|

市場調查報告書

商品編碼

1848308

農業噴霧器:市場佔有率分析、行業趨勢、統計數據和成長預測(2025-2030 年)Agricultural Sprayers - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

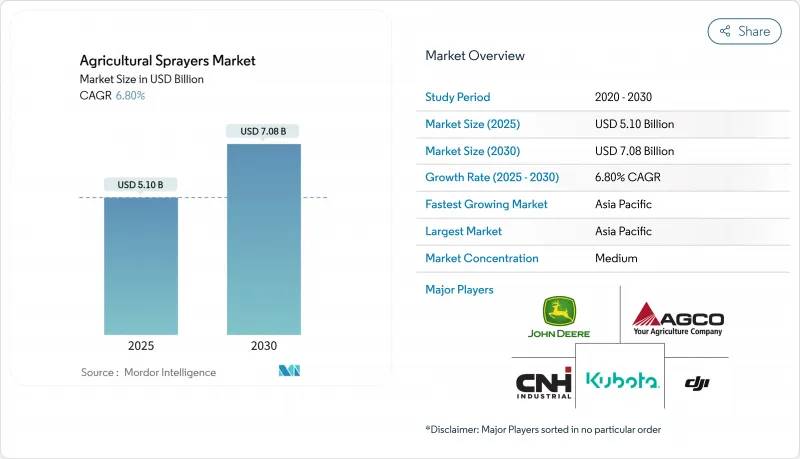

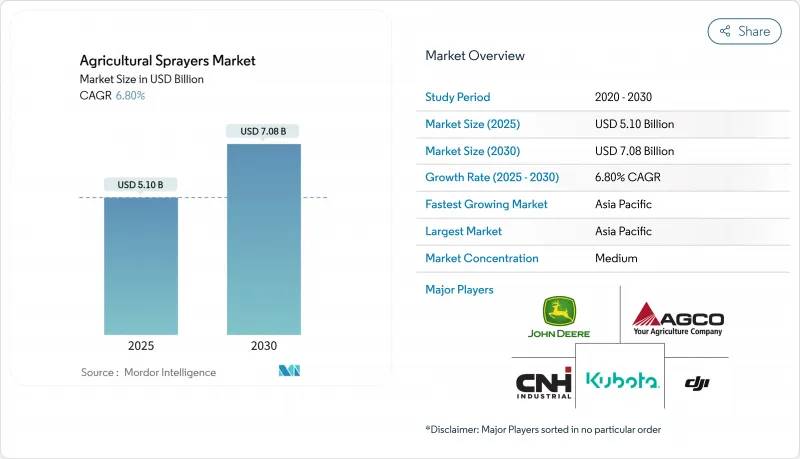

預計到 2025 年,農業噴霧器市場規模將達到 51 億美元,到 2030 年將達到 70.8 億美元,年複合成長率為 6.80%。

感測器、機器學習演算法和變數施肥技術的整合,正將機械噴霧器轉變為精準、數據驅動的平台,從而減少化學藥劑浪費並應對不斷上漲的人事費用。在鼓勵採用智慧機械的補貼計畫的支持下,亞太地區將在2024年佔據農業噴霧器市場最大的收入佔有率。由於農民優先考慮降低營業成本和獲得碳權額,電池驅動型噴霧器的成長速度最快。隨著法律規範的完善,無人機和自動噴霧器正從試點階段走向商業應用,而人工智慧系統也展現出顯著減少農藥用量的能力。隨著全球競爭對手將視覺系統和分析功能整合到其設備中,以及中小企業推出改造套件以升級現有設備,市場競爭日益激烈。

