|

市場調查報告書

商品編碼

1849916

汽車安全氣囊充氣機:市場佔有率分析、行業趨勢、統計數據和成長預測(2025-2030 年)Automotive Airbag Inflator - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

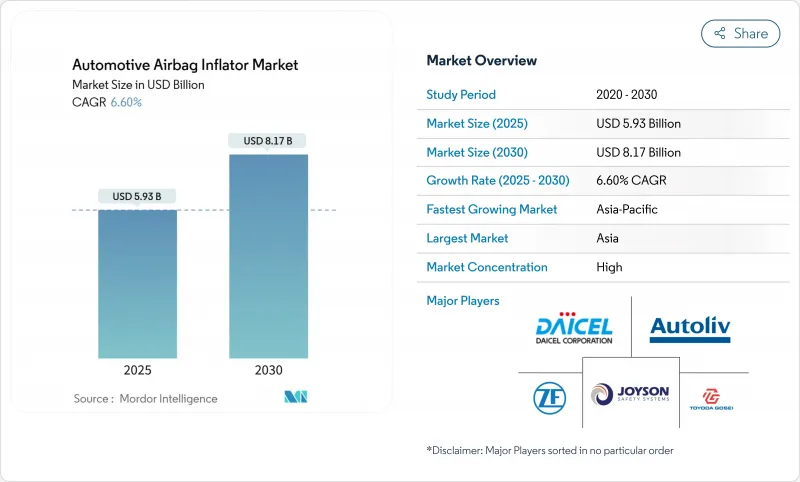

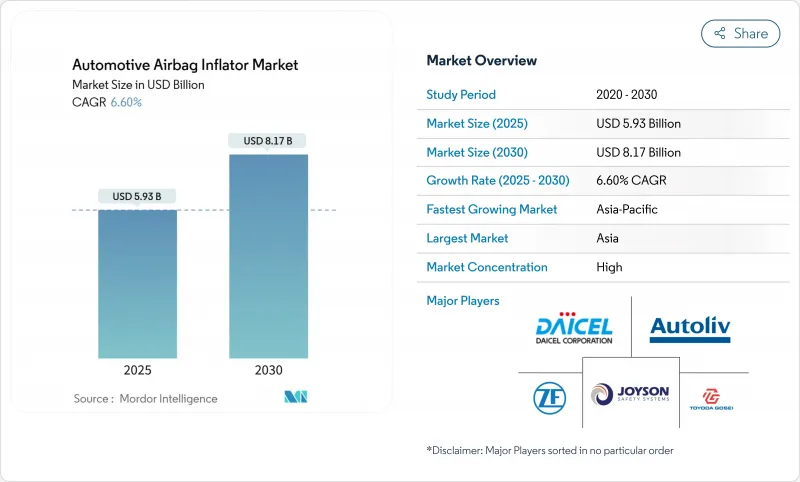

預計到 2025 年,汽車安全氣囊充氣機市場規模將達到 59.3 億美元,到 2030 年將達到 81.7 億美元,2025 年至 2030 年的複合年成長率為 6.60%。

日益嚴格的碰撞安全法規、消費者對乘員保護日益成長的關注,以及充氣機化學成分和包裝技術的不斷改進,共同推動了汽車安全氣囊充氣機市場的成長。掌控從設計到製造全流程的供應商,比依賴代工組裝的公司能夠更快地回應新的監管測試,從而確保更高的淨利率。北美和歐洲的監管機構已發出即將進行的側面碰撞和網路安全審核的訊號,這將推高成本並增加更換量,即使汽車生產週期趨於平緩,也能維持汽車安全氣囊充氣機市場的成長。亞太地區已呈現7.50%的複合年成長率,主要得益於技術實力雄厚的中國中型SUV項目以及快速擴張的出口中心印度。

