|

市場調查報告書

商品編碼

1851351

變頻器:市場佔有率分析、產業趨勢、統計數據和成長預測(2025-2030 年)Variable Frequency Drives - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

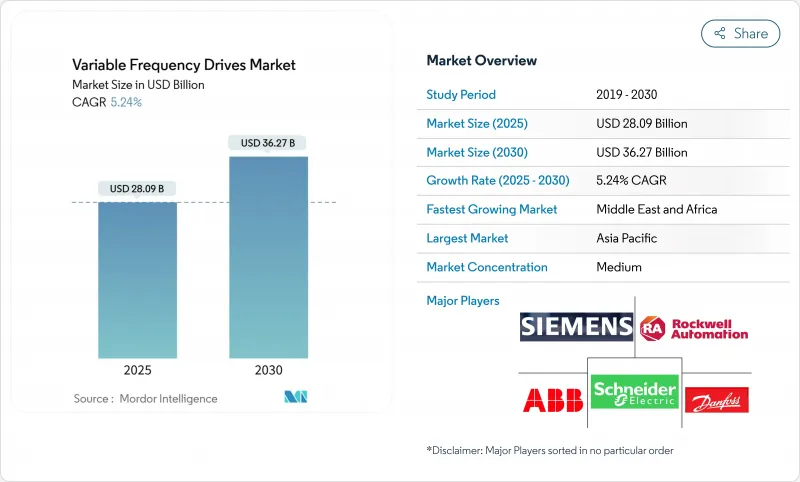

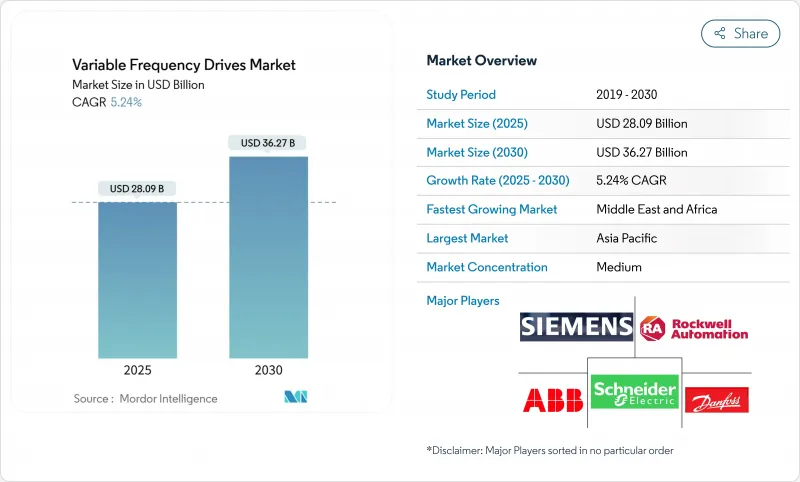

全球變頻器市場預計到 2025 年將達到 280.9 億美元,到 2030 年將達到 362.7 億美元,年複合成長率為 5.24%。

對馬達級能效的強勁政策壓力、節能帶來的快速回報以及向數位化生產線的轉型,正穩步擴大變頻器的應用範圍。即使在資本支出週期趨緊的情況下,市場需求仍然強勁,因為變頻器維修能夠立即降低高耗能工廠的電力成本。採礦和金屬行業的中壓升級計劃、中東地區的海水淡化廠建設以及商業建築中暖通空調(HVAC)能源效率的強制性要求,都為變頻器的應用提供了更多機會。將乙太網路、網路安全安全功能和碳化矽開關元件整合到產品組合中的供應商,保護了利潤率並確保了業務收益。碳化矽/氮化鎵晶片短缺和不斷上漲的電磁干擾合規成本帶來的不利因素抑制了變頻器的出貨量成長,但並未阻礙多年來持續的能源效率投資。

全球變頻器市場趨勢與洞察

尋求馬達級能耗最佳化的數位原民製程裝置

數位化工廠依靠現代變頻器 (VFD) 內部的預測分析功能,根據生產計劃和即時電價調整馬達負載。例如,羅克韋爾自動化的 PowerFlex 755TS 平台整合了邊緣分析功能,可在降低多條馬達生產線能耗的同時減少停機時間。半導體製造和製藥工廠率先採用了這項技術,因為產量比率取決於精確的速度控制和不間斷的服務連接。

