|

市場調查報告書

商品編碼

1851528

化妝品包裝:市場佔有率分析、行業趨勢、統計數據和成長預測(2025-2030 年)Cosmetic Packaging - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

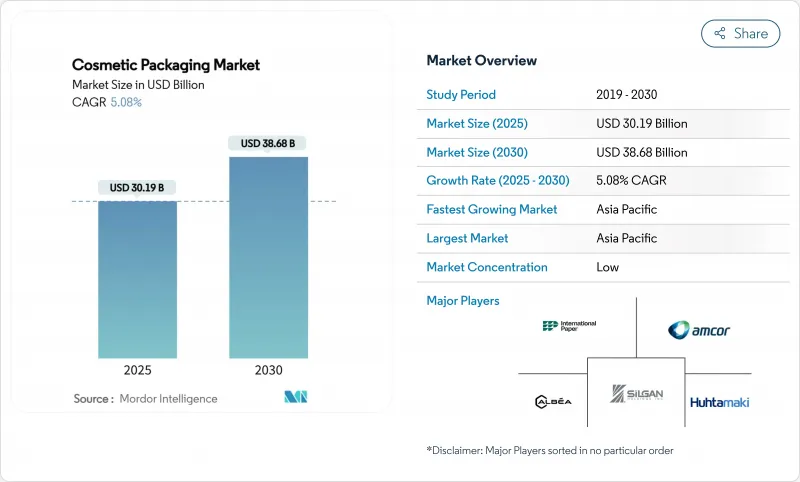

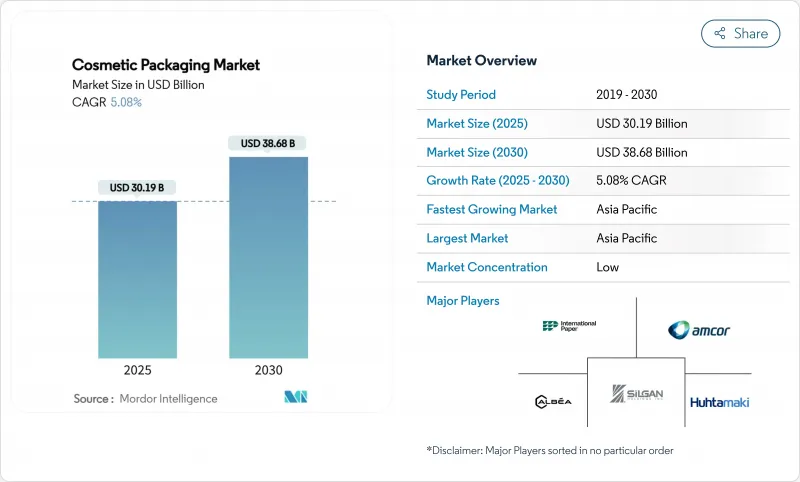

預計到 2025 年,化妝品包裝市場規模將達到 301.9 億美元,到 2030 年將成長至 386.8 億美元。

這反映了各大品牌對歐盟《包裝廢棄物法規》的回應。該法規將於2025年2月生效,強制要求包裝可回收並遵守生產者延伸責任制。由於地緣政治緊張局勢以及中國和歐洲的減產,聚對苯二甲酸乙二醇酯(PET)成本不斷上漲,各大品牌正在加速使用再生材料和輕量化設計。亞太地區仍是成長引擎,這得歸功於消費者日益成熟的消費習慣和強大的電商物流體系。面膜在中國的成功以及韓國和日本的優質化,都反映了該地區的影響力。雖然塑膠仍保持著成本優勢,但玻璃包裝憑藉其奢華感、可重複填充性以及循環經濟的優勢,正在蓬勃發展。同時,諸如安姆科(Amcor)和貝瑞全球(Berry Global)84.3億美元的合併等整合,正在將規模優勢與研發能力相結合,加速永續包裝的推廣應用。

全球化妝品包裝市場趨勢與洞察

高階和輕奢美容產品的消費量不斷增加

觸感豐富的飾面、質感上乘的玻璃和精美的瓶蓋塑造了品牌故事,將奢侈品帶入主流管道。為迎接2025年世界補充裝日,歐萊雅在五年內將其填充用產品種類增加了17倍,同時並未降低其高階定位。雅詩蘭黛旗下71%的產品均採用永續包裝,顯示環保與奢華可以並存。因此,供應商優先考慮能夠承受高階配方的高純度玻璃泵和一體式泵。這項機會也延伸至補充裝套件,它們能夠確保後續銷售並提高淨利率。奢侈品牌對環保性能的重視提高了化妝品包裝市場所有細分領域的標準。

