|

市場調查報告書

商品編碼

1850982

軟性電子產品:市場佔有率分析、產業趨勢、統計數據和成長預測(2025-2030 年)Flexible Electronics - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

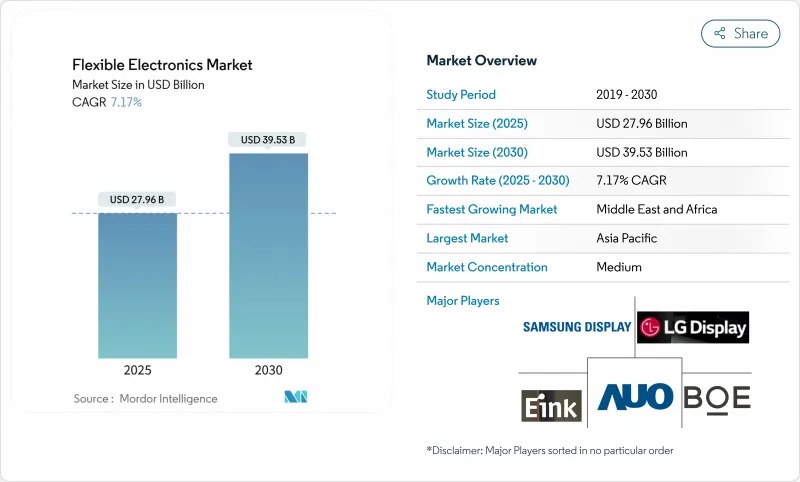

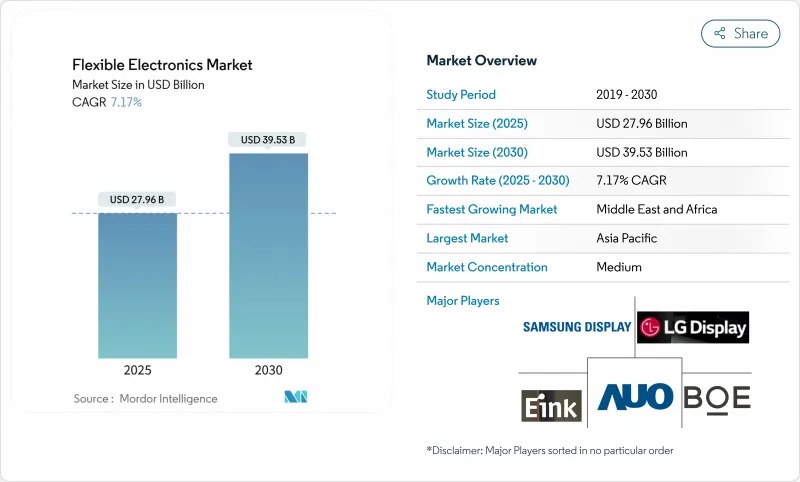

預計到 2025 年,軟性電子產品市場規模將達到 279.6 億美元,到 2030 年將達到 395.3 億美元。

超薄OLED堆疊技術、共形感測器技術的進步以及捲對捲製造程序降低的准入門檻,推動了軟性電子市場的擴張,使其從利基原型開發走向智慧型手機、汽車和醫療穿戴式裝置的主流應用。隨著曲面汽車抬頭顯示器(HUD)重塑駕駛座設計,以及北美醫療系統檢驗依賴可拉伸生物感測器的連續監測貼片,市場需求正在加速成長。京東方和三星對第8.6代AMOLED和超薄OLED生產線的投資,以及中東國防專案優先考慮輕型共形天線,進一步推動了軟性電子產品市場的發展。同時,供應鏈對高阻隔封裝薄膜的依賴以及可拉伸互連缺乏通用可靠性標準,增加了認證門檻和成本不確定性,削弱了市場成長前景。

