|

市場調查報告書

商品編碼

1851463

工業塗料:市場佔有率分析、產業趨勢、統計數據和成長預測(2025-2030 年)Industrial Coatings - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

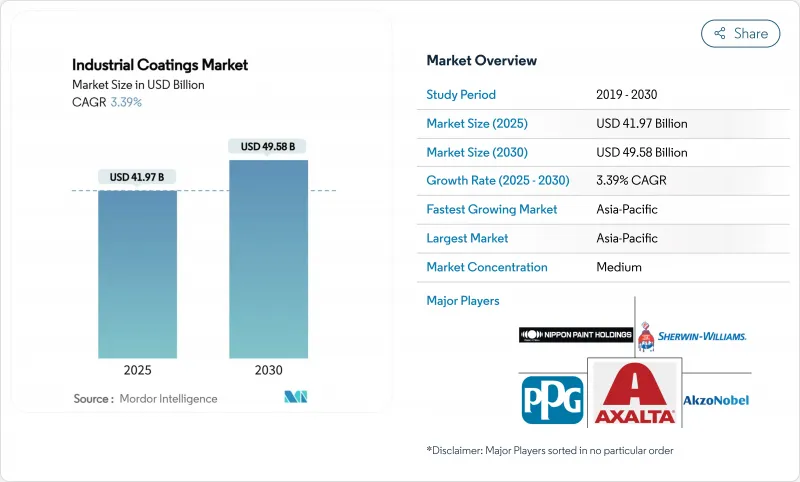

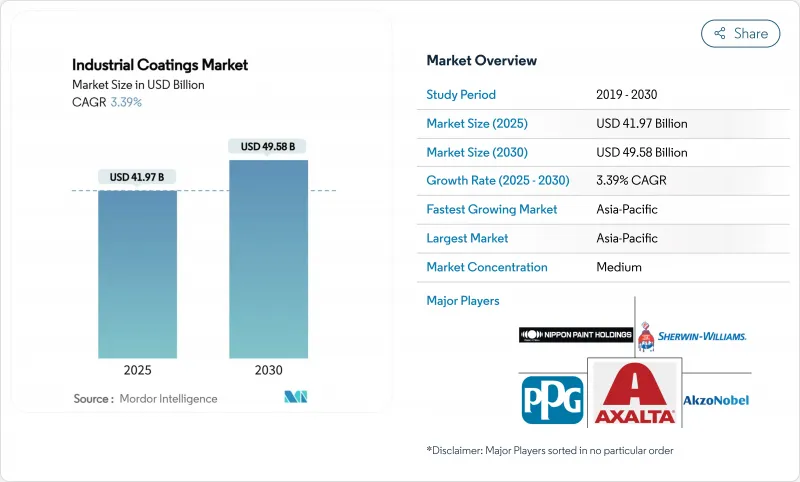

預計到 2025 年,工業塗料市場規模將達到 419.7 億美元,到 2030 年將達到 495.8 億美元,預測期(2025-2030 年)複合年成長率為 3.39%。

這項市場成長動能主要得益於奈米技術的加速應用,奈米技術在提升塗料性能的同時還能減少材料用量;此外,永續的水性塗料和粉末塗料技術也迅速取代溶劑型產品。亞太地區將在2024年佔據51%的市場佔有率,這主要得益於中國和印度的大規模基礎設施投資以及製造業的成長。環氧樹脂因其優異的耐化學性和黏合性,已成為能源、基礎設施和重工業等高性能應用領域不可或缺的材料,預計將以6%的複合年成長率成長,佔據31%的市場佔有率。在全球範圍內,日益嚴格的揮發性有機化合物(VOC)法規正促使製造商加速研發低VOC和零VOC化學品。同時,隨著主要供應商收購專業公司以擴大其區域覆蓋範圍和技術實力,產業整合也在加速進行。