全球農業噴霧器市場趨勢與洞察

農藥使用量增加

預計2022年作物保護需求將達370萬噸,比上年增加4%,幾乎是1990年的兩倍。全球農藥銷售量持續成長,尤其是除草劑,其需求量需要使用專用噴嘴。在中國,預計到2025年,植物保護無人機的需求將超過6萬台,隨著服務供應商擴大無人機機隊,農業噴霧器市場也將隨之擴張。向生物製品和精準配方的轉變需要配備更先進控制系統的噴霧器,因為這些產品比傳統化學品需要更專業的施用參數。巴西生物投入品產業的施用面積在上個季度增加了35%以上,推動了對用於施用活性微生物的超低容量噴霧器的投資。

噴嘴、感測器和基於人工智慧的控制方面的技術進步

在一項大面積測試中,約翰迪爾的「目視噴灑」(See and Spray)系統在保持有效雜草控制的同時,實現了除草劑用量減少77%,檢驗了嵌入式視覺和深度學習模型的有效性。紐荷蘭的IntelliSense自動化系統計畫於2026年安裝在Guardian噴霧器上,該系統在堪薩斯州的田間測試中,以25英里/小時的速度噴灑時,氮肥用量減少了10%。 Ecorobotix配備攝影機的ARA平台在2025年世界農業博覽會上進行了評估,實現了厘米級的精度,標誌著自動化噴灑應用領域的重大革新。

高額的初始資本投入與資金籌措障礙

自1990年以來,200馬力曳引機的價格上漲了287%,遠遠超過了農場收購價格的通膨率。自2017年以來,利率上漲了213%,迫使許多生產者轉向租賃,目前租賃交易佔11%。預計到2024年,農業淨現金收入將下降近20%,這將導致新噴霧器的流動性減少。二手設備庫存積壓嚴重,隨著經銷商減少庫存,競標成交率不斷上升。自2011年以來,化學品、肥料和機械的投入成本上漲了37.5%,為農場盈利和設備購買決策帶來了多重壓力。加拿大農業設備銷售也面臨類似的挑戰,尤其是在曳引機和聯合收割機等大型設備類別中,由於大宗商品價格下跌、營業成本上升和利潤下降,需求疲軟限制了2025年的銷售量。

細分市場分析

燃油動力噴霧器將在2024年佔據農業噴霧器市場47.0%的佔有率,這主要得益於完善的加油基礎設施和在長時間田間作業中的可靠性能。目前市佔率較小的電池動力噴霧器預計到2030年將以17.9%的複合年成長率成長,這主要得益於營運成本的降低、碳權獎勵以及柴油價格的上漲。研究表明,自動駕駛電動曳引機的溫室氣體排放量比柴油動力車輛減少72%。歐盟法規2023/1542要求電池必須含有回收成分並標註碳足跡,這將促進本地電池回收的發展,但也可能增加遵循成本。

內燃機在農業噴霧器領域仍佔據主導地位,尤其是在電力充電基礎設施有限的偏遠農業地區。製造商正透過推出混合動力系統和電池改裝套件來適應不斷變化的市場。約翰迪爾和GUSS Automation將於2024年底推出電動噴霧器,久保田已與Agtonomy合作開發用於特種作物的電動曳引機。在亞太地區,政府支持太陽能充電設施的舉措預示著市場正逐步轉型為電動噴霧器技術。

由於其附件相容性強且成本優勢優於自走式噴藥機,預計到2024年,曳引機式噴藥機將佔總收入的36.5%。農業無人機的複合年成長率將達到20.2%,這主要得益於簡化的許可要求以及其能夠在陡峭和積水地形上作業的能力。密蘇裡州的一項研究發現,當年度處理面積超過980英畝時,擁有無人機才具有經濟可行性,此時無人機所有者的營運成本為每英畝12.27美元,而租用無人機的成本僅為每英畝7.39美元。

對於北美的大規模農業生產而言,自走式機械仍然至關重要。約翰迪爾500R於2025年6月上市,它擁有更佳的操作員視野,採用PowrSpray管線技術,噴灑精度高達98%。對於規模較小的農場而言,背負式噴霧器由於投資成本低、漂移控制性能優異,在特種作物噴灑方面仍具有重要意義。儘管自主系統不斷革新傳統設備類別,但農業噴霧器技術的這種市場細分仍然存在。

