|

市場調查報告書

商品編碼

1851412

汽車被覆劑:市場佔有率分析、產業趨勢、統計數據和成長預測(2025-2030 年)Automotive Coatings - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

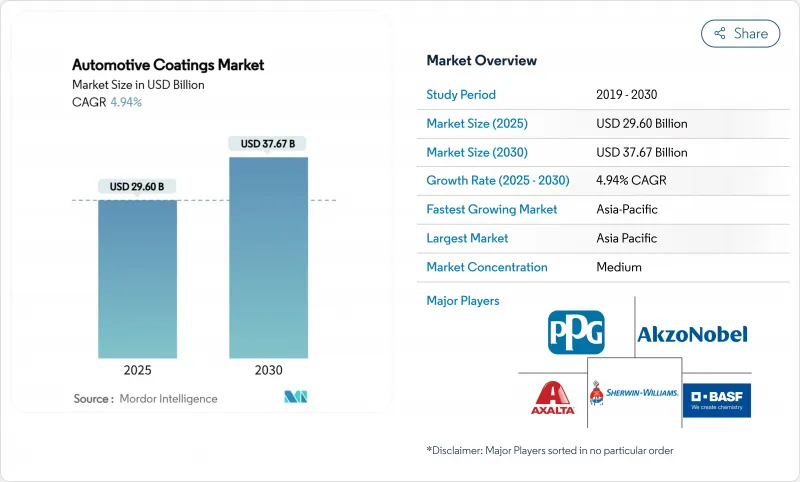

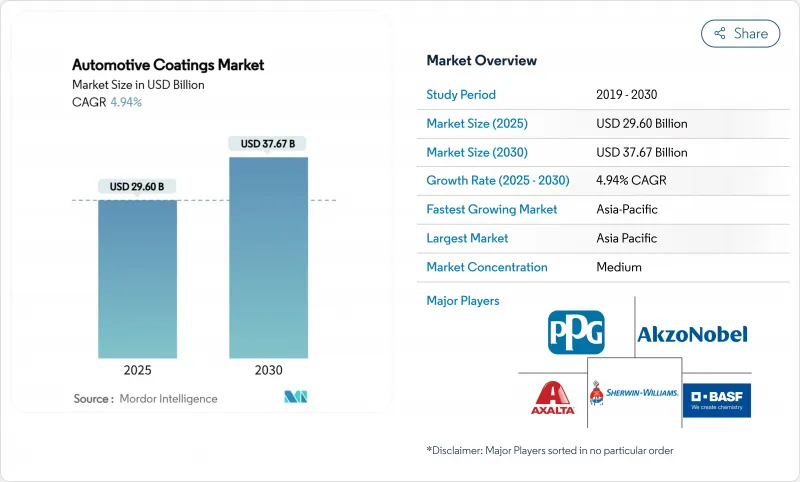

據估計,汽車被覆劑市場規模將在 2025 年達到 296 億美元,到 2030 年達到 376.7 億美元,在預測期(2025-2030 年)內複合年成長率為 4.94%。

全球汽車生產的復甦、向低揮發性有機化合物 (VOC) 配方的轉變以及電動車 (EV) 產量的激增,都在支撐著不斷成長的需求,儘管原料價格波動和更嚴格的溶劑法規限制了利潤淨利率。供應商正在加速推出水性塗料和粉末塗料系統,以滿足即將訂定的排放法規,同時提供與目標商標產品製造商 (OEM) 同等的耐久性。 OEM 塗裝車間的數位化,涵蓋線上固化、機器人檢測和雲端基礎的配色,正在提高生產效率並拓寬技術准入門檻。同時,市場分散仍在持續,中型區域供應商與能夠資助大規模永續性和自動化項目的跨國公司展開激烈的市場佔有率爭奪。

