|

市場調查報告書

商品編碼

1851394

高速攝影機:市場佔有率分析、產業趨勢、統計數據和成長預測(2025-2030 年)High Speed Cameras - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

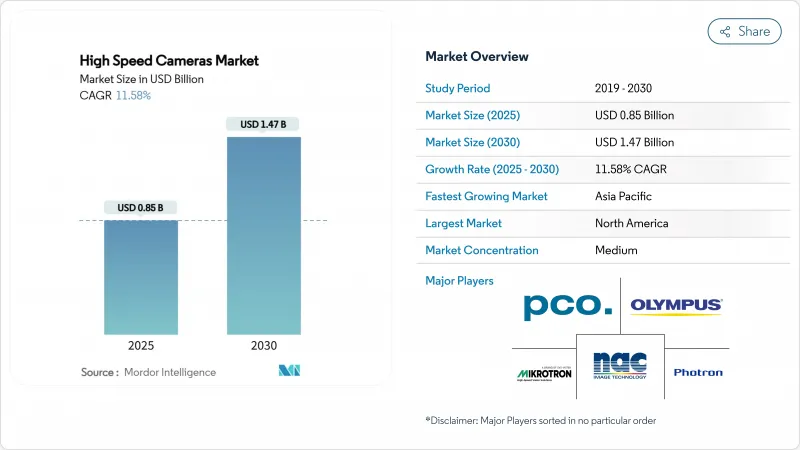

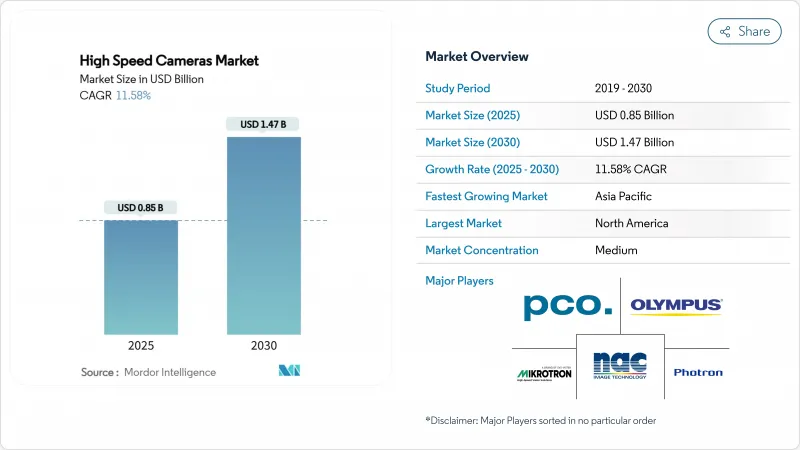

預計到 2025 年,高速攝影機市場規模將成長至 8.5 億美元,到 2030 年將成長至 14.7 億美元,複合年成長率為 11.58%。

推動這項技術廣泛應用的關鍵在於超高速影像處理能夠揭示以往難以測量的現象,例如碰撞測試中的微小形變以及高超音速衝擊波的傳播。半導體晶圓偵測、自動駕駛汽車安全檢驗以及8K體育賽事轉播等應用都需要遠高於1000幀/秒的影格速率,通常甚至超過10萬幀/秒。隨著邊緣儲存成本的下降、人工智慧主導的視覺分析技術的整合以及租賃管道的拓展,基本客群正在進一步擴大。亞太地區的晶圓廠和國防機構正在加大投資,而北美則憑藉國防研發和高階體育賽事製作保持領先地位。

全球高速攝影機市場趨勢及洞察

基於人工智慧的視覺分析技術在碰撞測試實驗室中迅速普及

如今,碰撞測試專案依賴機器學習演算法,以微秒級的精度分析變形、氣囊氣流傳播以及感測器融合事件。德國和日本的測試設施需要超過 50,000 FPS的影格速率才能提供訓練神經網路所需的資料密度,這加速了對即使在極高速度下也能保持低雜訊的旗艦級攝影機的需求。自動駕駛車輛檢驗需要以精細的時間尺度記錄所有合成碰撞場景。高速影像處理和人工智慧的協同發展形成了一個良性循環:更豐富的數據可以改進模型,而模型的改進反過來又會推動更高的影格速率閾值。一級供應商已經開始在其測試車上整合高速模組,以實現直接資料登錄。隨著監管機構收緊被動安全標準,駕駛者對高速攝影機市場的中期影響將會增強。