全球軟性電子產品市場趨勢與洞察

提升超薄OLED堆疊結構的耐用性,以實現折疊式智慧型手機

三星顯示器公司的Flex Magic Pixel演示樣機通過了軍用級耐久性測試,消除了可見的摺痕,滿足了用戶對堅固折疊式螢幕的期望。蘋果公司2026年訂購了900萬至1500萬塊7.8英寸面板用於其折疊式iPhone,這表明可折疊螢幕已具備商業性化條件,並預示著其即將被大規模採用。 2026年筆記型電腦面板重量減輕30%,功耗降低30%,將使可折疊設備的應用範圍超越行動電話。隨著OEM廠商將平板電腦和筆記型電腦轉向可折疊設計,這些進步對整個軟性電子產品市場產生了深遠的影響,也增強了供應鏈對高阻隔封裝和超薄玻璃的需求。

北美地區對穿戴式醫療貼片用貼合式感測器的需求不斷成長

X-trodes公司的智慧皮膚和加州大學聖地牙哥分校的1024通道腦部感測器陣列獲得FDA批准,使軟性生物感測器在連續監測領域得到認可。醫療保健系統的報銷模式正轉向以結果為導向的醫療服務,優先考慮能夠收集患者長期數據的設備。軟式電路板可以減少運動偽影,並在日常生活中保持訊號完整性。設備製造商正在利用有機電化學電晶體進行感測器內計算,以最大限度地減少延遲並保護患者隱私。隨著遠端監測被納入醫保報銷標準,軟性電子產品市場將受益於感測器和貼片的可重複使用性。

伸縮性互連可靠性測試的標準化程度有限

剛性電子標準無法同時捕捉穿戴式應用中常見的彎曲、扭轉和溫度循環。儘管IEEE的囊式充氣法草案可以測量多軸膨脹和收縮,但它仍屬自願性質,這阻礙了需要經認證的壽命數據的汽車和醫療OEM廠商。研究人員已提案聚合物中間層設計方案以減少應變引起的基板開裂,但由於缺乏統一的指標,投資者對大規模生產模具的投資意願降低。因此,在統一通訊協定訂定之前,軟性電子產品市場的設計和中標週期將面臨延誤。

細分市場分析

到2024年,軟性顯示器將佔據軟性電子產品市場54.7%的佔有率,這主要得益於折疊式智慧型手機和曲面汽車儀錶板的持續推出。三星的18.1吋折疊式原型機展示了其在筆記型電腦領域的擴充性,而LG的可拉伸microLED面板則為時尚和汽車照明領域解鎖了3D表面。與顯示器相輔相成的是,隨著醫院採用表皮心電圖(ECG)和腦電圖(EEG)貼片進行慢性病護理,感測器類別在2025年至2030年間的複合年成長率(CAGR)將達到9.2%。能夠承受1.5倍拉伸的量子點顯示-感測器混合裝置是多功能表面(可顯示和感知數據)的先驅,這使得感測器成為下一個成長引擎。儘管取得了進展,但由於安全性和產量比率方面的挑戰,軟性電池和記憶體的發展仍然滯後,這限制了目前完全整合軟性系統的發展。

隨著面板製造商利用透明OLED堆疊技術將指紋識別和血氧飽和度(SpO2)讀數直接整合到螢幕下方,軟性電子產品市場將受益匪淺,從而減少元件數量並縮小設備尺寸。整合生物感測顯示器為尋求差異化的智慧型手機廠商開闢了新的獲利途徑。能夠將振動轉化為微瓦能量的能源採集薄膜可以降低穿戴式裝置和工業標籤的電池負載,但實用化仍需高性能壓電聚合物的穩定供應。隨著各元件之間協同效應的日益成熟,設備設計人員將能夠設計出集視覺、觸覺和感測功能於一體的無縫外形規格。