區域分析

預計到2024年,亞太地區將以35.7%的市佔率主導農業噴霧器市場,年增率達8.0%。中國已調整補貼結構,優先扶持履帶式曳引機和智慧農具;印度的《農業機械化方案》(SMAM)則為小農戶購買噴霧器提供高達80%的成本補貼。機械化趨勢與環境目標相符,研究表明,農業機械化呈現U型排放模式:初期曳引機的引入導致排放增加,隨後隨著精準農業系統的應用,環境影響逐漸降低。

北美保持著其技術領先的市場地位。至2024年,精準噴灑技術將覆蓋超過100萬英畝的土地,並減少800萬加侖的除草劑用量。然而,該地區面臨許多挑戰,包括預計2024年農場現金收入下降20%,以及利率上升將延長資本投資的回收期。美國農業部撥款30億美元用於氣候智慧型試點項目,其中包括對精密農業設備的補貼,這將有助於緩解市場放緩的影響。

歐洲農業噴霧器市場的成長主要得益於管理方案。歐盟電池法規將實施回收材料含量要求,將從2028年起影響動力噴霧器的規格。歐洲領先的噴霧設備製造商Excel Industries報告稱,儘管由於農民推遲訂單下降,但其2023-2024會計年度的農業產品銷售額仍達到5.781億美元(5.03億歐元),佔總銷售額的46%。環境法規和「綠色新政」的要求持續推動精準設備的普及,有助於在充滿挑戰的經濟狀況下穩定市場。

其他福利:

- Excel格式的市場預測(ME)表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場情勢

- 市場概覽

- 市場促進因素

- 農藥使用量增加

- 噴嘴、感測器和基於人工智慧的控制方面的技術進步

- 人事費用上升和操作人員嚴重短缺

- 政府對機械化和智慧農業的補貼

- 碳權計畫旨在鼓勵浮動利率申請

- 自動噴霧器的商業化

- 市場限制

- 高昂的初始資本支出和資金籌措障礙

- 農藝師或操作人員技能有限

- 網路安全和資料完整性風險

- 電池報廢處置限制

- 監管環境

- 技術展望

- 波特五力分析

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭對手之間的競爭

第5章 市場規模及成長預測(價值及數量)

- 透過動力來源

- 手動的

- 電池供電/電動

- 太陽能發電

- 燃油動力

- 依產品類型

- 手持/背包

- 聯結機式

- 拖著

- 自推進式

- 無人機/無人噴灑器

- 透過使用

- 田間作物

- 果園和葡萄園

- 溫室作物

- 草坪和園藝

- 按噴霧量

- 超低容量

- 低容量

- 高容量

- 按技術水準

- 傳統的

- 精準/GPS導航

- 人工智慧賦能與自主

- 按地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 北美其他地區

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 俄羅斯

- 其他歐洲地區

- 亞太地區

- 中國

- 印度

- 日本

- 澳洲

- 亞太其他地區

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 中東

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 土耳其

- 其他中東地區

- 非洲

- 南非

- 其他非洲地區

- 北美洲

第6章 競爭情勢

- 市場集中度

- 策略趨勢

- 市佔率分析

- 公司簡介

- Deere & Company

- AGCO Corporation

- CNH Industrial NV

- Mahindra & Mahindra Ltd.

- Kubota Corporation

- DJI

- Exel Industries

- KUHN SAS

- ASPEE Agro Equipment Pvt. Ltd.

- Hockley International Ltd

- Jacto SA

- GUSS Automation LLC

- Yamaha Motor Co., Ltd.

- Hylio, Inc.

- Goldacres Pty Ltd

- Chafer Machinery Ltd.

第7章 市場機會與未來展望

The agricultural sprayers market size is valued at USD 5.10 billion in 2025 and is projected to reach USD 7.08 billion by 2030, growing at a CAGR of 6.80%.

