防費用

- 推動航太和國防平台減重

- 新興國家的快速士兵現代化計劃

- 研發一種防彈地形機動車輛

- 對自主地面車輛多打擊混合裝甲的需求日益成長

- 市場限制

- 高昂的加工和品質成本

- 揮發性芳香聚醯胺和超高分子量聚乙烯(UHMWPE)前驅物的供應

- 與全氟烷基和多氟烷基物質 (PFAS) 相關的芳香聚醯胺塗料環境法規

- 價值鏈分析

- 波特五力分析

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

第5章 市場規模與成長預測

- 依纖維類型

- 芳香聚醯胺

- 超高分子量聚乙烯(UHMWPE)

- S-玻璃

- 其他纖維類型(例如,碳纖維、生物基纖維和天然纖維混合物)

- 按矩陣類型

- 聚合物

- 聚合物/陶瓷

- 金屬

- 透過使用

- 裝甲車

- 防彈衣

- 頭盔和臉部防護

- 其他用途(飛機和船舶防護、高性能運動器材等)

- 按地區

- 亞太地區

- 中國

- 日本

- 印度

- 韓國

- 東南亞國協

- 亞太其他地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 俄羅斯

- 北歐國家

- 其他歐洲地區

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 其他中東和非洲地區

- 亞太地區

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率(%)/排名分析

- 公司簡介

- Atomic-6, Inc.

- Avient Corporation

- BAE Systems

- Barrday Inc.

- CoorsTek Inc.

- DuPont

- Gurit Services AG, Zurich

- Hardwire LLC

- Hexcel Corporation

- Honeywell International Inc.

- Integris

- MKU Limited

- Morgan Advanced Materials

- Plastic Reinforcement Fabrics Ltd

- Point Blank Enterprises, Inc.

- Rheinmetall AG

- Roihu Inc.

- Safariland,LLC

- Southern States, llc

- TEIJIN LIMITED

第7章 市場機會與未來展望

The Ballistic Composites Market size is estimated at USD 3.02 billion in 2025, and is expected to reach USD 4.11 billion by 2030, at a CAGR of 6.37% during the forecast period (2025-2030).

Steady gains come from defense modernization, autonomous vehicle shielding, and the aerospace sector's persistent drive to trim airframe mass without sacrificing crew safety. Demand growth concentrates on lighter yet tougher laminate configurations, wider adoption of hybrid fiber lay-ups, and the migration of advanced composite tooling from the aerospace supply chain into armor production lines. Aramid fibers reinforce much of today's armor solutions, while polymer matrices enable manufacturers to balance multi-hit performance with processing flexibility. North America retains its pole position thanks to the United States Army's high-budget soldier modernisation programs and next-generation vehicle platforms that rely on sophisticated armor architectures. Meanwhile, Asia-Pacific commands attention with accelerated procurement of personal protection gear for large infantry forces. Technology launches such as DuPont's Kevlar EXO, which delivers 30% higher tensile strength than standard aramid, showcase the innovation pace that underpins the ballistic composites market.

Global Ballistic Composites Market Trends and Insights

Rise in Global Defence Expenditure

Defense spending escalation across major economies fundamentally reshapes ballistic composites demand patterns, shifting procurement priorities toward advanced materials that deliver superior protection-to-weight ratios. The United States Army's Ground X-Vehicle Technologies program exemplifies this trend, targeting 50% weight reduction while maintaining survivability through innovative composite armor systems rather than traditional steel plating. This strategic pivot reflects military planners' recognition that future combat effectiveness depends on mobility and agility rather than passive armor thickness. Asian defense markets are experiencing parallel modernization drives, with countries like India integrating advanced ballistic helmets into standard infantry equipment, as demonstrated by MKU Limited's delivery of Kavro Doma 360 helmets to the Indian Army in 2025. The procurement shift toward composite materials creates sustained demand growth that transcends traditional cyclical defense spending patterns.