短波紅外線高速相機在半導體晶圓檢測的廣泛應用

5nm以下的先進邏輯節點需要超越可見光相機能力的缺陷偵測技術。短波紅外線(SWIR)成像儀通常基於InGaAs,能夠以每秒數千幀的速度穿透矽層,從而在微影術過程中實現對空洞、圖案崩壞和微污染的線上檢測。韓國和台灣的工廠正在將這些相機整合到多個製程中,以減少廢品並提高生產線產量比率。 SWIR升級的資本效率也影響高階晶圓廠以外的採購標準,中國當地和新加坡的代工廠也正在增加類似的功能。液態金屬散熱器和專有鏡頭塗層等溫度控管創新技術有助於在更高的速度下保持量子效率。這些因素將在短期內影響市場促進因素。

CoaXPress組件的進口關稅推高了物料清單成本。

針對CoaXPress專用晶片組和線纜不斷上漲的貿易關稅,推高了美國以乙太網路為基礎正在逐步推進,但延遲和確定性問題仍然存在。整合商正在增加庫存以對沖關稅波動風險,這加劇了其營運資金緊張的局面。儘管這些政策可能會取消,但高速攝影機市場短期內受到的拖累顯而易見。

細分市場分析

到2024年,影像感測器將佔銷售額的34%,在高速攝影機市場規模的討論中佔據關鍵地位。然而,由於10萬幀/秒突發拍攝對緩衝需求的爆炸性成長,儲存子系統將以13.8%的複合年成長率成長。製造商正在將堆疊式DRAM整合到更靠近感測器的位置,從而縮短走線長度並降低延遲。並行NVMe陣列能夠無遺失幀地記錄UHD輸出,而FPGA則可執行即時壓縮。散熱板和減震底盤也在不斷發展,以散發多餘的熱量並抑制暗電流。

邊緣儲存價格的日益親民使得東協地區的中小型企業能夠將高速影像處理引入以往只能依靠人工質檢的生產線。電源模組也緊接著,鋰硫電池組的出現延長了井下探針的無線運作時間。同時,鏡頭製造商正在改進用於短波紅外線(SWIR)傳輸的低色散光學元件,以滿足半導體檢測需求的激增。總而言之,正是組件創新使企業在高速相機市場中脫穎而出。

2-5MP 級感測器佔據了 42% 的市場佔有率,其兼具足夠的空間細節和永續的數據速率,因此在當前高速相機市場中佔據最大佔有率。然而,隨著像素架構量子效率和讀出速度的提升,5MP 以上的感測器正以 14.8% 的複合年成長率快速成長。 12MP 以上的相機目前已可用於半導體晶圓成像,使 AI 缺陷分類器能夠在不停機的情況下偵測亞微米級缺陷。

新興的全域百葉窗CMOS技術支援透過CoaXPress-12連結以71幀/秒的速度拍攝6500萬像素的影片。體育分析也從中受益:8K慢動作影片能夠展現以往難以察覺的動態細節。隨著主機PC採用PCIe 5.0,像素上限將會提高,進而推動高速攝影機市場向上發展。

高速攝影機市場報告按組件(影像感測器、處理器、底盤及其他)、解析度(低於2MP、2-5MP及其他)、影格速率(250-1K、1-5K、5-20K及其他)、頻譜(可見光、紅外線、X光及其他)、應用(全新、租賃、二手)、市場預測以美元計價。

區域分析

北美地區預計到2024年將維持33%的收入佔有率,主要得益於高超音速研發、8K體育賽事轉播管道以及完善的租賃生態系統。美國國防實驗室正在運作超過10萬幀/秒的攝影機研究等離子體激元引起的衝擊波,而加拿大航太設施則在評估結冰對複合材料機翼的影響。墨西哥的汽車產業走廊提供了穩定的撞擊測試需求。區域供應商透過雙重採購CoaXPress板材來規避關稅風險,從而維持供應鏈的韌性。

亞太地區複合年成長率最高,達13%。韓國和台灣的晶圓廠正全力投入5奈米以下製程的競賽,在微影術工藝流程中部署短波紅外線高速陣列。中國正將國防預算轉向超高速光學技術,以減少對進口感測器的依賴。日本正在將機器人和成像技術整合到需要毫秒級回饋的組裝中,而印度則透過其產品生命週期資訊(PLI)計劃來提升國內電子產品檢測能力。

