|

市場調查報告書

商品編碼

1844735

聚天冬胺酸塗料:市場佔有率分析、產業趨勢、統計數據和成長預測(2025-2030 年)Polyaspartic Coatings - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

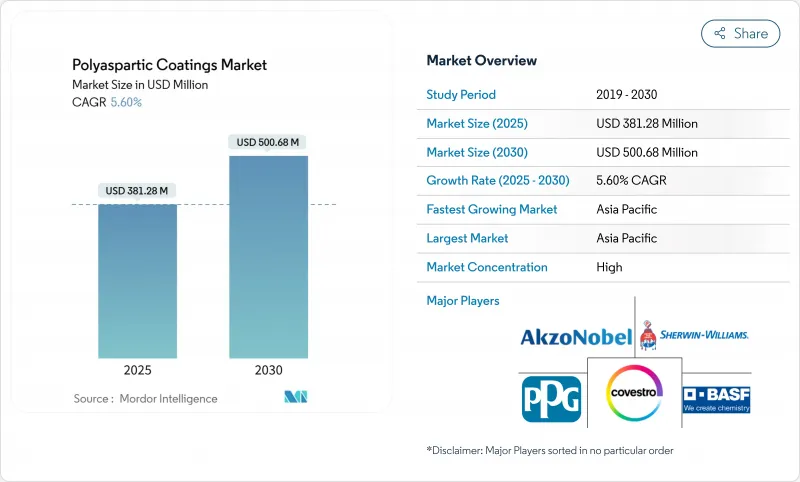

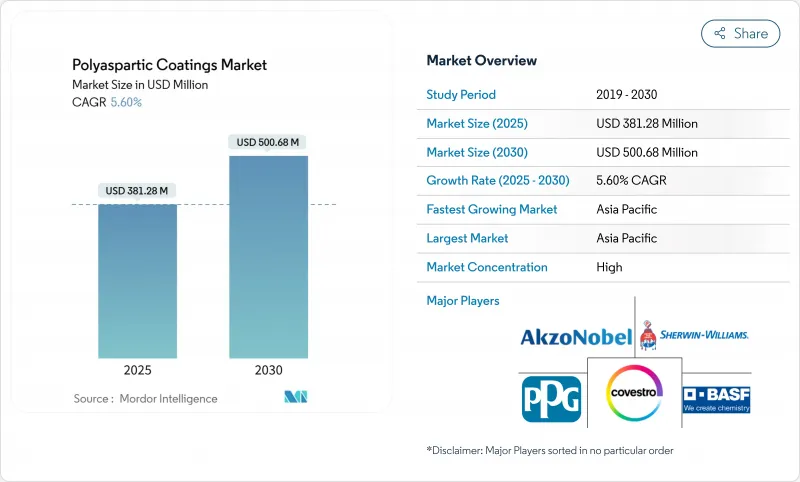

聚天冬胺酸塗料市場規模預計在 2025 年為 3.8128 億美元,預計到 2030 年將達到 5.0068 億美元,預測期內(2025-2030 年)的複合年成長率為 5.60%。

隨著建築商、製造商和業主尋求快速固化、低VOC(揮發性有機化合物)體系,以減少停機時間、符合嚴格的空氣品質法規並延長使用壽命,對水性塗料的需求日益成長。地板承包商依靠該技術實現一日恢復營運,以緩解技術純熟勞工短缺的問題;基礎設施業主則指定使用該技術來限制甲板和坡道的交通封閉。水性化學品的性能正在縮小與溶劑型系統的差距,並且由於其簡化了法規合規性,其規模化速度更快。亞洲以45%的市佔率引領全球水性塗料消費,這得益於中國和印度的大規模建築工程以及縮短快速推進計劃交付前置作業時間的區域供應鏈。

