|

市場調查報告書

商品編碼

1851382

安瓿包裝:市佔率分析、產業趨勢、統計、成長預測(2025-2030)Ampoules Packaging - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

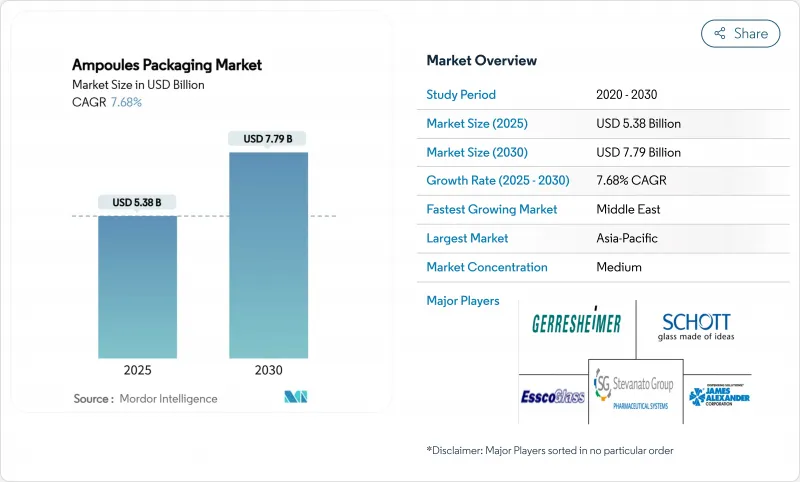

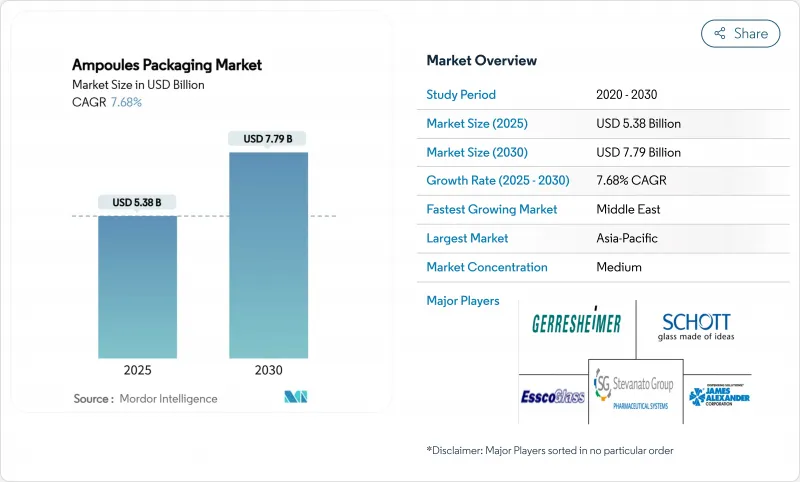

預計到 2025 年,安瓿包裝市場規模將達到 53.8 億美元,到 2030 年將擴大到 77.9 億美元,預測期內複合年成長率將達到 7.68%。

生技藥品的成長以及製藥業向單劑量注射劑型的轉型推動了市場擴張,而這項轉型又受到全球法規優先考慮防篡改和連續包裝容器的驅動。目前,玻璃安瓿因其化學惰性和已獲監管機構認可而佔據主導地位,但隨著吹灌封(BFS)平台展現出其無菌性和成本效益,塑膠安瓿的市場也迅速成長。亞太地區的需求領先,中國和韓國將於2024年核准肉毒桿菌毒素的新適應症,而人工智慧賦能的視覺檢測線正在加速提升大批量生產商的品質保證水準。市場競爭依然適中。主要供應商的差異化優勢並非體現在單價上,而是體現在防篡改系統設計、可追溯性功能和永續性項目上,這在能源成本波動的情況下,也使得利潤淨利率受到一定影響。