暖通空調和水系統強制性可變扭矩效率規則

能源效率法規使得在泵浦和空氣調節機中整合變頻器成為一項不容商榷的措施。美國能源局2028年發布的《循環泵浦規則》強制要求使用電子換向馬達和先進的驅動器。為此,特靈等原始設備製造商已與丹佛斯簽訂了多年採購協議,以確保符合規定的變頻器供應。

690V以上電壓的電磁干擾/諧波合規成本不斷上升

隨著監管機構收緊 IEEE 519 標準對 690V 以上電壓等級的限制,與電磁干擾和諧波失真相關的合規成本飆升。中壓計劃需要使用更大容量的電抗器、多脈衝變壓器和屏蔽電纜,這增加了材料、試運行和工程成本,可能導致已安裝驅動器的成本增加 15% 甚至更多。小型製造商受到的影響尤其嚴重,因為它們必須將設計和認證成本分攤到較少的出貨量上,這可能會阻礙新進入者,並加速行業整合。

細分市場分析

1 kV 以下的低壓變頻器仍是中小型工廠輸送機、攪拌機和暖通空調風扇控制的主要設備。到 2024 年,低壓變頻器將佔據 62.4% 的市場佔有率,從而支撐變頻驅動器市場的發展。經濟高效的安裝、豐富的整合商經驗和廣泛的供應商資源使其保持了市場佔有率。同時,鋼鐵廠和地下礦場的擴建項目促使採購轉向 1-6 kV 的解決方案,推動中壓變頻器市場以 6.8% 的複合年成長率成長。升級到 995 V 電網的礦場選擇專用變頻器來減少電纜敷設並提高電壓穩定性。

預計到2030年,中壓變頻驅動市場規模將達到104億美元,這得益於可再生能源併網推動了電網規範對諧波抑制的要求。供應商積極響應,推出了耐電弧機殼和模組化主動前端設計,將總諧波失真控制在3%以下。 6千伏特以上的高壓產品主要面向水泵和軋延等特定計劃,但由於價格高且安裝複雜,其應用受到限制。

功率低於 20 kW 的超緊湊型驅動器實現了最高的複合年成長率 (CAGR),達到 7.2%,這主要得益於工廠採用分散式控制技術,將小型馬達整合到自主移動機器人和智慧建築子系統中。此外,隨著配備豐富感測器的暖通空調分區控制系統和食品加工送料器的應用,此類驅動器的出貨量也隨之成長。低功率(20-200 kW)型號預計仍將貢獻 2024 年 40.3% 的收入,對於化學和水源產業的離心式幫浦和軸流風機至關重要。

開發商提高了散熱器容量並改用碳化矽二極體,從而提高了環境溫度高於 60°C 時的工作極限,這在沙漠太陽能領域是一項差異化優勢。雖然高功率級(600 kW 以上)變頻驅動器的市場佔有率不足 5%,但每筆銷售都透過長期服務合約帶來了可觀的售後收入,其中包括對功率模組繼電器和諧波濾波器的審核。

變頻器市場報告按電壓類型(低壓、中壓、高壓)、功率等級(微、低、中、高)、驅動類型(交流變頻器、直流驅動器、伺服/向量驅動器、其他)、應用(泵、風扇、鼓風機、其他)、最終用戶行業(基礎設施和建築、食品和飲料加工、其他)以及地區(北美、南美、其他)地區進行細分。

區域分析

亞太地區持續保持領先地位,佔2024年銷售額的46.3%,這主要得益於中國自動化家電工廠的發展以及印度鼓勵電機節能維修的生產關聯獎勵計劃。像威馳這樣的本土企業透過捆綁雲端閘道和持續監控服務,擴大了出口銷售,增強了其在該地區的成本競爭力。東南亞國協的政府補貼計畫和強制性IE3馬達政策維持了基準需求,而台灣和韓國的半導體工廠的伺服驅動器訂單也出現了成長。

