|

市場調查報告書

商品編碼

1850169

生物潤滑劑:市場佔有率分析、產業趨勢、統計數據和成長預測(2025-2030 年)Bio-Lubricants - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

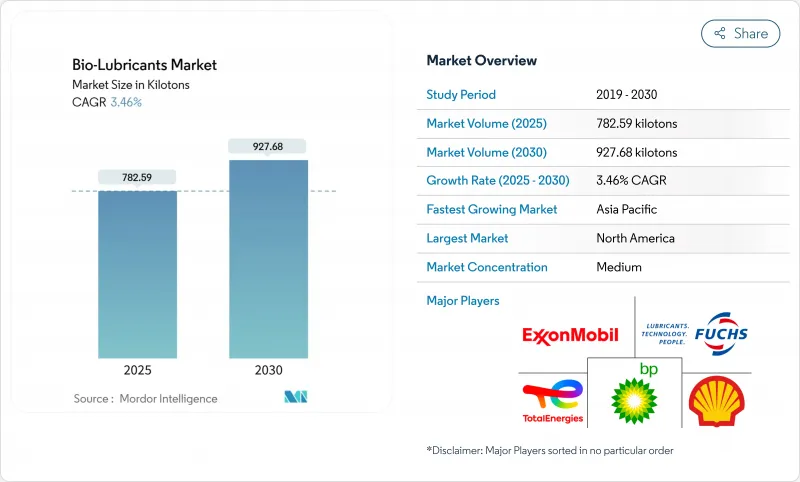

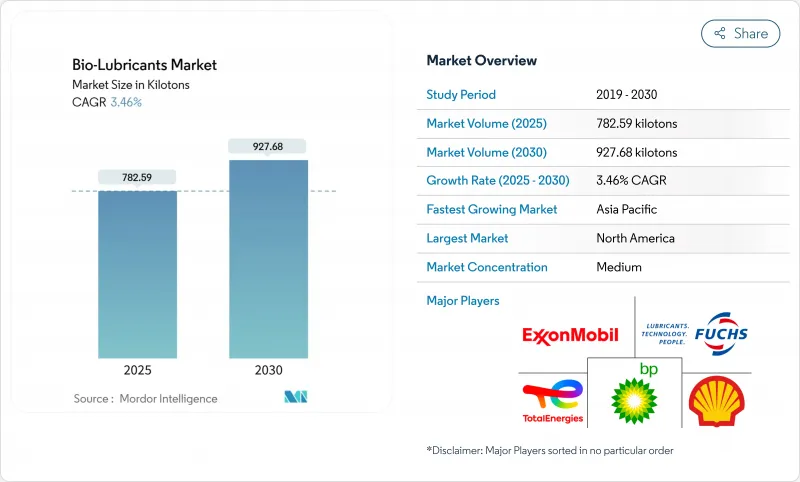

預計到 2025 年,生物潤滑劑市場規模將達到 782.59 千噸,到 2030 年將達到 927.68 千噸,在預測期(2025-2030 年)內複合年成長率為 3.46%。

穩定成長反映了日益嚴格的環境法規、不斷強化的企業永續性目標以及對高性能植物來源配方日益成長的依賴。在潤滑油洩漏可能污染土壤和水源的地區,需求成長最為迅速;根據產業估計,歷史上用於此類應用的石油產品中約有50%最終流入環境。目標商標產品製造商 (OEM) 正在其維修手冊中正式納入可生物分解潤滑油,而離岸風力發電、林業和海洋營運商正在修訂其採購政策,以避免因洩漏而受到處罰。同時,添加劑化學領域的進步,例如金屬氧化物奈米顆粒包,正在提高產品的抗氧化性和熱穩定性,並縮小與礦物油之間長久以來的性能差距。競爭的焦點在於規模化生產的經濟效益、專有酯類化學以及能夠為快速可再生的可再生能源資產提供長期供應的合作夥伴關係。