到2024年,塑膠基板將佔據軟性電子產品市場61.6%的佔有率,這主要得益於與顯示器工廠緊密相連的成熟的聚醯亞胺供應鏈。塑膠基材高達度C的熱穩定性可與銅線形成互補,最大限度地減少汽車儀錶板在劇烈溫度波動下發生的剝離現象。金屬箔(主要是銅和不銹鋼)憑藉其固有的導電性和電磁干擾屏蔽性能,預計將以8.4%的複合年成長率成長,這些特性使其在國防無線電和高速數據線纜領域備受青睞。石墨烯塗層銅奈米線在保持柔韌性的同時,還具有比氧化銦錫更低的薄層薄片電阻,因此在卷對卷觸摸感測器領域引起了廣泛關注。

超薄玻璃將推動高階折疊式設備的研發,因此需要具備卓越的光學性能和抗刮性。康寧公司最新研發的玻璃厚度僅30微米,雖然比聚合物玻璃昂貴,但其彎曲半徑可達5毫米而不破裂。杜邦公司於2024年收購C3Nano資產,加速了奈米銀線油墨技術的進步,將提升智慧窗戶的透明度和機械強度。碳基導電油墨無需使用稀缺的銦和有毒溶劑,符合環境、社會和治理(ESG)要求,因此對將軟性太陽能板整合到建築幕牆的製造商極具吸引力。隨著監管機構對電子廢棄物的審查日益嚴格,材料的選擇需要在成本、性能和可回收性之間取得平衡。

區域分析

到2024年,亞太地區將佔據軟性電子產品市場45.7%的佔有率,這主要得益於中國龐大的製造業規模和韓國OLED技術的創新發展。京東方在成都投資90億美元建設的第八代.6代AMOLED工廠是該市最大的工業投資項目,將擴大平板電腦和汽車駕駛座面板的產能。韓國研究機構將壓電採集器的產量提高了280倍,凸顯了其在顯示器、感測器和能源裝置領域的區域領先地位。日本則貢獻了精密沉澱設備和超薄玻璃,這些技術是折疊式行動裝置可靠性的關鍵。

北美正聚焦高價值的醫療保健和國防領域,充分利用美國食品藥物管理局(FDA)對軟性生物感測器的批准以及美國對戰場天線陣列的資助。三星在橫濱投資2.4億美元建立的封裝研發中心凸顯了跨國合作,將亞洲供應商與美國系統整合商聚集在一起。矽谷新興企業率先開發出軟性積體電路設計自動化技術,縮短了用於一次性診斷試劑的印刷邏輯晶片的流片週期。

汽車數位化和永續性是歐洲的優先事項。德國汽車製造商強制要求在2028年前整合全像顯示器(HUD),這推動了對符合嚴格防眩光和抗衝擊標準的可折疊顯示器的需求。歐盟關於建築整合光伏的指令正在促進軟性建築幕牆嵌入式光伏組件的測試。同時,嚴格的電子廢棄物法規正在提高可回收性,並加速可生物分解基板的研究。

中東和非洲地區將迎來最高的複合年成長率(CAGR),達到11.3%。國防現代化和智慧城市計畫正在採用共形電子技術,用於在惡劣氣候條件下運作的重量敏感型無人機和感測器。各國政府正在加速推動5G和邊緣網路建設,從而推動了對耐沙耐熱軟性天線的需求。該地區的大學正與歐洲研究機構合作,開發有機光伏技術,為離網物聯網節點供電,從而拓展其應用範圍。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 提高折疊式智慧型手機超薄OLED螢幕堆疊的耐用性