中東和非洲地區複合年成長率預計最高,達到7.3%,主要得益於海水淡化管道和銅礦帶電氣化改造對高抗衝擊性重型中壓驅動器的需求。 ACCIONA在舒蓋格3期計畫的里程碑凸顯了水安全的重要性,並促成了數兆瓦級水泵驅動合約的簽訂。資金緊張的非洲公共產業金融機構的資金,為大量採用變頻驅動器的水處理升級項目提供資金,從而擴大了區域訂單。

隨著北美和歐洲老舊設備接近使用壽命終點,能源效率法規日益嚴格,設備的更新換代週期也穩定加速。公用事業公司的回扣計劃和企業環境、社會及公司治理(ESG)目標加速了設備的普及,尤其是在電價上漲與積極的脫碳目標一致的情況下。一家歐洲粉末冶金廠採用了主動式前端驅動器來滿足諧波排放法規的要求,而美國中西部的一家化工廠則利用天然氣價格波動,透過預測性變頻器(VFD)演算法來調整馬達負載。網路安全要求的提高雖然延長了競標評估週期,但最終卻提升了提供修補程式管理和安全認證更新服務的供應商的業務收益。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 數位原民流程工廠需要馬達級能量最佳化。

- 暖通空調和水系統強制性可變扭矩效率規則

- 低延遲乙太網路馬達在工業4.0改裝的廣泛應用

- 海水淡化和水資源再利用基礎設施的快速發展(主要在中東地區)

- 地下礦業車輛的電氣化

- 與通貨膨脹掛鉤的電費加快了變頻器改造的投資維修。

- 市場限制

- 690V以上等級設備的EMI/諧波抑制措施成本不斷上漲

- 開發中國家公共產業的資本投資受限

- 網路加固成本減緩了傳統硬碟的更新換代週期。

- 電力電子級SiC/GaN晶片持續短缺

- 宏觀經濟因素的影響

- 投資分析

- 價值鏈分析

- 監管環境

- 技術概覽

- 波特五力分析

- 新進入者的威脅

- 供應商的議價能力

- 買方的議價能力

- 替代品的威脅

- 競爭程度

第5章 市場規模與成長預測

- 按電壓類型

- 低電壓(低於1千伏特)

- 中壓(1-6千伏特)

- 高壓(6千伏以上)

- 按額定輸出功率(kW)

- 微型(少於 20)

- 低(20-200)

- 中(200-600)

- 高(超過 600)

- 按驅動類型

- 交流變頻器

- 直流驅動器

- 伺服/向量驅動器

- 多級和矩陣驅動器

- 透過使用

- 泵浦

- 風扇和鼓風機

- 壓縮機

- 輸送帶

- 暖通空調系統

- 擠出機和混合機

- 按最終用戶行業分類

- 基礎設施和建築物

- 食品和飲料加工

- 能源與發電

- 石油、天然氣和石化

- 採礦和金屬

- 紙漿和造紙

- 用水和污水

- 其他

- 按地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 歐洲

- 英國

- 德國

- 法國

- 義大利

- 俄羅斯

- 其他歐洲地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 亞太其他地區

- 中東和非洲

- 中東

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 土耳其

- 其他中東地區

- 非洲

- 南非

- 奈及利亞

- 其他非洲地區

- 北美洲

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率分析

- 公司簡介

- ABB Ltd.

- Siemens AG

- Schneider Electric SE

- Danfoss A/S

- Rockwell Automation Inc.

- Mitsubishi Electric Corporation

- Yaskawa Electric Corporation

- Fuji Electric Co. Ltd.

- Eaton Corporation plc

- WEG Industries SA

- Nidec Corporation

- Toshiba Corporation

- Hitachi Ltd.

- Johnson Controls International plc

- Inovance Technology Co. Ltd.

- Delta Electronics Inc.

- Emerson Electric Co.

- LS Electric Co. Ltd.

- SEW-Eurodrive GmbH & Co KG

- Veichi Electric Co. Ltd.

- Control Techniques(Nidec)

- HARS Drives Co. Ltd.