儘管資料網路發展緩慢,歐洲仍保持穩定成長。德國的原始設備製造商(OEM)憑藉著結合機器視覺和數位雙胞胎的AI增強型防撞機車,引領著產業發展。英國正在推進航太渦輪扇引擎的研究,而法國則將高速影像處理應用於鐵路受電弓監控。在中東,堅固耐用的電池供電攝影機在150攝氏度的高溫下潛入油井,用於診斷堵塞物,證明了即使在惡劣環境下高速成像的可行性。非洲和南美洲仍在發展中,但礦井爆炸分析和大學研究計畫正在興起,這預示著高速攝影機的應用正在日益廣泛。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 在汽車碰撞測試實驗室(德國、日本),基於人工智慧、需要超高影格速率影像處理的視覺分析技術正日益普及。

- SWIR高速相機在半導體晶圓檢測的廣泛應用(韓國、台灣)

- 美國和中國國防預算優先考慮高超音速武器試驗,推動了對10萬幀/秒武器的需求。

- 8K體育賽事轉播加速租賃市場擴張(北美和歐盟)

- 用於井下診斷的耐用型電池供電攝影機(中東)

- 中小企業(東協)採用板載邊緣儲存驅動器的價格下降

- 市場限制

- CoaXPress組件的進口關稅推高了物料清單成本(美國)

- 超過 50k FPS 時,熱噪音和散熱需求限制了可攜式設備的性能。

- 訓練有素的高速影像技術人員短缺(新興市場)

- 歐洲傳統工廠網路導致資料流瓶頸(超過 10Gbps)

- 價值/供應鏈分析

- 監理展望

- 技術展望

- 波特五力分析

- 新進入者的威脅

- 買方的議價能力

- 供應商的議價能力

- 替代品的威脅

- 競爭對手之間的競爭

- 投資分析

第5章 市場規模與成長預測

- 按組件

- 影像感測器

- 處理器和控制器

- 鏡片

- 記憶體系統(板載和外置)

- 車身和底盤

- 冷卻系統

- 電池和電源模組

- 其他(線纜、配件、軟體)

- 通過決議

- 小於200萬像素

- 2-5 MP

- 5 MP-12 MP

- 1200萬像素或以上

- 按影格速率

- 250-1,000 fps

- 1,001-5,000 fps

- 5,001-20,000 fps

- 20,001-100,000 fps

- 超過 100,000 FPS

- 按頻譜類型

- 可見光(RGB)

- 紅外線(近紅外線和中波紅外線)

- 短波紅外線 (SWIR)

- X光

- 紫外線 (UV)

- 依用途類型

- 新相機

- 出租相機

- 二手/翻新相機

- 透過使用

- 汽車和運輸設備碰撞測試

- 航太與國防(風洞、彈道學)

- 工業製造-電子和半導體

- 工業製造 - 通用機械

- 研究與設計—大學與研究機構

- 媒體與娛樂製作

- 體育分析與廣播

- 醫療保健和醫學診斷

- 家用電子電器測試

- 其他(能源、採礦)

- 按地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 英國

- 德國

- 法國

- 義大利

- 其他歐洲地區

- 亞太地區

- 中國

- 日本

- 印度

- 韓國

- 亞太其他地區

- 中東

- 以色列

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 土耳其

- 其他中東地區

- 非洲

- 南非

- 埃及

- 其他非洲地區

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 北美洲

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率分析

- 公司簡介

- Vision Research Inc.

- Photron Ltd.

- Olympus Corporation

- nac Image Technology Inc.

- Mikrotron GmbH

- PCO AG

- Optronis GmbH

- Weisscam GmbH

- Fastec Imaging Corp.

- AOS Technologies AG

- Del Imaging Systems LLC

- IX Cameras Inc.

- Motion Capture Technologies LLC

- Teledyne DALSA Inc.

- Sony Group Corp.

- Grass Valley USA LLC

- Chronos Imaging Inc.

- High-Speed Vision GmbH

- Ametek Inc.(Phantom Brand)

- Red Digital Cinema LLC

第7章 市場機會與未來展望

The high-speed camera market size is valued at USD 0.85 billion in 2025 and is projected to advance to USD 1.47 billion by 2030, translating to an 11.58% CAGR.