全球汽車被覆劑市場趨勢與洞察

全球汽車產量成長的復甦

預計到2024年,北美輕型汽車產量將達到1550萬輛,並持續成長,這將支撐工廠對車身外部和底盤塗料的需求。目前,輕型卡車佔月銷量的84%,推動了高階耐刮透明塗層的消費。在中國,儘管面臨區域產能過剩的威脅,但產能的提升和出口的強勁勢頭支撐了塗料銷售的穩定性。全球汽車製造商在疫情相關干擾後已恢復了可預測的採購計劃,使供應商能夠最佳化批量生產和物流。隨著汽車製造商在追求品牌專屬美學的同時滿足耐久標準,對先進噴漆車間自動化和差異化塗裝技術的投資也隨之湧現。

為符合VOC法規,轉向水性及粉末塗料系統。

加州將於2025年實施更嚴格的VOC(揮發性有機化合物)法規,歐盟即將推出的綠色交易措施正在加速溶劑型塗料系統的改進。大型汽車修理廠已檢驗水性底塗層的商業性可行性,採用率高達64%。BASF的Glasurit 100系列產品就是一個高效能低VOC產品的典範,目前已被1000多家碰撞維修中心採用。粉末塗料在車輪、引擎室零件和電動車電池外殼等領域的市場佔有率不斷成長,這得益於雷射固化爐可降低50%的能耗。擁有豐富樹脂和顏料產品組合的供應商正在迅速贏得客戶,並在更嚴格的法規訂定之前搶先一步。

嚴格的溶劑和異氰酸酯暴露限值

美國職業安全與健康管理局 (OSHA) 的國家優先計劃增加了噴漆房的檢查次數,並強制要求加強通風和使用個人防護設備,以降低異氰酸酯相關氣喘和皮膚炎的風險。規模較小的噴漆企業若要建造符合標準的噴漆房,則需要投入高昂的資金,或者必須改用低異氰酸酯化學品,這可能會影響噴漆性能。底漆和透明塗層生產商正在將不含聚脲的產品推向市場,但在耐久性指標得到檢驗之前,他們對採用這些產品持謹慎態度。

細分市場分析

到2024年,丙烯酸類塗料將佔汽車被覆劑市場需求的48.55%,憑藉其成本效益和均衡的耐候性鞏固其市場地位。聚氨酯配方預計到2030年將以5.18%的複合年成長率成長,滿足高階透明塗層和軟式電路板的需求,尤其是在豪華運動型多用途車(SUV)和電動車領域,這些車型對耐刮擦性能的要求更高。隨著新型脂肪族二異氰酸酯化學品通過更嚴格的黃變測試,預計北美OEM生產線中聚氨酯體系的汽車被覆劑市場規模將顯著擴大。環氧樹脂將在對防腐蝕要求極高的陰極電著底漆領域保持其獨特的市場地位,而生物基混合塗料正在歐洲OEM主導的概念項目中嶄露頭角。

由於使用壽命延長,聚氨酯材料對耐久性的需求日益成長,同時,美國職業安全與健康管理局 (OSHA) 對異氰酸酯處理的嚴格監管也促使企業投資於封閉式混合單元和機器人噴塗設備。科思創等供應商目前提供含 33%可再生碳的聚氨酯,顯示其符合原始設備製造商 (OEM) 的永續性目標。丙烯酸酯化學家正在研發新一代交聯劑,以提高耐汞性能,同時不增加揮發性有機化合物 (VOC) 的含量。競爭優勢越來越依賴能夠將機械強度與低溫固化特性結合的專利組合,從而滿足能源使用要求和輕質基板的需求。

到2024年,溶劑型塗料仍將佔汽車被覆劑市場顯然正向替代方向發展。水性塗料目前在歐盟OEM底塗層佔據主導地位,而像馬自達這樣的日本OEM廠商已實現了15克/平方米的行業最低VOC排放。粉末塗料雖然目前市場佔有率較小,但隨著節能型雷射固化隧道成為電動車零件生產線的標準配置,預計將呈現最高的複合成長率。