全球生物潤滑劑市場趨勢與洞察

嚴格的環境法規和強制性生態標籤

美國潤滑油生態標章已發展成為永續性認證的標桿,對水生毒性、生物累積性和有害成分設定了限制,並要求其功能與礦物油等效。在美國,環保署的船舶通用許可證要求船舶在油海界面使用環境可接受潤滑油(EAL),為船東開闢了一條合規性主導的採購途徑。與先前的單一參數生物分解性測試不同,最新標準納入了全生命週期生態毒性分析,加速了產品改進。監管機構已發出進一步加強監管的訊號,一些亞洲司法管轄區正在製定與歐盟標準接軌的生態標籤。隨著執法力度的加大,擁有第三方認證產品線的供應商在公共競標和大型基礎設施計劃中獲得了優先考慮,生物潤滑油市場需求也被納入長期資本預算。

可生物分解液壓油的OEM規格

例如,採埃孚(ZF Friedrichshafen)推出了03H等級,專門用於符合公認環保標準的潤滑油。林業收割機、建築挖掘機和港口起重機等設備在出廠時擴大使用可生物分解的液壓油,如果操作人員改用礦物油,則可能導致保固失效。由於每台設備都要消耗數百公升液壓油,因此原始設備製造商(OEM)的採用會透過全球服務網路逐步推廣,從而在設備的整個生命週期內產生持續的需求。此類規範的結構性特徵穩定了消費模式,並保護生物潤滑油市場免受短期商品價格波動的影響。

生物潤滑劑的成本高於傳統潤滑劑。

酯類液壓油的平均售價仍是II類礦物油基液壓油的1.5至2.5倍,反映出其原料成本高、生產批量小以及添加劑配方特殊等問題。學術界一再指出,在規模經濟效益改善之前,成本仍然是監管細分市場之外的關鍵障礙。利潤率較低的終端用戶,例如小型漁船隊和獨立經營的金屬加工廠,通常會推遲採用酯類液壓油,除非法律或客戶合約強制要求使用可生物分解的等級。雖然隨著產量增加和廢油酯化技術的成熟,成本差異有望縮小,但價格仍可能對生物潤滑油市場的中期複合年成長率構成壓力。

細分市場分析

2024年,變速箱油和液壓油佔生物潤滑油市場31.19%的佔有率,預計到2030年將以3.58%的複合年成長率成長。這一成長是生物潤滑油產品類型中最大的市場佔有率,反映了林業收割機、港口起重機和河道疏浚船等行業嚴格的溢油預防法規。由於這些系統一旦發生故障就可能排放數十公升潤滑油,因此營運商願意為高生物分解性潤滑油支付更高的價格,以減少清理工作量並保護敏感的濕地。添加劑的突破性進展(例如無鋅抗磨化學配方)使得即使在負載變化的情況下,也能實現5000小時的換油週期,這促使原始設備製造商(OEM)將其原廠灌裝潤滑油更換為生物基潤滑油。

潤滑脂、機油和金屬加工液共同構成了一個快速且多元化的叢集。潤滑脂尤其受惠於離岸風力發電,因為軸承座通常位於水面以上數公尺處,洩漏路徑難以監測。金屬加工液在精密加工中心越來越受歡迎,其毒性較低的霧化液有助於提高工人的安全。在每個產品類別中,供應商擴大銷售針對特定應用的配方,而不是通用的「綠色」替代品,這種策略提高了產品轉換率,並鞏固了長期的客戶合約。

區域分析

預計到2024年,北美將以36.19%的市佔率引領生物潤滑油市場。美國海洋通用許可證的實施,以及加拿大先進的林業實踐,確保了水道和林區內符合環保空氣法(EAL)標準的設備的穩定安裝。礦業公司正在礦山復墾協議中引入可生物分解的液壓油,這一趨勢在《北美礦業》雜誌上得到了重點報告。較高的技術水準和密集的經銷商網路也進一步促進了這一轉變。

亞太地區是成長最快的地區,複合年成長率達4.45%,但各國趨勢不盡相同。中國正投資國內酯類生產能力和添加劑研發,以減少對進口配方的依賴。朗盛報告稱,中國和東南亞的機械加工叢集對環保金屬加工添加劑的需求激增。日本正將生物潤滑劑的研發重心轉向高精度機器人領域,而印度的農業部門則受益於可生物分解的曳引機液壓油,這種油能夠防止田間污染,從而推動了農業生產的成長。中國東岸和台灣海峽沿岸的離岸風力發電電場正在採用優質生物潤滑脂,以最大限度地降低其25年使用週期內的環境風險。