The integration of sensors, machine-learning algorithms, and variable-rate technologies is transforming mechanical sprayers into precise, data-driven platforms that reduce chemical waste and address increasing labor costs. The Asia-Pacific region dominates the agricultural sprayers market with the highest revenue share in 2024, supported by Chinese and Indian government subsidy programs that promote smart machinery adoption. Battery-powered units show the fastest growth as farmers prioritize reduced operating costs and carbon credits. Drone and autonomous sprayers are transitioning from pilot scale to commercial applications as regulatory frameworks develop, while AI-enabled systems demonstrate significant reductions in agrochemical usage. Market competition is intensifying as global OEMs integrate vision systems and analytics with equipment, and smaller companies introduce retrofit kits to upgrade existing fleets.

Global Agricultural Sprayers Market Trends and Insights

Growth in Agrochemical Usage

Pesticide demand reached 3.70 million metric tons in 2022, up 4% year on year and nearly double 1990 levels, compelling growers to acquire equipment capable of handling larger volumes with precise application. Global agrochemical sales continue to increase, particularly in herbicides that require specialized nozzles. In China, plant-protection drone demand is projected to exceed 60,000 units by 2025, expanding the agricultural sprayers market as service providers increase their fleets. The transition toward biological products and precision formulations necessitates sprayers with enhanced control systems, as these products require more specific application parameters compared to conventional chemicals. Brazil's bio-input segment increased treated acreage by more than 35% in the last season, driving investment in ultra-low-volume sprayers designed for live microbe applications.

Technological Advancements in Nozzle, Sensor and AI-Based Control

John Deere's See and Spray system demonstrated a 77% reduction in herbicide usage during broad-acre trials while maintaining weed control effectiveness, validating the efficacy of embedded vision and deep-learning models. New Holland's IntelliSense automation system, scheduled for implementation in 2026 Guardian sprayers, demonstrated 10% nitrogen reduction at 25 mph field speeds during Kansas field trials, establishing the correlation between enhanced productivity and decreased input costs, boosting adoption across the agricultural sprayer market. Ecorobotix's camera-equipped ARA platform, which received recognition at World Ag Expo 2025, achieves centimeter-level precision, indicating the evolution of automated spray applications.

High Upfront Capital Expenditure and Financing Hurdles

Prices for 200-horsepower tractors have climbed 287% since 1990, far outpacing farm-gate inflation, and interest rates have soared 213% since 2017, pushing many growers toward leases that now cover 11% of deals. Net cash farm income is forecast to fall nearly 20% in 2024, shrinking liquidity for new sprayers. Used equipment lists are bloated, and auction clearance rates are rising as dealers trim inventory. Input costs for chemicals, fertilizers, and machinery have increased 37.5% since 2011, creating compound pressure on farm profitability and equipment purchasing decisions. Canadian farm equipment sales face similar challenges, with weak demand limiting 2025 sales due to falling commodity prices, high operating costs, and reduced profits, particularly affecting large equipment categories like tractors and combines.

Other drivers and restraints analyzed in the detailed report include:

- Rising Labor-Cost and Acute Operator Shortages

- Government Mechanization and Smart-Farming Subsidies

- Limited Agronomist or Operator Skill Sets

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Fuel-powered sprayers dominated the agricultural sprayers market with a 47.0% revenue share in 2024, supported by widespread refueling infrastructure and reliable performance in extended field operations. Battery-powered units, currently representing a smaller market segment, are projected to grow at a 17.9% CAGR through 2030, driven by reduced operational costs, carbon credit incentives, and increasing diesel prices. Research indicates that autonomous electric tractors generate 72% lower greenhouse gas emissions compared to diesel alternatives. The EU Regulation 2023/1542 implementation requires recycled content and carbon-footprint labeling for batteries, potentially increasing compliance expenses while encouraging regional battery recycling development.