全球聚天冬胺酸塗料市場趨勢與洞察

歐洲綠建築認證成為強制性要求

歐洲新訂定的脫碳法規對建築產品中的揮發性有機化合物 (VOC) 含量進行了限制,而英國建築研究院環境評估法 (BREEAM)、德國建築環境評估委員會 (DGNB) 和歐盟生態標籤計劃則對低排放塗料進行獎勵。聚天冬胺酸供應商可以透過按照 ISO 標準記錄排放情況來確保規範優勢。像弗勞恩霍夫 WKI 這樣的實驗室提供第三方測試,並加快了認證時間。因此,水性和生物基塗料的訂單正在增加,配方師正在加速歐洲工廠的規模擴張。跨國公司正在透過在現有的溶劑型產品上使用環保化學品進行標註來擴大市場佔有率,而當地專家正在與樹脂製造商合作推出噴塗套件。

建設產業需求快速成長

與環氧樹脂相比,聚天冬胺酸酯地板材料可將計劃工期縮短一到兩天,使建築商能夠以固定的施工團隊每年安裝更多面積。在人流量大的零售和物流中心,業主可以獲得15年以上的使用壽命,儘管初始材料價格高出30-50%,但仍可降低終身維護成本。勞動力短缺推動了其應用:一日系統使未充分利用的施用器能夠立即轉入下一項工作。為了兼顧美觀和耐用性,建築公司正在將聚天冬氨酸酯面漆融入裝飾性混凝土設計中,並將應用範圍從倉庫擴展到購物中心和體育場館大廳。

與其他方案相比高成本

純聚天冬胺酸塗料比同類環氧塗料貴30-50%,這限制了其在價格敏感的住宅領域的應用。這項溢價反映了胺酯原料成本的上升和加工公差的縮小。缺乏生命週期成本模型的承包商會選擇價格較低的體系,儘管這些體系的使用壽命較短。供應商們推出了混合丙烯酸和聚氨酯樹脂的混合產品,以保持快速固化和抗紫外線性能,同時將標價降低15-20%。隨著經驗的成長,供應商正在向純聚天冬胺酸塗料過渡。

細分分析

到 2024 年,溶劑型塗料的銷售額將佔到 55%,但隨著監管機構降低 VOC 限值,水性產品預計將以 6.10% 的複合年成長率成長,成為所有技術類別中最高的。路博潤的 Solsperse W60 等水性分散劑可提高顏料穩定性,實現先前只有使用溶劑載體才能實現的色彩一致性。生產商也正在引進含生物胺以減少二氧化碳排放。在亞洲,市政綠建築法規正在採用歐洲 VOC 限值,加速了其在沒有聯邦法規的經濟體中的應用。大型承包商重視其水沖洗和低氣味的特性,以及降低已佔用場地的控制成本,因此將聚天冬胺酸塗料市場視為醫院和學校的首選解決方案。

正在進行的樹脂研究正在縮小水性和溶劑型系統之間機械性能的差距。與傳統的溶劑型系統相比,科思創的 INSQIN 聚氨酯可減少 95% 的製程用水量和 45% 的二氧化碳排放。這些優勢使塗料供應商能夠推動環境關鍵性能指標 (KPI) 以及固化速度和硬度的提升。因此,聚天冬胺酸塗料市場目前呈現出層級遞進的產品格局:適用於成本敏感型室內裝潢的入門級水性混合塗料、適用於商業地板材料的中檔通用體系,以及適用於建築幕牆和覆層的高階戶外水性純級塗料。

至2024年,純配方塗料將佔銷售額的70%,但隨著消費者尋求性能與價格的平衡,混合體系預計將以6.50%的複合年成長率成長。 Advanced Polymer Coatings的TriFLEX DTM等產品將聚氨酯的柔韌性與聚天冬胺酸的紫外線耐久性相結合,打造出一種可直接塗覆在金屬上的塗層,具有抗鹽霧和抗褪色的特性。混合系統通常具有更長的開放時間,有利於在溫暖氣候下進行大面積施工,並解決了人們對快速純級凝膠塗料的常見問題。