- Vacon(Part of Danfoss)

- Parker Hannifin-SSD Drives

- Kollmorgen Corporation

- Bonfiglioli Riduttori SpA

第7章 市場機會與未來展望

The global variable frequency drives market size was valued at USD 28.09 billion in 2025 and is forecast to reach USD 36.27 billion by 2030, advancing at a 5.24% CAGR.

Strong policy pressure for motor-level efficiency, fast paybacks from energy savings, and the migration toward digitalized production lines have steadily widened the adoption base. Demand remained resilient even as capital-spending cycles tightened, because VFD retrofits deliver immediate electricity cost relief in energy-intensive plants. Medium-voltage upgrade projects in mining and metals, desalination build-outs in the Middle East, and HVAC efficiency mandates in commercial buildings collectively broadened the addressable opportunity. Suppliers that embedded Ethernet, cybersecurity features, and silicon-carbide switching devices into their portfolios protected margins and unlocked service revenues. Headwinds tied to SiC/GaN chip shortages and higher electromagnetic-interference compliance costs slightly tempered shipment growth yet did not derail the multiyear efficiency investment trend.

Global Variable Frequency Drives Market Trends and Insights

Digital-native process plants demanding motor-level energy optimisation

Digitally designed plants relied on predictive analytics inside modern VFDs to align motor load with production schedules and real-time electricity prices. Rockwell Automation's PowerFlex 755TS platform, for example, bundled edge analytics and delivered downtime cuts while trimming energy usage across multi-motor lines. Semiconductor fabrication and pharmaceutical facilities led adoption because yield depends on precise speed control and uninterrupted service connectivity.

Mandatory variable-torque efficiency rules in HVAC and water verticals

Efficiency legislation made VFD integration non-negotiable in pumps and air-handling units. The U.S. Department of Energy's 2028 circulator-pump rule in effect required electronically commutated motors paired with sophisticated drives. In anticipation, OEMs such as Trane locked multi-year purchase agreements with Danfoss to guarantee compliant VFD supply.

Rising EMI/harmonics compliance costs above 690 V

Compliance costs linked to electromagnetic interference and harmonic distortion rose sharply after regulators tightened IEEE 519 limits for installations above 690 V. Medium-voltage projects now require oversized reactors, multi-pulse transformers, and shielded cable runs, adding material, commissioning, and engineering expenses that can raise installed drive cost by more than 15%. Smaller manufacturers are disproportionately affected because the design and certification overhead must be spread across lower shipment volumes, which can deter new entrants and accelerate consolidation.

Other drivers and restraints analyzed in the detailed report include:

- Surge in low-latency Ethernet-enabled motors for Industry 4.0 retrofits

- Rapid build-out of desalination and water-reuse infrastructure

- Persistent shortage of power-electronics-grade SiC/GaN chips

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Low-voltage units below 1 kV remained the workhorse, controlling conveyors, mixers, and HVAC fans across small and mid-sized plants. In 2024 they captured 62.4% revenue, anchoring the variable frequency drives market. Cost-effective installation, plentiful integrator expertise, and abundant supplier catalogs sustained share. Parallelly, brownfield expansions in steel mills and underground mines shifted procurement toward 1-6 kV solutions, propelling the medium-voltage tier at a 6.8% CAGR. Mines upgrading to 995 V grids selected purpose-built drives to limit cable runs and improve voltage stability.

The variable frequency drives market size for medium-voltage equipment is forecast to reach USD 10.4 billion by 2030, benefiting from renewable energy in-feed, which heightens grid-code requirements for harmonic mitigation. Vendors responded with arc-resistant enclosures and modular active-front-end designs that cut total harmonic distortion below 3%. High-voltage products above 6 kV served niche hydro-pumping and rolling-mill projects; their uptake stayed limited by premium price tags and installation complexity.

Micro drives under 20 kW delivered the highest 7.2% CAGR as factories embraced distributed control, embedding small motors in autonomous mobile robots and smart building subsystems. Volume shipments climbed in tandem with sensor-rich HVAC zoning and food-processing feeders. Low-power (20-200 kW) models still underpinned 40.3% of 2024 revenue, proving indispensable to centrifugal pumps and axial fans across chemical and water utilities.