Combustion engines remain prevalent in agricultural sprayers, particularly in remote farming areas with limited electric charging infrastructure. Manufacturers are adapting to market changes by introducing hybrid systems and battery conversion kits. John Deere and GUSS Automation introduced an electric sprayer variant in late 2024, while Kubota partnered with Agtonomy to develop electric tractors for specialty crop applications. In the Asia-Pacific region, government initiatives supporting solar-powered charging facilities indicate a gradual market transition toward electric sprayer technologies.

Tractor-mounted sprayers constituted 36.5% of 2024 sales due to their attachment compatibility and cost advantages compared to self-propelled units. Agricultural drones demonstrate a 20.2% CAGR, attributed to streamlined licensing requirements and their capability to operate in steep or waterlogged terrain. Missouri research indicates that drone ownership becomes economically viable when annual treated areas exceed 980 acres, with operational costs of USD 12.27 per acre for owners compared to USD 7.39 for custom hiring services.

Self-propelled machines remain essential for large-scale North American agricultural operations. The John Deere 500R, released in June 2025, incorporates enhanced operator visibility and PowrSpray plumbing technology, delivering 98% application precision. In small-scale farming operations, knapsack units maintain their relevance for specialized crop applications due to reduced capital requirements and superior drift management. This market segmentation in agricultural sprayer technology persists while autonomous systems continue to transform traditional equipment categories.

The Agricultural Sprayers Market Report is Segmented by Source of Power (Manual, and More), by Product Type (Handheld/Knapsack, Tractor-Mounted, and More), by Application/Usage (Field Crops, and More), by Spray Volume Capacity (Ultra-Low Volume, and More), Technology Level (Conventional, and More), and by Geography (North America, Europe, and More). The Market Forecasts are Provided in Terms of Value (USD) and Volume (Units).

Geography Analysis

Asia-Pacific dominates the agricultural sprayers market with a 35.7% share in 2024 and projects an 8.0% annual growth rate. China has modified its subsidy structure to prioritize crawler tractors and smart implements, while India's Sub-Mission on Agricultural Mechanization (SMAM) provides up to 80% cost coverage for smallholder sprayer purchases. The mechanization trend aligns with environmental objectives, as research indicates a U-shaped emissions pattern where initial tractor adoption increased emissions, but subsequent precision system implementation reduced environmental impact.

North America maintains a technologically advanced market position. In 2024, See and Spray technology covered more than 1 million acres, reducing herbicide usage by 8 million gallons. However, the market faces challenges from a projected 20% decrease in 2024 cash farm income and increased interest rates, extending equipment investment recovery periods. The USDA's USD 3 billion allocation for climate-smart pilot programs, which includes precision agriculture equipment reimbursement, helps mitigate market slowdown impacts.

Europe's agricultural sprayers market growth stems from regulatory initiatives. The EU Battery Regulation implements recycled-content requirements that will influence electric sprayer specifications post-2028. EXEL Industries, the region's primary spray equipment manufacturer, reported agriculture revenue of USD 578.1 million (Euro 503 million) in fiscal 2023-2024, comprising 46% of total revenue, despite noting reduced orders due to farmers postponing equipment updates. Environmental regulations and green-deal requirements continue to drive precision equipment adoption, supporting market stability despite challenging economic conditions.

- Deere & Company

- AGCO Corporation

- CNH Industrial N.V.

- Mahindra & Mahindra Ltd.

- Kubota Corporation

- DJI

- Exel Industries

- KUHN SAS

- ASPEE Agro Equipment Pvt. Ltd.

- Hockley International Ltd

- Jacto S.A.

- GUSS Automation LLC

- Yamaha Motor Co., Ltd.

- Hylio, Inc.