Lightweighting Push in Aerospace and Defence Platforms

Aerospace and defense manufacturers are pursuing aggressive weight reduction strategies that position ballistic composites as critical enablers of next-generation platform performance. Carbon fiber composites in missile applications demonstrate 40-50% weight reductions compared to aluminum alternatives, enabling extended operational ranges and enhanced payload capacities that directly translate to tactical advantages . The trend extends to extreme-temperature hypersonic systems. In 2025, Canopy Aerospace secured a USD 2.8 million U.S. Air Force contract for reusable thermal-protection tiles that withstand ballistic impact during re-entry. Cross-pollination of thermal and ballistic requirements gives the ballistic composites market new growth vectors.

High Processing and Qualification Costs

The ballistic composites industry faces substantial barriers from complex processing requirements and extensive qualification protocols that significantly inflate production costs and market entry thresholds. NIJ Standard 0101.07, implemented in 2024, introduces more rigorous testing methodologies for ballistic-resistant body armor, requiring manufacturers to invest in advanced testing facilities and extended qualification timelines . Military standards such as STANAG 4569 add further complexity with multi-angle, multi-velocity shot matrices that only a handful of laboratories can deliver. Investment in controlled-atmosphere hot presses, fibre tension rigs, and computerised drape forming lines inflates entry costs, favouring incumbents within the ballistic composites market.

Other drivers and restraints analyzed in the detailed report include:

- Rapid Soldier-Modernisation Programmes in Emerging Economies

- Development of Terrain Motor Vehicles With Ballistic Protection

- Volatile Aramid and Ultra-high Molecular Weight Polyethylene (UHMWPE) Precursor Supply

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Aramid fibre held 43.69% share of ballistic composites market size in 2024 and is forecast to expand at a 6.40% CAGR. The latest Kevlar EXO fibre improves tensile strength by 30% while maintaining flame resistance, enabling thinner armour panels and improved soldier mobility. UHMWPE is narrowing the gap, appealing to customers that prioritise weight reduction and moisture resistance. S-glass remains prominent in vehicular armour where high-temperature exposure is common. Competitive tension is intensifying as research laboratories demonstrate carbon-nanotube yarns with dynamic strength above 14 GPa, a level that could redefine the ballistic composites market.

Aramid suppliers defend their position through improved surface treatments that enhance matrix adhesion and through partnerships with fabric weavers that can tailor multiaxial lay-ups for multi-hit scenarios. UHMWPE producers are expanding capacity in Asia to stabilise lead times and costs. Hybrid laminates that blend aramid, UHMWPE, and carbon fibres balance tensile strength, delamination resistance, and thermal robustness. Bio-based fibre initiatives, though still niche, attract defence agencies focused on sustainability targets, signalling the long-term diversification path within the ballistic composites market.

The Ballistic Composites Market Report is Segmented by Fiber Type (Aramids, Ultra-High Molecular Weight Polyethylene, and More), Matrix Type (Polymer, Polymer-Ceramic, and Metal), Application (Vehicle Armor, Body Armor, Helmet and Face Protection, and Others), and Geography (Asia-Pacific, North America, Europe, South America, and Middle East and Africa). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

North America led the ballistic composites market with 43.16% revenue share in 2024 and is expected to grow at a 6.51% CAGR through 2030. The Future Long-Range Assault Aircraft program relies on Integris Composites armour fitted into the Bell V-280 Valor airframe, a clear sign of sustained demand. Robust federal defense budgets, resilient supply chains, and university-backed testing infrastructure underpin regional dominance.

Asia-Pacific is the fastest-scaling region outside North America. China, India, Japan, and South Korea invest in lighter individual protection equipment and domestically produced vehicle armour. India's Light Combat Vehicle program specifies composite applique kits to reduce curb weight, reflecting a shift from steel-only hulls. South Korea integrates fibre-metal laminates in K2 Black Panther tanks to improve mine resistance without weight penalties.

Europe revives timid defence budgets amid heightened security concerns. Manufacturers such as International Armored Group operate an expanded vehicle plant in Bulgaria, ensuring shorter lead times for NATO contracts. Germany tests the Leopard 2 ARC 3.0 with an active protection suite and modular composite skirts, pushing demand for interchangeable composite modules across allied fleets.

- Atomic-6, Inc.

- Avient Corporation

- BAE Systems

- Barrday Inc.