在歐盟生態標章計畫的支持下,歐洲仍然是一個成熟且充滿創新精神的市場。德國和北歐國家正在推動林業收割機和水力發電廠採用生物分解潤滑劑。 2025 年在萊比錫舉行的國際摩擦學與永續潤滑大會重點介紹了符合循環經濟目標的下一代生物分解化學品。南美洲和整個中東/非洲地區是生物分解潤滑劑的早期應用區域。在巴西的風電場和墨西哥灣的海水淡化廠等跨國基礎設施計劃中,外國投資者正在強制執行環境、社會和治理 (ESG) 條款,要求使用生物分解潤滑劑。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 嚴格的環境法規和生態標章要求

- 可生物分解液壓油的OEM規格

- 企業淨零排放與ESG採購目標

- 離岸風力發電齒輪箱對長效生物潤滑脂的需求

- 來自海洋產業的需求不斷成長

- 市場限制

- 生物潤滑劑的成本高於傳統潤滑劑。

- 氧化和熱穩定性限制

- 生物潤滑劑有效期限

- 價值鏈分析

- 波特五力模型

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

第5章 市場規模與成長預測

- 依產品類型

- 機油

- 傳動和液壓油

- 金屬加工油

- 通用工業油

- 齒輪油

- 潤滑脂

- 加工油

- 其他產品類型

- 按最終用戶行業分類

- 發電

- 汽車和其他交通工具

- 重型機械

- 食品/飲料

- 冶金與金屬加工

- 化學製造

- 其他終端用戶產業

- 依基油類型

- 植物油

- 動物脂肪

- 合成酯

- 按地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 亞太其他地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 義大利

- 法國

- 俄羅斯

- 其他歐洲地區

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 其他中東和非洲地區

- 亞太地區

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率(%)/排名分析

- 公司簡介

- Axel Christiernsson

- BP plc

- Cargill, Incorporated.

- Carl Bechem Lubricants

- Chevron Corporation

- Cortec Corporation

- Croda International plc

- Emery Oleochemicals

- Environmental Lubricants Manufacturing, Inc.

- Exxon Mobil Corporation

- FUCHS

- KCM Petro Chemicals

- Lubrication Engineers

- Novvi LLC

- Quaker Chemical Corporation

- Renewable Lubricants Inc.

- Saudi Arabian Oil Co.

- Shell plc

- TotalEnergies SE

第7章 市場機會與未來展望

The Bio-Lubricants Market size is estimated at 782.59 kilotons in 2025, and is expected to reach 927.68 kilotons by 2030, at a CAGR of 3.46% during the forecast period (2025-2030).

Steady growth reflects tightening environmental rules, stronger corporate sustainability targets, and rising confidence in high-performance, plant-derived formulations. Demand is expanding fastest where lubricant losses can contaminate soil or water, and industry estimates indicate that roughly 50% of the petroleum oil historically used in such applications eventually escapes into the environment. Original equipment manufacturers (OEMs) are formally listing biodegradable fluids in service manuals, while offshore wind, forestry, and marine operators are rewriting procurement policies to avoid penalties linked to spills. Parallel progress in additive chemistry, such as metal-oxide nanoparticle packages, has lifted oxidative and thermal stability, narrowing the historic performance gap with mineral oils. Competitive dynamics now center on scale-up economics, intellectual-property-protected ester chemistries, and partnerships that lock in long-term supply to high-growth renewable-energy assets.

Global Bio-Lubricants Market Trends and Insights

Stringent Environmental Regulations & Eco-labeling Mandates

The EU Ecolabel for lubricants has evolved into the benchmark sustainability certification, setting limits on aquatic toxicity, bioaccumulation, and hazardous components while demanding functional parity with mineral oils. In the United States, the EPA's Vessel General Permit obliges vessels to use Environmentally Acceptable Lubricants (EALs) across oil-to-sea interfaces, creating a compliance-driven purchasing lane for shipowners. Unlike earlier single-parameter biodegradability tests, modern standards incorporate full life-cycle eco-toxicity analysis, accelerating product reformulation. Regulators have signaled additional tightening, and several Asian jurisdictions are working on EU-aligned eco-label drafts. As enforcement widens, suppliers with third-party certified lines enjoy preferred status in public tenders and major infrastructure projects, embedding bio-lubricants market demand into long-term capital budgets.

