|

市場調查報告書

商品編碼

1851405

智慧布料:市場佔有率分析、產業趨勢、統計數據和成長預測(2025-2030 年)Smart Fabrics - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

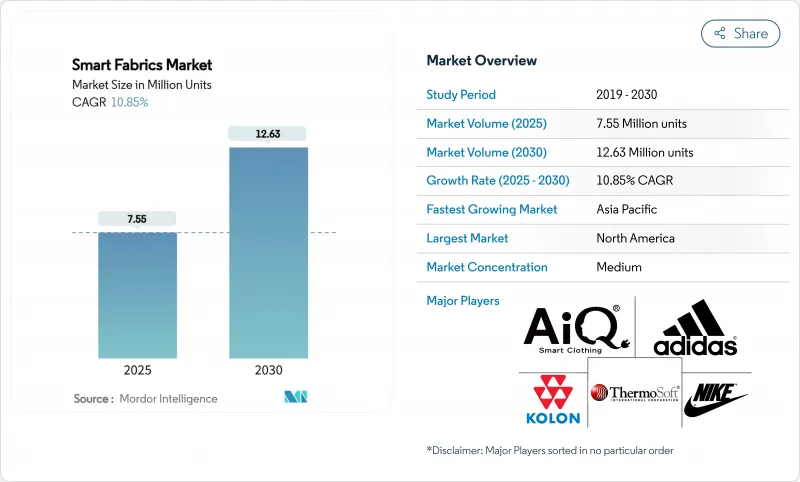

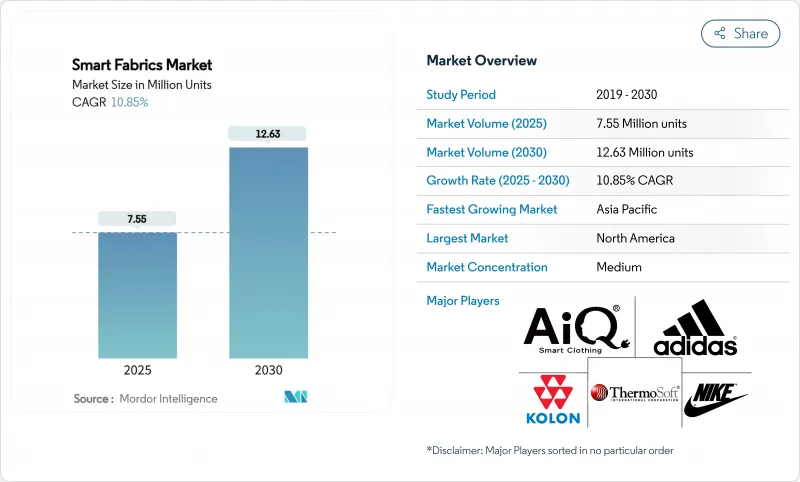

預計到 2025 年,智慧布料市場銷售量將達到 775 萬件,到 2030 年將達到 1,263 萬件,複合年成長率為 10.85%。

國防、醫療保健和體育領域的應用日益廣泛,正加速傳統紡織品向智慧布料的轉型,這些布料能夠感知、收集能量並通訊。軍方合約中對認知負荷監測服飾的指定要求、利用紡織電腦進行即時診斷的醫療保健試點項目,以及消費者對高性能服飾的需求,都在推動著市場機會。隨著導電紗線和軟性積體電路專利活動的持續成長,以及紡織集團與電子供應商之間的合作擴大了生產規模,投資者信心仍然強勁。在永續性壓力、元件小型化和自主電源系統協同作用的推動下,智慧布料市場正處於變革性發展階段。

全球智慧布料市場趨勢與洞察

穿戴式電子產品生態系統正在不斷發展壯大

隨著穿戴式裝置的蓬勃發展,智慧服裝的需求也隨之飆升。滑鐵盧大學的研究人員展示了一種能夠利用太陽能和體熱能的布料,無需外接電池。康乃爾大學的「Seam Fit Shirt」智慧貼合襯衫,將導電線縫入日常T卹中,能夠以93.4%的準確率識別運動。加州理工學院的智慧繃帶能夠以專家級的準確度預測創傷治療。 《衛報》報導了一種基於紡織材料的電子產品,它能夠利用環境電磁能,將人體變成電路的一部分,為嵌入服裝中的超低功耗感測器供電。這些進步正在模糊服裝和電子產品之間的界限,並將智慧布料市場拓展到生活方式、醫療和工業等領域。

