|

市場調查報告書

商品編碼

1851448

乙醇胺:市場佔有率分析、行業趨勢、統計數據和成長預測(2025-2030 年)Ethanolamines - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

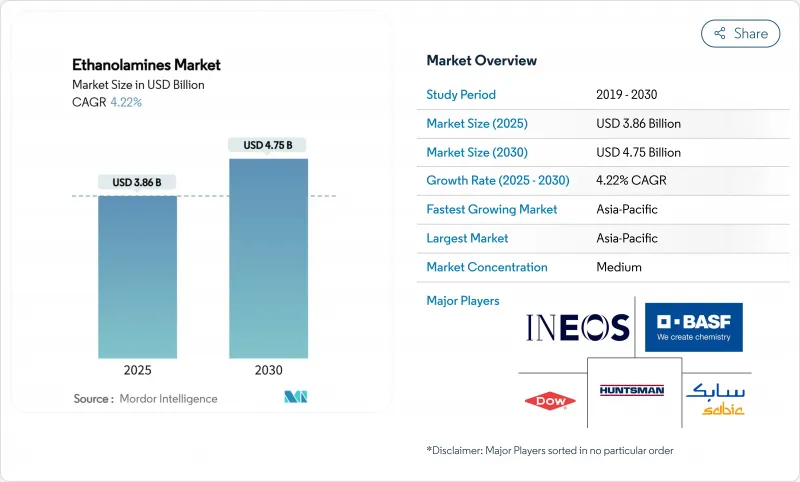

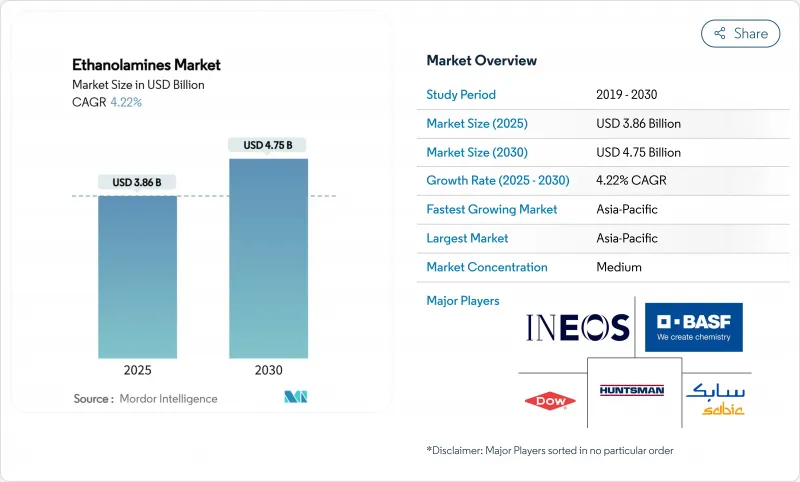

預計到 2025 年乙醇胺市場規模將達到 38.6 億美元,到 2030 年將達到 47.5 億美元,年複合成長率為 4.22%。

來自天然氣加工、清潔劑、農業化學品和先進製造業的強勁需求,使乙醇胺的銷售保持穩定,即便生產商面臨日益嚴格的安全和環境法規。原料的後向整合交易,例如英力士收購利安德巴塞爾的環氧乙烷及其衍生物資產,顯示主要供應商如何在確保供應安全的同時獲得成本優勢。以美國環保署將於2025年8月生效的乙醇胺新用途重要規則為首的監管變革,正在鼓勵對生物基路線的投資,同時又不影響傳統應用領域的近期消費。同時,BASF在安特衛普和諾力昂在瑞典等老牌企業擴大產能,使乙醇胺市場能夠在滿足日益成長的永續性需求的同時,維持區域供應安全。

全球乙醇胺市場趨勢與洞察

新興國家的快速工業化

中國、印度、印尼和越南固定資產投資的快速成長刺激了乙醇胺在氣體脫硫劑、水泥添加劑和製程化學品領域的新消費。中國針對先進電池原料的一攬子政策將直接增加電解液精煉計劃對單乙醇胺的需求。印度不斷擴大的生質乙醇產能將增強未來可再生乙醇胺工廠的原料供應,支持其出口導向特種化學品叢集,同時降低進口依賴。東南亞建設計畫的擴張將增加對水泥助磨劑用三乙醇胺的需求,同時區域公用事業公司正在部署胺基二氧化碳捕集裝置,以實現燃煤和燃氣發電廠的脫碳。都市化的加速將提高人均清潔劑和個人保養用品的購買量,從而對錶面活性劑級乙醇胺產生結構性拉動。這些趨勢共同推動了乙醇胺市場的中期擴張。