全球安瓿包裝市場趨勢與洞察

對防竄改藥品包裝的需求

為了滿足美國食品藥品監督管理局 (FDA) 21 CFR 211.132 和歐盟《反假藥指令》的要求,製藥公司正大力投資研發可見的防拆封,推動安瓿瓶規格向折環和刻痕線技術發展,這些技術能夠產生清晰的篡改痕跡。肖特製藥 (SCHOTT Pharma) 的單點切割系統預計到 2024 年將佔據全球折斷系統細分市場 62% 的佔有率,這標誌著病患安全功能正從高階配置轉變為標準配置。防篡改技術也能降低高價值生技藥品的責任風險,因為完整性受損會直接威脅治療效果。醫院擴大將簡化的真偽驗證作為採購標準,促使供應商優先考慮堅固耐用的折斷設計。因此,替代材料的資質標準日益嚴格,鞏固了玻璃在重症加護製劑中的主導地位。

I型玻璃的可回收性和循環價值

永續性要求正促使相關人員傾向於選擇能夠在不影響品質的前提下重新進入生產循環的容器。肖特製藥、Corplex 和武田製藥於 2024 年開展的一項閉合迴路初步試驗表明,與原生玻璃相比,這種容器可減少 50% 的溫室氣體排放,同時滿足美國藥典 (USP) <660> 的耐化學性標準。歐洲監管機構目前正將採購獎勵與可回收性評分掛鉤,並鼓勵當地醫療保健系統優先選擇玻璃屑玻璃。 SGS 的審核已證實,回收的 I 型玻璃保持了相同的水解穩定性,確保了藥品品質基準值不受影響。隨著品牌所有者追求範圍 3 的脫碳目標,能夠保證可追溯回收成分的安瓿瓶製造商在供應合約中獲得了優勢。這一趨勢也正在蔓延至亞太地區,跨國公司正將歐盟 ESG 標準納入競標流程中。

預填充式注射器佔銷售量

面向零售市場的生技藥品和患者自用療法正轉向預充式注射器,這種包裝方式能夠提供更精準的劑量和更便捷的患者使用體驗。 Stevanato集團2024年注射器銷售成長15%,而管瓶銷售量卻下降了34%,凸顯了注射器替代西林瓶的巨大壓力。注射器更高的淨利率促使生產商將生產時間從安瓿瓶轉移到預充式注射器。重磅GLP-1促效劑將加速這一轉變,因為自行注射的依從性是支付方選擇預充式注射器的主要原因。儘管如此,對於一些對注射器塞子中矽油和鎢殘留物敏感的藥物而言,安瓿瓶仍然必不可少。分散的需求迫使安瓿瓶生產商將目光投向那些對穩定性要求極高的小眾分子藥物,並加大行銷投入,強調玻璃純度的優勢。

細分市場分析

到2024年,玻璃仍將佔據安瓿包裝市場87%的佔有率,這反映了其成熟的監管信譽和無與倫比的化學耐久性。然而,到2030年,塑膠的複合年成長率將達到9.78%,這主要得益於免除無菌驗證步驟並降低人事費用的BFS生產線。在玻璃配方方面,i型硼矽酸在生技藥品、腫瘤藥物和高活性化合物的包裝中佔據主導地位。康寧的Valor配方在維持水解等級i級性能的同時,有效防止了分層現象,從而拓寬了玻璃在嚴苛低溫運輸環境中的應用範圍。

製造商正在採用多元化的經營模式:肖特製藥公司2024年銷售額的55%將來自高價值、高價位的玻璃製品,而聚合物專家則專注於疫苗和學名藥的銷售量。一次完成容器的成型、填充和密封,減少了對二次包裝的需求,簡化了供應鏈,從而提升了塑膠製品的經濟效益。儘管如此,到2025年,玻璃基解決方案的市場規模將達到46.9億美元,超過塑膠的6.9億美元。這一發展趨勢取決於治療風險接受度、所需的保存期限以及永續性評估,表明兩者將共存而非相互替代。

預計到2024年,直柄安瓿將以63%的市場佔有率領先安瓿包裝市場,而諸如單點切割(OPC)、刻痕和色環易斷設計等更人性化的包裝形式也將以9.21%的複合年成長率成長。醫療保健機構越來越重視減少針刺傷和破損申訴,並將此作為採購標準之一,因此,易於開啟的包裝在護理和居家照護機構中至關重要。同時,漏斗形安瓿仍適用於黏稠製劑和懸浮液,其寬口設計便於高效填充。

