|

市場調查報告書

商品編碼

1846225

丙醇:市佔率分析、產業趨勢、統計、成長預測(2025-2030)Propanol - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

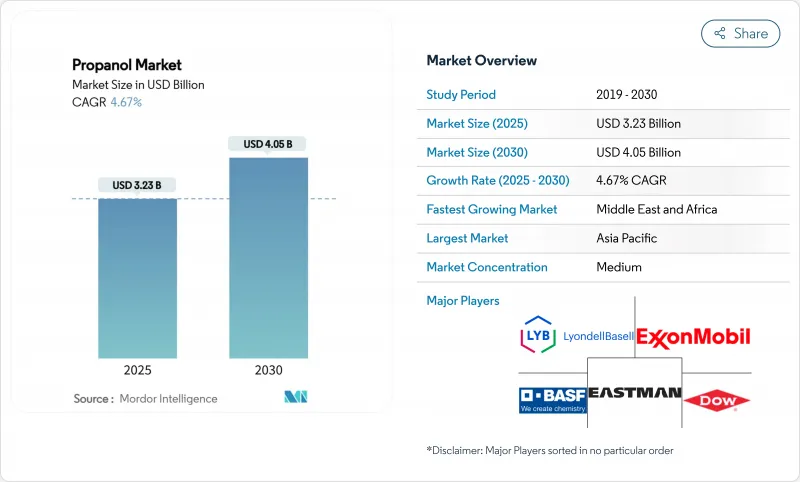

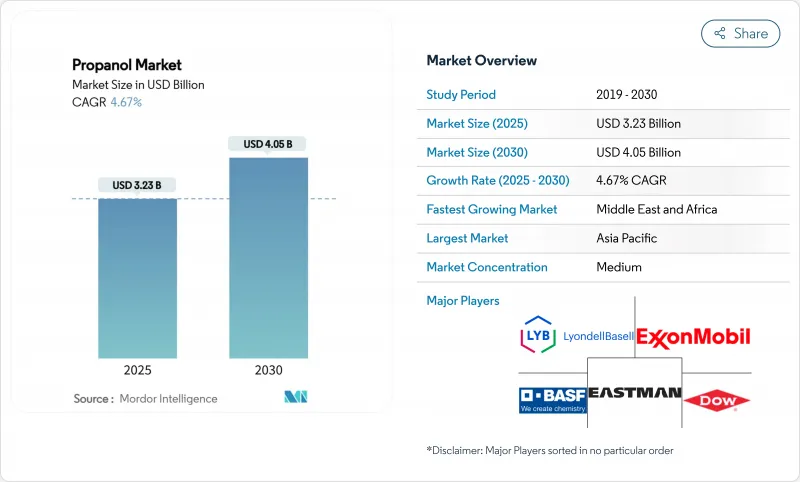

丙醇市場規模預計在 2025 年為 32.3 億美元,預計到 2030 年將達到 40.5 億美元,預測期內(2025-2030 年)的複合年成長率為 4.67%。

半導體清潔、永續航空燃料途徑和藥物合成領域應用的日益普及推動了異丙醇的適度擴張,同時監管壓力正在重塑溶劑配方。 5奈米以下晶片製造對高純度異丙醇的需求、亞洲新的原料藥)生產基地以及北美的酒精噴射計劃,支撐著整體銷量的穩健成長。儘管原料波動和不斷變化的揮發性有機化合物(VOC)法規抑制了成長勢頭,但持續的Oxo醇一體化和對淨化技術的投資正在幫助生產商確保利潤。因此,綜合石化製造商保持了成本優勢,而生物基參與企業則在整個丙醇市場中開拓出成長利基。

全球丙醇市場趨勢與洞察

電子產品清潔對高純度 IPA 的需求

純度超過99.999%的超高純度異丙醇已成為先進節點半導體製造的關鍵原料。埃克森美孚正在升級其位於巴吞魯日的工廠,以便在2027年前供應該等級的異丙醇,確保美國晶片製造商的國內供應。兆分之一的污染會降低晶圓產量比率,促使設備製造商需要更乾淨的溶劑。因此,電子產品清潔劑的成長速度超過了丙醇市場的整體成長速度,供應商正在增加蒸餾塔、過濾系統和即時分析設備,以驗證產品純度。由此產生的溢價部分抵消了原料的波動性,使綜合製造商能夠在滿足嚴格的客戶審核的同時保護價差。

建築業主導對油漆和塗料溶劑的需求

亞太地區和中東地區住宅和商業建築的蓬勃發展,推動了對建築被覆劑的需求。這些塗料依賴丙醇基助溶劑來平衡黏度、開放時間和成膜性能。美國和歐洲的監管機構持續收緊揮發性有機化合物 (VOC)基準值,促使配方轉向水性體系,而水性體系則需要控制丙醇含量以控制閃蒸。美國環保署已將氣溶膠塗料的合規截止日期延長至2027年1月,這為製造商提供了在保持性能的同時重新設計產品的關鍵時間。持續的溶劑創新正在幫助塗料製造商在不違反排放法規的情況下滿足耐久性標準,從而支持丙醇整體消費量的增加。