在受監管地區,水性塗料在汽車被覆劑市場的佔有率已超過60%,這主要得益於汽車修理廠為遵守環保授權規定所採取的措施。樹脂乳化和閃蒸控制的技術突破縮小了水性塗料與溶劑型底漆的性能差距。透過利用模組化樹脂結構,一級供應商能夠在新的法規收緊VOC和HAPS(有害空氣污染物)排放限值時實現快速再製造,從而確保客戶不會因中途合規要求而措手不及。

區域分析

到2024年,亞太地區將佔全球銷售額的58.82%,這主要得益於中國作為淨出口國的崛起及其在電動車生產領域的領先地位。印尼年產100萬噸的塗料廠和越南蓬勃發展的供應商園區等新增產能,將支撐該地區預計6.32%的複合年成長率。本地整車製造商正與跨國配方商合作,在保持與溶劑型塗料視覺效果一致的前提下,實現水性樹脂的本地化生產。政府對新能源汽車的獎勵策略也進一步推動了對電池專用功能塗料的需求。

預計2024年北美輕型車產量將成長9.6%,導致產能受限的廠經常超負荷運轉,進而推高被覆劑價格。美國農業部(USDA)嚴格的BioPreferred法規以及美國環保署(EPA)即將訂定的全氟和多氟烷基物質(PFAS)法規,正在推動無氟面漆的快速認證,並迫使供應商加快研發步伐。隨著加拿大和墨西哥的生產營運與美國法規接軌,低VOC汽車被覆劑系統的市場佔有率預計將會擴大。

歐洲對碳中和的重視促使原始設備製造商(OEM)致力於打造100%使用可再生電力的噴漆車間和溶劑回收焚化爐。二氧化鈦反傾銷稅推高了成本,但乾式清洗噴漆房和閉合迴路污泥回收技術的廣泛應用在一定程度上抵消了這些成本。東歐地區(包括波蘭和匈牙利)的叢集發展迅速,在提供低成本組裝的同時,也要求供應商建立一級噴漆模組的準時制生產中心。

在南美洲,南方共同市場關稅下調促使汽車製造商將新的SUV平台分配給巴西和阿根廷,增加了整車漆的消耗量。然而,由於外匯波動,油漆製造商往往採用與美國掛鉤的合約。中東和非洲的油漆市場雖然仍處於起步階段,但前景廣闊,沙烏地阿拉伯的「2030願景」正在推動相關油漆產能的擴張,以滿足國內汽車生產和出口市場的需求。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 全球汽車生產復甦

- 為符合VOC法規,轉向水性及粉末塗料系統。

- 對用於電池溫度控管的電動車專用塗層的需求不斷成長

- 成熟市場的碰撞維修量復甦

- OEM廠商採用數位配色和線上固化技術

- 市場限制

- 嚴格的溶劑和異氰酸酯暴露規定

- 波動劇烈的石油化學原料價格

- 電動滑板平台,減少噴漆面積

- 價值鏈分析

- 波特五力模型

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

第5章 市場規模與成長預測

- 依樹脂類型

- 聚氨酯

- 環氧樹脂

- 丙烯酸纖維

- 其他

- 透過技術

- 溶劑型

- 水系統

- 粉末

- 塗層

- 電著底漆

- 底漆

- 底塗層

- 透明塗層

- 透過使用

- OEM

- 翻新

- 按地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 澳洲、紐西蘭

- 印尼

- 馬來西亞

- 泰國

- 其他東協國家

- 亞太其他地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 法國

- 英國

- 義大利

- 西班牙

- 俄羅斯

- 其他歐洲地區

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 埃及

- 其他中東和非洲地區

- 亞太地區

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率分析

- 公司簡介

- Akzo Nobel NV

- Asian Paints PPG Pvt., Ltd.

- Axalta Coating Systems, LLC

- BASF

- Beckers Group

- Cabot Corporation

- Eastman Chemical Company

- Hempel A/S

- HMG Paints Limited

- Jotun

- Kansai Nerolac Paints Limited

- KCC Corporation

- Nippon Paint Holdings Co., Ltd.