轉向更適合電子商務的輕量級格式

抗破損性以及尺寸和重量上的節省是推動線上銷售的關鍵因素。由於軟包裝袋可以平放運輸,減少空隙填充和運輸成本,其複合年成長率高達7.67%。 KISS Cosmetics 在其佔地48萬平方英尺的工廠中實現了自動化,配備了智慧揀選車和A型架分發器,充分展現了採用統一輕便包裝在物流配送方面的履約優勢。預計到2032年,包裝機器人領域的投資將達到75億美元,凸顯了自動化在最佳化多SKU產品流轉的重要角色。針對宅配網路而非零售貨架進行最佳化的品牌,能夠確保更快的周轉時間和更低的排放,進而增強全球化妝品包裝市場抵禦物流不穩定的能力。

全球再生樹脂價格波動

2024年,由於反傾銷法規收緊供應,迫使加工商展開競標競價,歐洲PET價格徘徊在每噸1,130歐元至1,170歐元之間。 2025年初,由於原料成本上漲,聚乙烯和聚丙烯的價格分別上漲了每磅5美分和4美分。因此,承諾50%回收率的品牌可以吸收利潤衝擊,或透過垂直整合(例如自建清洗廠)來對沖風險。由於高品質食品級消費後再生樹脂(PCR)價格較高,供應風險可能限制設計自由度,並延緩化妝品包裝市場對原生樹脂的替代。

細分市場分析

由於成本效益、透明度和生產線速度相容性,塑膠將在2024年佔據化妝品包裝市場64.58%的佔有率。聚對苯二甲酸乙二醇酯用於個人護理瓶,聚丙烯用於泵桿和瓶蓋,低密度聚乙烯用於軟管。然而,玻璃將領先,到2030年將以8.67%的複合年成長率成長,這主要得益於奢侈品牌對玻璃堅固手感、耐刮擦性和無限可回收性的追求。高階消費趨勢將推動玻璃化妝品包裝實現兩位數的收入佔有率,即使其包裝總量低於塑膠。玻璃回收計劃,例如雅詩蘭黛與Strategic Materials的合作,提高了玻璃屑的品質和熔爐產量比率,從而減輕了環境方面的批評。 [2] 金屬化鋁和鋼仍主要應用於香水和禮品包裝領域,其優異的阻隔性能和清爽的觸感使其在貨架上脫穎而出。纖維板在運輸包裝和禮品套裝中的應用日益廣泛,滿足了電子商務的緩衝需求,且無需承擔塑膠稅的額外負擔。

第二代材料模糊了不同類別之間的界線。曾經用於軟管的多層PET鋁塑複合材料正逐漸被單層EVOH阻隔PET取代,後者更易於回收。聚乳酸等生物基樹脂正被用於限量版標籤的試驗,但其耐熱性和填充線摩擦力不足,限制了其規模化應用。那些能夠克服這些障礙的供應商所取得的早期成功,反映出永續性表現如今已成為化妝品包裝市場供應商選擇的重要標準。同時,可回收玻璃瓶項目以及填充用站的出現,顯示高階品質和低環境影響的目標正在融合,推動玻璃瓶進入更主流的產品系列。

2024年,瓶裝和罐裝產品的銷售額將成長44.56%,這主要得益於快速填充速度和消費者的熟悉度。寬口罐裝產品仍將主導乳霜市場,而窄口寶特瓶在洗髮精和卸妝水中佔據主導地位。然而,小袋和立式袋也將實現7.67%的強勁成長,它們不僅減少了每次使用的容量,也降低了宅配運輸過程中破損的風險。輕量化技術使品牌能夠將每月的包裝量從一瓶減少到每信封五袋,從而降低運輸排放。管狀和棒狀產品迎合了防曬油、固態精華和潤色膏的需求,符合旅行裝容量規定和零洩漏要求。折疊式紙盒是玻璃瓶和精華液管瓶的理想包裝選擇,其柔軟的塗層和燙金工藝營造出高階質感,傳遞品牌理念。

運輸包裝盒也將隨之演變。瓦楞紙板供應商正在引入演算法製盒技術來減少填充物,並藉助Packsize機器即時切割紙板,使其尺寸與訂單一致。消費者的開箱體驗將使全通路體驗脫穎而出,並鼓勵使用印有2D碼的插頁,從而觸發數位會員獎勵。軟包裝上的阻隔塗層將升級為二氧化矽和氧化鋁,以確保香氣保持並減少氧氣透過,同時又不影響可回收性。諸如此類的進步將拓展化妝品軟包裝市場,並重新定義大眾高階包裝的美學,使其不再局限於硬質容器。