Developers enlarged heat-sink capacity and switched to SiC diodes to lift ambient operating limits beyond 60 °C, a critical differentiator in desert solar fields. The variable frequency drives market share for high-power classes above 600 kW remained below 5%, yet each sale generated sizable aftermarket revenue streams through long-term service agreements covering power-module relays and harmonic filter audits.

The Variable Frequency Drives Market Report is Segmented by Voltage Type (Low Voltage, Medium Voltage, High Voltage), Power Rating (Micro, Low, Medium, High), Drive Type (AC Drives, DC Drives, Servo/Vector Drives, and More), Application (Pumps, Fans and Blowers, and More), End-User Industry (Infrastructure and Buildings, Food and Beverage Processing, and More), and Geography (North America, South America, and More).

Geography Analysis

Asia-Pacific maintained leadership with 46.3% 2024 revenue, underpinned by China's automated appliance plants and India's production-linked incentive schemes that encouraged motor-efficiency retrofits. Local champions such as VEICHI scaled export sales by bundling cloud gateways for continuous monitoring, reinforcing regional cost competitiveness. Government rebate programs and mandatory IE3 motor policies in several ASEAN states sustained baseline demand, while semiconductor fabs in Taiwan and South Korea accelerated servo-drive orders.

The Middle East and Africa posted the highest 7.3% CAGR outlook as sovereign desalination pipelines and copper-belt mining electrification demanded rugged medium-voltage drives with high ingress protection. ACCIONA's Shuqaiq 3 milestone highlighted how water-security imperatives generate multi-megawatt pump-drive contracts. African utilities, though capital-constrained, tapped development-finance institutions to fund VFD-rich water-treatment upgrades, amplifying regional order books.

North America and Europe delivered steady replacement-cycle growth as older installations approached end-of-life and as stricter efficiency codes compelled upgrades. Utility rebate schemes and corporate ESG targets hastened adoption, especially where tariff escalation aligned with aggressive decarbonisation goals. European powder-metallurgy plants opted for active-front-end drives to meet harmonic quotas, while US Midwest chemical plants exploited natural-gas price volatility by modulating motor load with predictive VFD algorithms. Cyber-security hardening requirements extended bid evaluation timelines, yet ultimately enlarged service revenue for vendors offering patch-management and security-certificate renewal packages.

- ABB Ltd.

- Siemens AG

- Schneider Electric SE

- Danfoss A/S

- Rockwell Automation Inc.

- Mitsubishi Electric Corporation

- Yaskawa Electric Corporation

- Fuji Electric Co. Ltd.

- Eaton Corporation plc

- WEG Industries S.A.

- Nidec Corporation

- Toshiba Corporation

- Hitachi Ltd.

- Johnson Controls International plc

- Inovance Technology Co. Ltd.

- Delta Electronics Inc.

- Emerson Electric Co.

- LS Electric Co. Ltd.

- SEW-Eurodrive GmbH & Co KG

- Veichi Electric Co. Ltd.

- Control Techniques (Nidec)

- HARS Drives Co. Ltd.

- Vacon (Part of Danfoss)

- Parker Hannifin - SSD Drives

- Kollmorgen Corporation

- Bonfiglioli Riduttori S.p.A.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Digital-native process plants demanding motor-level energy-optimisation

- 4.2.2 Mandatory variable torque efficiency rules in HVAC and water verticals

- 4.2.3 Surge in low-latency, Ethernet-enabled motors for Industry 4.0 retrofits

- 4.2.4 Rapid build-out of desalination and water-reuse infrastructure (Middle-East focus)

- 4.2.5 Electrification of underground mining fleets

- 4.2.6 Inflation-linked electricity tariffs accelerating ROI on VFD retrofits

- 4.3 Market Restraints

- 4.3.1 Rising EMI / harmonics compliance costs above 690 V class

- 4.3.2 Cap-ex squeeze in developing-world utilities

- 4.3.3 Cyber-hardening spend delaying refresh cycles of legacy drives

- 4.3.4 Persistent shortage of power-electronics grade SiC/GaN chips

- 4.4 Impact of Macroeconomic Factors

- 4.5 Investment Analysis

- 4.6 Value Chain Analysis

- 4.7 Regulatory Landscape

- 4.8 Technology Snapshot

- 4.9 Porter's Five Forces Analysis

- 4.9.1 Threat of New Entrants

- 4.9.2 Bargaining Power of Suppliers

- 4.9.3 Bargaining Power of Buyers

- 4.9.4 Threat of Substitutes

- 4.9.5 Degree of Competition

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Voltage Type

- 5.1.1 Low Voltage (<1 kV)