為耐除草劑作物,Glyphosate產量激增

儘管關於雜草抗藥性的爭論日益激烈,巴西、阿根廷和美國的抗除草劑大豆和玉米種植面積仍在持續擴大,這維持了Glyphosate的大規模合成,而草甘膦的合成依賴於乙醇胺中和步驟。跨國製劑生產商正將生產轉移到成本更具競爭力的亞洲,這為乙醇胺市場提供了新的需求管道,但並未改變全球消費量。在開發中國家,農業機械化宣傳活動正在增加Glyphosate的使用量。新的雙敲除方案將Glyphosate與互補活化劑混合使用,通常會增加每公頃的總胺需求量。雖然歐盟監管機構呼籲減少合成農藥的使用,但這些法規通常只是將生產轉移到更友善的地區,而不是限制絕對使用。因此,Glyphosate帶來的短期成長動能有利於乙醇胺市場的成長。

環氧乙烷原料價格不穩定

環氧乙烷現貨價格對石腦油和天然氣價格波動高度敏感,在價格突然上漲期間,這會對獨立乙醇胺生產商造成壓力。 2025年初,由於烯烴利潤為負且營運成本過高,韓國多家裂解裝置停產,導致亞太地區環氧乙烷供應趨緊。BASF和陶氏等大型綜合企業透過將環氧乙烷的流向利潤更高的衍生性商品來應對市場波動,凸顯了其結構性優勢,從而鞏固了市場集中度。蘇伊士運河和巴拿馬運河的貨物運輸中斷進一步增加了原料套利流動的不確定性。小型配方商透過降低開工率或轉嫁額外費用來應對,但持續的價格衝擊可能會擾亂對價格敏感的應用領域(例如通用清潔劑)的需求。在原料價格趨勢恢復正常之前,乙醇胺市場在短期內將被拖累。

細分市場分析

2024年,單乙醇胺的銷售額將佔總銷售額的45.18%,這主要得益於穩定的天然氣脫硫劑產量、蓬勃發展的碳捕集試點計畫以及在清潔劑領域的廣泛應用。預計到2030年,該細分市場將以6.80%的複合年成長率成長,進一步鞏固其在乙醇胺市場的核心地位。單乙醇胺的高反應活性使其配方師能夠客製廣泛的pH頻譜,從而保持其在各行業的應用價值。同時,二乙醇胺在金屬加工液和除草劑中和劑領域保持著強勁的地位,其優異的緩蝕性能提升了其價值。三乙醇胺在水泥助磨劑領域取得了顯著進展,可使水泥抗壓強度提高高達5兆帕,從而縮短大型基礎設施計劃的維護時間。

三大主要等級產品的多元化配置能夠幫助供應商抵禦下游產業需求波動的影響。煉油廠和鋼鐵廠碳捕獲技術的進步可能會大幅增加單乙醇胺的需求,而個人護理產業的優質化則有助於提升三乙醇胺的利潤率。這些因素共同動態,使得乙醇胺市場在產品層面保持了良好的平衡。

傳統的環氧乙烷工藝,由於數十年的最佳化和沈沒資本的積累,到2024年將佔全球加工產能的92.16%。然而,在可再生能源含量強制性要求和企業淨零排放目標的推動下,生質乙醇路線預計將以7.24%的複合年成長率加速發展。泰國和巴西的早期商業化工廠表明,農業廢棄物衍生的生物乙烯可以無縫整合到現有的胺化製程中,從而降低下游認證的門檻。歐洲的碳邊境調節機制可以透過對隱含排放進行定價來縮小成本差距,引導未來的支出轉向低碳路線。

製程強化措施,包括連續反應器系統、膜分離和催化重排等,使傳統技術在成本上保持競爭力。然而,願意為經認證的低碳分子支付溢價的品牌所有者,為生物基供應商提供了極具吸引力的市場立足點。由此形成的雙路線框架,既能確保充足的供應,又能促進整個乙醇胺市場的技術升級。

區域分析

亞太地區預計到2024年將佔全球收入佔有率的46.81%,這主要得益於不斷擴張的石化聯合企業、具有競爭力的勞動力以及下游製造地。中國煉油企業持續推動單乙醇胺生產線的產能提升,以滿足國內清潔劑和電子化學品客戶的需求;而印度生質乙醇的蓬勃發展,則使印度次大陸成為未來可再生乙醇胺的出口中心。東南亞作物保護製劑生產商,主要集中在泰國和越南,將受益於該地區作物保護支出的成長。