全球汽車安全氣囊充氣機市場趨勢及洞察

加強碰撞安全法規

加強正面、側面和行人保護的通訊協定迫使汽車製造商採用更先進的約束系統,從而擴大了汽車安全氣囊充氣機的市場。北美聯邦機動車輛安全標準 (FMVSS) 的更新和歐洲通用安全法規提高了側面軀幹和簾式氣囊解決方案的基準基準。如今,原始設備製造商 (OEM)競標時會要求供應商提供合規文件,這縮短了設計週期,並傾向於選擇垂直整合的供應商。審核頻率的提高促使製造商在靠近組裝線的位置安裝現場推進劑測試裝置,從而將認證週期縮短了多達四周。不斷成長的更換量部分抵消了成本轉嫁,使充氣機的整體需求保持強勁。監管機構開始將網路安全準備與氣體輸出指標結合起來考慮,引導產業朝向智慧充氣機模組發展。

ADAS主導了多級充氣裝置的應用

一款由中國品牌生產的、配備豐富感測器的中型SUV,將碰撞嚴重程度數據與充氣機邏輯融合,實現精準的氣體釋放,從而更好地保護乘員。五星級新車評估項目(NCAP)評分提升了該車在展示室的吸引力,並切實證明了多級充氣機在高級駕駛輔助系統(ADAS)中的價值。在多級充氣機方面落後的汽車製造商將面臨展示室銷售對比不佳和來自其他廠商的快速跟進壓力。軟體更新支援未來的校準微調,從而避免了OEM廠商重新校準的成本。零件供應商利用這一趨勢,推銷韌體提升銷售契約,增加了類似年金的收入來源。因此,感測器融合和充氣機調節技術的結合,使得汽車安全氣囊充氣機在市場上保持了較高的價格分佈。

氦氣供不應求

地緣政治動盪推高了工業氦氣現貨價格,進而推高了儲氣式充氣裝置的材料成本,擠壓了淨利率。坦尚尼亞的探勘宣傳活動旨在尋找綠色氦氣,初步流量數據顯示,安全系統製造商可以獲得可行的商業性供應。原始設備製造商(OEM)正在透過轉向混合式充氣裝置來應對這項挑戰,該裝置使用煙火氣體稀釋氦氣。合約條款中現在包含了氦氣價格調整條款,將部分風險轉移回供應商。儘管成本上漲只是暫時的,但它已經延緩了新型儲氣式充氣裝置的設計,並減緩了汽車安全氣囊充氣裝置市場這一細分領域的近期成長。

細分市場分析

側簾式氣囊在汽車氣囊充氣機市場佔有34.10%的佔有率。側簾式氣囊的主導地位源自於星級評定通訊協定,該標準要求其具備強大的側撞保護能力。近期的改進主要集中在分段式氣體通道上,以提高沿著狹窄車頂導軌的充氣均勻性。由於最新的Gigacast EV框架使導軌更加纖細,橢截面氣缸可在不增加車頂高度限制的情況下確保氣體容量。汽車氣囊充氣機市場持續青睞那些將創新外型與可靠化學技術結合的平台。

膝部氣囊預計將以8.60%的複合年成長率實現最快成長。碰撞測試假碰撞測試人偶專注於下肢損傷的保險評分模型正在推動其普及。供應商現在提供可卡入現有儀表板下方橫樑的一體成型外殼,從而縮短生產線上的組裝時間。車隊採購商強調膝部保護可以減少工傷賠償,這推動了膝部氣囊的選配率上升。不斷成長的市場需求鞏固了汽車氣囊充氣機行業的長期多元化發展趨勢,該行業受益於多個成長點,而不是單一的主導類別。

預計到2024年,煙火式安全氣囊充氣裝置的銷售額將達到32.8億美元,佔汽車安全氣囊充氣裝置市佔率的59.25%。其緊湊的外形、久經考驗的可靠性以及對氦氣供應波動的耐受性,使其成為駕駛側安全氣囊的首選。由於不含疊氮化物,工程師可以使用更薄的金屬壁,從而減輕重量並符合車隊平均排放目標。工廠數據顯示,以硝酸胍混合物取代傳統混合物可以減少展開後的顆粒物排放,並簡化無塵室維護。

混合式充氣裝置預計將以7.90%的複合年成長率成長。混合式充氣裝置的設計理念是將小型儲氣室與煙火式主裝藥結合,從而在保持調節靈活性的同時降低氦氣消耗。原始設備製造商(OEM)將混合式組件視為一種採購對沖手段,並指出雙化學生產線能夠緩解供應鏈衝擊。發展藍圖顯示,混合式充氣裝置將在雙級側簾式氣囊和遠端氣囊中廣泛使用。因此,汽車氣囊充氣裝置產業將混合式充氣裝置視為應對未來大宗商品價格波動的保障。