- Parker Hannifin Corp

- PPG Industries Inc.

- RPM International Inc.

- Shanghai Kinlita Chemical Co., Ltd.

- The Sherwin-Williams Company

第7章 市場機會與未來展望

The Automotive Coatings Market size is estimated at USD 29.60 Billion in 2025, and is expected to reach USD 37.67 Billion by 2030, at a CAGR of 4.94% during the forecast period (2025-2030).

The rebound in global vehicle production, the pivot toward low-Volatile Organic Compound (VOC) formulations, and surging electric-vehicle (EV) output underpin demand expansion, even as raw-material price swings and tightening solvent regulations constrain margins. Suppliers are accelerating launches of water-borne and powder systems that comply with imminent emissions caps while still delivering Original Equipment Manufacturer (OEM)-level durability. OEM paint-shop digitalization spanning inline curing, robotic inspection, and cloud-based color matching is raising throughput and widening technical barriers to entry. Meanwhile, fragmentation persists as regional midsized suppliers vie for share against multinationals that can fund large-scale sustainability and automation programs.

Global Automotive Coatings Market Trends and Insights

Growing Global Vehicle Production Rebound

North American light-vehicle output reached 15.5 Million units in 2024 and continues rising, sustaining factory demand for exterior and under-body coatings. Light trucks now represent 84% of monthly sales, propelling the consumption of premium, scratch-resistant clear coats. In China, capacity additions and export momentum reinforce steady coating volumes, even as localized overcapacity looms. Automakers worldwide reinstate predictable sourcing schedules after pandemic disruptions, enabling suppliers to optimize batch production and logistics. Parallel investments in advanced paint-shop automation and differentiated finishes surfaced as OEMs seek brand-distinctive aesthetics while meeting durability standards .

Shift Toward Water-borne & Powder Systems to Meet VOC Caps

The 2025 enforcement of stricter VOC ceilings in California and forthcoming EU Green Deal measures are accelerating reformulation of solvent-borne systems. Leading body shops already report 64% penetration of water-borne basecoats, validating commercial viability. BASF's Glasurit 100 Line exemplifies high-efficiency, low-VOC products now used by more than 1,000 collision centers. Powder coatings are gaining share in wheels, under-hood parts, and EV battery casings, helped by laser-curing ovens that cut energy use by 50%. Suppliers with broad resin and pigment portfolios are fastest to convert customers, establishing early-mover advantages before regulations tighten further.

Stringent Solvent & Isocyanate Exposure Limits

Occupational Safety and Health Administration (OSHA)'s National Emphasis Program intensifies inspections of paint booths, mandating enhanced ventilation and personal protective equipment to mitigate asthma and dermatitis risks from isocyanates . Small refinishing operations face steep capital costs for compliant spray booths or must migrate to low-isocyanate chemistries that may sacrifice performance. Primer and clear-coat formulators commercialize polyurea-free variants, although adoption remains cautious while durability benchmarks are validated.

Other drivers and restraints analyzed in the detailed report include:

- Rising EV-specific Coating Demand for Battery Thermal Management

- Recovery of Collision-repair Volumes in Mature Markets

- Volatile Petrochemical-based Raw-material Pricing

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

In 2024, acrylics supplied 48.55% of the Automotive Coatings market demand, cementing their status owing to cost-efficiency and balanced weatherability. Polyurethane formulations, advancing at a 5.18% CAGR to 2030, fulfill premium clear-coat and flexible-substrate needs, especially on luxury Sports Utility Vehicles (SUVs) and EVs requiring superior scratch resistance. The automotive coatings market size for polyurethane systems is expected to widen notably in North American OEM lines as new aliphatic diisocyanate chemistries meet stricter yellowing tests. Epoxy resins continue niche dominance in cathodic e-coats where corrosion protection is critical, while bio-based hybrids are emerging in concept programs led by European OEMs.