Strong uptake stems from the ability of ultra-fast imaging to unravel phenomena that once escaped measurement-ranging from crash-test micro-deformations to hypersonic shock-wave propagation. Semiconductor wafer inspection, autonomous-vehicle safety validation, and live 8K sports broadcasting each demand frame rates well above 1,000 FPS, and often beyond 100,000 FPS. Edge storage cost declines, integration of AI-driven vision analytics, and widening rental access further broaden the customer base. Regional dynamics are shifting as Asia-Pacific fabs and defense agencies scale investment, while North America preserves leadership through defense R&D and premium sports production.

Global High Speed Cameras Market Trends and Insights

Surge in AI-Based Vision Analytics for Crash-Test Labs

Crash-test programs now rely on machine-learning algorithms that dissect micro-second deformation, airbag plume propagation, and sensor fusion events. German and Japanese facilities require frame rates beyond 50,000 FPS to deliver the data density that feeds neural-network training, accelerating demand for flagship cameras able to maintain low noise at extreme speeds. Autonomous-vehicle validation compounds the need as every synthetic crash scenario must be documented in granular temporal layers. The co-evolution of high-speed imaging and AI creates a virtuous cycle: richer data improves models, which in turn push frame-rate thresholds higher. Tier-1 suppliers are already embedding high-speed modules inside sleds to ensure direct datalogging. As regulatory bodies tighten passive-safety standards, the driver's medium-term impact on the high-speed camera market strengthens.

Proliferation of SWIR High-Speed Cameras for Semiconductor Wafer Inspection

Advanced logic nodes below 5 nm demand defect detection that visible-light cameras cannot deliver. SWIR imagers, often based on InGaAs, penetrate silicon layers while operating at thousands of frames per second, allowing inline detection of voids, pattern collapse, and micro-contamination during lithography. South Korean and Taiwanese fabs have integrated these cameras across multiple process steps, reducing scrap and elevating line yield. The capital efficiency of SWIR upgrades has influenced procurement standards beyond premium fabs, with foundries in mainland China and Singapore adding similar capability. Thermal-management innovations-liquid-metal heat spreaders and proprietary lens coatings-are helping maintain quantum efficiency at high speeds. These factors underpin the driver's immediate, short-term weight on market growth.

Import Tariffs on CoaXPress Components Raising BOM Costs

Escalating trade duties on specialized CoaXPress chipsets and cables inflate system costs for U.S. assemblers. CoaXPress remains unrivaled for carrying 25 Gbps over coaxial links, so substitution is limited. Vendors absorb part of the surcharge, yet full systems still list 8-12% higher. Incremental redesign toward Ethernet-based alternatives inches forward, but latency and determinism concerns persist. Integrators queue additional stock to hedge tariff swings, straining working capital. While policy could unwind, its short-term drag on the high-speed camera market is tangible.

Other drivers and restraints analyzed in the detailed report include:

- Defense Budgets Prioritizing Hypersonic Weapon Testing

- Live 8K Sports Broadcast Accelerating Rental Uptake

- Thermal Noise & Cooling Needs Above 50 k FPS Limiting Portables

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Image sensors captured 34% of 2024 revenue, underscoring their centrality to any high-speed camera market size discussion. Yet memory subsystems are the flashpoint for future gains, climbing at a 13.8% CAGR as buffering demand explodes during 100,000 FPS bursts. Manufacturers integrate stacked DRAM closer to the sensor, shortening trace lengths and lowering latency. Parallel NVMe arrays now log UHD output without dropped frames, while FPGAs conduct on-the-fly compression. Cooling plates and vibration-damped chassis evolve to dissipate the extra thermal load, keeping dark current in check.

Edge storage affordability lets SMEs in ASEAN deploy high-speed imaging on factory lines previously limited to manual QC. Power modules follow suit; lithium-sulfur packs yield longer untethered runtime for down-hole probes. Meanwhile, lens manufacturers refine low-dispersion optics coated for SWIR transmission, complementing the surge in semiconductor inspection. Overall, component innovation sustains competitive differentiation inside the high-speed camera market.