全球工業塗料市場趨勢與洞察

防護塗層需求不斷成長:防蝕驅動創新

隨著資產所有者將耐久性和生命週期成本管理置於優先地位,防護塗層變得至關重要。例如,NEI 公司的 NANOMYTE TC-3001 等產品可在極少維護的情況下提供長達 15 年的耐腐蝕性,使營運商能夠推遲資本密集的更換。下游煉油廠、化工廠和海上平台擴大指定使用多層環氧樹脂和富鋅體系,這些體系既能提供屏障保護,又能提供陰極保護。將感測器整合到這些塗層中,正在將維護策略從被動檢測轉向預測分析,從而在確保安全的同時減少非計劃性停機時間。同時,各國政府正在強制要求公共基礎設施擁有更長的使用壽命,這推動了對能夠抵禦沿海鹽度、除冰鹽和工業污染物的下一代解決方案的需求。這些動態共同強化了市場動態,促使研究重點轉向在不增加膜厚或固化時間的情況下延長塗層壽命。

在石油和天然氣產業不斷拓展的應用:針對嚴苛條件量身訂做的解決方案

深水和高溫油井的限制限制了傳統塗料的應用,促使人們致力於研發混合化學塗料,將環氧酚醛樹脂與陶瓷和矽酮組分相結合,以增強其對碳氫化合物和超過150 度C高溫的耐受性。 PPG的專有系統可在單一整合方案中保護海底管線免受酸性氣體的侵蝕,同時為上部結構提供膨脹型防火保護。塗料設計也在不斷發展,以承受大規模二氧化碳捕集與儲存(CCS)計劃中預期的高壓二氧化碳流。中東地區的本地供應商正在獲得這些先進技術的許可,以滿足該地區快速成長的鑽井專案需求,但嚴格的認證通訊協定意味著產品推廣週期較長。隨著產業投資於數位孿生技術以保護資產,具有嵌入式遠端狀態監測功能的塗料在油氣產業的工業塗料市場中變得越來越普遍,並具有重要的戰略意義。

溶劑型塗料對環境的有害影響:監管壓力加速轉型

在美國和歐洲經濟區,針對揮發性有機化合物 (VOC) 的新法規已經訂定,收緊了工業塗裝車間的排放,迫使操作人員安裝減排設備或改用低溶劑替代品。因此,水性塗料和粉末塗料的市場需求日益成長,即使是小面積塗料也是如此。供應商維修現有分散生產線而非新建溶劑型設施,這表明他們對生命週期成本進行了審慎的考量,並相信環境合規支出將顯著轉向替代化學品。隨著參與企業憑藉永續性資質贏得多年供應契約,這進一步強化了反饋機制,使得符合監管要求成為市場准入的先決條件,而非競爭優勢。

細分市場分析

預計到2024年,環氧塗料將佔工業塗料市場31%的佔有率,而聚氨酯塗料的複合年成長率將達到5.02%,顯著高於整個行業的平均水平。聚氨酯塗料的領先地位歸功於其卓越的附著力、耐化學性和與多種基材的相容性,使其在煉油廠、污水廠和加工廠等場所得到廣泛應用。奈米二氧化矽改質環氧樹脂正在興起,它不僅具有優異的耐磨性,還能維持低VOC含量,滿足了監管機構對更環保解決方案的需求。相較之下,聚氨酯樹脂的市場佔有率正在逐步擴大,尤其是在對紫外線穩定性和柔韌性要求較高的室外應用領域,例如風力發電機塔架和鐵路車輛。丙烯酸乳化。

環氧樹脂供應商正增加研發投入,以縮短重塗週期,並滿足日益加快的計劃進度。耐濕無溶劑酚醛環氧樹脂在海上平台上的應用日益廣泛,有效減少了因天氣原因造成的延誤。同時,埃洛石奈米管增強技術在不改變配方黏度的前提下,顯著提升了塗料的耐鹽霧性能,吸引了致力於實現30年使用壽命目標的管道業主。總而言之,這些技術進步鞏固了工業塗料市場對環氧樹脂化學在關鍵服務運作中的依賴,同時也為聚氨酯和丙烯酸工業創新者在更具挑戰性的環境中提供了新的商機。