易開啟設計也受到疫苗和化妝品領域自我給藥趨勢的推動。肖特製藥的easyOPC設計可將開啟力差異降低60%,進而降低配製過程中液體溢出的風險。隨著斷裂系統專利的到期,中型製造商將能夠複製這些功能,從而加劇低利潤治療層級的價格競爭。然而,高階生技藥品仍傾向於採用專有的斷裂技術,以確保無菌性和可追溯性,從而增強創新領先企業的利潤彈性。預計到2030年,易開啟型安瓿包裝市場規模將超過21億美元,主要得益於差異化的人體工學價值。

區域分析

到2024年,亞太地區將佔全球銷售額的39%,這主要得益於中國、印度和韓國產能的擴張,以及各國政府推動注射劑供應鏈在地化進程。中國生物製藥產值預計在2024年達到5,653億元(7,84億美元),到2029年將超過1.4兆元(1,940億美元)。在韓國,江南區美容產業叢集帶動了對一體化小批量玻璃製品的訂單;而在印度,「印度製造」獎勵則支持了疫苗瓶罐罐產能的擴張。同時,東南亞國協透過稅收優惠和簡化GMP核准來吸引合約研發生產企業(CDMO),從而提升了該地區的競爭力。

北美市場正經歷穩定成長,這得益於生技藥品的商業化進程以及《藥品供應鏈安全法案》(DSCSA) 合規期限對連續式初級包裝容器的要求。美國主要受高價值訂單的推動,這些訂單包括符合美國藥典 (USP) <1790> 中關於注射劑目視檢查建議的 I 型玻璃包裝和人工智慧檢測線。加拿大鼓勵供應商提供雙語包裝和 GS1 相容條碼,以滿足美國的可追溯性標準。值得注意的是,除草劑訴訟和供應鏈衝擊正促使製藥公司從墨西哥採購安瓿瓶,擴大了北美內部貿易。

歐洲是一個經濟發達且成熟的地區,永續性和循環經濟目標驅動著採購決策。歐盟對包裝和包裝廢棄物法規的修訂要求到2030年回收率至少達到70%,這將推動對閉合迴路I型玻璃的需求。德國醫院於2024年組成採購聯盟,與供應商簽訂五年合約,確保供應商提供的玻璃屑含量至少達到50%。同時,由於天然氣供應中斷導致能源價格波動,加劇了人們對熔爐停機的擔憂,促使一些公司囤積硼矽酸玻璃管。然而,歐盟為生命科學基礎建設撥出的復甦資金將補貼下一代檢測設備,部分抵銷成本的擔憂。

在中東地區,沙烏地阿拉伯和阿拉伯聯合大公國的複合年成長率最高,到2030年將達到9.03%,這得益於兩國將公共衛生預算轉向本地製造業。利雅德的「2030願景」醫藥計畫將共同資助一座無菌注射劑工廠,從而創造對灌封式注射器(BFS)和管狀生產線的待開發區需求。海灣合作理事會(波灣合作理事會)的競標規則優先考慮成本效益,這使得印度和歐洲的中型企業能夠獲得市場佔有率。然而,技術純熟勞工有限,因此需要透過技術轉移夥伴關係,包括設備供應和長期服務協議。

在拉丁美洲,宏觀經濟不穩定阻礙了疫苗的普及,儘管巴西國家衛生監督局(ANVISA)正按照歐盟口蹄疫疫苗的要求推廣疫苗序列化,從而為可追溯安瓿瓶的出現創造了可能。然而,非洲聯盟(非盟)提出的2040年實現60%國內疫苗生產的目標,可望在預測期的後半段刺激疫苗生產設施(BFS)的投資。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 對防篡改包裝的需求