北美擁有強大的生產基地,以德克薩斯州和路易斯安那州的氧化物衍生物產業叢集為核心。英力士斥資7億美元收購利安德巴塞爾的工廠,確保了與天然氣脫硫劑授權商簽訂的長期供應協議所需的原料供應。亨斯邁在伍德蘭茲的E-GRADE擴建項目瞄準半導體精煉市場,並為該地區提供了一種能夠抵禦大宗商品利潤週期波動的增值對沖手段。

歐洲嚴格的碳政策,例如BASF在安特衛普的14萬噸產能升級項目,正在推動低排放裝置的投資。諾力昂在斯滕松德獲得的ISCC PLUS認證,透過確保可追溯的可再生原料,刺激了個人護理產品的需求。碳邊境定價預計將提高高排放氣體乙醇胺的進口溢價,間接有利於獲得認證的歐洲產品。這些區域動態有助於建立一個平衡的全球網路,從而保障乙醇胺的穩定供應。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 新興國家的快速工業化

- 為耐除草劑作物,Glyphosate產量激增

- 電動汽車製造業對水基金屬加工液的需求不斷成長

- 在農藥產業中不斷擴大應用

- 生物基界面活性劑配方在個人護理領域的成長

- 市場限制

- 環氧乙烷原料價格不穩定

- 雜草抗藥性的增強抑制了對Glyphosate的需求。

- 環境友善生物溶劑的出現,對乙醇胺構成挑戰

- 價值鏈分析

- 波特五力模型

- 供應商的議價能力

- 消費者議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

第5章 市場規模與成長預測

- 依產品類型

- 單乙醇胺(MEA)

- 二乙醇胺(DEA)

- 三乙醇胺(TEA)

- 透過技術

- 環氧乙烷路線

- 生質乙醇路線

- 透過使用

- 氣體處理

- 除草劑(Glyphosate)

- 界面活性劑和清潔劑

- 水泥和混凝土添加劑

- 個人護理配方

- 金屬加工油

- 其他用途

- 按最終用戶行業分類

- 石油和天然氣

- 農業

- 建造

- 個人護理

- 紡織品

- 冶金與金屬加工

- 其他終端用戶產業

- 按地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 亞太其他地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 其他歐洲地區

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 其他中東和非洲地區

- 亞太地區

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率(%)/排名分析

- 公司簡介

- Amines & Plasticizers ltd.

- BASF

- Dow

- Huntsman Corporation

- INEOS

- NIPPON SHOKUBAI CO., LTD.

- Nouryon

- OUCC

- SABIC

- Sintez OKA Group

- Thai Ethanolamines Co.

- Tosoh Corp.

第7章 市場機會與未來展望

The ethanolamines market size reached USD 3.86 billion in 2025 and is projected to touch USD 4.75 billion by 2030, advancing at a 4.22% CAGR.

Healthy demand from gas treatment, detergents, agrochemicals and advanced manufacturing keeps volumes stable even as producers confront stricter safety and environmental rules. Feedstock-backward integration deals, such as INEOS's purchase of LyondellBasell's ethylene oxide and derivatives assets, illustrate how leading suppliers secure cost advantages while locking in supply certainty. Regulatory shifts-most notably the United States Environmental Protection Agency's significant-new-use rules for ethanolamines entering force in August 2025-encourage investments in bio-based routes without eroding near-term consumption in conventional applications. Meanwhile, incremental capacity expansions by incumbents like BASF in Antwerp and Nouryon in Sweden position the ethanolamines market to meet rising sustainability requirements while preserving regional supply security.

Global Ethanolamines Market Trends and Insights

Rapid industrialisation in emerging economies

Surging fixed-asset investment across China, India, Indonesia and Vietnam stimulates fresh consumption of ethanolamines for gas sweetening, cement additives and process chemicals. Chinese policy packages that target advanced battery raw materials directly raise monoethanolamine offtake for electrolyte purification projects. India's widening bio-ethanol capacity reinforces future feedstock availability for renewable ethanolamines plants, lowering import dependence while supporting export-oriented specialty chemicals clusters. Expanding construction programs in Southeast Asia lift triethanolamine demand for cement grinding aids, while regional utilities deploy amine-based CO2 capture to decarbonize coal and gas-fired plants. Urbanisation unlocks higher per-capita purchases of detergents and personal-care items, embedding a structural pull for surfactant-grade ethanolamines. Collectively, these trends embed a broad-based, medium-term uplift in the ethanolamines market.