在工業塗料市場,溶劑型塗料預計到2024年將保持37%的市場佔有率,而水性塗料由於其在不同氣候帶的優異性能,將實現4.89%的複合年成長率。然而,隨著承包商逐漸適應更低的溶劑含量、更少的異味以及更安全的使用要求,水性塗料目前在維護性重塗領域佔據了更大的佔有率。預計到2030年,隨著歐洲和北美更嚴格的VOC法規過渡期的結束,水性塗料在重型設備工業塗料市場的佔有率將進一步成長。無溶劑粉末塗料持續快速成長,廣泛應用於農業機械和家用電器的外表面。宣偉公司的Powdura ECO系列產品在不犧牲耐腐蝕性的前提下,融入了再生聚對苯二甲酸乙二醇酯(rPET),展現了永續創新,與品牌所有者對循環經濟的承諾相契合。

紫外光固化塗料可即時施工,並可減少高達95%的烘箱能耗,因此在地板、電子機殼和金屬包裝等領域越來越受歡迎。然而,視線限制和基板溫度敏感度限制了其在複雜幾何形狀中的應用。在更廣泛的工業塗料市場中,資產所有者優先考慮的是總應用成本、性能和法規合規性,這促使許多企業採用混合方法,將水性底漆與溶劑型或聚氨酯面漆混合,以實現性能平衡。在預測期內,配方師可望改善無胺促進劑和快乾醇酸乳液,從而進一步推動水性塗料在工業塗料市場的成長。

區域分析

預計到2024年,亞太地區將佔據工業塗料市場51%的佔有率,並在2030年之前以4.31%的複合年成長率成長。中國正大力投資石化綜合體和電動車製造,而印度的國家基礎建設也推動了公路、機場和鐵路塗料的需求。跨國供應商正在推進本地化生產,以規避關稅並縮短前置作業時間,越南和泰國最近成立的合資企業便是例證,該合資企業將樹脂聚合和麵漆調配集中在同一廠房內進行。

在北美,銷售量成長放緩,但隨著資產所有者轉向高階、高固含量技術,銷售額卻顯著提升。 PPG以5.5億美元的價格出售了美國和加拿大的建築塗料業務,使經營團隊能夠將資金重新部署到其工業塗料產品組合中,包括採用機器人技術的粉末生產線。加拿大的脫碳藍圖也鼓勵使用低揮發性有機化合物(VOC)和可再生電力進行生產。

在嚴格的揮發性有機化合物(VOC)法規和雄心勃勃的氣候中和目標的推動下,歐洲仍然是技術領域的領導者。BASF決定將其位於德國和荷蘭的主要塗料工廠全部採用再生能源,每年可減少11,000噸二氧化碳排放,從而增強其對尋求減少範圍3排放的原始設備製造商(OEM)的價值提案。該地區也正在見證以非食用油料作物為原料的生物基醇酸樹脂的早期商業化,儘管工業客戶要求在廣泛應用之前進行嚴格的耐久性檢驗。

儘管中東和非洲的市場佔有率較小,但其成長速度卻最高,這主要得益於沙烏地阿拉伯NEOM等大型企劃對先進金屬和混凝土防護系統的需求。當地配方商正與跨國技術合作夥伴攜手,以滿足高鹽度、高紫外線沙漠環境中嚴苛的防火防腐蝕要求。以巴西為首的南美洲正受益於石化投資和持續的都市化,儘管宏觀經濟的不確定性限制了公共部門的資本支出。在全部區域,知識轉移計畫和本地培訓計畫正在提升施工人員的技能水平,而這正是充分發揮現代工業塗料性能潛力的關鍵因素。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 對防護塗料的需求不斷成長