OEM Specifications for Biodegradable Hydraulic Fluids

Major machinery brands now codify bio-hydraulic fluid classes inside their technical manuals; ZF Friedrichshafen, for example, introduced class 03H exclusively for lubricants certified under recognized environmental standards. Forestry harvesters, construction excavators, and port cranes increasingly ship with factory fills of biodegradable fluids, and warranty coverage can be voided if operators revert to mineral oils. Because each piece of equipment can consume several hundred liters of fluid, OEM adoption cascades through global service networks and drives repeat demand over the equipment life cycle. The structural nature of these specifications stabilizes consumption patterns and insulates the bio-lubricants market from short-term commodity price swings.

High Price of Bio-lubricants in Comparison to Conventional Lubricants

Average selling prices for ester-based hydraulic oils remain 1.5-2.5 times those of Group II mineral equivalents, reflecting higher feedstock costs, smaller batch runs, and specialized additive packages. Academic reviews reiterate that until economies of scale improve, cost remains a decisive barrier outside regulated niches. End-users with thin operating margins, such as small fishing fleets or independent metalworking shops, often delay adoption unless legislation or client contracts mandate biodegradable grades. While the cost delta is projected to narrow as production volumes climb and waste-oil-to-ester technologies mature, pricing will weigh on the bio-lubricants market CAGR over the medium term.

Other drivers and restraints analyzed in the detailed report include:

- Corporate Net-zero & ESG Procurement Targets

- Offshore-Wind Gearbox Demand for Long-life Bio-greases

- Oxidative & Thermal Stability Limitations

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Transmission and hydraulic fluids commanded 31.19% of the bio-lubricants market in 2024 and are forecast to grow at 3.58% CAGR to 2030. This advance equates to the largest slice of bio-lubricants market size among product categories and mirrors strict leakage-prevention rules in forestry harvesters, harbor cranes, and river dredgers. Because these systems can discharge dozens of liters per failure, operators willingly pay premiums for readily biodegradable grades that reduce cleanup obligations and protect sensitive wetlands. Additive breakthroughs-such as tailored zinc-free antiwear chemistries-now support 5,000-hour change intervals even under fluctuating loads, convincing OEMs to switch factory fill fluids to bio-based lines.

Greases, engine oils, and metalworking fluids together form a fast-diversifying cluster. Greases in particular benefit from offshore-wind deployments because bearing housings often sit meters above water and leak paths are hard to monitor. Metalworking fluids gain traction inside precision machining centers, where low mist toxicity enhances worker safety. Across categories, suppliers increasingly sell application-specific formulations rather than generic "green" substitutes, a strategy that bolsters switching rates and cements long-term customer contracts.

The Bio-Lubricants Market Report Segments the Industry by Product Type (Engine Oil, Transmission and Hydraulic Fluid, Metalworking Fluid, and More), End-User Industry (Power Generation, Automotive and Other Transportation, Heavy Equipment, and More), Base Oil Type (Vegetable Oils, Animal Fats and Synthetic Esters), and Geography (Asia-Pacific, North America, Europe, South America, and Middle East and Africa).

Geography Analysis

North America led the bio-lubricants market with 36.19% share in 2024. Enforcement of the U.S. Vessel General Permit, combined with progressive forestry practices in Canada, ensures a stable installed base of EAL-compliant equipment across waterways and timberlands. Mining companies are retrofitting haul trucks and drills with biodegradable hydraulic fluids as part of mine-reclamation agreements, a trend profiled by North American Mining magazine. High technical literacy and dense distributor networks further ease conversions.

Asia-Pacific, the fastest-growing region at a 4.45% CAGR, shows divergent national dynamics. China invests in domestic ester capacity and additive research to reduce reliance on imported formulations. Lanxess reports surging demand for environmentally-optimized metalworking additives across Chinese and Southeast Asian machining clusters. Japan channels bio-lubricant R&D into high-precision robotics, whereas India's agriculture sector seeds volume growth via biodegradable tractor hydraulic oils that prevent field contamination. Offshore wind farms along China's eastern seaboard and Taiwan Strait are adopting premium bio-greases to minimize environmental risk during 25-year service cycles.