- 北美對穿戴式醫療貼片用貼合式感測器的需求

- 汽車駕駛座數位化推動了歐洲曲面抬頭顯示器(HUD)的普及。

- 降低亞洲印刷積體電路卷軸式製造成本

- 英國國防部在中東地區推廣用於無人機的輕型共形天線

- 以環境、社會及公司治理(ESG)主導,在商業建築中推廣軟性光伏面板。

- 市場限制

- 大面積金屬油墨印刷的產量比率損失

- 可拉伸互連可靠性測試缺乏標準化

- 阻隔性封裝膜供應鏈集中化

- 聚醯亞胺基板的處置與回收的複雜性

- 產業價值鏈分析

- 技術展望

- 波特五力分析

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭對手之間的競爭

- 投資分析

第5章 市場規模與成長預測

- 按組件

- 軟性顯示器

- 有機發光二極體

- 電子紙

- 其他

- 軟性感測器

- 生物感測器

- 壓力感測器

- 溫度感測器

- 其他

- 軟性電池

- 軟性記憶體

- 靈活的太陽能發電

- 其他

- 軟性顯示器

- 材料

- 塑膠基板

- 玻璃(超薄)

- 金屬箔

- 導電油墨

- 介電/封裝

- 透過技術

- 印刷電子

- 有機電子學

- 薄膜無機電子學

- 混合系統

- 透過使用

- 感測

- 照明

- 展示

- 能源採集

- RFID和智慧標籤

- 其他

- 按最終用戶行業分類

- 家用電器

- 汽車與運輸

- 醫療保健和醫療設備

- 軍事與國防

- 工業與物聯網

- 其他

- 按地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 北歐國家

- 其他歐洲地區

- 南美洲

- 巴西

- 其他南美洲

- 亞太地區

- 中國

- 日本

- 印度

- 東南亞

- 亞太其他地區

- 中東和非洲

- 中東

- GCC

- 土耳其

- 其他中東地區

- 非洲

- 南非

- 其他非洲地區

- 北美洲

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率分析

- 公司簡介

- Samsung Display Co. Ltd

- LG Display Co. Ltd

- BOE Technology Group Co. Ltd

- AU Optronics Corp.

- Royole Corporation

- E Ink Holdings Inc.

- OLEDWorks LLC

- FlexEnable Ltd

- PragmatIC Semiconductor Ltd

- Imprint Energy Inc.

- Blue Spark Technologies Inc.

- Flexpoint Sensor Systems Inc.

- Universal Display Corporation

- Kyocera Corporation

- Panasonic Holdings Corp.

- Sony Group Corp.

- Polyera Corporation

- Cambrios Advanced Materials Corp.

- Heliatek GmbH

- First Solar Inc.(Flex PV Division)

第7章 市場機會與未來展望

The flexible electronics market size reached USD 27.96 billion in 2025 and is forecast to climb to USD 39.53 billion by 2030, reflecting a 7.17% CAGR over 2025-2030.

The expansion stems from a shift away from niche prototypes toward mainstream deployments in smartphones, automobiles, and healthcare wearables, supported by ultra-thin OLED stacks, conformal sensor breakthroughs, and roll-to-roll production economics that lower entry costs. Demand accelerates as curved automotive head-up displays (HUDs) reshape cockpit design, while North American healthcare systems validate continuous monitoring patches that rely on stretchable biosensors. Investments from BOE and Samsung in Gen-8.6 AMOLED and ultra-thin OLED lines, coupled with Middle East defense programs prioritizing lightweight conformal antennas, further elevate the flexible electronics market's momentum. At the same time, supply-chain concentration in high-barrier encapsulation films and the absence of universal reliability standards for stretchable interconnects temper growth prospects by raising qualification hurdles and cost uncertainty.

Global Flexible Electronics Market Trends and Insights

Improved durability of ultra-thin OLED stacks enabling foldable smartphones

Samsung Display's Flex Magic Pixel demonstrator passed military-grade durability tests, eliminating visible creases and meeting user expectations for robust folding screens. Apple's 2026 foldable iPhone order for 9-15 million 7.8-inch panels validates commercial readiness and signals mass adoption. Weight reductions of 30% and power savings of 30% in 2026 laptop panels widen the addressable device pool beyond phones. These advances resonate across the flexible electronics market as OEMs migrate tablets and laptops toward bendable formats, reinforcing supply-chain demand for high-barrier encapsulation and ultra-thin glass.