- 5.1.2 Medium Voltage (1-6 kV)

- 5.1.3 High Voltage (>6 kV)

- 5.2 By Power Rating (kW)

- 5.2.1 Micro (<20)

- 5.2.2 Low (20-200)

- 5.2.3 Medium (200-600)

- 5.2.4 High (>600)

- 5.3 By Drive Type

- 5.3.1 AC Drives

- 5.3.2 DC Drives

- 5.3.3 Servo / Vector Drives

- 5.3.4 Multilevel and Matrix Drives

- 5.4 By Application

- 5.4.1 Pumps

- 5.4.2 Fans and Blowers

- 5.4.3 Compressors

- 5.4.4 Conveyors

- 5.4.5 HVAC Systems

- 5.4.6 Extruders and Mixers

- 5.5 By End-user Industry

- 5.5.1 Infrastructure and Buildings

- 5.5.2 Food and Beverage Processing

- 5.5.3 Energy and Power Generation

- 5.5.4 Oil, Gas and Petrochemicals

- 5.5.5 Mining and Metals

- 5.5.6 Pulp and Paper

- 5.5.7 Water and Wastewater

- 5.5.8 Others

- 5.6 By Geography

- 5.6.1 North America

- 5.6.1.1 United States

- 5.6.1.2 Canada

- 5.6.1.3 Mexico

- 5.6.2 South America

- 5.6.2.1 Brazil

- 5.6.2.2 Argentina

- 5.6.2.3 Rest of South America

- 5.6.3 Europe

- 5.6.3.1 United Kingdom

- 5.6.3.2 Germany

- 5.6.3.3 France

- 5.6.3.4 Italy

- 5.6.3.5 Russia

- 5.6.3.6 Rest of Europe

- 5.6.4 Asia-Pacific

- 5.6.4.1 China

- 5.6.4.2 India

- 5.6.4.3 Japan

- 5.6.4.4 South Korea

- 5.6.4.5 Rest of Asia-Pacific

- 5.6.5 Middle East and Africa

- 5.6.5.1 Middle East

- 5.6.5.1.1 Saudi Arabia

- 5.6.5.1.2 UAE

- 5.6.5.1.3 Turkey

- 5.6.5.1.4 Rest of Middle East

- 5.6.5.2 Africa

- 5.6.5.2.1 South Africa

- 5.6.5.2.2 Nigeria

- 5.6.5.2.3 Rest of Africa

- 5.6.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 ABB Ltd.

- 6.4.2 Siemens AG

- 6.4.3 Schneider Electric SE

- 6.4.4 Danfoss A/S

- 6.4.5 Rockwell Automation Inc.

- 6.4.6 Mitsubishi Electric Corporation

- 6.4.7 Yaskawa Electric Corporation

- 6.4.8 Fuji Electric Co. Ltd.

- 6.4.9 Eaton Corporation plc

- 6.4.10 WEG Industries S.A.

- 6.4.11 Nidec Corporation

- 6.4.12 Toshiba Corporation

- 6.4.13 Hitachi Ltd.

- 6.4.14 Johnson Controls International plc

- 6.4.15 Inovance Technology Co. Ltd.

- 6.4.16 Delta Electronics Inc.

- 6.4.17 Emerson Electric Co.

- 6.4.18 LS Electric Co. Ltd.

- 6.4.19 SEW-Eurodrive GmbH & Co KG

- 6.4.20 Veichi Electric Co. Ltd.

- 6.4.21 Control Techniques (Nidec)

- 6.4.22 HARS Drives Co. Ltd.

- 6.4.23 Vacon (Part of Danfoss)

- 6.4.24 Parker Hannifin - SSD Drives

- 6.4.25 Kollmorgen Corporation

- 6.4.26 Bonfiglioli Riduttori S.p.A.

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-Need Assessment