- Goldacres Pty Ltd

- Chafer Machinery Ltd.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Growth in Agrochemical Usage

- 4.2.2 Technological Advancements in Nozzle, Sensor and AI-Based Control

- 4.2.3 Rising Labor-Cost and Acute Operator Shortages

- 4.2.4 Government Mechanization and Smart-Farming Subsidies

- 4.2.5 Carbon-Credit Programs Rewarding Variable-Rate Applications

- 4.2.6 Commercialization of Autonomous Sprayers

- 4.3 Market Restraints

- 4.3.1 High Upfront Capital Expenditure and Financing Hurdles

- 4.3.2 Limited Agronomist or Operator Skill Sets

- 4.3.3 Cyber-Security and Data-Integrity Risks

- 4.3.4 Battery End-of-Life Disposal Constraints

- 4.4 Regulatory Landscape

- 4.5 Technological Outlook

- 4.6 Porter's Five Forces Analysis

- 4.6.1 Bargaining Power of Suppliers

- 4.6.2 Bargaining Power of Buyers

- 4.6.3 Threat of New Entrants

- 4.6.4 Threat of Substitute Products

- 4.6.5 Intensity of Competitive Rivalry

5 Market Size and Growth Forecasts (Value and Volume)

- 5.1 By Source of Power

- 5.1.1 Manual

- 5.1.2 Battery-Operated/Electric

- 5.1.3 Solar-Powered

- 5.1.4 Fuel-Operated

- 5.2 By Product Type

- 5.2.1 Handheld/Knapsack

- 5.2.2 Tractor-Mounted

- 5.2.3 Trailed/Pull-Type

- 5.2.4 Self-Propelled

- 5.2.5 UAV/Drone Sprayers

- 5.3 By Application/Usage

- 5.3.1 Field Crops

- 5.3.2 Orchards and Vineyards

- 5.3.3 Greenhouse Crops

- 5.3.4 Turf and Gardening

- 5.4 By Spray Volume Capacity

- 5.4.1 Ultra-Low Volume

- 5.4.2 Low Volume

- 5.4.3 High Volume

- 5.5 By Technology Level

- 5.5.1 Conventional

- 5.5.2 Precision/GPS-Guided

- 5.5.3 AI-Enabled and Autonomous

- 5.6 By Geography

- 5.6.1 North America

- 5.6.1.1 United States

- 5.6.1.2 Canada

- 5.6.1.3 Mexico

- 5.6.1.4 Rest of North America

- 5.6.2 Europe

- 5.6.2.1 Germany

- 5.6.2.2 United Kingdom

- 5.6.2.3 France

- 5.6.2.4 Italy

- 5.6.2.5 Spain

- 5.6.2.6 Russia

- 5.6.2.7 Rest of Europe

- 5.6.3 Asia-Pacific

- 5.6.3.1 China

- 5.6.3.2 India

- 5.6.3.3 Japan

- 5.6.3.4 Australia

- 5.6.3.5 Rest of Asia-Pacific

- 5.6.4 South America

- 5.6.4.1 Brazil

- 5.6.4.2 Argentina

- 5.6.4.3 Rest of South America

- 5.6.5 Middle East

- 5.6.5.1 Saudi Arabia

- 5.6.5.2 UAE

- 5.6.5.3 Turkey

- 5.6.5.4 Rest of Middle East

- 5.6.6 Africa

- 5.6.6.1 South Africa

- 5.6.6.2 Rest of Africa

- 5.6.1 North America

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Deere & Company

- 6.4.2 AGCO Corporation

- 6.4.3 CNH Industrial N.V.

- 6.4.4 Mahindra & Mahindra Ltd.

- 6.4.5 Kubota Corporation

- 6.4.6 DJI

- 6.4.7 Exel Industries

- 6.4.8 KUHN SAS

- 6.4.9 ASPEE Agro Equipment Pvt. Ltd.

- 6.4.10 Hockley International Ltd

- 6.4.11 Jacto S.A.

- 6.4.12 GUSS Automation LLC

- 6.4.13 Yamaha Motor Co., Ltd.

- 6.4.14 Hylio, Inc.

- 6.4.15 Goldacres Pty Ltd

- 6.4.16 Chafer Machinery Ltd.