|

市場調查報告書

商品編碼

1844720

去氧劑:市場佔有率分析、產業趨勢、統計數據和成長預測(2025-2030)Oxygen Scavengers - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

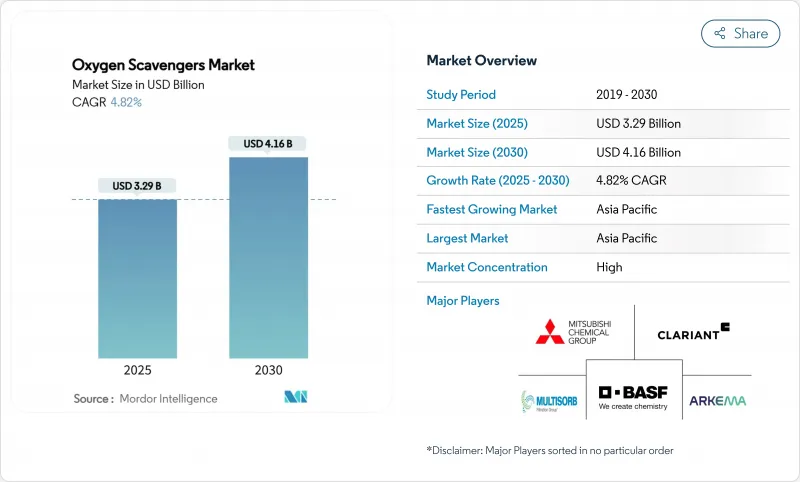

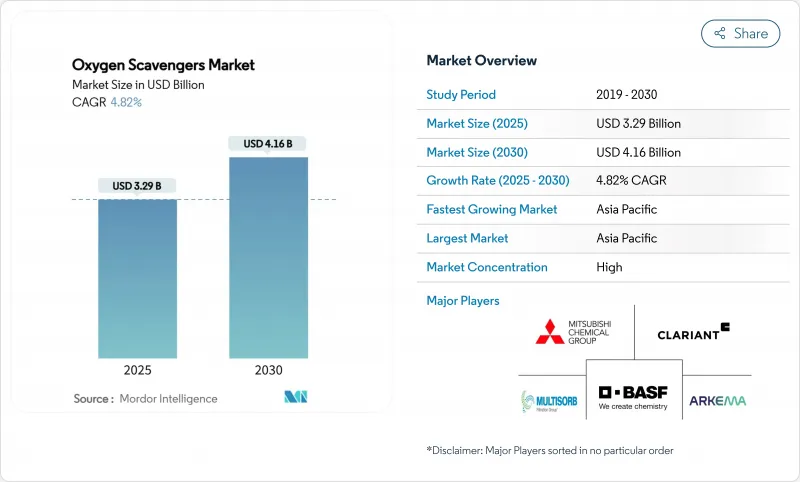

去氧劑市場規模預計在 2025 年達到 32.9 億美元,預計到 2030 年將達到 41.6 億美元,預測期內(2025-2030 年)的複合年成長率為 4.82%。

需求正從傳統的鐵粉轉向聚合物整合和基於酶的系統,以幫助品牌所有者滿足更嚴格的保存期限、純度和可回收性目標。亞太地區是多層包裝薄膜的生產中心,而北美則是高價值醫藥應用的領導者。美國食品藥物管理局(FDA)的人類食品計畫和歐盟法規2025/40等法規正在加速向避免金屬離子遷移的非金屬配方的轉變。在終端用途方面,電子商務的蓬勃發展正鼓勵品牌所有者選擇即使在數週複雜的履約網路中也能保持有效的氧氣管理技術,從而維持去氧劑市場的中期成長。

全球去氧劑市場趨勢與洞察

新鮮即食食品和冷藏包裝食品快速成長

消費者習慣向便利食品的轉變,推動了主動氧氣管理技術在肉類、海鮮和熟食類別中的廣泛應用。品牌商正在將無袋空氣清除層融入熱成型托盤中,以確保產品在長期冷藏和零售保存期限內保持顏色穩定。區域超級市場表示,減少廢棄物和提高商品行銷彈性是其主要優勢,這促使代加工商指定能夠在低溫下快速啟動的解決方案。因此,設備供應商正在改進高速托盤封口線,以適應預先裝載空氣清除樹脂的多層薄膜,這些樹脂不會損害密封的完整性。這種採用為美國和德國的薄膜擠出機帶來了穩定的訂單,鞏固了去氧劑市場的基準成長。