化妝品包裝市場按材料類型(塑膠、玻璃、金屬、紙/紙板)、產品類型(瓶/罐、管/棒、折疊式紙盒、瓦楞紙箱、其他)、分配方式(泵、滴管/吸管、噴霧/霧化、其他)、化妝品類型(護髮、彩妝品、護膚、其他)和地區進行細分。市場規模和預測以美元計價。

區域分析

亞太地區預計到2024年將佔全球化妝品包裝市場收入的42.89%,並在2030年之前以7.45%的複合年成長率成長,這主要得益於可支配收入的增加、韓式美妝的普及以及行動商務的高滲透率。面膜在中國市場的主導地位反映了當地消費者對一次性使用且包裝精緻的產品的需求,使該地區成為簡約實用型包裝袋的熱門市場。日本和韓國正在向全球輸出氣墊粉底和纖細旋轉膏等設計理念,這使得該地區的包裝加工商擁有先發優勢。

由於高階護膚的普及和電子商務的快速發展,北美市場保持著強勁的價值。專業美妝零售商正在試行填充用站,玻璃墨盒供應商也贏得了新的服務合約。自動化解決方案正在推動機器人友善紙板標籤和無底紙標籤的廣泛應用。各州層級的塑膠減量立法正在加速向輕量化、單一材料解決方案的轉變,並引導投資流向再生PET和纖維替代品。儘管成熟品類已滲透到市場,但這些趨勢仍在推動化妝品包裝市場蓬勃發展。

歐洲正在建立具有全球影響力的法律規範。在法國,PPWR(包裝材料回收條例)的實施和不斷上漲的環保費用明確了包裝可回收性的閾值,加速了對可拆卸設計的投資。法國和義大利的奢侈香水叢集正在積極推動玻璃創新,例如用於減少刮痕的先進熱端塗層。同時,中歐和東歐正在擴大瓶體成型產能,以滿足本地品牌和出口生產的需求。世界各地不同的企業正在影響材料策略和技術轉移速度,從而推動化妝品包裝市場的需求。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 高階和輕奢美容產品的消費量不斷增加

- 轉向更適合電子商務的輕量級格式

- 高階通路中可填入/可重複使用配送系統的興起

- 具備認證功能的智慧包裝可遏止假冒仿冒品

- 品牌對符合碳標籤標準的包裝的需求

- 第三方物流履約中機器人輔助二次包裝的快速普及

- 市場限制

- 全球再生樹脂價格上漲

- 一次性塑膠製品的監管上限

- 新型生物材料與填充線的不相容性

- 掩埋容量減少導致生產者責任費擴大

- 供應鏈分析

- 監管環境

- 技術展望

- 波特五力分析

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭對手之間的競爭

第5章 市場規模與成長預測

- 依材料類型

- 塑膠

- 聚對苯二甲酸乙二醇酯(PET)

- 聚丙烯

- 聚乙烯(PE)

- 其他塑膠

- 玻璃

- 金屬

- 紙和紙板

- 塑膠

- 依產品類型

- 瓶子和罐子

- 管子和棍子

- 折疊式紙盒

- 瓦楞紙箱

- 軟性包裝袋

- 其他產品類型

- 透過分配機制

- 泵浦底座

- 滴管/移液器

- 噴霧/霧

- 黏/扭轉向上

- 罐子/湯匙

- 依化妝品類型

- 護膚

- 臉部保養

- 身體保養

- 護髮

- 彩妝品

- 香水及香氛

- 其他化妝品類型

- 護膚

- 按地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 俄羅斯

- 其他歐洲地區

- 亞太地區

- 中國

- 日本

- 印度

- 韓國

- 澳洲

- 亞太其他地區

- 中東和非洲

- 中東

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 土耳其

- 其他中東地區

- 非洲

- 南非

- 奈及利亞

- 肯亞

- 其他非洲地區

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 北美洲

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率分析

- 公司簡介

- Albea SA

- AptarGroup Inc.

- Amcor Group GmbH

- Silgan Holdings Inc.

- DS Smith PLC

- Graham Packaging LP

- Quadpack Industries SA

- Libo Cosmetics Co. Ltd

- Gerresheimer AG

- Ball Corporation

- Verescence France SA

- SKS Bottle & Packaging Inc.