The 2-5 MP tier held 42% share, pairing adequate spatial detail with maintainable data rates, giving it the largest slice of current high-speed camera market share. However, sensors above 5 MP are rising at a 14.8% CAGR as pixel architectures gain quantum efficiency and read-out speeds. Cameras exceeding 12 MP now film semiconductor wafers, enabling AI defect classifiers to spot sub-micron anomalies without halting the line.

Emergent global-shutter CMOS tech supports 65 MP at 71 FPS, routed over CoaXPress-12 links. Sports analytics similarly benefits: 8K slow-motion clips reveal biomechanical subtleties once invisible. As host PCs adopt PCIe 5.0, the ceiling on megapixels will climb, reinforcing upward migration within the high-speed camera market.

The High-Speed Camera Report is Segmented by Component (Image Sensors, Processors, Body and Chassis, and More), Resolution (Less Than 2 MP, 2-5 MP, and More), Frame Rate (250-1K, 1-5K, 5-20K, and More), Spectrum (Visible, Infrared, X-Ray, and More), Usage (New, Rental, Used), Application (Automotive and Transportation, Industrial, and More), and Geography. The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

North America retained 33% of 2024 revenue, driven by hypersonic R&D, 8K sports broadcast pipelines, and an entrenched rental ecosystem. U.S. defense laboratories run cameras beyond 100,000 FPS to study plasma-induced shock, while Canadian aerospace facilities evaluate icing impacts on composite wings. Mexico's automotive corridor brings steady crash-test demand. Regional suppliers hedge tariff risk by dual-sourcing CoaXPress boards, keeping supply chains resilient.

Asia-Pacific presents the steepest trajectory at a 13% CAGR. South Korean and Taiwanese fabs, locked in sub-5 nm competition, deploy SWIR high-speed arrays across lithography tracks. China channels defense budgets into ultra-fast optics, shrinking reliance on imported sensors. Japan fuses robotics and imaging for assembly lines requiring millisecond-level feedback, while India's PLI schemes incentivize domestic electronics inspection capacity.

Europe grows steadily despite data-network inertia. German OEMs lead AI-enhanced crash loci, combining machine vision with digital twins. The United Kingdom advances aerospace turbofan research, and France integrates high-speed imaging into rail pantograph monitoring. In the Middle East, rugged, battery-powered cameras descend oil wells at 150 °C to diagnose obstructions, proving high-speed viability in harsh zones. Africa and South America remain embryonic but show upticks in mining blast analysis and university research programs, foreshadowing broader penetration of the high-speed camera market.

- Vision Research Inc.

- Photron Ltd.

- Olympus Corporation

- nac Image Technology Inc.

- Mikrotron GmbH

- PCO AG

- Optronis GmbH

- Weisscam GmbH

- Fastec Imaging Corp.

- AOS Technologies AG

- Del Imaging Systems LLC

- IX Cameras Inc.

- Motion Capture Technologies LLC

- Teledyne DALSA Inc.

- Sony Group Corp.

- Grass Valley USA LLC

- Chronos Imaging Inc.

- High-Speed Vision GmbH

- Ametek Inc. (Phantom Brand)

- Red Digital Cinema LLC

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Surge in AI-based Vision Analytics Requiring Ultra-High Frame-Rate Imaging in Automotive Crash Test Labs (Germany and Japan)

- 4.2.2 Proliferation of SWIR High-speed Cameras for Semiconductor Wafer Inspection (South Korea and Taiwan)

- 4.2.3 Defense Budgets Prioritizing Hypersonic Weapon Testing Boosting 100 k FPS Demand (U.S. and China)

- 4.2.4 Live 8K Sports Broadcast Accelerating Rental Uptake (North America and EU)

- 4.2.5 Rugged Battery-Powered Cameras for Down-hole Diagnostics (Middle East)

- 4.2.6 On-board Edge Storage Price Declines Enabling SME Adoption (ASEAN)

- 4.3 Market Restraints

- 4.3.1 Import Tariffs on CoaXPress Components Raising BOM Costs (U.S.)