第二波混合塗料將聚天門冬胺酸與聚矽氧烷混合,以提高煙囪和海洋結構的耐熱性。材料科學家正在利用寡聚物設計來客製化固化曲線,使標準無氣泵能夠取代多組分鑽機,並提高承包商的接受度。混合塗料可使每加侖原料成本降低兩位數,使聚天冬胺酸塗料產業成為環氧塗料的升級選擇,使買家能夠輕鬆進入高階市場,而無需承受高昂的價格衝擊。

聚天冬胺酸塗料市場報告按技術(溶劑型、水性、粉末、紫外線固化)、類型(純聚天冬胺酸塗料、混合聚天冬胺酸塗料)、應用(地板、防水/防潮、其他)、最終用戶產業(建築/施工、海洋、基礎設施、其他)和地區(亞太地區、北美、歐洲、南美洲、中東和非洲)。

區域分析

隨著特大城市對交通、資料中心和智慧製造群的投資,到2024年,亞太地區將佔全球塗料市場收入的45%,到2030年,複合年成長率將達到6.90%。在中國,從待開發區項目轉向維修工程的趨勢正在推動對快速固化橋面維修的需求;而在印度,智慧城市計劃正在將公共資金用於人行天橋和地鐵站,並指定使用低維護塗料。印尼和越南正在成為二線塗料熱點地區,這得益於當地供應商擴大混合塗料的銷售,從而減少了對進口的依賴。

在北美,倉庫自動化、冷藏容量的擴大以及2022年頒布的1.2兆美元聯邦基礎設施計畫正在推動價值成長。橋樑業主正在利用夜間化學品再利用來最大程度地減少車道關閉。各州運輸部部門正在將此納入其資產管理指南。商業地產業主正在安排夜間地板重新粉刷,以避免業務中斷,從而在新建築市場放緩的時期支撐售後市場的需求。承包商認證計劃的廣泛採用正在推動加拿大和美國的聚天冬胺酸塗料市場的發展。

歐洲嚴格的空氣品質法規和成熟的綠建築認證生態系統為水性塗料的應用奠定了穩定的基礎。德國正在透過工業地坪維修來確保區域銷量,而斯堪地那維亞則在木結構建築上採用聚天冬氨酸膜,以延長在嚴酷的凍融氣候條件下的維護週期。南歐正在試驗將聚天冬胺酸黏合劑與紅外線反射顏料結合的冷屋頂配方,以降低建築能耗。在歐盟一體化基金的支持下,東歐國家正在指定使用快速固化橋樑塗料,以縮短嚴苛的施工工期,從而增強市場滲透率。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場狀況

- 市場概況

- 市場促進因素

- 歐洲強制性綠建築認證加速低VOC聚天門冬胺酸系統的採用

- 建設產業需求快速成長

- 新興經濟體基礎建設活性化

- 優於傳統塗料

- 市場限制

- 與其他方案相比高成本

- 亞太地區原物料價格波動

- 新興市場認知度較低

- 價值鏈分析

- 監理展望

- 五力分析

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭對手之間的競爭

第5章市場規模及成長預測

- 依技術

- 溶劑型

- 水性

- 粉末

- UV固化型

- 按類型

- 純聚天門冬胺酸塗層

- 雜化聚天冬胺

- 按用途

- 地板材料

- 防水防潮

- 防鏽面漆

- 按行業

- 建築/施工

- 海洋

- 基礎設施

- 發電

- 其他最終用戶產業

- 按地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 澳洲

- 紐西蘭

- 其他亞太地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 義大利

- 法國

- 北歐的

- 其他歐洲國家

- 南美洲

- 巴西

- 阿根廷

- 其他南美

- 中東和非洲

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 南非

- 奈及利亞

- 其他中東和非洲地區

- 亞太地區

第6章 競爭態勢

- 市場集中度

- 策略舉措

- 市佔率分析

- 公司簡介

- ADVACOAT

- Akzo Nobel NV

- BASF SE

- Carboline Company

- Citadel Floors

- Covestro AG

- Crown Polymers

- Duraamen Engineered Products Inc.