藥典對藥品包裝中殘留氧氣的規定日益嚴格

最新的 USP 和 EMA 指南設定了腸外和固態劑量包裝中殘留氧氣的上限,鼓勵藥品製造商檢驗在規定的保存期限內保持低於 0.5% 氧氣的屏障系統。聚合物為基礎的清除劑(如 Colorcon 的 PharmaKeep 系列)可在 10-90% 的相對濕度下發揮作用,解決藥品的濕度敏感性問題,同時避免金屬離子的風險。歐洲法規的發展軌跡類似,修訂後的歐盟食品接觸材料法規於 2025 年 3 月生效,引入了影響藥品包裝材料的更高的純度要求和遷移限值。這些進步對於生技藥品尤其明顯,因為微量的氧氣可以催化蛋白質分解,而對濕度敏感的小分子療法則需要多年的穩定性數據。

對金屬離子和官能基污染的擔憂

鐵基小袋會釋放微量離子,這些離子會催化敏感膳食補充劑中的氧化反應,或導致高檔茶和咖啡中出現金屬異味。監管審核現在要求在最惡劣的濕度條件下進行遷移測試,這促使一些品牌商在高價值SKU中完全淘汰鐵基系統。聚合物封裝降低了直接接觸風險,但增加了原料成本,小型製造商難以承受。這種權衡阻礙了傳統小袋包裝在短期內滲透到藥品和特殊食品管道,並在一定程度上抑制了去氧劑市場的發展。

細分分析

受成熟供應鏈、快速吸收率和低單位成本的推動,預計到 2024 年金屬系統將佔據去氧劑市場的 57.89%。該細分市場的規模優勢,加上與全球肉類加工商和零嘴零食製造商的批量契約,支撐了入門級去氧劑的市場規模。然而,非金屬系統預計將以 8.60% 的複合年成長率成長,是所有材料組中成長最快的。聚合物整合系統無需在生產線末端插入包裝袋,從而減少了高速灌裝封口生產線的轉換時間。酵素和抗壞血酸配方進一步擴大了限制金屬添加劑的清真、猶太潔食和潔淨標示品牌的選擇範圍。製藥審核越來越強調聚合物系統與控濕倉庫的兼容性,鼓勵泡殼膜擠出機採用 Amosorb 和 PharmaKeep 濃縮液。奈米複合催化劑的持續研究和開發表明,非金屬解決方案可能在 2030 年後取代鐵鉛。總之,這些動態增強了去氧劑市場材料部分的多樣性。

第二代化學品也符合回收法規的要求,將清除功能融入單晶片 PET 或 PP 結構而非貼合加工鋁箔中,這種方法支持歐盟法規 2025/40 的循環經濟目標。樹脂供應商正在展示瓶到瓶的可回收性,同時將霧度增加降至最低,從而實現了飲料品牌到 2030 年回收率達到 30% 的承諾。同時,金屬袋製造商正在透過最佳化粉末粒度和添加吸濕緩衝劑來延緩海運過程中的過早活化。因此,材料平台之間的競爭集中在平衡活化抑制、單位經濟性和下游可回收性上,這種競爭將影響去氧劑市場中轉化商和全球快速消費品買家的採購決策。

全球去氧劑市場報告按類型(金屬去氧劑和非金屬去氧劑)、最終用戶行業(食品飲料、製藥、石油天然氣、電力等)以及地區(北美、南美、歐洲、中東和非洲)對該行業進行了細分。市場預測以美元計算。