快速小型化和靈活的積體電路整合

整合電子技術提升了布料的舒適閾值。麻省理工學院的工程師們製造出一種可機洗的彈力紡織電腦,其內部整合了微型裝置、感測器和藍牙模組,使其成為北極任務中監測生命徵象的穿戴式設備,且不會增加衣物的體積。香港大學開發的有機電化學電晶體可在布料上局部處理數據,從而降低傳輸負載並提升隱私性。這些突破性進展將先進的處理能力融入紡織品內部,同時保持了布料的垂墜性和柔韌性,從而提高了消費者的接受度。

高昂的製造成本和網路安全風險

生產線需要專用設備來嵌入導體、感測器和微控制器,這使得單位成本高於標準紡織品。 2024年的通膨和供應鏈中斷進一步擠壓了美國的淨利率,許多紡織廠因此將資本投資從自動化升級轉向其他領域。資料安全也是一個值得關注的問題,因為服飾會收集生物識別資訊,而這些資訊受健康數據法規的約束。加密需要額外的組件成本,而且產品生命週期內強制性的軟體更新也會增加總擁有成本。小型品牌在獲得合規設計所需的資金方面面臨重重困難,減緩了它們進入低收入市場的步伐。

細分市場分析

隨著預測分析和自動化適應技術從實驗室走向大規模生產,預計到2030年,超智慧布料將以11.2%的複合年成長率領先該細分市場。由於被動式布料在基礎感測任務中展現出卓越的耐用性,目前仍佔據智慧布料市場45.3%的佔有率。能夠根據刺激改變透氣性等特性的主動式布料填補了這一市場空白,但必須克服性能和耐用性之間的權衡問題。

這種採用壓電紗線的智慧聲學布料,能夠將彎曲和觸摸轉化為精確的電訊號,即使全天穿著也能保持透氣性和溫度穩定性。目前正在開發平臺的是一種整合在布料上的神經網路,它可以學習磨損模式、預測異常情況並主動發出健康警報。這些功能賦予了超智慧布料明顯的價值溢價,推動了智慧布料在高性能運動服、國防和慢性病監測等領域的市場佔有率成長。

智慧聲學技術將惠及被動式和主動式產品。巧妙的分層技術將提高訊號雜訊比,進而提升入門級平衡監控腰帶和經濟型姿勢矯正器的效能。被動式產品製造商可以利用成熟的織布機技術,因此其規模擴張速度比超智慧的新興企業更快。隨著生產線的融合,織布機製造商和晶片供應商共用專利,導致產量比率下降,並平衡了各層級產品的成長。

到2024年,感測功能將維持智慧布料市場56.1%的佔有率,而能源採集功能預計將以13.5%的最高複合年成長率成長。利用相變油墨和微流體通道加熱和冷卻的恆溫毛衣滿足了特定的性能需求,而發光布料則為美觀的鞋履和活動服裝增添了光彩。

這款手環內建高效摩擦奈米發電機,在劇烈運動期間可提供超過 3mW/cm² 的功率,無需外部電源即可永續發出藍牙訊號。與這些發電機配套的耐濕超級電容可維持數天的電量,無需每日充電。這種供電系統有望實用化救援隊的自主式野戰服和即使在病人臥床不起的情況下也能監測生命徵象的醫院罩衣。

感測技術憑藉著運動T卹中普遍存在的心率和體溫模組,保持著領先地位。基於纖維的感應線圈可以測量肌肉氧合情況,從而拓展了運動裝備在預防運動傷害方面的作用。隨著製造商將多功能紗線融入產品線,感測技術與微能量單元結合,使得這些技術類別相輔相成,而非相互排斥。