- 在石油和天然氣產業中不斷擴展的應用

- 基礎設施建設和都市化

- 電力和海事領域的需求不斷成長

- 人們對美感價值重要性的認知日益增強

- 市場限制

- 溶劑型塗料對環境的有害影響

- 原物料價格波動

- 替代塗料產品的供應情況

- 價值鏈分析

- 監理展望

- 波特五力模型

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

第5章 市場規模與成長預測

- 依樹脂類型

- 環氧樹脂

- 聚氨酯

- 丙烯酸纖維

- 聚酯纖維

- 其他樹脂(醇酸樹脂、氟樹脂、乙烯基酯樹脂)

- 透過技術

- 溶劑型

- 水溶液

- 粉末

- 紫外線技術

- 按最終用途行業分類

- 一般工業

- 保護塗層

- 石油和天然氣

- 礦業

- 電力

- 基礎設施

- 其他保護塗層

- 按基礎材料

- 金屬

- 具體的

- 按地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- ASEAN

- 澳洲

- 紐西蘭

- 亞太其他地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 俄羅斯

- 北歐國家

- 其他歐洲地區

- 南美洲

- 巴西

- 阿根廷

- 智利

- 其他南美洲

- 中東和非洲

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 土耳其

- 南非

- 奈及利亞

- 其他中東和非洲地區

- 亞太地區

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率分析

- 公司簡介

- 3M

- AkzoNobel NV

- Arkema

- Asian Paints

- Axalta Coating Systems

- BASF SE

- Beckers Group

- Chugoku Marine Paints Ltd.

- Daikin Industries Ltd.

- Hempel A/S

- Henkel AG & Co. KGaA

- Jotun

- Kansai Paint Co., Ltd.

- Nippon Paint Holdings Co., Ltd.

- OC Oerlikon Management AG

- PPG Industries, Inc.

- RPM International Inc.

- Rust-Oleum Corporation

- Sika AG

- The Sherwin-Williams Company

- Tikkurila

- Wacker Chemie AG

第7章 市場機會與未來展望

The Industrial Coatings Market size is estimated at USD 41.97 billion in 2025, and is expected to reach USD 49.58 billion by 2030, at a CAGR of 3.39% during the forecast period (2025-2030).

The market's momentum is shaped by the accelerating adoption of nanotechnology, which improves coating performance while reducing material usage, and by a rapid substitution of solvent-borne products with sustainable water-borne and powder technologies. Asia-Pacific leads with a 51% share in 2024, powered by extensive infrastructure investments and manufacturing growth in China and India. Epoxy resins dominate with a 31% share, advancing at a 6% CAGR on account of their superior chemical resistance and adhesion properties, making them indispensable in high-performance applications across energy, infrastructure, and heavy industry. Regulatory mandates on volatile organic compounds (VOCs) are tightening globally, prompting manufacturers to accelerate innovation in low- and zero-VOC chemistries and thereby creating fresh opportunities for producers equipped with green technologies. Meanwhile, consolidation is accelerating as leading suppliers acquire specialized firms to bolster regional reach and technology depth, even as more than 20 sizable competitors maintain a fragmented landscape.

Global Industrial Coatings Market Trends and Insights

Rising Demand for Protective Coatings: Corrosion Mitigation Drives Innovation

Protective coatings have become pivotal as asset owners prioritize durability and lifecycle cost control. Products such as NEI Corporation's NANOMYTE TC-3001 offer up to 15 years of corrosion resistance with minimal maintenance, enabling operators to defer capital-intensive replacements. Downstream oil refineries, chemical plants, and offshore platforms increasingly specify multi-layer epoxy and zinc-rich systems that deliver both barrier and cathodic protection. The integration of embedded sensors within these coatings is shifting maintenance strategies from reactive inspections to predictive analytics, cutting unexpected downtime while preserving safety. Concurrently, governments are mandating longer service lives for public infrastructure, a requirement that boosts demand for next-generation solutions able to withstand coastal salinity, de-icing salts, and industrial pollutants. Collectively, these dynamics reinforce the industrial coatings market's focus on research that extends coating lifespan without increasing film thickness or curing time.