- i-玻璃的可回收性與循環價值

- 加強注射劑可追溯性監管

- 生技藥品CDMO轉向單劑量安瓿瓶

- 利用人工智慧實現零缺陷視覺偵測線

- 亞太地區注射美容的興起

- 市場限制

- 預填充式注射器蠶食了銷售量

- 廢棄利器和化學廢棄物的負擔

- 低碳爐管材供應不穩定

- 玻璃分層召回風險

- 價值鏈分析

- 監管環境

- 技術展望

- 波特五力分析

- 新進入者的威脅

- 買方的議價能力

- 供應商的議價能力

- 替代品的威脅

- 競爭對手之間的競爭

- 評估市場宏觀經濟趨勢

第5章 市場規模與成長預測

- 依材料類型

- 玻璃

- 塑膠

- 按安瓿類型

- 直莖

- 漏斗型

- 封閉式(D 型)

- 簡易開局(OPC、評分、CBR)

- 以體積(毫升)

- 2毫升或更少

- 3-5 mL

- 6-10 mL

- 10毫升或更多

- 透過製造技術

- 傳統管材成型

- 吹塑-灌封-密封塑膠

- 高級雷射評分

- 按最終用戶行業分類

- 製藥

- 個人護理和化妝品

- 按地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 英國

- 德國

- 法國

- 義大利

- 西班牙

- 俄羅斯

- 其他歐洲地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 亞太其他地區

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 中東

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 其他中東地區

- 非洲

- 南非

- 奈及利亞

- 其他非洲地區

- 北美洲

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率分析

- 公司簡介

- Schott Pharma AG and Co. KGaA

- Gerresheimer AG

- Stevanato Group SpA

- SGD Pharma

- Nipro PharmaPackaging International NV

- Shandong Pharmaceutical Glass Co., Ltd.

- James Alexander Corporation

- Global Pharmatech Pvt. Ltd.

- Essco Glass Pvt. Ltd.

- AAPL Solutions Pvt. Ltd.

- Hindusthan National Glass and Industries Ltd.

- Ardagh Group SA

- PGP Glass Pvt. Ltd.(Piramal)

- Amcor plc(Rigid Plastics)

- Unicep Packaging LLC

- Catalent Pharma Solutions, Inc.

- Recipharm AB(BFS)

- Weiler Engineering, Inc.

- Owens-Illinois, Inc.(OI)

- Vetropack Holding AG

第7章 市場機會與未來展望

The ampoules packaging market reached USD 5.38 billion in 2025 and is projected to climb to USD 7.79 billion by 2030, translating to a 7.68% CAGR over the forecast period.

Expansion is anchored in the pharmaceutical sector's pivot toward single-dose injectable formats, propelled by biologics growth and global regulations that prioritize tamper-evident, serialised containers. Glass ampoules currently dominate because they combine chemical inertness with established regulatory acceptance, yet plastic formats are scaling quickly as blow-fill-seal (BFS) platforms prove their sterility and cost benefits. Asia-Pacific leads demand after China and South Korea approved new botulinum toxin indications in 2024, while AI-enabled visual inspection lines accelerate quality-assurance gains for high-volume producers. Competitive intensity remains moderate: leading suppliers differentiate on break-system design, traceability features and sustainability programs instead of unit price, cushioning margins even as energy-related costs fluctuate.

Global Ampoules Packaging Market Trends and Insights

Demand for Tamper-Evident Pharmaceutical Packs

Drug manufacturers are investing heavily in visible tamper-evidence to satisfy FDA 21 CFR 211.132 and EU Falsified Medicines Directive requirements, steering ampoule specifications toward break-ring and score-line technologies that produce unmistakable indicators of interference. SCHOTT Pharma's One-Point-Cut system captured 62% of the global break-system sub-market by 2024, demonstrating how patient-safety features have moved from premium to standard expectation. Tamper-evidence also lowers liability risk for high-value biologics because compromised integrity directly threatens therapeutic efficacy. Hospitals increasingly cite simplified authenticity checks as a procurement criterion, encouraging suppliers to prioritise robust break designs. The resulting shift tightens qualification windows for alternative materials, reinforcing glass dominance in critical-care formulations.