智慧布料市場按類型(被動式智慧布料、主動式智慧布料、超智慧布料)、功能(感測、溫度調節、其他)、材質(棉基、聚酯纖維/尼龍、高性能)、應用(時尚娛樂、運動健身、其他)和地區進行細分。市場預測以銷售量(單位)為單位。

區域分析

預計到2024年,北美將以28.5%的市場佔有率領先市場,這主要得益於強勁的國防預算、蓬勃發展的健康科技生態系統以及消費者對創新運動服裝的熱情。美國國防部正在資助纖維電腦和氣候適應型製服的研發,從而確保了國內對高規格材料的需求。麻省理工學院(MIT)、滑鐵盧大學和加州理工學院(Caltech)正在扶持那些授權其紡織平台的新興企業,從而豐富了該地區的創新管道。一些工廠已將生產轉移到近岸地區以緩解供應衝擊,而旨在重組本地製造業的政府激勵措施也已被取消。

亞太地區是經濟成長的引擎,預計到2030年將以12.3%的複合年成長率成長。中國產業用紡織品產業已佔紡織業總量的20%以上,在醫療、過濾和防護等領域實現了9%至13%的年成長率。北京矩陣科技的Y-Warm隔熱材料具有優異的隔熱和抗菌性能,為寒冷氣候運動服裝品牌提供了出口潛力。一家日本供應商正在改進超細導電長絲,一家韓國企業正在將可水洗的OLED紗線圖案商業化,用於互動服裝。印度正在扶持新興企業,這展現了該地區廣泛的應用前景。

歐洲正處於永續性需求與先進工程技術的交會點。歐盟正在推進全氟烷基和多氟烷基物質(PFAS)的監管,並研究既能保持導電性又能降低有害物質風險的替代塗層。蘭精公司已收購TreeToTextile公司的少數股權,該公司正快速開發水和能源消耗更低的纖維素纖維。德國、法國和西班牙正在培育紡織品回收叢集,而消費者調查顯示,消費者對永續性溢價非常敏感。一所大學正與一家汽車零件製造商合作開發能夠檢測駕駛員疲勞的座椅布料,這將擴大該技術在工業領域的應用,並鞏固歐洲作為智慧布料市場創新中心的地位。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 穿戴式電子產品的生態系統正在不斷發展

- 快速小型化和靈活的積體電路整合

- 導電紗線專利申請數量快速成長(自2025年起)

- 能源採集超級電容

- 軍方強制要求使用認知負荷監測設備

- 來自循環紡織品牌的永續性溢價

- 市場限制

- 高昂的製造成本和網路安全風險

- 缺乏全球電子紡織品互通性標準

- 奈米塗層毒性新規

- 電子紡織廢棄物消費後回收的複雜性

- 供應鏈分析

- 監管環境

- 技術展望

- 波特五力分析

- 新進入者的威脅

- 供應商的議價能力

- 買方的議價能力

- 替代品的威脅

- 競爭對手之間的競爭

- 評估市場的宏觀經濟因素

第5章 市場規模與成長預測

- 按類型

- 被動式智慧織物

- 主動式智慧布料

- 超智慧布料

- 功能

- 感測

- 體溫調節

- 能源採集

- 明亮美觀

- 材料

- 棉基

- 聚酯纖維和尼龍

- 高性能材料(克維拉、Dyneema等)

- 透過使用

- 時尚與娛樂

- 運動與健身

- 醫療保健

- 交通運輸-汽車和航太

- 軍事/國防

- 工業與安全

- 按地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 俄羅斯

- 其他歐洲地區

- 亞太地區

- 中國

- 日本

- 韓國

- 印度

- 澳洲和紐西蘭

- 亞太其他地區

- 中東和非洲

- 中東

- 土耳其

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 其他中東地區

- 非洲

- 南非

- 奈及利亞

- 其他非洲地區

- 北美洲

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率分析

- 公司簡介

- Adidas AG

- NIKE Inc.

- AIQ Smart Clothing Inc.

- DuPont de Nemours Inc.

- Kolon Industries Inc.

- Sensoria Inc.

- ThermoSoft International Corp.

- Interactive Wear AG

- Ohmatex ApS

- Schoeller Textil AG

- Toray Industries Inc.