Increasing Applications in Oil and Gas Industry: Specialized Solutions for Extreme Conditions

Deep-water and high-temperature wells challenge conventional coatings, driving innovation toward hybrid chemistries that combine epoxy phenolics with ceramic or silicone components for enhanced resistance to hydrocarbons and temperatures exceeding 150 °C. PPG's purpose-built systems guard subsea pipelines from sour gas, while offering intumescent fire protection on topside structures in one integrated scheme. Coating designs are also evolving to tolerate high-pressure carbon dioxide streams expected in large-scale carbon capture and storage (CCS) projects. Localized suppliers in the Middle East are licensing these advanced technologies to meet rapidly expanding regional drilling programs, although stringent qualification protocols lengthen product adoption cycles. As the industry invests in digital twins for asset integrity, coatings compatible with remote condition-monitoring embedment stand to gain further traction, reinforcing the oil and gas sector's strategic importance to the industrial coatings market.

Harmful Environmental Impact of Solvent-borne Coating: Regulatory Pressure Accelerates Transition

Fresh limits on volatile organic compounds (VOC) in the United States and the European Economic Area have tightened allowable emissions for industrial paint shops, forcing operators to install abatement equipment or switch to low-solvent alternatives. Water-borne and powder varieties are therefore capturing incremental Industrial Coatings market size even when total painted surface area expands only modestly. Suppliers that retrofit existing dispersion lines instead of constructing new solvent facilities illustrate a calculated response to lifetime cost, signaling confidence that environmental compliance spending will tilt decisively toward alternative chemistries. As early movers win multi-year supply contracts on sustainability credentials, they reinforce a feedback loop that makes regulatory alignment a prerequisite for market entry rather than a competitive bonus.

Other drivers and restraints analyzed in the detailed report include:

- Infrastructure Development & Urbanization: Driving Demand for Durable Solutions

- Sustainability-Driven Shift Toward Low-VOC Technologies: Regulatory Pressure Accelerates Transition

- Fluctuating Raw Material Prices: Supply Chain Vulnerabilities Impact Market Dynamics

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Epoxy coatings represented 31% of the industrial coatings market in 2024, while polyurethane is projected to grow at a 5.02% CAGR, firmly outpacing the overall industry. Their leadership stems from exceptional adhesion, chemical resistance, and compatibility with a broad spectrum of substrates, enabling widespread adoption in refineries, wastewater plants, and fabrication workshops. Hybrid nano-silica-modified epoxies are emerging, delivering superior abrasion resistance while maintaining low VOC levels, which satisfies regulatory calls for greener solutions. In contrast, polyurethane resins are gradually taking share in exterior segments where UV stability and flexibility are critical, particularly in wind-turbine towers and railcars. Acrylics retain an important niche in light-duty equipment due to fast dry-to-touch times and low cost, and recent capital investments such as Lubrizol's USD 20 million expansion in North Carolina signal continued growth potential in water-borne acrylic emulsions.

Epoxy suppliers intensify R&D to shorten recoat windows and meet rapid project schedules, a top procurement criterion for contractors seeking to finish multiple passes in a single shift. Solvent-free novolac epoxies that tolerate moisture during cure are gaining momentum on offshore platforms, reducing weather-related delays. Meanwhile, halloysite-nanotube enhancements deliver double-digit improvements in salt-spray performance without altering formulation viscosity, attracting pipeline owners committed to 30-year service targets. Collectively, these advances strengthen the industrial coatings market's reliance on epoxy chemistries for critical-service duties, while opening incremental opportunities for polyurethane and acrylic innovators in less aggressive environments within the industrial coatings industry.

Solvent-borne coatings retained a 37% share of the industrial coatings market in 2024, while water-borne posting a resilient 4.89% CAGR thanks to their proven performance across diverse climatic zones. However, water-borne products now capture a growing share of maintenance repaints as contractors adapt to lower solvent levels, odor reduction, and safer handling requirements. The industrial coatings market share for water-borne technologies on heavy machinery is expected to rise by 2030 as phase-in periods for tightened VOC limits expire in Europe and North America. Powder coatings, free of solvents, remain the fastest-growing platform, adding capacity for agricultural equipment and appliance exteriors. Sherwin-Williams' Powdura ECO line integrates recycled polyethylene terephthalate (rPET) without sacrificing corrosion resistance, illustrating sustainable innovation that resonates with brand owners' circular-economy commitments.