- Enviro Epoxy Products Inc.

- Flexmar Polyaspartics

- Hempel A/S

- Henkel AG & Co. KGaA

- Iron Man Coatings

- LATICRETE International Inc.

- Polyval Coatings Inc.

- PPG Industries Inc.

- RPM International Inc.

- Sika AG

- The Sherwin-Williams Company

- The VersaFlex Companies

第7章 市場機會與未來展望

The Polyaspartic Coatings Market size is estimated at USD 381.28 million in 2025, and is expected to reach USD 500.68 million by 2030, at a CAGR of 5.60% during the forecast period (2025-2030).

Demand is expanding as builders, manufacturers, and asset owners search for fast-curing, low-VOC systems that reduce downtime, meet tightening air-quality rules, and prolong service life. Flooring contractors rely on the technology's one-day return-to-service to mitigate skilled-labor shortages, while infrastructure owners specify it to limit traffic closures on decks and ramps. Water-borne chemistries are narrowing the performance gap with solvent-borne systems and are scaling faster because they simplify regulatory compliance. Asia leads global consumption with a 45% share, propelled by high-volume construction in China and India and by regional supply chains that shorten lead times for fast-moving projects.

Global Polyaspartic Coatings Market Trends and Insights

Green-Building Certification Mandates in Europe

Europe's new decarbonization rules cap VOC content in construction products and reward low-emission coatings within BREEAM, DGNB, and EU Ecolabel schemes. Polyaspartic suppliers that document ISO-compliant emissions secure specification advantages because developers use certifications as marketing assets to command rent premiums. Laboratories such as Fraunhofer WKI provide third-party testing, shortening time to proof. The resulting pull-through boosts orders for water-borne and bio-content grades, prompting formulators to accelerate scale-up at European plants. Multinationals re-label existing solvent-based lines with greener chemistries to defend share, while regional specialists partner with resin producers to launch ready-to-spray kits.

Rapidly Increasing Demand from Building and Construction Industry

Builders embrace polyaspartic flooring because it cuts project schedules by one to two days over epoxy, enabling contractors to complete more square footage annually with fixed crews. Owners gain 15-plus-year service life in heavy-traffic retail and logistics centers, reducing lifetime maintenance costs even when initial material prices run 30-50% higher. Labor scarcity intensifies adoption: single-day systems free scarce applicators for the next job sooner. Architectural firms integrate polyaspartic topcoats into decorative concrete designs to meet both aesthetic and durability targets, expanding use cases from warehouses to shopping malls and stadium concourses.

High Cost Compared to Alternatives

Pure polyaspartic coatings cost 30-50% more than comparable epoxy, constraining penetration in price-sensitive housing segments. The premium reflects higher amine ester feedstock prices and tighter processing tolerances. Contractors without lifecycle-cost models default to cheaper systems despite shorter service life. Suppliers answer with hybrid lines that blend acrylic or polyurethane resins to shave 15-20% off list prices while retaining fast cure and UV resistance, planting a migration path toward pure grades as experience deepens.

Other drivers and restraints analyzed in the detailed report include:

- Rising Infrastructure Development in Emerging Economies

- Superior Performance over Traditional Coatings

- Feedstock Price Volatility in Asia-Pacific

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Solvent-borne grades held a 55% revenue share in 2024; however, water-borne products are forecast to register a 6.10% CAGR, the highest among technology categories, as regulators impose lower VOC ceilings. Water-based dispersants such as Lubrizol's Solsperse W60 improve pigment stability, delivering color consistency once achievable only with solvent carriers. Producers also introduce bio-content amines to cut carbon footprints. In Asia, municipal green-building codes adopt European VOC limits, accelerating specification even in economies without federal mandates. Large contractors appreciate water clean-up and lower odor, which reduces containment costs on occupied sites, turning the polyaspartic coatings market into a preferred solution in hospitals and schools.