Demand for conformal sensors in wearable medical patches across North America

FDA clearance for X-trodes' Smart Skin and UC San Diego's 1,024-channel brain sensor array legitimizes flexible biosensors for continuous monitoring. Health-system reimbursement models pivot toward outcome-based care, favoring devices that capture longitudinal patient data. Flexible substrates reduce motion artifacts, maintaining signal integrity during everyday activities. Device makers tap organic electrochemical transistors for in-sensor computing, minimizing latency and protecting patient privacy. As reimbursement codes codify remote monitoring, the flexible electronics market benefits from recurrent sensor and patch replacements.

Limited standardization of stretchable interconnect reliability tests

Rigid-electronics standards fail to capture simultaneous bending, twisting, and temperature cycling seen in wearable use. IEEE's draft bladder-inflation method measures multi-axis stretch but remains voluntary, deterring automotive and medical OEMs that require certified lifetime data. Researchers propose polymer interlayer designs to curb substrate cracking under strain, yet without consensus metrics investors hesitate to fund high-volume tooling. The flexible electronics market thus faces slower design-win cycles until unified protocols emerge.

Other drivers and restraints analyzed in the detailed report include:

- Automotive cockpit digitization driving curved HUD adoption in Europe

- Roll-to-roll manufacturing cost reduction in Asia for printed ICs

- Yield Losses in Large-area Printing of Metallic Inks

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Flexible displays accounted for 54.7% of flexible electronics market share in 2024, powered by relentless foldable smartphone launches and curved automotive dashboards. Samsung's 18.1-inch foldable prototype proves scalability into laptops, while LG's stretchable micro-LED panel unlocks 3D surfaces in fashion and in-vehicle lighting. Complementing displays, the sensor category yields a 9.2% CAGR over 2025-2030 as hospitals adopt epidermal ECG and EEG patches for chronic care. Quantum-dot display-sensor hybrids that tolerate 1.5X stretching herald multifunctional surfaces that both show and sense data, positioning sensors as the next growth catalyst. Despite progress, flexible batteries and memory lag due to safety and yield hurdles, limiting fully integrated flexible systems today.

The flexible electronics market benefits from panel makers leveraging transparent OLED stacks to embed fingerprint and SpO2 reading directly under the screen, condensing component count and thinning device profiles. Integrated biosensing displays open new monetization avenues for smartphone vendors seeking differentiation. Energy-harvesting films that convert vibration into micro-watts reduce battery load in wearables and industrial tags, though commercialization awaits stable supply of high-performance piezoelectric polymers. As cross-component synergies mature, device architects can design seamless form factors that merge visual, haptic, and sensing capabilities.

Plastic substrates represented 61.6% of flexible electronics market size in 2024, driven by mature polyimide supply chains aligned with display fabs. Their thermal stability up to 400 °C pairs well with copper traces, minimizing delamination in automotive dashboards exposed to wide temperature swings. Metal foils, chiefly copper and stainless steel, post an 8.4% CAGR thanks to innate conductivity and EMI shielding valued in defense radios and high-speed data cables. Graphene-coated copper nanowires offer lower sheet resistance than indium-tin-oxide while retaining flexibility, attracting interest for roll-to-roll touch sensors.

Ultra-thin glass gains traction in premium foldable devices requiring pristine optics and scratch resistance. At just 30 µm, Corning's latest glass can bend to 5 mm radius without fracture, albeit at a higher price point than polymer. Silver-nanowire ink advances, accelerated by DuPont's 2024 C3Nano asset purchase, improve transparency and mechanical resilience for smart windows. Carbon-based conductive inks address ESG mandates by eliminating scarce indium and toxic solvents, appealing to builders of flexible photovoltaics integrated into facades. Material selection now balances cost, performance, and recyclability as regulators scrutinize electronic waste.