Recyclability and Circular Value of Type-I Glass

Sustainability mandates push stakeholders to prefer containers that can re-enter production loops without downgrading quality. Type-I borosilicate satisfies this need: a 2024 closed-loop pilot by SCHOTT Pharma, Corplex and Takeda trimmed greenhouse-gas emissions by 50% versus virgin glass while meeting USP <660> chemical resistance benchmarks. European regulators now tie procurement incentives to recyclability scores, encouraging local health systems to favour glass derived from cullet streams. SGS audits confirm recycled Type-I maintains identical hydrolytic stability, so pharmaceutical-quality thresholds remain intact. As brand owners target Scope 3 decarbonisation, ampoule producers that guarantee traceable recycled content secure supply-agreement advantages. These developments extend to Asia-Pacific as multinationals transplant EU ESG criteria into regional tender processes.

Prefilled Syringes Cannibalising Volumes

Retail-oriented biologics and self-administered therapies are migrating to ready-to-inject syringes that offer dosing accuracy and patient convenience. Stevanato Group's 15% surge in syringe revenue in 2024 coincided with a 34% slump in vial sales, exemplifying format substitution pressure. Syringes carry superior margins, prompting producers to reallocate furnace hours away from ampoules. The shift is accelerated by blockbuster GLP-1 agonists, where self-injection adherence drives payer preference. Nevertheless, ampoules remain vital for drugs sensitive to silicone oil or tungsten residue associated with syringe stoppers. The segmented demand profile obliges ampoule suppliers to target niche, stability-critical molecules and invest in marketing that highlights glass purity advantages.

Other drivers and restraints analyzed in the detailed report include:

- Regulatory Push on Injectable Traceability

- Biologics CDMO Shift Toward Single-Dose Ampoules

- Tubing Supply Volatility from Low-Carbon Furnaces

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Glass maintained an 87% share of the ampoules packaging market in 2024, reflecting entrenched regulatory confidence and unmatched chemical durability. Plastic formats, however, are logging a 9.78% CAGR through 2030, powered by BFS lines that cut sterility validation steps and shrink labor outlays. Within glass, Type-I borosilicate remains the default for biologics, oncology drugs and highly reactive compounds. Corning's Valor composition eliminates delamination while retaining hydrolytic class I properties, widening glass's applicability to high-stress cold-chain environments.

Manufacturers adopt divergent business models: SCHOTT Pharma derived 55% of 2024 revenue from high-value glass offerings that command premium pricing, whereas polymer specialists chase volume in vaccines and generics. Supply-chain simplicity strengthens plastic economics because containers form, fill and seal in one pass, reducing secondary packaging needs. Still, the ampoules packaging market size for glass-based solutions stood at USD 4.69 billion in 2025, dwarfing plastic's USD 690 million contribution. The trajectory indicates coexistence rather than displacement, hinging on therapeutic risk tolerance, required shelf-life and sustainability calculus.

Straight-stem ampoules led with 63% of ampoules packaging market share in 2024, but user-friendly formats such as One-Point-Cut (OPC), score-ring and color-breakring designs are rising at 9.21% CAGR. Healthcare providers increasingly rank reduced needlestick injuries and breakage complaints as procurement criteria, making easy-open options indispensable for nursing and at-home care settings. In parallel, funnel-type ampoules retain relevance for viscous or suspension formulations where wider necks enable efficient filling.

Easy-open uptake is also fueled by self-administration trends in vaccines and aesthetics. SCHOTT Pharma's easyOPC design cuts opening force variability by 60%, thereby decreasing spillage risk during dose preparation. As break-system patents expire, mid-tier producers can emulate these features, intensifying price competition in lower-margin therapeutic classes. Nonetheless, premium biologics continue to favor proprietary break technologies that guarantee sterility and traceability, reinforcing margin resilience for innovation leaders. The ampoules packaging market size for easy-open variants is projected to surpass USD 2.1 billion by 2030, supported by differentiating ergonomic value.