Surging glyphosate production for herbicide-tolerant crops

Even as weed-resistance debates intensify, acreage sown with herbicide-tolerant soybean and maize varieties keeps expanding in Brazil, Argentina and the United States, sustaining large synthesis volumes for glyphosate that rely on ethanolamines neutralisation steps. Multinational formulators are relocating production to cost-competitive Asian hubs, giving the ethanolamines market fresh demand corridors without altering global consumption totals. In developing economies, farm-mechanisation campaigns elevate glyphosate usage because labour-saving herbicides remain cheaper than manual weeding. New double-knock programs that mix glyphosate with complementary actives often boost total amine requirements per hectare. Although regulators in the European Union push for reduced synthetic loads, these restrictions typically shift manufacturing to friendlier jurisdictions rather than curbing absolute tonnage. Consequently, near-term momentum from glyphosate maintains a positive swing factor for ethanolamines market growth.

Volatile ethylene oxide feedstock prices

Spot ethylene-oxide quotes remain highly sensitive to naphtha and natural-gas swings, squeezing standalone ethanolamines producers during sudden upcycles. Several South Korean crackers idled in early 2025 because negative olefin margins rendered operations uneconomic, tightening ethylene-oxide supply in the wider Asia-Pacific basin. Integrated majors such as BASF and Dow weather volatility better by reallocating oxide streams to the highest-margin derivatives, underscoring structural advantages that reinforce market concentration. Freight disruptions through the Suez and Panama canals add further unpredictability to feedstock arbitrage flows. Smaller formulators respond by trimming run rates or passing through surcharges, yet prolonged price shocks risk demand destruction in price-sensitive applications like commodity detergents. Net impact is a near-term drag on the ethanolamines market until feedstock trends normalise.

Other drivers and restraints analyzed in the detailed report include:

- Rising demand for water-based metal-working fluids in EV manufacturing

- Increasing utilization in the agrochemical industry

- Increasing weed resistance to weaken glyphosate demand

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Monoethanolamine held 45.18% of 2024 revenues, supported by steady gas-sweetening runs, burgeoning carbon-capture pilots and broad detergent usage. The segment is forecast to post a 6.80% CAGR to 2030, reinforcing its anchor role in the ethanolamines market. Monoethanolamine's high reactivity allows formulators to tailor a wide pH spectrum, sustaining cross-industry relevance. Meanwhile, diethanolamine retains a solid niche in metal-working fluids and herbicide neutralisation, with coproduct value uplift from improved corrosion-inhibition performance. Triethanolamine advances in cement grinding aids, delivering up to 5 MPa compressive-strength gains that shorten curing times on major infrastructure projects.

Diversification across three primary grades protects suppliers from demand swings in any one downstream sector. Carbon-capture retrofits in refineries and steel mills could sharply raise monoethanolamine call-offs, whereas personal-care premiumisation supports triethanolamine margin resilience. Together, these dynamics keep the ethanolamines market well balanced at the product level.

The legacy ethylene-oxide process represented 92.16% of global throughput in 2024, reflecting decades of optimisation and sunk-capital advantages. Even so, the bio-ethanol pathway is predicted to accelerate at a 7.24% CAGR, propelled by renewable-content mandates and corporate net-zero targets. Early commercial plants in Thailand and Brazil demonstrate that agricultural-residue-derived bio-ethylene can integrate seamlessly into existing amination trains, reducing downstream qualification hurdles. Carbon-border-adjustment schemes in Europe tighten the cost gap by pricing embedded emissions, tilting future expenditures toward low-carbon routes.

Process intensification efforts-continuous reaction systems, membrane-based separations and catalysed rearrangements-keep legacy technology competitive on cash cost. Still, brand owners willing to pay premiums for certified-low-carbon molecules grant bio-based suppliers an attractive foothold. The resulting dual-pathway framework ensures ample supply while catalysing technology upgrades across the wider ethanolamines market.

The Ethanolamines Market Report is Segmented by Product Type (Monoethanolamine, Diethanolamine, and More), Technology (Ethylene Oxide Route and Bio-Ethanol Route), Application (Gas Treatment, Herbicides, and More), End-User Industry (Oil and Gas, Agriculture, and More), and Geography (Asia-Pacific, North America, Europe, South America, Middle East and Africa). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific dominated with a 46.81% revenue share in 2024, buoyed by integrated petrochemical complexes, competitive labour and expanding downstream manufacturing hubs. Chinese refiners continually debottleneck mono-ethanolamine lines to serve domestic detergent and electronic-chemicals customers, while India's bio-ethanol surge positions the subcontinent as a future export base for renewable ethanolamines. Southeast Asia's agrochemical formulators, concentrated in Thailand and Vietnam, offer further pull as regional crop-protection spending climbs.