- Hexoskin/Carre Technologies Inc.

- Gentherm Inc.

- VF Corporation(The North Face)

- Under Armour Inc.

- Laird PLC(Advanced Thermal)

- Jabil Inc.(BlueSky e-textile)

- Google LLC(Jacquard by Levi's)

- Textronics Inc.

- Wearable X

- VT Garment Co.(Gravitech)

第7章 市場機會與未來展望

The smart fabrics market recorded volume sales of 7.75 million units in 2025 and is on course to reach 12.63 million units by 2030, representing a compound annual growth rate (CAGR) of 10.85%.

Rising adoption across defense, healthcare, and sports segments is accelerating the transition from conventional textiles to intelligent fabrics that sense, harvest energy, and communicate. Military contracts that specify cognitive-load monitoring garments, healthcare pilots that use fiber computers for real-time diagnostics, and consumer demand for performance apparel are broadening commercial opportunities. Investor confidence remains solid as patent activity in conductive yarns and flexible integrated circuits continues to grow, while partnerships between textile groups and electronics suppliers scale manufacturing. The interplay of sustainability pressures, miniaturized components, and autonomous power systems keeps the smart fabrics market on a transformative trajectory.

Global Smart Fabrics Market Trends and Insights

Growth in Wearable-Electronics Ecosystem

Demand for smart garments has surged in tandem with the wider wearable device boom. Researchers at the University of Waterloo demonstrated fabrics that harvest solar and body-heat energy, removing the need for external batteries. Cornell University's SeamFit shirts classified exercises with 93.4% accuracy using conductive threads stitched into everyday tees. Healthcare prototypes are progressing quickly, including smart bandages from the California Institute of Technology that predict wound-healing timelines at expert-level precision. The Guardian reported fiber-based electronics that draw ambient electromagnetic energy, turning the human body into part of the circuit and fueling ultra-low-power sensors embedded inside clothing. Collectively, these advances blur the line between attire and electronics, expanding the smart fabrics market into lifestyle, medical, and industrial realms.

Rapid Miniaturization and Flexible-IC Integration

The threshold at which integrated electronics compromise fabric comfort has shifted. MIT engineers produced elastic fiber computers containing micro-devices, sensors, and Bluetooth modules that survive machine washes, enabling Arctic mission wearables that monitor vital signs without bulk.Embroidered triboelectric nanogenerators yielded 307.5 µJ per sliding cycle, showcasing viable energy capture through regular garment motion. Organic electrochemical transistors developed at the University of Hong Kong now process data locally on the fabric, lowering transmission loads and boosting privacy. These breakthroughs place sophisticated processing power inside textiles while preserving drape and flexibility, enhancing consumer acceptance.

High Fabrication Cost and Cybersecurity Risks

Production lines require specialized equipment for embedding conductors, sensors, and microcontrollers, pushing unit costs above those of regular textiles. Inflation and supply chain disruptions in 2024 further squeezed margins for U.S. textile mills, many of which diverted capex away from automation upgrades. Data security remains a parallel concern because garments collect biometrics that fall under health-data regulations. Encryption adds component expense and mandates software updates throughout a product's life, increasing total cost of ownership. Smaller brands face hurdles securing capital for compliant design, slowing penetration in low-income markets.

Other drivers and restraints analyzed in the detailed report include:

- Textile-Embedded Energy-Harvesting Supercapacitors

- Military Mandates for Cognitive-Load Monitoring Gear

- Absence of Global E-Textile Interoperability Standards

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Ultra-smart variants are forecast to post the segment-leading 11.2% CAGR to 2030 as predictive analytics and automated adaptation move from labs into volume production. Passive formats still command 45.3% of the smart fabrics market due to proven durability across basic sensing tasks. Active fabrics, which modify properties like breathability in response to stimuli, bridge the gap but must overcome power and durability trade-offs.

Smart acoustic cloth using piezoelectric threads translates bending and touch into precise electrical signals, maintaining airflow and thermal stability for day-long wear. R&D pipelines are embedding on-textile neural networks that learn wearer patterns and predict anomalies, unlocking proactive wellness alerts. These capabilities give Ultra-smart fabrics a clear value premium, propelling their share of the smart fabrics market in high-performance sportswear, defense, and chronic-care monitoring.