The Ampoules Packaging Market Report is Segmented by Material Type (Glass, and Plastic), Ampoule Type (Straight-Stem, Funnel-Type, Closed Form D, and More), Capacity (<=2 ML, 3-5 ML, and Above 10 ML), End-User Industry (Pharmaceutical, and Personal Care and Cosmetics), Manufacturing Technology (Conventional Tubular Forming, Blow-Fill-Seal Plastic, and More), and Geography. The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific controlled 39% of global revenue in 2024, buoyed by capacity expansions across China, India and South Korea as governments localise injectable drug supply chains. China's biopharmaceutical output hit CNY 565.3 billion (USD 78.4 billion) in 2024 and could eclipse CNY 1.4 trillion (USD 194 billion) by 2029, sustaining demand for ampoules despite sporadic API export restrictions tied to the 2024 Anti-Espionage Law. South Korea's aesthetics cluster in Gangnam fuels consistent small-volume glass orders, while India's "Make in India" incentives support BFS capacity additions for vaccines. Concurrently, ASEAN members court CDMOs by offering tax holidays and streamlined GMP approvals, amplifying regional competitiveness.

North America's growth is steadier, underpinned by biologics commercialisation pipelines and DSCSA compliance deadlines that require serialised primary containers. The United States drives high-value orders for Type-I glass and AI-enabled inspection lines that satisfy USP <1790> recommendations for parenteral visual inspection. Canada works to align with US traceability norms, spurring suppliers to provide bilingual packaging and GS1-compatible codes. Notably, herbicide litigation and supply-chain shocks have encouraged drug makers to dual-source ampoules from Mexico, broadening North American intra-regional trade.

Europe remains a value-rich but mature territory where sustainability and circular-economy targets dictate purchasing. The revised EU Packaging and Packaging Waste Regulation obliges recyclability scores above 70% by 2030, elevating demand for closed-loop Type-I glass streams. German hospitals formed a buying consortium in 2024 that gives 5-year contracts to vendors meeting >=50% cullet content, signalling future procurement norms. Meanwhile, energy-price volatility tied to gas supply cuts heightened concern over furnace downtime, prompting some firms to stockpile borosilicate tubing. Yet EU Recovery Funds earmarked for life-science infrastructure will subsidise next-generation inspection gear, partially offsetting cost fears.

The Middle East recorded the highest regional CAGR at 9.03% through 2030 as Saudi Arabia and the UAE channel public-health budgets into local manufacturing. Riyadh's Vision 2030 pharmaceutical programme co-funds sterile injectables plants, creating greenfield demand for BFS and tubular lines. Gulf Cooperation Council tender rules prioritize cost-effectiveness, positioning Indian and European mid-tier firms to capture share. However, limited skilled labour necessitates technology-transfer partnerships that intertwine equipment supply with long-term service contracts.

Latin America's uptake is hindered by macroeconomic instability, yet Brazil's ANVISA pushes serialization that mirrors EU-FMD requirements, opening opportunities for traceability-enabled ampoules. Africa remains nascent outside Egypt's vaccine complex; nonetheless, the African Union's 2040 target for 60% local vaccine manufacturing may catalyse BFS investments later in the forecast horizon.

- Schott Pharma AG and Co. KGaA

- Gerresheimer AG

- Stevanato Group S.p.A.

- SGD Pharma

- Nipro PharmaPackaging International NV

- Shandong Pharmaceutical Glass Co., Ltd.

- James Alexander Corporation

- Global Pharmatech Pvt. Ltd.

- Essco Glass Pvt. Ltd.

- AAPL Solutions Pvt. Ltd.

- Hindusthan National Glass and Industries Ltd.

- Ardagh Group S.A.

- PGP Glass Pvt. Ltd. (Piramal)

- Amcor plc (Rigid Plastics)

- Unicep Packaging LLC

- Catalent Pharma Solutions, Inc.

- Recipharm AB (BFS)

- Weiler Engineering, Inc.