溶劑混合物的VOC法規更加嚴格

美國國家揮發性有機化合物(VOC)排放標準正在降低消費和商用塗料的允許限值,迫使其在2027年1月的最後期限前進行再製造。歐盟也正在推行類似的政策,迫使用戶取代或減少傳統溶劑的使用。合規成本、額外的測試和認證要求正在減緩傳統被覆劑、油墨和黏合劑應用的需求成長,從而削弱了丙醇市場的部分潛力。

細分分析

異丙醇憑藉其快速蒸發、抗菌功效和在醫藥、個人護理和工業清潔領域的廣泛溶解性,將在2024年佔據丙醇市場的54.77%。半導體製造商透過簽訂99.999%純度的供應契約,進一步凸顯了異丙醇的優勢,埃克森美孚的巴吞魯日生產線也已承諾為超高純度批次提供資本支持。正丙醇在特種油墨和化學中間體領域保持小眾但可靠的地位,使需要較低蒸發速度和特定反應性的配方設計師受益。受永續航空燃料政策獎勵的推動,生物基丙醇將經歷最強勁的成長軌跡,複合年成長率達到6.89%。美國生物能源公司的投資增強了人們對承購協議將為規模化擴張提供保障,並使可再生能源生產商能夠進入更廣闊的丙醇市場的信心。

異丙醇擁有廣泛的全球分銷網路和成熟的製造地,確保可靠的供應,但日益成長的半導體需求給物流和品管能力帶來了壓力。生產商正在更新淨化系統,採用離子交換、超過濾和先進的氣相層析法技術,以檢驗兆分之一的雜質閾值。相反,生物基生產必須克服發酵生產力的限制和原料供應的波動。可再生等級的加速成長將在預測期內縮小差距,但丙醇的絕對市場規模仍遠超異丙醇,這顯示了穩固的生產資產和客戶熟悉度所造成的慣性。

區域分析

至2024年,亞太地區將以40.24%的市佔率引領丙醇市場。印度的PLI計畫和大宗藥品園區等政府計畫正在鼓勵使用藥用級丙醇的原料藥(API)合成生產線進行投資。中國仍是全球最大的化學品生產國,佔全球產量的50%,推動了塗料、油墨和電子組裝領域的溶劑需求。日本和韓國的先進半導體製程將進一步擴大高純度溶劑的需求,因為這些國家的工廠對污染門檻要求嚴格。在東南亞,煉油廠和化工園區的整合程度不斷提高,進一步穩定了該地區的原料供應。

北美消費市場成熟且富有韌性。預計2023年美國丙醇出口額將達3.45億美元,進口額將達1.28億美元,反映了美國國內自給自足的現況以及對特種丙醇的需求。埃克森美孚計畫在路易斯安那州生產純度高達99.999%的異丙醇,這與美國國內半導體產業的激勵措施一致,並減少了對進口高規格原料的依賴。同時,美國生物能源公司在德克薩斯的SAF計劃正在提升該地區可再生丙醇的知名度,預示著需求的多元化。

歐洲面臨能源價格上漲和環境標準趨嚴帶來的成本壓力。BASF2023年的銷售額下降21%,顯示工業生產放緩,但醫藥和個人護理專用級產品仍保持盈利。中東和非洲地區未來複合年成長率潛力最高。先進石化和SK Gas正在朱拜勒建造一座異丙醇工廠,利用當地過剩的丙烯和綜合基礎設施。南美洲成長溫和,巴西推廣利用甘蔗廢棄物和生物甲烷生產SAF,釋放了未來對生物丙醇的需求。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場狀況

- 市場概況

- 市場促進因素

- 電子設備清潔對高純度(異丙醇)IPA的需求

- 建設產業主導油漆和塗料的溶劑需求

- 增加亞太地區的原料藥產量

- 生物丙醇作為低碳航空燃料的興起

- 透過持續整合Oxo醇來降低成本

- 市場限制

- 丙烯原料價格不穩定

- 溶劑配方中VOC法規更加嚴格

- 生物丙醇發酵規模化的障礙

- 價值鏈分析

- 五力分析

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

第5章市場規模及成長預測

- 依產品類型

- 正丙醇

- 異丙醇

- 生物基丙醇

- 按最終用途行業

- 製藥

- 化學(溶劑和中間體)

- 個人護理和化妝品

- 印刷油墨

- 油漆和塗料

- 電子產品清潔

- 黏合劑和密封劑

- 其他

- 按地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 其他亞太地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 其他歐洲國家

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地區

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 其他中東和非洲地區

- 亞太地區

第6章 競爭態勢

- 市場集中度

- 策略舉措

- 市佔率分析

- 公司簡介

- BASF SE

- Deepak Fertilisers & Petrochemicals

- Dow

- Eastman Chemical Company

- Exxon Mobil Corporation

- HiMedia Laboratories

- Honeywell International Inc.