Smart acoustics also benefit Passive and Active categories. Tailored layering schemes now boost signal-to-noise ratios, enhancing entry-level balance monitoring belts and low-cost posture trainers. Builders of Passive goods leverage established looms, so they scale faster than Ultra-smart newcomers. As manufacturing lines converge, patent sharing between loom makers and chip vendors will compress yields, balancing growth across tiers.

Energy Harvesting functions show the highest forecast CAGR of 13.5%, though Sensing retained a 56.1% share of the smart fabrics market in 2024. Thermoregulation sweaters that heat or cool through phase-change inks and microfluidic channels fulfill niche performance needs, while luminescent fabrics enrich aesthetic footwear and event costumes.

Efficient triboelectric nanogenerators woven into arm bands now deliver over 3 mW cm-2 during intense motion, enabling continuous Bluetooth beacons without external power arxiv.org. Moisture-enabled supercapacitors pair with those generators to retain charge for days, removing the daily charging chore. These power systems make autonomous field jackets viable for rescue crews and enable hospital gowns that track vitals even when patients lack mobility.

Sensing retains leadership through ubiquitous heart-rate and temperature modules in workout tees. Textile-based inductive coils measure muscle oxygenation, expanding the role of sports gear in injury prevention. As manufacturers integrate multi-functional yarns, product families combine sensing with micro-energy cells, making the categories mutually reinforcing rather than mutually exclusive.

Smart Fabrics Market is Segmented by Type (Passive Smart Fabrics, Active Smart Fabrics, Ultra-Smart Fabrics), Functionality (Sensing, Thermoregulation, and More), Material (Cotton-Based, Polyester and Nylon, High-Performance), Application (Fashion and Entertainment, Sports and Fitness, and More), and Geography. The Market Forecasts are Provided in Terms of Volume (Units).

Geography Analysis

North America led with 28.5% market share in 2024 on the back of strong defense budgets, vibrant health-tech ecosystems, and consumer enthusiasm for innovative sportswear. The Department of Defense funds fiber computers and climate-adaptive uniforms, ensuring domestic demand for high-spec fabrics. MIT, University of Waterloo, and Caltech spin out start-ups that license their textile platforms, keeping regional innovation pipelines full. Several mills moved to near-shore production to mitigate supply shocks, unlocking government incentives aimed at rebuilding local manufacturing.

Asia Pacific is the growth engine, projected at a 12.3% CAGR through 2030. China's technical textile segment already forms over 20% of its broader textile industry, posting 9-13% annual growth in medical, filtration, and protective categories. Beijing MatrixTech's Y-Warm insulation delivers superior thermal retention and antimicrobial properties, offering export potential to cold-weather sportswear brands. Japanese suppliers refine ultrafine conductive filaments, while Korean groups commercialize washable OLED thread patterns for interactive apparel. India nurtures start-ups that craft price-competitive smart bandages for rural clinics, demonstrating the region's wide application spread.

Europe sits at the convergence of sustainability mandates and advanced engineering. The bloc's progressive PFAS restrictions drive research into alternative coatings that cut toxic risk yet retain conductivity. Lenzing's minority stake in TreeToTextile fast-tracks cellulose fibers that lower water and energy footprints. Germany, France, and Spain foster textile recycling clusters, but consumer surveys reveal price sensitivity to sustainability premiums. Universities collaborate with automotive suppliers on seat fabrics that detect driver fatigue, broadening industrial uptake and reinforcing Europe's role as an innovation hub in the smart fabrics market.

- Adidas AG

- NIKE Inc.

- AIQ Smart Clothing Inc.

- DuPont de Nemours Inc.

- Kolon Industries Inc.

- Sensoria Inc.

- ThermoSoft International Corp.

- Interactive Wear AG

- Ohmatex ApS

- Schoeller Textil AG

- Toray Industries Inc.

- Hexoskin / Carre Technologies Inc.

- Gentherm Inc.

- VF Corporation (The North Face)

- Under Armour Inc.