區域分析

預計到2024年,北美將佔全球銷售額的近31.10%。美國國家公路交通安全管理局(NHTSA)對某些安全氣囊充氣裝置的調查,導致潛在的法律訴訟風險增加,促使原始設備製造商(OEM)優先考慮成熟的設計和可追溯的生產記錄。符合UN-R155標準的網路安全型安全氣囊充氣裝置模組正變得越來越普遍,為區域供應鏈增加了一層軟體檢驗。市場的成熟推動了競爭向全生命週期服務(例如碰撞數據分析)的轉移,並將關注點從硬體定價轉向增值支援。

亞太地區將以7.50%的複合年成長率領跑,主要驅動力來自中國、印度和東協。中國中型SUV平台配備雙級充氣裝置,展現了本土創新如何達到全球標準,其五星級安全評級也提升了其出口吸引力。印度製造中心將憑藉成本優勢和本地供應商集群,填補其他地區的產能缺口,從而佔據更大的汽車安全氣囊充氣裝置市場佔有率。在清奈和普納附近擁有推進劑實驗室和測試設施的供應商可以降低物流風險,縮短認證週期。

歐洲市場需求穩定,主要受合規性驅動。該地區已基本完成向非疊氮化物化學製程的過渡,並透過改造項目維持了健康的售後市場銷售。碳中和承諾使材料選擇與企業永續性目標保持一致,並鼓勵在充氣機外殼中使用再生鋁。碳邊境關稅正在影響採購和單位成本,促使加工業務逐步轉移到東歐。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場促進因素

- 歐盟和日本逐步淘汰疊氮化物推進劑推動了改造需求。

- ADAS主導的多級充氣裝置在國產中型SUV的應用

- 印度出口基地的崛起導致國內對充氣機的需求增加

- 電動車千兆廣播底盤催生了對超薄簾幕充氣機的需求

- 北美地區採用 UN-R155 網路安全合規性驅動智慧充氣模組

- L4/L5級自動駕駛車輛的部署需要先進的多方向充氣裝置陣列。

- 市場限制

- 氦氣供不應求,儲氣充氣機的價格

- 歐盟碳排放邊境關稅提高亞洲通膨產品進口成本

- MEA地區假冒充氣泵氾濫破壞了OEM項目

- 鋰離子電池起火風險延緩電動車安全氣囊系統的整合

- 價值/供應鏈分析

- 監管或技術前景

- 波特五力模型

- 新進入者的威脅

- 買方/消費者的議價能力

- 供應商的議價能力

- 替代品的威脅

- 競爭對手之間的競爭

第5章 市場規模及成長預測(價值及數量)

- 依安全氣囊類型

- 乘客

- 窗簾

- 膝蓋

- 邊

- 行人保護

- 依充氣機類型

- 焰火

- 儲存氣體

- 混合

- 按車輛類型

- 搭乘用車

- 輕型商用車

- 大型商用車輛

- 透過推進劑化學

- 疊氮鹼

- 非疊氮化物(例如,硝酸胍)

- 按技術水平

- 單級

- 雙級和多級

- 按銷售管道

- 原廠適配

- 售後/召回更換

- 按地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 北美其他地區

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 歐洲

- 德國

- 英國

- 法國

- 北歐國家

- 其他歐洲地區

- 亞太地區

- 中國

- 日本

- 印度

- 韓國

- 亞太其他地區

- 中東

- 波灣合作理事會

- 其他中東地區

- 非洲

- 南非

- 奈及利亞

- 其他非洲地區

- 北美洲

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率分析

- 公司簡介

- Autoliv Inc.

- ZF Friedrichshafen AG

- Joyson Safety Systems(Key SS)

- Daicel Corporation

- Nippon Kayaku Co.

- ARC Automotive Inc.

- Toyoda Gosei Co.

- Hyundai Mobis Co.

- Continental AG

- Denso Corporation

- Yanfeng Safety Systems

- Nihon Plast Co.