- INEOS

- LCY

- LyondellBasell Industries NV

- Mitsui Chemicals Inc.

- Moeve

- Sasol Limited

- Shell plc

- Solvay

- Solventis

- Tokuyama Corporation

第7章 市場機會與未來展望

The Propanol Market size is estimated at USD 3.23 billion in 2025, and is expected to reach USD 4.05 billion by 2030, at a CAGR of 4.67% during the forecast period (2025-2030).

Moderate expansion stems from rising adoption in semiconductor cleaning, sustainable aviation fuel pathways, and pharmaceutical synthesis, even as regulatory pressures reshape solvent formulations. High-purity isopropanol demand for 5 nm and below chip fabrication, new API production hubs in Asia, and alcohol-to-jet projects in North America collectively underpin steady volume gains. Feedstock volatility and evolving VOC limits temper momentum, but continuous oxo-alcohol integration and investment in purification technologies help producers defend margins. Integrated petrochemical players therefore retain cost advantages, while bio-based entrants carve out growth niches within the wider propanol market.

Global Propanol Market Trends and Insights

High-purity IPA Demand in Electronics Cleaning

Ultra-high-purity isopropanol exceeding 99.999% purity has become indispensable for advanced node semiconductor fabrication. ExxonMobil is upgrading its Baton Rouge unit to supply this grade by 2027, ensuring secure domestic supply for United States chipmakers. Contamination at parts-per-trillion levels can impair wafer yields, pushing device makers to specify ever-cleaner solvents. Electronics cleaning consequently grows faster than the overall propanol market, and suppliers are installing additional distillation columns, filtration trains, and real-time analytics to certify product purity. The resulting price premiums partly offset feedstock volatility, allowing integrated producers to protect spreads while meeting stringent customer audits.

Construction-led Solvent Demand in Paints & Coatings

Strong residential and commercial construction in Asia Pacific and the Middle East is driving demand for architectural coatings that rely on propanol-based co-solvents to balance viscosity, open time, and film formation. Regulators in the United States and Europe continue tightening VOC thresholds, spurring formulation shifts toward waterborne systems that still require controlled levels of propanol for flash-off control. The U.S. Environmental Protection Agency has extended aerosol coating compliance deadlines to January 2027, giving manufacturers critical runway to redesign products while maintaining performance. Continuous solvent innovation helps coatings producers satisfy durability criteria without breaching emission limits, supporting incremental consumption across the propanol market.

Stricter VOC Rules for Solvent Formulations

The U.S. National VOC Emission Standards impose lower allowable limits on consumer and commercial coatings, forcing reformulation to meet January 2027 deadlines. Similar policies are unfolding in the European Union, compelling users to substitute or reduce traditional solvent volumes. Compliance costs, additional testing, and certification requirements slow demand growth in legacy coatings, inks, and adhesives application areas, dampening part of the propanol market's potential.

Other drivers and restraints analyzed in the detailed report include:

- Rising Pharma API Output in Asia Pacific

- Emerging Bio-propanol for Low-carbon Aviation Fuel

- Scale-up Hurdles for Bio-propanol Fermentation

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Isopropanol accounted for 54.77% of the propanol market in 2024, leveraging its quick evaporation rate, antimicrobial efficacy, and versatile solvency for pharmaceuticals, personal care, and industrial cleaning. Semiconductor manufacturers are sharpening this dominance by contracting supply of 99.999% grades, and ExxonMobil's upcoming Baton Rouge line illustrates capital commitment toward ultra-high-purity batches. N-propanol maintains a niche but reliable presence in specialty inks and chemical intermediates, benefiting formulators requiring slower evaporation and distinct reactivity. Bio-based propanol delivers the steepest growth curve at 6.89% CAGR, aided by policy incentives targeting sustainable aviation fuel. USA BioEnergy's investment has increased confidence that offtake agreements can underwrite scale-up, positioning renewable producers for entry into the broader propanol market.

Isopropanol's extensive global distribution network and mature manufacturing footprint underpin reliable supply, yet escalating semiconductor demand is pressuring logistics and quality-control capacity. Producers are updating purification trains with ion-exchange, ultrafiltration, and advanced gas chromatography to verify part-per-trillion impurity thresholds. Conversely, bio-based output must overcome fermentation productivity limits and variable feedstock availability. Over the forecast horizon, the faster growth of renewable grades narrows the gap, but the absolute propanol market size for isopropanol remains well ahead, illustrating the inertia of entrenched production assets and customer familiarity.