The Flexible Electronics Market Report is Segmented by Component (Flexible Displays, Flexible Sensors, and More), Material (Plastic Substrate, Glass, and More), Technology (Printed Electronics, Organic Electronics, and More), Application (Sensing, Lighting, Display, and More), End-User Industry (Consumer Electronics, Automotive and Transportation, and More), and Geography. The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific commanded 45.7% of flexible electronics market share in 2024, anchored by China's manufacturing scale and Korea's OLED innovation pipeline. BOE's USD 9 billion Gen-8.6 AMOLED fab in Chengdu-the city's largest single industrial investment-expands panel capacity for tablets and automotive cockpits. Korean institutes pushed piezoelectric harvester output 280X, underscoring regional leadership across displays, sensors, and energy devices. Japan contributes precision deposition tools and ultra-thin glass that support foldable handset reliability.

North America focuses on high-value healthcare and defense niches, leveraging FDA clearances for flexible biosensors and Pentagon funding for battlefield antenna arrays. Samsung's USD 240 million Yokohama packaging R&D hub highlights cross-border collaboration, as Asian suppliers co-locate near U.S. system integrators. Silicon Valley startups pioneer flexible IC design automation, shortening tape-out cycles for printed logic that feeds disposable diagnostics.

Europe prioritizes automotive digitization and sustainability. German OEMs mandate holographic HUD integration by 2028, driving demand for bendable displays meeting stringent glare and impact standards. EU directives on building-integrated photovoltaics spur trials of facade-embedded flexible PV skins. Simultaneously, strict e-waste rules push recyclability, accelerating research into biodegradable substrates.

Middle East and Africa posts the highest 11.3% CAGR as defense modernization and smart-city programs embrace conformal electronics for weight-sensitive drones and harsh-climate sensors. Governments fast-track 5G and edge networks, creating pull for flexible antennas resistant to sand and heat. Regional universities partner with European labs on organic PV to power off-grid IoT nodes, broadening application diversity.

- Samsung Display Co. Ltd

- LG Display Co. Ltd

- BOE Technology Group Co. Ltd

- AU Optronics Corp.

- Royole Corporation

- E Ink Holdings Inc.

- OLEDWorks LLC

- FlexEnable Ltd

- PragmatIC Semiconductor Ltd

- Imprint Energy Inc.

- Blue Spark Technologies Inc.

- Flexpoint Sensor Systems Inc.

- Universal Display Corporation

- Kyocera Corporation

- Panasonic Holdings Corp.

- Sony Group Corp.

- Polyera Corporation

- Cambrios Advanced Materials Corp.

- Heliatek GmbH

- First Solar Inc. (Flex PV Division)

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Improved Durability of Ultra-thin OLED Stacks Enabling Foldable Smartphones

- 4.2.2 Demand for Conformal Sensors in Wearable Medical Patches across North America