- CoorsTek Inc.

- DuPont

- Gurit Services AG, Zurich

- Hardwire LLC

- Hexcel Corporation

- Honeywell International Inc.

- Integris

- MKU Limited

- Morgan Advanced Materials

- Plastic Reinforcement Fabrics Ltd

- Point Blank Enterprises, Inc.

- Rheinmetall AG

- Roihu Inc.

- Safariland,LLC

- Southern States, llc

- TEIJIN LIMITED

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Rise in Global Defence Expenditure

- 4.2.2 Lightweighting Push in Aerospace and Defence Platforms

- 4.2.3 Rapid Soldier-modernisation Programmes in Emerging Economies

- 4.2.4 Development of Terrain Motor Vehicles With Ballistic Protection

- 4.2.5 Growing Demand for Multi-hit Hybrid Armour for Autonomous Ground Vehicles

- 4.3 Market Restraints

- 4.3.1 High Processing and Qualification Costs

- 4.3.2 Volatile Aramid and Ultra-high Molecular Weight Polyethylene (UHMWPE) Precursor Supply

- 4.3.3 Perfluoroalkyl and Polyfluoroalkyl Substances (PFAS)-related Environmental Regulations on Aramid Finishing

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces Analysis

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts (Value)

- 5.1 By Fiber Type

- 5.1.1 Aramids

- 5.1.2 Ultra-High Molecular Weight Polyethylene (UHMWPE)

- 5.1.3 S-glass

- 5.1.4 Other Fiber Types (Carbon Fiber, Bio-based and Natural Fiber Hybrids, etc.)

- 5.2 By Matrix Type

- 5.2.1 Polymer

- 5.2.2 Polymer-Ceramic

- 5.2.3 Metal

- 5.3 By Application

- 5.3.1 Vehicle Armor

- 5.3.2 Body Armor

- 5.3.3 Helmet and Face Protection

- 5.3.4 Other Applications (Aircraft and Marine Protection, High-performance Sporting Goods, etc.)

- 5.4 By Geography

- 5.4.1 Asia-Pacific

- 5.4.1.1 China

- 5.4.1.2 Japan

- 5.4.1.3 India

- 5.4.1.4 South Korea

- 5.4.1.5 ASEAN Countries

- 5.4.1.6 Rest of Asia-Pacific

- 5.4.2 North America

- 5.4.2.1 United States

- 5.4.2.2 Canada

- 5.4.2.3 Mexico

- 5.4.3 Europe

- 5.4.3.1 Germany

- 5.4.3.2 United Kingdom

- 5.4.3.3 France

- 5.4.3.4 Italy

- 5.4.3.5 Spain

- 5.4.3.6 Russia

- 5.4.3.7 NORDIC Countries

- 5.4.3.8 Rest of Europe

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Rest of South America

- 5.4.5 Middle East and Africa

- 5.4.5.1 Saudi Arabia

- 5.4.5.2 South Africa

- 5.4.5.3 Rest of Middle East and Africa

- 5.4.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share(%)/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Atomic-6, Inc.

- 6.4.2 Avient Corporation

- 6.4.3 BAE Systems

- 6.4.4 Barrday Inc.

- 6.4.5 CoorsTek Inc.

- 6.4.6 DuPont

- 6.4.7 Gurit Services AG, Zurich

- 6.4.8 Hardwire LLC

- 6.4.9 Hexcel Corporation

- 6.4.10 Honeywell International Inc.

- 6.4.11 Integris

- 6.4.12 MKU Limited

- 6.4.13 Morgan Advanced Materials

- 6.4.14 Plastic Reinforcement Fabrics Ltd

- 6.4.15 Point Blank Enterprises, Inc.

- 6.4.16 Rheinmetall AG

- 6.4.17 Roihu Inc.

- 6.4.18 Safariland,LLC

- 6.4.19 Southern States, llc

- 6.4.20 TEIJIN LIMITED

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-Need Assessment

- 7.2 Development of Bio-Based Ballistic Fibers

![防彈複合材料市場:趨勢、機會與競爭分析 [2024-2030]](/sample/img/cover/42/default_cover_5.png)