The Propanol Market Report is Segmented by Product Type (n-Propanol, Isopropanol, Bio-Based Propanol), End-Use Industry (Pharmaceutical, Chemicals, Personal Care & Cosmetics, Printing Inks, Paints & Coatings, Electronics Cleaning, Adhesives & Sealants, Others), and Geography (Asia-Pacific, North America, Europe, South America, Middle East and Africa). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia Pacific leads the propanol market with 40.24% share in 2024. Government programmes like India's PLI scheme and Bulk Drug Parks funnel investment into API synthesis lines that consume pharmaceutical-grade propanol. China remains the largest chemical producer globally, commanding 50% share of world output and driving solvent needs across paints, inks, and electronics assembly. High-purity demand is amplified by advanced node semiconductor activity in Japan and South Korea, where fabs stipulate stringent contamination thresholds. Growing integration between refineries and chemical complexes in Southeast Asia further stabilizes regional feedstock supply.

North America exhibits mature but resilient consumption. The United States exported USD 345 million of propanol in 2023 while importing USD 128 million, a sign of domestic self-sufficiency coupled with specialized grade requirements. ExxonMobil's plan to produce 99.999% purity isopropanol in Louisiana aligns with the domestic semiconductor incentive framework, reducing dependence on imported high-spec material. Concurrently, USA BioEnergy's Texas SAF project elevates the region's renewable propanol profile, signaling diversification of demand.

Europe faces cost-side pressure from energy prices and stricter environmental norms. BASF saw a 21% sales decline in 2023, emblematic of subdued industrial output, yet specialty grades for pharmaceuticals and personal care protect pockets of profitability. The Middle East and Africa region holds the highest forward CAGR potential. Advanced Petrochemical and SK Gas are constructing an isopropanol plant at Jubail, harnessing local propylene surpluses and integrated infrastructure. South America registers moderate growth, with Brazil's push toward SAF via sugarcane waste and biomethane unlocking future bio-propanol demand.

- BASF SE

- Deepak Fertilisers & Petrochemicals

- Dow

- Eastman Chemical Company

- Exxon Mobil Corporation

- HiMedia Laboratories

- Honeywell International Inc.

- INEOS

- LCY

- LyondellBasell Industries N.V.

- Mitsui Chemicals Inc.

- Moeve

- Sasol Limited

- Shell plc

- Solvay

- Solventis

- Tokuyama Corporation

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 High-purity (isopropyl alcohol) IPA demand in electronics cleaning

- 4.2.2 Construction-led solvent demand in paints and coatings

- 4.2.3 Rising pharma API output in Asia Pacific

- 4.2.4 Emerging bio-propanol for low-carbon aviation fuel

- 4.2.5 Cost cuts via continuous oxo-alcohol integration

- 4.3 Market Restraints

- 4.3.1 Volatile propylene feedstock prices

- 4.3.2 Stricter VOC rules for solvent formulations

- 4.3.3 Scale-up hurdles for bio-propanol fermentation

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts

- 5.1 By Product Type

- 5.1.1 n-Propanol

- 5.1.2 Isopropanol

- 5.1.3 Bio-based Propanol

- 5.2 By End-use Industry

- 5.2.1 Pharmaceutical

- 5.2.2 Chemicals (Solvents and Intermediates)

- 5.2.3 Personal Care and Cosmetics

- 5.2.4 Printing Inks

- 5.2.5 Paints and Coatings

- 5.2.6 Electronics Cleaning

- 5.2.7 Adhesives and Sealants

- 5.2.8 Others

- 5.3 By Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 South Korea

- 5.3.1.5 Rest of Asia-Pacifc

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 France

- 5.3.3.4 Italy

- 5.3.3.5 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Rest of South America

- 5.3.5 Middle East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 South Africa

- 5.3.5.3 Rest of Middle East and Africa

- 5.3.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, Recent Developments)

- 6.4.1 BASF SE

- 6.4.2 Deepak Fertilisers & Petrochemicals

- 6.4.3 Dow

- 6.4.4 Eastman Chemical Company

- 6.4.5 Exxon Mobil Corporation

- 6.4.6 HiMedia Laboratories

- 6.4.7 Honeywell International Inc.

- 6.4.8 INEOS

- 6.4.9 LCY

- 6.4.10 LyondellBasell Industries N.V.

- 6.4.11 Mitsui Chemicals Inc.

- 6.4.12 Moeve

- 6.4.13 Sasol Limited

- 6.4.14 Shell plc

- 6.4.15 Solvay

- 6.4.16 Solventis

- 6.4.17 Tokuyama Corporation

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-need Assessment

- 7.2 Substituting Gasoline as Fuel