Europe maintains a mature but innovative market underpinned by the EU Ecolabel scheme. Germany and the Nordic nations drive uptake in forestry harvesters and hydro-electric plants. The 2025 International Conference on Tribology and Sustainable Lubrication in Leipzig spotlighted next-generation biodegradable chemistries tailored for circular-economy targets. South America and the Middle East & Africa collectively form an early-stage adoption bloc. Uptake often aligns with multinational infrastructure projects-such as Brazilian wind farms or Gulf desalination plants-where foreign investors impose ESG clauses mandating biodegradable lubricants.

- Axel Christiernsson

- BP p.l.c.

- Cargill, Incorporated.

- Carl Bechem Lubricants

- Chevron Corporation

- Cortec Corporation

- Croda International plc

- Emery Oleochemicals

- Environmental Lubricants Manufacturing, Inc.

- Exxon Mobil Corporation

- FUCHS

- KCM Petro Chemicals

- Lubrication Engineers

- Novvi LLC

- Quaker Chemical Corporation

- Renewable Lubricants Inc.

- Saudi Arabian Oil Co.

- Shell plc

- TotalEnergies SE

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Stringent Environmental Regulations and Eco-labeling Mandates

- 4.2.2 OEM Specifications for Biodegradable Hydraulic Fluids

- 4.2.3 Corporate Net-zero and ESG Procurement Targets

- 4.2.4 Offshore-wind Gearbox Demand for Long-life Bio-Greases

- 4.2.5 Increasing Demand from Marine Industry

- 4.3 Market Restraints

- 4.3.1 High Price of Bio lubricants in Comparison to Conventional Lubricants

- 4.3.2 Oxidative and Thermal Stability Limitations

- 4.3.3 Limited Shelf Life of Bio-Lubricants

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts (Volume)

- 5.1 By Product Type

- 5.1.1 Engine Oil

- 5.1.2 Transmission and Hydraulic Fluid

- 5.1.3 Metalworking Fluid

- 5.1.4 General Industrial Oil

- 5.1.5 Gear Oil

- 5.1.6 Grease

- 5.1.7 Process Oil

- 5.1.8 Other Product Types

- 5.2 By End-user Industry

- 5.2.1 Power Generation

- 5.2.2 Automotive and Other Transportation

- 5.2.3 Heavy Equipment

- 5.2.4 Food and Beverage

- 5.2.5 Metallurgy and Metalworking

- 5.2.6 Chemical Manufacturing

- 5.2.7 Other End-user Industries

- 5.3 By Base Oil Type

- 5.3.1 Vegetable Oils

- 5.3.2 Animal Fats

- 5.3.3 Synthetic Esters

- 5.4 By Geography

- 5.4.1 Asia-Pacific

- 5.4.1.1 China

- 5.4.1.2 India

- 5.4.1.3 Japan

- 5.4.1.4 South Korea

- 5.4.1.5 Rest of Asia-Pacific

- 5.4.2 North America

- 5.4.2.1 United States

- 5.4.2.2 Canada

- 5.4.2.3 Mexico

- 5.4.3 Europe

- 5.4.3.1 Germany

- 5.4.3.2 United Kingdom

- 5.4.3.3 Italy

- 5.4.3.4 France

- 5.4.3.5 Russia

- 5.4.3.6 Rest of Europe

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Rest of South America

- 5.4.5 Middle East and Africa

- 5.4.5.1 Saudi Arabia

- 5.4.5.2 South Africa

- 5.4.5.3 Rest of Middle East and Africa

- 5.4.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share(%)/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Axel Christiernsson

- 6.4.2 BP p.l.c.

- 6.4.3 Cargill, Incorporated.

- 6.4.4 Carl Bechem Lubricants

- 6.4.5 Chevron Corporation

- 6.4.6 Cortec Corporation

- 6.4.7 Croda International plc

- 6.4.8 Emery Oleochemicals

- 6.4.9 Environmental Lubricants Manufacturing, Inc.

- 6.4.10 Exxon Mobil Corporation

- 6.4.11 FUCHS

- 6.4.12 KCM Petro Chemicals

- 6.4.13 Lubrication Engineers

- 6.4.14 Novvi LLC

- 6.4.15 Quaker Chemical Corporation

- 6.4.16 Renewable Lubricants Inc.

- 6.4.17 Saudi Arabian Oil Co.

- 6.4.18 Shell plc

- 6.4.19 TotalEnergies SE

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-Need Assessment

- 7.2 Growing Advancements in Technological Developments