- Ashimori Industry Co.

- Takata(Residual Recall Operations)

- Kolon Industries Inc.

- GWR Safety Systems

- ARC China Ltd.

- Tenaris Inflators

- Jinzhou Jinheng Automotive

第7章 市場機會與未來展望

The automotive airbag inflator market size stands at USD 5.93 billion in 2025 and is forecast to touch USD 8.17 billion by 2030, advancing at a 6.60% CAGR between 2025 and 2030.

Stronger crash-safety legislation, heightened consumer attention to occupant protection, and continuous inflator chemistry and packaging gains underpin the automotive airbag inflator market climb. Suppliers that control design-to-manufacture workflows secure higher margins because they answer new regulatory tests faster than firms that rely on contract assemblers. Regulators in North America and Europe have signalled upcoming side-impact and cybersecurity audits, which will raise costs and lift replacement volumes, sustaining the automotive airbag inflator market even during flat vehicle-production cycles. The Asia-Pacific region already shows a 7.50% CAGR, led by technology-rich Chinese mid-SUV programs and India's fast-scaling export hubs, suggesting the region could represent nearly half of new inflator units by the decade's close

Global Automotive Airbag Inflator Market Trends and Insights

Stricter Crash-Safety Mandates

Upgraded frontal, side-impact, and pedestrian-protection protocols push automakers to adopt higher-performance restraint systems, expanding the automotive airbag inflator market. North American FMVSS updates and Europe's General Safety Regulation lift baseline fitment for side-torso and curtain solutions. OEMs now tender inflators with compliance documentation, compressing design windows, and favouring vertically integrated suppliers. Increased audit frequency has prompted on-site propellant test cells near final assembly lines, shortening certification loops by up to four weeks. Higher replacement volumes partially offset cost pass-through, keeping overall inflator demand buoyant. Regulators have begun referencing cybersecurity readiness alongside gas-output metrics, nudging the industry toward smart inflator modules.

ADAS-Led Adoption of Multi-Stage Inflators

Sensor-rich mid-SUVs manufactured by Chinese brands fuse crash-severity data with inflator logic, allowing tailored gas releases that protect a wider occupant range. Five-star New Car Assessment Program scores support showroom appeal and showcase multi-stage inflators as visible proof of ADAS value. Automakers that lag in multi-stage deployment risk negative showroom comparisons, creating fast-follower pressure. Software updates allow future calibration tweaks, shielding OEMs from retooling costs. Component suppliers leverage the trend to upsell firmware maintenance contracts, adding an annuity-style revenue layer. Therefore, the convergence of sensor fusion and inflator modulation sustains premium price points within the automotive airbag inflator market.

Helium Supply Crunch

Geopolitical disruptions lifted industrial-grade helium spot prices, inflating the bill of materials for stored-gas inflators and squeezing margins. Exploration campaigns in Tanzania seek green helium, with preliminary flow-rate data suggesting a viable commercial supply for safety-system producers. OEMs react by shifting procurements toward hybrid inflators that dilute helium use with pyrotechnic gas. Contract clauses now include helium-price adjustment formulas, transferring part of the risk back to suppliers. While temporary, cost spikes have already slowed new stored-gas design iterations, moderating near-term growth for that sub-segment of the automotive airbag inflator market.

Other drivers and restraints analyzed in the detailed report include:

- Phase-Out of Azide Propellants

- Emergence of Indian Export Hubs

- EU Carbon Border Tariff

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Curtain airbags representing 34.10% of the automotive airbag inflator market share. Their dominance rests on star-rating protocols that mandate robust side-impact protection. Recent refreshes reveal interest in segmented gas channels that enhance fill uniformity along narrow roof rails. Emerging giga-cast EV frames create slimmer rails, so oval-section cylinders preserve gas volume without raising roof-height constraints. The automotive airbag inflator market continues to reward platforms that mix shape innovation with reliable chemistry.

Knee airbags register the fastest 8.60% CAGR outlook. Crash dummies that weigh more on lower-leg injuries and insurance scoring models reinforce uptake. Suppliers now offer one-piece housings that clip into existing under-dash beams, trimming line-side assembly minutes. Fleet buyers highlight lower worker-compensation claims when knee protection is present, boosting specification rates. Growing traction strengthens the long-term diversity of the automotive airbag inflator industry, which benefits from multiple growth vectors rather than a single dominant category.