UV-curable coatings, which provide instant throughput and slash oven-energy use by up to 95%, are penetrating wood flooring, electronics housings, and metal packaging segments. Nevertheless, their line-of-sight limitation and substrate temperature sensitivity restrain adoption in complex geometries. In the broader industrial coatings market, asset owners weigh total applied cost, performance, and regulatory compliance, leading many to adopt hybrid schemes that blend water-borne primers with solvent-borne or polyurethane topcoats for balanced properties. Over the forecast horizon, formulators are expected to refine amine-free accelerators and fast-dry alkyd emulsions to unlock further water-borne growth within the industrial coatings market.

The Industrial Coatings Market Report Segments the Industry by Resin Type (Epoxy, Polyurethane, and More), Technology (Solvent-Borne, Water-Borne, and More), End-Use Industry (General Industrial, and Protective Coatings), Substrate (Metal and Concrete), and Geography (Asia-Pacific, North America, Europe, South America, and Middle East and Africa). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific secured a 51% share of the industrial coatings market in 2024 and is poised to grow at a 4.31% CAGR through 2030. China commands heavy investment in petrochemical complexes and electric-vehicle manufacturing, while India's National Infrastructure Pipeline underwrites coatings demand for highways, airports, and railways. Multinational suppliers localize production to avoid tariffs and reduce lead times, evidenced by recent joint ventures in Vietnam and Thailand that integrate resin polymerization and finished-paint blending under one roof.

North America exhibits modest volume growth but strong value expansion as asset owners shift to premium, high-solids technologies. PPG's divestment of its U.S. and Canadian architectural coatings unit for USD 550 million allows management to redeploy capital toward its industrial coatings portfolio, including robotics-enabled powder lines. Infrastructure law outlays accelerate demand for bridge and pipeline coatings across the United States, while Canada's decarbonization roadmap incentivizes the adoption of low-VOC, renewable-electricity-based production.

Europe remains a technology leader, driven by strict VOC limits and ambitious climate-neutrality targets. BASF's decision to power key German and Dutch coating plants entirely with renewable electricity eliminates 11,000 tons of CO2 annually and strengthens its value-proposition for OEMs pursuing Scope 3 emission reductions. The region is also seeing early commercialization of bio-based alkyds sourced from non-food oil crops, though industrial customers demand rigorous durability validation before widespread adoption.

The Middle East & Africa, while owning a smaller share, records some of the highest growth rates as mega-projects such as Saudi Arabia's NEOM drive demand for advanced metal and concrete protective systems. Local formulators align with multinational technology partners to meet stringent fire- and corrosion-protection specifications required for high-salinity, high-UV desert environments. South America, led by Brazil, benefits from petrochemical investments and continued urbanization, though macroeconomic uncertainty tempers public-sector capital spending. Across these developing regions, knowledge transfer initiatives and localized training programs bolster applicator proficiency, a critical factor in realizing the full performance potential of modern industrial coatings.

- 3M

- AkzoNobel N.V.

- Arkema

- Asian Paints

- Axalta Coating Systems

- BASF SE

- Beckers Group

- Chugoku Marine Paints Ltd.

- Daikin Industries Ltd.

- Hempel A/S

- Henkel AG & Co. KGaA

- Jotun

- Kansai Paint Co., Ltd.

- Nippon Paint Holdings Co., Ltd.

- OC Oerlikon Management AG

- PPG Industries, Inc.

- RPM International Inc.