- Altium Packaging

- Cosmopak Ltd

- Raepak Ltd

- Rieke Corporation

- Essel Propack Ltd

- Huhtamaki Oyj

- Alpla Werke Alwin Lehner GmbH

- RPC M&H Plastics

- HCP Packaging Co. Ltd

第7章 市場機會與未來展望

The cosmetic packaging market size reached USD 30.19 billion in 2025 and is set to climb to USD 38.68 billion by 2030, reflecting a steady 5.08% CAGR.

The advance mirrors brand responses to the European Union's Packaging and Packaging Waste Regulation, effective February 2025, which obliges recyclability and extended producer responsibility compliance. Brands counter rising polyethylene terephthalate costs driven by geopolitical tension and production cuts in China and Europe by accelerating recycled-content usage and lightweight designs. Asia-Pacific remains the growth engine, propelled by sophisticated consumer routines and strong e-commerce logistics; Chinese facial sheet-mask success and premiumization across South Korea and Japan typify the region's influence. Material choice continues to bifurcate: plastics retain cost leadership while glass advances on luxury, refillable, and circular-economy appeal. Meanwhile, corporate consolidation highlighted by Amcor's USD 8.43 billion merger with Berry Global bundles scale and R&D to quicken sustainable-packaging rollouts.

Global Cosmetic Packaging Market Trends and Insights

Growing Consumption of Premium and Masstige Beauty Products

Luxury cues have migrated into mainstream channels as tactile finishes, heavy-wall glass, and ornate closures shape brand storytelling. L'Oreal's 2025 World Refill Day push lifted refillable options seventeen-fold in five years without diluting premium positioning. Estee Lauder already supplies 71% of its portfolio in sustainable formats, confirming that environmental progress and upscale image can co-exist. Suppliers thus prioritise high-clarity glass and mono-material pumps that tolerate prestige formulations. The opportunity extends to refill kits that guarantee adjacency sales and invite higher margins. Luxury's embrace of environmental performance raises the bar for all tiers of the cosmetic packaging market.

Shift Toward E-commerce-Friendly Lightweight Formats

Online sales make damage resistance and dimensional-weight savings decisive. Flexible pouches grow at 7.67% CAGR because they ship flat, cut void fill, and slash freight spend. KISS Cosmetics automated its 480,000 ft2 facility with intelligent cart-picking and A-Frame dispensing, demonstrating fulfilment economics that favour uniform, lighter packs. Packaging-robot investments are projected to reach USD 7.5 billion by 2032, underlining automation's role in smoothing multi-SKU flows. Brands that optimise for courier networks rather than retail shelves secure faster cycle times and lower emissions, fortifying the global cosmetic packaging market against logistics volatility.

Escalating Global Recycled-Resin Price Volatility

European PET hovered at EUR 1,130-1,170 per t in 2024 as anti-dumping rules tightened supply, forcing converters into spot-market bidding wars. Polyethylene and polypropylene followed with five-cent and four-cent per-lb upticks in early 2025 as feedstock costs rose. Brands with 50%-recycled-content pledges thus absorb margin shocks or hedge via vertical integration, such as on-site washing plants. Because high-quality food-grade PCR commands premiums, availability risk constrains design freedom and may slow substitutions away from virgin resin in the cosmetic packaging market.

Other drivers and restraints analyzed in the detailed report include:

- Rise of Refillable/Reusable Delivery Systems in Prestige Channels

- Rapid Adoption of Robot-Ready Secondary Packs in 3-PL Fulfilment

- Regulatory Caps on Single-Use Plastic

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Plastics held a 64.58% cosmetic packaging market share in 2024 thanks to cost efficiency, clarity, and line-speed compatibility. Polyethylene terephthalate leads for personal-care bottles, polypropylene secures pump stems and closures, while low-density polyethylene shapes flexible tubes. Yet glass races ahead at 8.67% CAGR to 2030 because prestige brands crave heft, scratch resistance, and infinite recyclability. The premium shift lifts the cosmetic packaging market size for glass to meaningful double-digit revenue slices even as total pack count stays lower than plastic. Glass-recycling initiatives such as Estee Lauder's work with Strategic Materials Inc.improve cullet quality and furnace yields, soothing environmental criticisms[2]. Metallised aluminium and steel remain niche for fragrances and gifting editions where barrier performance and tactile coolness drive shelf impact. Fibre-based board escalates in transit shippers and gift sets, answering e-commerce cushioning needs without raising plastic tax exposure.