Continuous resin research has narrowed mechanical-property gaps between water-borne and solvent-borne systems. Covestro's INSQIN polyurethane reduces process-water use by 95% and CO2 emissions by 45% compared with legacy solvent routes. These gains enable coating suppliers to promote environmental key-performance indicators alongside cure speed and hardness. As a result, the polyaspartic coatings market sees tiered product ladders: entry water-borne hybrids for cost-sensitive interiors, mid-tier universal systems for commercial flooring, and premium exterior water-borne pure grades for facade cladding.

Pure formulations generated 70% of 2024 sales, yet hybrid systems are projected to grow at 6.50% CAGR as applicators seek balanced performance and price. Products such as Advanced Polymer Coatings' TriFLEX DTM merge polyurethane flexibility with polyaspartic UV durability to create a direct-to-metal coating that withstands salt spray and color fade. Hybrids often lengthen open time to ease large-area application in warm climates, resolving a common complaint about rapid pure-grade gel.

A second hybrid wave blends polyaspartic with polysiloxane to improve heat resistance in flue-gas stacks and offshore structures. Material scientists leverage oligomer design to tune cure profiles, enabling use of standard airless pumps instead of plural-component rigs, thus broadening contractor acceptance. Because hybrids cut raw-material cost per gallon by double-digit percentages, the polyaspartic coatings industry positions them as step-up options from epoxy, easing buyers into the premium category without sticker shock.

The Polyaspartic Coatings Market Report is Segmented by Technology (Solvent-Borne, Water-Borne, Powder, and UV-Cured), Type (Pure Polyaspartic Coatings and Hybrid Polyaspartic), Application (Flooring, Waterproofing and Moisture-Barrier, and More), End-User Industry (Building and Construction, Marine, Infrastructure, and More), and Geography (Asia-Pacific, North America, Europe, South America, and Middle East and Africa).

Geography Analysis

Asia-Pacific generated 45% of global revenue in 2024 and is tracking a 6.90% CAGR through 2030 as megacities invest in transit, data centers, and smart manufacturing clusters. China's shift to renovation over greenfield builds sustains demand for rapid-cure deck refurbishment, while India's Smart Cities Mission channels public funds into pedestrian bridges and metro stations that specify low-maintenance coatings. Indonesia and Vietnam emerge as second-tier hotspots, aided by local suppliers scaling blended hybrids that lower import dependence.

North America's value is driven by warehouse automation, expansions in cold-storage capacity, and the USD 1.2 trillion federal infrastructure program enacted in 2022. Bridge owners exploit the chemistry's overnight return-to-service to minimize lane closures; state departments of transportation incorporate it into asset-management guidelines. Commercial real-estate owners schedule overnight floor recoats to sidestep business interruptions, which sustains aftermarket demand even during new-build slowdowns. High adoption of contractor certification programs accelerates the polyaspartic coatings market across Canada and the United States.

Europe's stringent air-quality statutes and mature green-building certification ecosystem create a stable platform for water-borne adoption. Germany anchors regional volume through industrial floor upgrades, while Scandinavia deploys polyaspartic membranes on timber structures to lengthen maintenance cycles in harsh freeze-thaw climates. Southern Europe experiments with cool-roof formulations that combine polyaspartic binders with infrared-reflective pigments to curb building energy use. Eastern European countries, encouraged by EU cohesion funds, specify rapid-cure bridge coatings to compress tight construction seasons, bolstering market penetration.

- ADVACOAT

- Akzo Nobel N.V.

- BASF SE

- Carboline Company

- Citadel Floors

- Covestro AG

- Crown Polymers

- Duraamen Engineered Products Inc.

- Enviro Epoxy Products Inc.

- Flexmar Polyaspartics

- Hempel A/S

- Henkel AG & Co. KGaA

- Iron Man Coatings

- LATICRETE International Inc.

- Polyval Coatings Inc.