- Laird PLC (Advanced Thermal)

- Jabil Inc. (BlueSky e-textile)

- Google LLC (Jacquard by Levi's)

- Textronics Inc.

- Wearable X

- VT Garment Co. (Gravitech)

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Growth in wearable-electronics ecosystem

- 4.2.2 Rapid miniaturization and flexible-IC integration

- 4.2.3 Surge in conductive-yarn patent filings (post-2025)

- 4.2.4 Textile-embedded energy-harvesting supercapacitors

- 4.2.5 Military mandates for cognitive-load monitoring gear

- 4.2.6 Sustainability premiums from circular-textile brands

- 4.3 Market Restraints

- 4.3.1 High fabrication cost and cybersecurity risks

- 4.3.2 Absence of global e-textile interoperability standards

- 4.3.3 Emerging toxicity rules on nano-coatings

- 4.3.4 End-of-life recycling complexity of e-textile waste

- 4.4 Supply-Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Threat of New Entrants

- 4.7.2 Bargaining Power of Suppliers

- 4.7.3 Bargaining Power of Buyers

- 4.7.4 Threat of Substitutes

- 4.7.5 Competitive Rivalry

- 4.8 Assesment of Macroeconomic Factors on the Market

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Type

- 5.1.1 Passive Smart Fabrics

- 5.1.2 Active Smart Fabrics

- 5.1.3 Ultra-smart Fabrics

- 5.2 By Functionality

- 5.2.1 Sensing

- 5.2.2 Thermoregulation

- 5.2.3 Energy Harvesting

- 5.2.4 Luminescent and Aesthetic

- 5.3 By Material

- 5.3.1 Cotton-based

- 5.3.2 Polyester and Nylon

- 5.3.3 High-performance (Kevlar, Dyneema, etc.)

- 5.4 By Application

- 5.4.1 Fashion and Entertainment

- 5.4.2 Sports and Fitness

- 5.4.3 Medical and Healthcare

- 5.4.4 Transportation - Automotive and Aerospace

- 5.4.5 Military and Defense

- 5.4.6 Industrial and Safety

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 South America

- 5.5.2.1 Brazil

- 5.5.2.2 Argentina

- 5.5.2.3 Rest of South America

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Spain

- 5.5.3.6 Russia

- 5.5.3.7 Rest of Europe

- 5.5.4 Asia-Pacific

- 5.5.4.1 China

- 5.5.4.2 Japan

- 5.5.4.3 South Korea

- 5.5.4.4 India

- 5.5.4.5 Australia and New Zealand

- 5.5.4.6 Rest of Asia-Pacific

- 5.5.5 Middle East and Africa

- 5.5.5.1 Middle East

- 5.5.5.1.1 Turkey

- 5.5.5.1.2 Saudi Arabia

- 5.5.5.1.3 United Arab Emirates

- 5.5.5.1.4 Rest of Middle East

- 5.5.5.2 Africa

- 5.5.5.2.1 South Africa

- 5.5.5.2.2 Nigeria

- 5.5.5.2.3 Rest of Africa

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Adidas AG

- 6.4.2 NIKE Inc.

- 6.4.3 AIQ Smart Clothing Inc.

- 6.4.4 DuPont de Nemours Inc.

- 6.4.5 Kolon Industries Inc.

- 6.4.6 Sensoria Inc.

- 6.4.7 ThermoSoft International Corp.

- 6.4.8 Interactive Wear AG

- 6.4.9 Ohmatex ApS

- 6.4.10 Schoeller Textil AG

- 6.4.11 Toray Industries Inc.

- 6.4.12 Hexoskin / Carre Technologies Inc.

- 6.4.13 Gentherm Inc.

- 6.4.14 VF Corporation (The North Face)

- 6.4.15 Under Armour Inc.

- 6.4.16 Laird PLC (Advanced Thermal)

- 6.4.17 Jabil Inc. (BlueSky e-textile)

- 6.4.18 Google LLC (Jacquard by Levi's)

- 6.4.19 Textronics Inc.

- 6.4.20 Wearable X

- 6.4.21 VT Garment Co. (Gravitech)

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-need Assessment