Pyrotechnic inflators earned USD 3.28 billion in revenue during 2024, equal to 59.25% of the automotive airbag inflator market size. Their compact form, proven reliability, and immunity to helium supply swings keep them the default for driver airbags. Non-azide compounds let engineers thin metal walls, saving grams and supporting fleet-average emissions objectives. Plant data show particulate emissions after deployment drop when guanidine-nitrate blends replace legacy mixes, easing clean-room maintenance.

Hybrid inflators are forecast for a 7.90% CAGR. Their design marries a small stored-gas chamber with a pyrotechnic main charge, cutting helium volumes while retaining modulation latitude. OEMs view hybrid assemblies as procurement hedges, noting that dual-chemistry lines dampen supply-chain shocks. Development road maps point to wider use in dual-stage curtain and far-side airbags. The automotive airbag inflator industry, therefore, treats hybrid capacity as an insurance policy against future commodity swings.

The Automotive Airbag Inflator Market Report is Segmented by Airbag Type (Driver, Passenger, and More), Inflator Type (Pyrotechnic, Stored Gas, Hybrid), Vehicle Type (Passenger Cars, LCV, and More), Propellent Chemistry (Azide-Based, Non-Azide), Technology Stage ( Single Stage and Multi-Stage), Sales Channel (OEM Fitted and Aftermarket) and Geography. The Market Forecasts are Provided in Terms of Value (USD) and Volume (Units).

Geography Analysis

North America contributed nearly 31.10% of global revenue in 2024. The National Highway Traffic Safety Administration's probe into specific inflator variants focuses on legal exposure, motivating OEMs to favour proven designs and traceable manufacturing records. Cyber-secure inflator modules that comply with UN-R155 have gained traction, adding software validation layers to the regional supply chain. High market maturity channels competition toward lifecycle services such as crash-data analytics, shifting emphasis from hardware pricing to value-added support.

Asia-Pacific records the strongest 7.50% CAGR, driven by China, India, and ASEAN economies. Chinese mid-SUV platforms with dual-stage inflators demonstrate how local innovations meet global benchmarks, and five-star safety ratings raise export appeal. Indian manufacturing hubs leverage cost advantages and local supplier parks to backfill capacity gaps elsewhere, thereby capturing a larger slice of the automotive airbag inflator market. Suppliers that co-locate propellant labs and test rigs near Chennai and Pune compress logistics risk and win shorter certification cycles.

Europe shows steady, compliance-centred demand. The region's near-complete shift to non-azide chemistry keeps aftermarket volumes healthy through retrofit programs. Carbon-neutrality pledges drive aluminium recyclate adoption for inflator casings, aligning material choices with corporate sustainability goals. Pedestrian safety requirements encourage research into external airbags, which could incrementally widen the inflator addressable market.Carbon border tariffs influence sourcing as much as unit price, prompting a gradual relocation of machining steps to Eastern Europe.

- Autoliv Inc.

- ZF Friedrichshafen AG

- Joyson Safety Systems (Key SS)

- Daicel Corporation

- Nippon Kayaku Co.

- ARC Automotive Inc.

- Toyoda Gosei Co.

- Hyundai Mobis Co.

- Continental AG

- Denso Corporation

- Yanfeng Safety Systems

- Nihon Plast Co.

- Ashimori Industry Co.

- Takata (Residual Recall Operations)

- Kolon Industries Inc.

- GWR Safety Systems

- ARC China Ltd.