North America retains a robust production backbone anchored by Texas and Louisiana oxide-derivative clusters. INEOS's USD 700 million purchase of LyondellBasell's facility secures feedstock for long-term supply contracts with gas-sweetening licensors. Huntsman's E-GRADE expansion in The Woodlands targets semiconductor-purification niches, giving the region a value-added hedge against commodity margin cycles.

Europe's stringent carbon agenda steers investment toward low-emission units, exemplified by BASF's 140,000-ton upgrade in Antwerp. Nouryon's ISCC PLUS accreditation at Stenungsund spurs personal-care demand by enabling traceable renewable content. Carbon-border-adjustment pricing is expected to elevate import premiums on high-emission ethanolamines, indirectly favouring certified European output. Collectively, these regional dynamics sustain a balanced global network that underpins steady flows in the ethanolamines market.

- Amines & Plasticizers ltd.

- BASF

- Dow

- Huntsman Corporation

- INEOS

- NIPPON SHOKUBAI CO., LTD.

- Nouryon

- OUCC

- SABIC

- Sintez OKA Group

- Thai Ethanolamines Co.

- Tosoh Corp.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions & Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Rapid industrialisation in emerging economies

- 4.2.2 Surging glyphosate production for herbicide-tolerant crops

- 4.2.3 Rising demand for water-based metal-working fluids in EV manufacturing

- 4.2.4 Increasing utilization in the agrochemical industry

- 4.2.5 Growth in bio-based surfactant formulation in personal-care

- 4.3 Market Restraints

- 4.3.1 Volatile ethylene oxide feedstock prices

- 4.3.2 Increasing Weed Resistance to Weaken the Demand for Glyphosate

- 4.3.3 Emergence of greener bio-solvents challenging ethanolamines

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Consumers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitute Products

- 4.5.5 Degree of Competition

5 Market Size & Growth Forecasts (Value)

- 5.1 By Product Type

- 5.1.1 Monoethanolamine (MEA)

- 5.1.2 Diethanolamine (DEA)

- 5.1.3 Triethanolamine (TEA)

- 5.2 By Technology

- 5.2.1 Ethylene Oxide Route

- 5.2.2 Bio-ethanol Route

- 5.3 By Application

- 5.3.1 Gas Treatment

- 5.3.2 Herbicides (Glyphosate)

- 5.3.3 Surfactants & Detergents

- 5.3.4 Cement & Concrete Additives

- 5.3.5 Personal-care Formulations

- 5.3.6 Metal-working Fluids

- 5.3.7 Other Applications

- 5.4 By End-user Industry

- 5.4.1 Oil and Gas

- 5.4.2 Agriculture

- 5.4.3 Construction

- 5.4.4 Personal Care

- 5.4.5 Textile

- 5.4.6 Metallurgy and Metalworking

- 5.4.7 Other End-user Industries

- 5.5 By Geography

- 5.5.1 Asia-Pacifc

- 5.5.1.1 China

- 5.5.1.2 India

- 5.5.1.3 Japan

- 5.5.1.4 South Korea

- 5.5.1.5 Rest of Asia-Pacific

- 5.5.2 North America

- 5.5.2.1 United States

- 5.5.2.2 Canada

- 5.5.2.3 Mexico

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Rest of Europe

- 5.5.4 South America

- 5.5.4.1 Brazil

- 5.5.4.2 Argentina

- 5.5.4.3 Rest of South America

- 5.5.5 Middle East and Africa

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 South Africa

- 5.5.5.3 Rest of Middle East and Africa

- 5.5.1 Asia-Pacifc

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share(%)/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products & Services, and Recent Developments)

- 6.4.1 Amines & Plasticizers ltd.

- 6.4.2 BASF

- 6.4.3 Dow

- 6.4.4 Huntsman Corporation

- 6.4.5 INEOS

- 6.4.6 NIPPON SHOKUBAI CO., LTD.

- 6.4.7 Nouryon

- 6.4.8 OUCC

- 6.4.9 SABIC

- 6.4.10 Sintez OKA Group

- 6.4.11 Thai Ethanolamines Co.

- 6.4.12 Tosoh Corp.

7 Market Opportunities & Future Outlook

- 7.1 White-space & Unmet-need Assessment