- Rust-Oleum Corporation

- Sika AG

- The Sherwin-Williams Company

- Tikkurila

- Wacker Chemie AG

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Rising Demand for Protective Coatings

- 4.2.2 Increasing Applications in Oil and Gas Industry

- 4.2.3 Infrastructure Development and Urbanization

- 4.2.4 Growing Demand in Power and Marine Sectors

- 4.2.5 Rising Awareness of the Importance of Aesthetic Value

- 4.3 Market Restraints

- 4.3.1 Harmful Environmental Impact Of Solvent-borne Coating

- 4.3.2 Fluctuating Raw Material Prices

- 4.3.3 Availability of Alternative Coating Products

- 4.4 Value Chain Analysis

- 4.5 Regulatory Outlook

- 4.6 Porter's Five Forces

- 4.6.1 Bargaining Power of Suppliers

- 4.6.2 Bargaining Power of Buyers

- 4.6.3 Threat of New Entrants

- 4.6.4 Threat of Substitutes

- 4.6.5 Degree of Competition

5 Market Size and Growth Forecasts (Value)

- 5.1 By Resin Type

- 5.1.1 Epoxy

- 5.1.2 Polyurethane

- 5.1.3 Acrylic

- 5.1.4 Polyester

- 5.1.5 Other Resins (Alkyd, Fluoropolymer, Vinyl Ester)

- 5.2 By Technology

- 5.2.1 Solvent-borne

- 5.2.2 Water-borne

- 5.2.3 Powder

- 5.2.4 UV Technology

- 5.3 By End-use Industry

- 5.3.1 General Industrial

- 5.3.2 Protective Coatings

- 5.3.2.1 Oil and Gas

- 5.3.2.2 Mining

- 5.3.2.3 Power

- 5.3.2.4 Infrastructure

- 5.3.2.5 Other Protective Coatings

- 5.4 By Substrate

- 5.4.1 Metal

- 5.4.2 Concrete

- 5.5 By Geography

- 5.5.1 Asia-Pacific

- 5.5.1.1 China

- 5.5.1.2 India

- 5.5.1.3 Japan

- 5.5.1.4 South Korea

- 5.5.1.5 ASEAN

- 5.5.1.6 Australia

- 5.5.1.7 New Zealand

- 5.5.1.8 Rest of Asia-Pacific

- 5.5.2 North America

- 5.5.2.1 United States

- 5.5.2.2 Canada

- 5.5.2.3 Mexico

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Russia

- 5.5.3.6 Nordics

- 5.5.3.7 Rest of Europe

- 5.5.4 South America

- 5.5.4.1 Brazil

- 5.5.4.2 Argentina

- 5.5.4.3 Chile

- 5.5.4.4 Rest of South America

- 5.5.5 Middle East and Africa

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 United Arab Emirates

- 5.5.5.3 Turkey

- 5.5.5.4 South Africa

- 5.5.5.5 Nigeria

- 5.5.5.6 Rest of Middle-East and Africa

- 5.5.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles {(includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)}

- 6.4.1 3M

- 6.4.2 AkzoNobel N.V.

- 6.4.3 Arkema

- 6.4.4 Asian Paints

- 6.4.5 Axalta Coating Systems

- 6.4.6 BASF SE

- 6.4.7 Beckers Group

- 6.4.8 Chugoku Marine Paints Ltd.

- 6.4.9 Daikin Industries Ltd.

- 6.4.10 Hempel A/S

- 6.4.11 Henkel AG & Co. KGaA

- 6.4.12 Jotun

- 6.4.13 Kansai Paint Co., Ltd.

- 6.4.14 Nippon Paint Holdings Co., Ltd.

- 6.4.15 OC Oerlikon Management AG

- 6.4.16 PPG Industries, Inc.

- 6.4.17 RPM International Inc.

- 6.4.18 Rust-Oleum Corporation

- 6.4.19 Sika AG

- 6.4.20 The Sherwin-Williams Company

- 6.4.21 Tikkurila

- 6.4.22 Wacker Chemie AG

7 Market Opportunities and Future Outlook

- 7.1 Technological Advancements in Coating Formulations

- 7.2 White-space and Unmet-need Assessment