Second-generation materials blur lines between categories. Multi-layer PET-aluminium laminates once seen in tubes migrate toward mono-material EVOH-barrier PET that retains recycling stream compatibility. Bio-sourced resins such as polylactic acid win trial runs for limited-edition labels but still battle heat resistance and filling-line friction, limiting scale. Suppliers addressing these hurdles gain early-mover contracts, reflecting how sustainability performance now shapes vendor selection criteria across the cosmetic packaging market. Meanwhile, returnable glass programs aligned with refill stations exemplify how premium credentials fuse with low-impact ambitions to pull glass farther into mainstream assortments.

Bottles and jars delivered 44.56% revenue in 2024, supported by high filling speeds and shopper familiarity. Wide-mouth jars continue to anchor face creams, while narrow-neck PET bottles dominate shampoos and micellar waters. However, sachets and stand-up pouches compound at a brisk 7.67% CAGR, cutting grams per dose and resisting breakage during courier drops. Right-size technology lets brands switch from one bottle-per-month to five flat sachets per envelope, lowering freight-emissions intensity. Tubes and sticks address on-the-go sunscreen, solid serum, and colour-balm trends, meshing with travel-size regulation and zero-leak expectations. Folding cartons remain favoured in luxury presentations, housing glass flacons or booster vials while conveying brand narratives through soft-touch varnish and foil embossing.

Transit boxes evolve too. Corrugated suppliers deploy algorithmic box-making to trim void fill, supported by Packsize machines that cut board in line with real-time order dimensions. Consumer unboxing gains differentiate omnichannel experiences, prompting QR-printed inserts that trigger digital loyalty rewards. Flexible-pack barrier coatings upgrade to silicon oxide or aluminium oxide, securing fragrance retention and reducing oxygen transmission without disqualifying recyclability. Such advances swell the cosmetic packaging market size credited to flexible formats and re-define mass-premium aesthetics away from solely rigid containers.

Cosmetic Packaging Market is Segmented by Material Type (Plastic, Glass, Metal, Paper and Paperboard), Product Type (Bottles and Jars, Tubes and Sticks, Folding Cartons, Corrugated Transit Boxes, and More), Dispensing Mechanism (Pump-Based, Dropper / Pipette, Spray / Mist, and More), Cosmetic Type (Hair Care, Color Cosmetics, Skin Care, and More), and Geography. The Market Sizes and Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific owned 42.89% of cosmetic packaging market revenue in 2024 and will grow at a 7.45% CAGR to 2030, lifted by rising disposable income, advanced K-beauty regimens, and high mobile-commerce penetration. Sheet-mask dominance in China illustrates local appetite for single-use but sophisticated pack forms, making the region a hotbed for minimalist yet functional pouches. Japan and South Korea export design cues globally, such as airless cushion compacts and slim twist balms, giving regional converters first-mover advantages.

North America holds firm value through premium skincare adoption and rapid e-commerce. Refill station pilots appear in beauty specialty retailers, rewarding glass cartridge suppliers with new service contracts. Automation readiness drives widespread acceptance of robot-friendly corrugate and linerless labels. State-level plastic-reduction bills add urgency to lightweight mono-material shifts, redirecting investment towards recycled-content PET and fibre substitution. These moves keep the cosmetic packaging market buoyant despite mature category penetration.

Europe shapes regulatory frameworks that ripple worldwide. Enforcement of the PPWR and escalating eco-contribution fees in France imposes clear packaging recyclability thresholds, accelerating investment in design for disassembly. Luxury fragrance clusters in France and Italy champion glass innovation, including advanced hot-end coating for scratch reduction. Meanwhile, Central and Eastern Europe attract bottle moulding capacity expansions to serve both local brands and export production. Collectively, global regions influence material strategies and technology transfer rates, interlocking demand drivers for the cosmetic packaging market.

- Albea SA

- AptarGroup Inc.

- Amcor Group GmbH

- Silgan Holdings Inc.

- DS Smith PLC

- Graham Packaging LP

- Quadpack Industries SA

- Libo Cosmetics Co. Ltd

- Gerresheimer AG

- Ball Corporation

- Verescence France SA

- SKS Bottle & Packaging Inc.