- Owens-Illinois, Inc. (O-I)

- Vetropack Holding AG

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Demand for tamper-evident pharma packs

- 4.2.2 Recyclability and circular value of Type-I glass

- 4.2.3 Regulatory push on injectable traceability

- 4.2.4 Biologics CDMO shift toward single-dose ampoules

- 4.2.5 AI-enabled zero-defect visual inspection lines

- 4.2.6 Rise of injectable aesthetics in APAC

- 4.3 Market Restraints

- 4.3.1 Prefilled syringes cannibalising volumes

- 4.3.2 Post-use sharps and chemical waste burden

- 4.3.3 Tubing supply volatility from low-carbon furnaces

- 4.3.4 Glass delamination recall risk

- 4.4 Value Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Threat of New Entrants

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Bargaining Power of Suppliers

- 4.7.4 Threat of Substitutes

- 4.7.5 Intensity of Competitive Rivalry

- 4.8 Assessment of Macro Economic Trends on the Market

5 MARKET SIZE AND GROWTH FORECASTS (VALUES)

- 5.1 By Material Type

- 5.1.1 Glass

- 5.1.2 Plastic

- 5.2 By Ampoule Type

- 5.2.1 Straight-stem

- 5.2.2 Funnel-type

- 5.2.3 Closed (Form D)

- 5.2.4 Easy-Open (OPC, Score-Ring, CBR)

- 5.3 By Capacity (mL)

- 5.3.1 <=2 mL

- 5.3.2 3-5 mL

- 5.3.3 6-10 mL

- 5.3.4 >10 mL

- 5.4 By Manufacturing Technology

- 5.4.1 Conventional Tubular Forming

- 5.4.2 Blow-Fill-Seal Plastic

- 5.4.3 Advanced Laser Scoring

- 5.5 By End-user Industry

- 5.5.1 Pharmaceutical

- 5.5.2 Personal Care and Cosmetics

- 5.6 By Geography

- 5.6.1 North America

- 5.6.1.1 United States

- 5.6.1.2 Canada

- 5.6.1.3 Mexico

- 5.6.2 Europe

- 5.6.2.1 United Kingdom

- 5.6.2.2 Germany

- 5.6.2.3 France

- 5.6.2.4 Italy

- 5.6.2.5 Spain

- 5.6.2.6 Russia

- 5.6.2.7 Rest of Europe

- 5.6.3 Asia-Pacific

- 5.6.3.1 China

- 5.6.3.2 India

- 5.6.3.3 Japan

- 5.6.3.4 South Korea

- 5.6.3.5 Rest of Asia-Pacific

- 5.6.4 South America

- 5.6.4.1 Brazil

- 5.6.4.2 Argentina

- 5.6.4.3 Rest of South America

- 5.6.5 Middle East

- 5.6.5.1 Saudi Arabia

- 5.6.5.2 United Arab Emirates

- 5.6.5.3 Rest of Middle East

- 5.6.6 Africa

- 5.6.6.1 South Africa

- 5.6.6.2 Nigeria

- 5.6.6.3 Rest of Africa

- 5.6.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Schott Pharma AG and Co. KGaA

- 6.4.2 Gerresheimer AG

- 6.4.3 Stevanato Group S.p.A.

- 6.4.4 SGD Pharma

- 6.4.5 Nipro PharmaPackaging International NV

- 6.4.6 Shandong Pharmaceutical Glass Co., Ltd.

- 6.4.7 James Alexander Corporation

- 6.4.8 Global Pharmatech Pvt. Ltd.

- 6.4.9 Essco Glass Pvt. Ltd.

- 6.4.10 AAPL Solutions Pvt. Ltd.

- 6.4.11 Hindusthan National Glass and Industries Ltd.

- 6.4.12 Ardagh Group S.A.

- 6.4.13 PGP Glass Pvt. Ltd. (Piramal)

- 6.4.14 Amcor plc (Rigid Plastics)

- 6.4.15 Unicep Packaging LLC

- 6.4.16 Catalent Pharma Solutions, Inc.

- 6.4.17 Recipharm AB (BFS)

- 6.4.18 Weiler Engineering, Inc.

- 6.4.19 Owens-Illinois, Inc. (O-I)

- 6.4.20 Vetropack Holding AG

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-Need Assessment