- PPG Industries Inc.

- RPM International Inc.

- Sika AG

- The Sherwin-Williams Company

- The VersaFlex Companies

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Green-Building Certification Mandates in Europe Accelerating Adoption of Low-VOC Polyaspartic Systems

- 4.2.2 Rapidly Increasing Demand from the Building and Construction Industry

- 4.2.3 Rising Infrastructure Development in Emerging Economies

- 4.2.4 Superior Performance over Traditional Coatings

- 4.3 Market Restraints

- 4.3.1 High Cost Compared to Alternatives

- 4.3.2 Feedstock Price Volatility in Asia-Pacific

- 4.3.3 Limited Awareness in Developing Markets

- 4.4 Value Chain Analysis

- 4.5 Regulatory Outlook

- 4.6 Porter's Five Forces

- 4.6.1 Bargaining Power of Suppliers

- 4.6.2 Bargaining Power of Buyers

- 4.6.3 Threat of New Entrants

- 4.6.4 Threat of Substitutes

- 4.6.5 Competitive Rivalry

5 Market Size and Growth Forecasts (Value)

- 5.1 By Technology

- 5.1.1 Solvent-borne

- 5.1.2 Water-borne

- 5.1.3 Powder

- 5.1.4 UV-Cured

- 5.2 By Type

- 5.2.1 Pure Polyaspartic Coatings

- 5.2.2 Hybrid Polyaspartic

- 5.3 By Application

- 5.3.1 Flooring

- 5.3.2 Waterproofing and Moisture-Barrier

- 5.3.3 Anti-Corrosive Top-Coat

- 5.4 By End-Use Industry

- 5.4.1 Building and Construction

- 5.4.2 Marine

- 5.4.3 Infrastructure

- 5.4.4 Power Generation

- 5.4.5 Other End-user Industries

- 5.5 By Geography

- 5.5.1 Asia-Pacific

- 5.5.1.1 China

- 5.5.1.2 India

- 5.5.1.3 Japan

- 5.5.1.4 South Korea

- 5.5.1.5 Australia

- 5.5.1.6 New Zealand

- 5.5.1.7 Rest of Asia-Pacific

- 5.5.2 North America

- 5.5.2.1 United States

- 5.5.2.2 Canada

- 5.5.2.3 Mexico

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 Italy

- 5.5.3.4 France

- 5.5.3.5 Nordics

- 5.5.3.6 Rest of Europe

- 5.5.4 South America

- 5.5.4.1 Brazil

- 5.5.4.2 Argentina

- 5.5.4.3 Rest of South America

- 5.5.5 Middle East and Africa

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 United Arab Emirates

- 5.5.5.3 South Africa

- 5.5.5.4 Nigeria

- 5.5.5.5 Rest of Middle east and Africa

- 5.5.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global Level Overview, Market Level Overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share, Products and Services, Recent Developments)

- 6.4.1 ADVACOAT

- 6.4.2 Akzo Nobel N.V.

- 6.4.3 BASF SE

- 6.4.4 Carboline Company

- 6.4.5 Citadel Floors

- 6.4.6 Covestro AG

- 6.4.7 Crown Polymers

- 6.4.8 Duraamen Engineered Products Inc.

- 6.4.9 Enviro Epoxy Products Inc.

- 6.4.10 Flexmar Polyaspartics

- 6.4.11 Hempel A/S

- 6.4.12 Henkel AG & Co. KGaA

- 6.4.13 Iron Man Coatings

- 6.4.14 LATICRETE International Inc.

- 6.4.15 Polyval Coatings Inc.

- 6.4.16 PPG Industries Inc.

- 6.4.17 RPM International Inc.

- 6.4.18 Sika AG

- 6.4.19 The Sherwin-Williams Company

- 6.4.20 The VersaFlex Companies

7 Market Opportunities and Future Outlook

- 7.1 Increasing Demand for Bio-based Products

- 7.2 White-space and Unmet-need Assessment