The polyurethane push is amplified by longer ownership cycles driving demand for durability, though OSHA scrutiny around isocyanate handling is prompting investment in closed-mixing cells and robot-spray enclosures. Suppliers such as Covestro now offer 33% renewable-carbon polyurethanes, illustrating alignment with OEM sustainability targets. Acrylic chemists are responding with next-generation crosslinkers that improve mar resistance without raising VOC levels. Competitive advantage increasingly hinges on patent portfolios that combine mechanical robustness with low-temperature cure profiles, addressing both energy-use mandates and lightweight-substrate requirements.

Solvent-borne finishes still held 70.85% revenue in 2024, propelled by superior flow and color depth demanded on metallic and pearlescent shades. Yet the automotive coatings market is unmistakably tilting toward alternatives as global VOC ceilings narrow. Water-borne systems now dominate EU OEM base-coat lines, with Japanese OEMs such as Mazda achieving industry-low emissions of 15 g VOC/m2. Powder coatings, while presently a minority, post the highest compound growth as energy-efficient laser-cure tunnels become standard on EV component lines.

The automotive coatings market share for water-borne refinish lines has surpassed 60% in regulated regions as body shops align with environmental permits. Technological breakthroughs in resin emulsification and flash-off control have closed the performance gap with solvent-borne primers. Tier-one suppliers leverage modular resin architectures, enabling fast reformulation when each new rule tightens permissible VOCs or HAPS (hazardous air pollutants), insulating customers from mid-cycle compliance surprises.

The Automotive Coatings Market Report is Segmented by Resin Type (Polyurethane, Epoxy, Acrylic, and Others), Technology (Solvent-Borne, Water-Borne, and Powder), Coating Layer (E-Coat, Primer, Base Coat, and Clear Coat), Application (OEM and Refinish), and Geography (Asia-Pacific, North America, Europe, South America, and Middle East and Africa). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific accounted for 58.82% of global 2024 revenue, buoyed by China's ascent as a net exporter and leadership in EV output. Capacity additions such as Indonesia's million-ton paint plant and Vietnam's fast-growing supplier parks underpin a 6.32% regional CAGR forecast. Local OEMs collaborate with multinational formulators to localize water-borne resins while preserving appearance parity with solvent benchmarks. Government stimulus on new-energy vehicles further amplifies demand for battery-specific functional coatings.

North America, with light-vehicle builds rising 9.6% in 2024, exhibits that constrained capacity plants regularly exceed rated throughput, creating favorable pricing for coatings. Stringent United States Department of Agriculture (USDA) BioPreferred and upcoming Environmental Protection Agency (EPA) per- and polyfluoroalkyl substances (PFAS) rules spur rapid qualification of fluorine-free top coats, compelling suppliers to accelerate R&D. The automotive coatings market share of low-VOC systems is poised to expand as Canadian and Mexican operations align with United States regulations.

Europe's focus on carbon neutrality pushes OEMs toward 100% renewable-electric paint shops and solvent-capture incinerators. Anti-dumping duties on titanium dioxide elevate cost structures, but wide adoption of dry-scrubber booths and closed-loop sludge recycling partially offsets outlays. Eastern European cluster growth, including Poland and Hungary offers lower-wage assembly yet requires suppliers to establish just-in-sequence hubs for tier-one paint modules.

South America benefits from Mercosur tariff reductions that encourage automakers to allocate new SUV platforms to Brazil and Argentina, lifting OEM-paint consumption. Nonetheless, currency volatility prompts formulators to adopt US-dollar-pegged contracts. Middle East & Africa remains nascent but shows promise as Saudi Arabia's Vision 2030 sparks domestic vehicle production and related coating capacity build-outs targeting export markets.

- Akzo Nobel N.V.

- Asian Paints PPG Pvt., Ltd.