- Tenaris Inflators

- Jinzhou Jinheng Automotive

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions & Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Drivers

- 4.1.1 Phase-out of Azide Propellants Driving EU & Japan Retrofit Demand

- 4.1.2 ADAS-Led Adoption of Multi-Stage Inflators in Chinese Mid-SUVs

- 4.1.3 Emergence of Indian Export Hubs Elevating Captive Inflator Off-take

- 4.1.4 EV Giga-Casting Chassis Creating Need for Ultra-Slim Curtain Inflators

- 4.1.5 UN-R155 Cyber-Security Compliance Boosting Smart Inflator Modules in NA

- 4.1.6 L4/L5 Autonomous Vehicle Rollout Demanding Advanced Multi-Directional Inflator Arrays

- 4.2 Market Restraints

- 4.2.1 Helium Supply Crunch Inflating Stored-Gas Inflator Pricing

- 4.2.2 EU Carbon Border Tariff Raising Cost of Asian Inflator Imports

- 4.2.3 Proliferation of Counterfeit Inflators in MEA Eroding OEM Programs

- 4.2.4 Lithium-ion Battery Fire Risks Delaying EV Airbag System Integration

- 4.3 Value / Supply-Chain Analysis

- 4.4 Regulatory or Technological Outlook

- 4.5 Porter's Five Forces

- 4.5.1 Threat of New Entrants

- 4.5.2 Bargaining Power of Buyers/Consumers

- 4.5.3 Bargaining Power of Suppliers

- 4.5.4 Threat of Substitute Products

- 4.5.5 Intensity of Competitive Rivalry

5 Market Size & Growth Forecasts (Value & Volume)

- 5.1 By Airbag Type

- 5.1.1 Passenger

- 5.1.2 Curtain

- 5.1.3 Knee

- 5.1.4 Side

- 5.1.5 Pedestrian Protection

- 5.2 By Inflator Type

- 5.2.1 Pyrotechnic

- 5.2.2 Stored-Gas

- 5.2.3 Hybrid

- 5.3 By Vehicle Type

- 5.3.1 Passenger Cars

- 5.3.2 Light Commercial Vehicles

- 5.3.3 Heavy Commercial Vehicles

- 5.4 By Propellant Chemistry

- 5.4.1 Azide-Based

- 5.4.2 Non-Azide (e.g., Guanidine Nitrate)

- 5.5 By Technology Stage

- 5.5.1 Single-Stage

- 5.5.2 Dual-Stage & Multi-Stage

- 5.6 By Sales Channel

- 5.6.1 OEM Fitted

- 5.6.2 Aftermarket / Recall Replacement

- 5.7 By Geography

- 5.7.1 North America

- 5.7.1.1 United States

- 5.7.1.2 Canada

- 5.7.1.3 Mexico

- 5.7.1.4 Rest of North America

- 5.7.2 South America

- 5.7.2.1 Brazil

- 5.7.2.2 Argentina

- 5.7.2.3 Rest of South America

- 5.7.3 Europe

- 5.7.3.1 Germany

- 5.7.3.2 United Kingdom

- 5.7.3.3 France

- 5.7.3.4 Nordics

- 5.7.3.5 Rest of Europe

- 5.7.4 Asia-Pacific

- 5.7.4.1 China

- 5.7.4.2 Japan

- 5.7.4.3 India

- 5.7.4.4 South Korea

- 5.7.4.5 Rest of Asia-Pacific

- 5.7.5 Middle East

- 5.7.5.1 Gulf Cooperation Council

- 5.7.5.2 Rest of Middle East

- 5.7.6 Africa

- 5.7.6.1 South Africa

- 5.7.6.2 Nigeria

- 5.7.6.3 Rest of Africa

- 5.7.1 North America

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles {(includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products & Services, and Recent Developments)}

- 6.4.1 Autoliv Inc.

- 6.4.2 ZF Friedrichshafen AG

- 6.4.3 Joyson Safety Systems (Key SS)

- 6.4.4 Daicel Corporation

- 6.4.5 Nippon Kayaku Co.

- 6.4.6 ARC Automotive Inc.

- 6.4.7 Toyoda Gosei Co.

- 6.4.8 Hyundai Mobis Co.

- 6.4.9 Continental AG

- 6.4.10 Denso Corporation

- 6.4.11 Yanfeng Safety Systems

- 6.4.12 Nihon Plast Co.

- 6.4.13 Ashimori Industry Co.

- 6.4.14 Takata (Residual Recall Operations)

- 6.4.15 Kolon Industries Inc.

- 6.4.16 GWR Safety Systems

- 6.4.17 ARC China Ltd.

- 6.4.18 Tenaris Inflators

- 6.4.19 Jinzhou Jinheng Automotive