- 4.2.3 Automotive Cockpit Digitization Driving Curved HUD Adoption in Europe

- 4.2.4 Roll-to-Roll Manufacturing Cost Reduction in Asia for Printed ICs

- 4.2.5 Defense Push for Lightweight, Conformal Antennas in Middle East UAVs

- 4.2.6 ESG-Led Push toward Flexible PV Skins on Commercial Buildings

- 4.3 Market Restraints

- 4.3.1 Yield Losses in Large-area Printing of Metallic Inks

- 4.3.2 Limited Standardization of Stretchable Interconnect Reliability Tests

- 4.3.3 Supply-chain Concentration of High-barrier Encapsulation Films

- 4.3.4 Disposal and Recycling Complexities of Poly-imide Substrates

- 4.4 Industry Value Chain Analysis

- 4.5 Technological Outlook

- 4.6 Porter's Five Forces Analysis

- 4.6.1 Bargaining Power of Suppliers

- 4.6.2 Bargaining Power of Buyers

- 4.6.3 Threat of New Entrants

- 4.6.4 Threat of Substitutes

- 4.6.5 Intensity of Competitive Rivalry

- 4.7 Investment Analysis

5 MARKET SIZE AND GROWTH FORECASTS (VALUES)

- 5.1 By Component

- 5.1.1 Flexible Displays

- 5.1.1.1 OLED

- 5.1.1.2 E-Paper

- 5.1.1.3 Others

- 5.1.2 Flexible Sensors

- 5.1.2.1 Biosensors

- 5.1.2.2 Pressure Sensors

- 5.1.2.3 Temperature Sensors

- 5.1.2.4 Others

- 5.1.3 Flexible Batteries

- 5.1.4 Flexible Memory

- 5.1.5 Flexible Photovoltaics

- 5.1.6 Others

- 5.1.1 Flexible Displays

- 5.2 By Material

- 5.2.1 Plastic Substrate

- 5.2.2 Glass (Ultra-thin)

- 5.2.3 Metal Foils

- 5.2.4 Conductive Inks

- 5.2.5 Dielectrics/Encapsulation

- 5.3 By Technology

- 5.3.1 Printed Electronics

- 5.3.2 Organic Electronics

- 5.3.3 Thin-Film Inorganic Electronics

- 5.3.4 Hybrid Systems

- 5.4 By Application

- 5.4.1 Sensing

- 5.4.2 Lighting

- 5.4.3 Display

- 5.4.4 Energy Harvesting

- 5.4.5 RFID and Smart Labels

- 5.4.6 Others

- 5.5 By End-User Industry

- 5.5.1 Consumer Electronics

- 5.5.2 Automotive and Transportation

- 5.5.3 Healthcare and Medical Devices

- 5.5.4 Military and Defense

- 5.5.5 Industrial and IoT

- 5.5.6 Others

- 5.6 By Geography

- 5.6.1 North America

- 5.6.1.1 United States

- 5.6.1.2 Canada

- 5.6.1.3 Mexico

- 5.6.2 Europe

- 5.6.2.1 Germany

- 5.6.2.2 United Kingdom

- 5.6.2.3 France

- 5.6.2.4 Nordics

- 5.6.2.5 Rest of Europe

- 5.6.3 South America

- 5.6.3.1 Brazil

- 5.6.3.2 Rest of South America

- 5.6.4 Asia-Pacific

- 5.6.4.1 China

- 5.6.4.2 Japan

- 5.6.4.3 India

- 5.6.4.4 South-East Asia

- 5.6.4.5 Rest of Asia-Pacific

- 5.6.5 Middle East and Africa

- 5.6.5.1 Middle East

- 5.6.5.1.1 Gulf Cooperation Council Countries

- 5.6.5.1.2 Turkey

- 5.6.5.1.3 Rest of Middle East

- 5.6.5.2 Africa

- 5.6.5.2.1 South Africa

- 5.6.5.2.2 Rest of Africa

- 5.6.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global Level Overview, Market Level Overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Samsung Display Co. Ltd

- 6.4.2 LG Display Co. Ltd

- 6.4.3 BOE Technology Group Co. Ltd

- 6.4.4 AU Optronics Corp.

- 6.4.5 Royole Corporation

- 6.4.6 E Ink Holdings Inc.

- 6.4.7 OLEDWorks LLC

- 6.4.8 FlexEnable Ltd

- 6.4.9 PragmatIC Semiconductor Ltd

- 6.4.10 Imprint Energy Inc.

- 6.4.11 Blue Spark Technologies Inc.

- 6.4.12 Flexpoint Sensor Systems Inc.

- 6.4.13 Universal Display Corporation

- 6.4.14 Kyocera Corporation

- 6.4.15 Panasonic Holdings Corp.

- 6.4.16 Sony Group Corp.

- 6.4.17 Polyera Corporation

- 6.4.18 Cambrios Advanced Materials Corp.

- 6.4.19 Heliatek GmbH

- 6.4.20 First Solar Inc. (Flex PV Division)

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-Need Assessment