- Axalta Coating Systems, LLC

- BASF

- Beckers Group

- Cabot Corporation

- Eastman Chemical Company

- Hempel A/S

- HMG Paints Limited

- Jotun

- Kansai Nerolac Paints Limited

- KCC Corporation

- Nippon Paint Holdings Co., Ltd.

- Parker Hannifin Corp

- PPG Industries Inc.

- RPM International Inc.

- Shanghai Kinlita Chemical Co., Ltd.

- The Sherwin-Williams Company

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions & Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Growing Global Vehicle Production Rebound

- 4.2.2 Shift Toward Water-borne & Powder Systems to Meet VOC Caps

- 4.2.3 Rising EV-specific Coating Demand for Battery Thermal Management

- 4.2.4 Recovery of Collision-repair Volumes in Mature Markets

- 4.2.5 OEM Adoption of Digital Color-matching & Inline Curing

- 4.3 Market Restraints

- 4.3.1 Stringent Solvent & Isocyanate Exposure Limits

- 4.3.2 Volatile Petrochemical-based Raw-material Pricing

- 4.3.3 EV Skateboard Platforms Reducing Painted Surface Area

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitute Products & Services

- 4.5.5 Degree of Competition

5 Market Size & Growth Forecasts (Value)

- 5.1 By Resin Type

- 5.1.1 Polyurethane

- 5.1.2 Epoxy

- 5.1.3 Acrylic

- 5.1.4 Others

- 5.2 By Technology

- 5.2.1 Solvent-borne

- 5.2.2 Water-borne

- 5.2.3 Powder

- 5.3 By Coating Layer

- 5.3.1 E-coat

- 5.3.2 Primer

- 5.3.3 Base Coat

- 5.3.4 Clear Coat

- 5.4 By Application

- 5.4.1 OEM

- 5.4.2 Refinish

- 5.5 By Geography

- 5.5.1 Asia-Pacific

- 5.5.1.1 China

- 5.5.1.2 India

- 5.5.1.3 Japan

- 5.5.1.4 South Korea

- 5.5.1.5 Australia and New Zealand

- 5.5.1.6 Indonesia

- 5.5.1.7 Malaysia

- 5.5.1.8 Thailand

- 5.5.1.9 Rest of ASEAN

- 5.5.1.10 Rest of Asia-Pacific

- 5.5.2 North America

- 5.5.2.1 United States

- 5.5.2.2 Canada

- 5.5.2.3 Mexico

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 France

- 5.5.3.3 United Kingdom

- 5.5.3.4 Italy

- 5.5.3.5 Spain

- 5.5.3.6 Russia

- 5.5.3.7 Rest of Europe

- 5.5.4 South America

- 5.5.4.1 Brazil

- 5.5.4.2 Argentina

- 5.5.4.3 Rest of South America

- 5.5.5 Middle East and Africa

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 South Africa

- 5.5.5.3 Egypt

- 5.5.5.4 Rest of Middle East and Africa

- 5.5.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products & Services, and Recent Developments)

- 6.4.1 Akzo Nobel N.V.

- 6.4.2 Asian Paints PPG Pvt., Ltd.

- 6.4.3 Axalta Coating Systems, LLC

- 6.4.4 BASF

- 6.4.5 Beckers Group

- 6.4.6 Cabot Corporation

- 6.4.7 Eastman Chemical Company

- 6.4.8 Hempel A/S

- 6.4.9 HMG Paints Limited

- 6.4.10 Jotun

- 6.4.11 Kansai Nerolac Paints Limited

- 6.4.12 KCC Corporation

- 6.4.13 Nippon Paint Holdings Co., Ltd.

- 6.4.14 Parker Hannifin Corp

- 6.4.15 PPG Industries Inc.

- 6.4.16 RPM International Inc.

- 6.4.17 Shanghai Kinlita Chemical Co., Ltd.

- 6.4.18 The Sherwin-Williams Company

7 Market Opportunities & Future Outlook

- 7.1 White-space & Unmet-need Assessment

- 7.2 Self-Cleaning Coating Technology