- Altium Packaging

- Cosmopak Ltd

- Raepak Ltd

- Rieke Corporation

- Essel Propack Ltd

- Huhtamaki Oyj

- Alpla Werke Alwin Lehner GmbH

- RPC M&H Plastics

- HCP Packaging Co. Ltd

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Growing consumption of premium and masstige beauty products

- 4.2.2 Shift toward e-commerce-friendly lightweight formats

- 4.2.3 Rise of refillable / reusable delivery systems in prestige channels

- 4.2.4 Authentication-enabled smart packaging to curb counterfeits

- 4.2.5 Brand demand for carbon-label-ready packs

- 4.2.6 Rapid adoption of robot-ready secondary packs in 3-PL fulfilment

- 4.3 Market Restraints

- 4.3.1 Escalating global recycled-resin price volatility

- 4.3.2 Regulatory caps on single-use plastics

- 4.3.3 Filling-line incompatibility of novel bio-materials

- 4.3.4 Shrinking landfill capacity driving extended-producer-responsibility fees

- 4.4 Supply-Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Threat of New Entrants

- 4.7.4 Threat of Substitute Products

- 4.7.5 Intensity of Competitive Rivalry

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Material Type

- 5.1.1 Plastics

- 5.1.1.1 Polyethylene Terephthalate (PET)

- 5.1.1.2 polypropylene (PP)

- 5.1.1.3 Polyethylene (PE)

- 5.1.1.4 Other Plastics

- 5.1.2 Glass

- 5.1.3 Metal

- 5.1.4 Paper and Paperboard

- 5.1.1 Plastics

- 5.2 By Product Type

- 5.2.1 Bottles and Jars

- 5.2.2 Tubes and Sticks

- 5.2.3 Folding Cartons

- 5.2.4 Corrugated Transit Boxes

- 5.2.5 Flexible Sachets and Pouches

- 5.2.6 Other Product Type

- 5.3 By Dispensing Mechanism

- 5.3.1 Pump-based

- 5.3.2 Dropper / Pipette

- 5.3.3 Spray / Mist

- 5.3.4 Stick / Twist-up

- 5.3.5 Jar / Scoop

- 5.4 By Cosmetic Type

- 5.4.1 Skin Care

- 5.4.1.1 Facial Care

- 5.4.1.2 Body Care

- 5.4.2 Hair Care

- 5.4.3 Color Cosmetics

- 5.4.4 Perfumes and Fragrances

- 5.4.5 Other Cosmetics Type

- 5.4.1 Skin Care

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 Europe

- 5.5.2.1 Germany

- 5.5.2.2 United Kingdom

- 5.5.2.3 France

- 5.5.2.4 Italy

- 5.5.2.5 Spain

- 5.5.2.6 Russia

- 5.5.2.7 Rest of Europe

- 5.5.3 Asia-Pacifc

- 5.5.3.1 China

- 5.5.3.2 Japan

- 5.5.3.3 India

- 5.5.3.4 South Korea

- 5.5.3.5 Australia

- 5.5.3.6 Rest of Asia-Pacific

- 5.5.4 Middle East and Africa

- 5.5.4.1 Middle East

- 5.5.4.1.1 Saudi Arabia

- 5.5.4.1.2 United Arab Emirates

- 5.5.4.1.3 Turkey

- 5.5.4.1.4 Rest of Middle East

- 5.5.4.2 Africa

- 5.5.4.2.1 South Africa

- 5.5.4.2.2 Nigeria

- 5.5.4.2.3 Kenya

- 5.5.4.2.4 Rest of Africa

- 5.5.5 South America

- 5.5.5.1 Brazil

- 5.5.5.2 Argentina

- 5.5.5.3 Rest of South America

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Albea SA

- 6.4.2 AptarGroup Inc.

- 6.4.3 Amcor Group GmbH

- 6.4.4 Silgan Holdings Inc.

- 6.4.5 DS Smith PLC

- 6.4.6 Graham Packaging LP

- 6.4.7 Quadpack Industries SA

- 6.4.8 Libo Cosmetics Co. Ltd

- 6.4.9 Gerresheimer AG

- 6.4.10 Ball Corporation

- 6.4.11 Verescence France SA

- 6.4.12 SKS Bottle & Packaging Inc.

- 6.4.13 Altium Packaging

- 6.4.14 Cosmopak Ltd

- 6.4.15 Raepak Ltd

- 6.4.16 Rieke Corporation

- 6.4.17 Essel Propack Ltd

- 6.4.18 Huhtamaki Oyj

- 6.4.19 Alpla Werke Alwin Lehner GmbH

- 6.4.20 RPC M&H Plastics

- 6.4.21 HCP Packaging Co. Ltd

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-Space and Unmet-Need Assessment