- 4.3.2 Thermal Noise and Cooling Needs Above 50 k FPS Limiting Portables

- 4.3.3 Shortage of Trained High-speed Imaging Technicians (Emerging Markets)

- 4.3.4 Data-Stream Bottlenecks (greater than 10 Gbps) with Legacy Factory Networks (Europe)

- 4.4 Value / Supply-Chain Analysis

- 4.5 Regulatory Outlook

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Threat of New Entrants

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Bargaining Power of Suppliers

- 4.7.4 Threat of Substitutes

- 4.7.5 Intensity of Competitive Rivalry

- 4.8 Investment Analysis

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Component

- 5.1.1 Image Sensors

- 5.1.2 Processors and Controllers

- 5.1.3 Lens

- 5.1.4 Memory Systems (On-board and External)

- 5.1.5 Body and Chassis

- 5.1.6 Cooling Systems

- 5.1.7 Battery and Power Modules

- 5.1.8 Others (Cables, Accessories, Software)

- 5.2 By Resolution

- 5.2.1 Less than 2 MP

- 5.2.2 2 - 5 MP

- 5.2.3 5 MP - 12 MP

- 5.2.4 Greater than 12 MP

- 5.3 By Frame Rate

- 5.3.1 250 - 1,000 FPS

- 5.3.2 1,001 - 5,000 FPS

- 5.3.3 5,001 - 20,000 FPS

- 5.3.4 20,001 - 100,000 FPS

- 5.3.5 Greater than 100,000 FPS

- 5.4 By Spectrum Type

- 5.4.1 Visible (RGB)

- 5.4.2 Infrared (NIR and MWIR)

- 5.4.3 Short-Wave Infrared (SWIR)

- 5.4.4 X-ray

- 5.4.5 Ultraviolet (UV)

- 5.5 By Usage Type

- 5.5.1 New Cameras

- 5.5.2 Rental Cameras

- 5.5.3 Used / Refurbished Cameras

- 5.6 By Application

- 5.6.1 Automotive and Transportation Crash Testing

- 5.6.2 Aerospace and Defense (Wind-Tunnel, Ballistics)

- 5.6.3 Industrial Manufacturing - Electronics and Semiconductor

- 5.6.4 Industrial Manufacturing - General Machinery

- 5.6.5 Research and Design - Universities and Labs

- 5.6.6 Media and Entertainment Production

- 5.6.7 Sports Analytics and Broadcast

- 5.6.8 Healthcare and Medical Diagnostics

- 5.6.9 Consumer Electronics Testing

- 5.6.10 Others (Energy, Mining)

- 5.7 By Geography

- 5.7.1 North America

- 5.7.1.1 United States

- 5.7.1.2 Canada

- 5.7.1.3 Mexico

- 5.7.2 Europe

- 5.7.2.1 United Kingdom

- 5.7.2.2 Germany

- 5.7.2.3 France

- 5.7.2.4 Italy

- 5.7.2.5 Rest of Europe

- 5.7.3 Asia-Pacific

- 5.7.3.1 China

- 5.7.3.2 Japan

- 5.7.3.3 India

- 5.7.3.4 South Korea

- 5.7.3.5 Rest of Asia-Pacific

- 5.7.4 Middle East

- 5.7.4.1 Israel

- 5.7.4.2 Saudi Arabia

- 5.7.4.3 United Arab Emirates

- 5.7.4.4 Turkey

- 5.7.4.5 Rest of Middle East

- 5.7.5 Africa

- 5.7.5.1 South Africa

- 5.7.5.2 Egypt

- 5.7.5.3 Rest of Africa

- 5.7.6 South America

- 5.7.6.1 Brazil

- 5.7.6.2 Argentina

- 5.7.6.3 Rest of South America

- 5.7.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles {(includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)}

- 6.4.1 Vision Research Inc.

- 6.4.2 Photron Ltd.

- 6.4.3 Olympus Corporation

- 6.4.4 nac Image Technology Inc.

- 6.4.5 Mikrotron GmbH

- 6.4.6 PCO AG

- 6.4.7 Optronis GmbH

- 6.4.8 Weisscam GmbH

- 6.4.9 Fastec Imaging Corp.

- 6.4.10 AOS Technologies AG

- 6.4.11 Del Imaging Systems LLC

- 6.4.12 IX Cameras Inc.

- 6.4.13 Motion Capture Technologies LLC

- 6.4.14 Teledyne DALSA Inc.

- 6.4.15 Sony Group Corp.

- 6.4.16 Grass Valley USA LLC

- 6.4.17 Chronos Imaging Inc.

- 6.4.18 High-Speed Vision GmbH

- 6.4.19 Ametek Inc. (Phantom Brand)

- 6.4.20 Red Digital Cinema LLC

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-Need Assessment