區域分析

預計到2024年,亞太地區將佔全球38.05%的需求,到2030年,複合年成長率將達到7.50%,這得益於中國不斷擴大的醫藥出口基地和印度軟膜轉化產能的快速擴張。該地區各國政府持續補貼低溫運輸物流,並設定減少食品廢棄物的國家目標,刺激了主動阻隔解決方案的採用。該地區受益於成熟的原料供應鏈和食品加工行業日益成長的需求,滿足了國內和出口市場的需求。三菱去氧劑化學透過其子公司——日本的MGC Ageless和泰國的Ageless——在該地區擁有強大的影響力,展現出其完善的基礎設施,以支持脫氧劑的生產和分銷。

北美是一個成熟且技術先進的去氧劑市場。嚴格的FDA監管要求進行全面的遷移測試,這推動了對完整記錄的聚合物配方的需求。品牌所有者優先考慮符合州級「生產者責任延伸」法規規定的機械回收目標的解決方案。加拿大肉類加工商指定使用大容量包裝袋和自動裝填設備,以滿足對亞洲的出口需求,從而維持穩定的替換需求。在墨西哥,新興的便利食品產業進一步支撐了區域成長,但成本壓力也造成了一系列被動和主動的障礙。

歐洲的監管驅動力與北美相似,但也進一步擁抱循環經濟的野心。歐盟法規 2025/40 要求到 2030 年所有包裝都必須可回收,這刺激了對具有內建回收功能的整體結構的投資。法國和德國的主要飲料集團正在試用含有非金屬添加劑的 寶特瓶瓶坯,以使氧氣保護與押金返還系統保持一致。東歐薄膜擠出機製造商正在從西方供應商進口聚合物濃縮物,以縮小技術差距並推動應用。雖然中東/非洲和南美洲在絕對數量上落後,但隨著現代食品零售業態的擴張,人們的興趣正在加速成長。在這些新興市場,開發銀行資助的示範計劃已經證明了活性氧管理在減少食品腐敗方面的益處,預示著去氧劑市場在中期的需求將穩定成長。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場狀況

- 市場概況

- 市場促進因素

- 新鮮即食食品和冷藏包裝食品快速成長

- 藥典對藥品包裝中殘留氧氣的規定更加嚴格

- 擴大無菌低溫運輸郵件套件物流

- 奈米複合聚合物清除劑的商業化

- 電子商務導致運送時間延長

- 市場限制

- 對金屬離子污染和感官污染的擔憂

- 經濟高效、阻隔性薄膜替代品

- 鐵礦石和特殊催化劑價格波動劇烈

- 價值鏈分析

- 五力分析

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

第5章市場規模及成長預測

- 按類型

- 金屬去氧劑

- 非金屬去氧劑

- 按最終用戶產業

- 飲食

- 製藥

- 石油和天然氣

- 電力

- 化學

- 紙漿和造紙

- 其他終端用戶產業(水處理、污水處理等)

- 按地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 泰國

- 印尼

- 越南

- 馬來西亞

- 菲律賓

- 其他亞太地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 俄羅斯

- 北歐國家

- 土耳其

- 其他歐洲國家

- 南美洲

- 巴西

- 阿根廷

- 哥倫比亞

- 其他南美

- 中東和非洲

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 卡達

- 南非

- 奈及利亞

- 埃及

- 其他中東和非洲地區

- 亞太地區

第6章 競爭態勢

- 市場集中度

- 策略舉措

- 市佔率(%)/排名分析

- 公司簡介

- Accepta Water Treatment

- Arkema

- Avient Corporation

- BASF

- Clariant

- Desiccare Inc.

- Ecolab

- MITSUBISHI GAS CHEMICAL COMPANY, INC.

- Multisorb

- Solenis

- Veolia

第7章 市場機會與未來展望

The Oxygen Scavengers Market size is estimated at USD 3.29 billion in 2025, and is expected to reach USD 4.16 billion by 2030, at a CAGR of 4.82% during the forecast period (2025-2030).

Demand pivots from conventional iron powders toward polymer-integrated and enzyme-based systems that help brand owners satisfy stricter shelf-life, purity and recyclability targets. Asia-Pacific represents the core production base for multilayer packaging films while North America drives high-value pharmaceutical applications, and both regions influence raw-material sourcing strategies for global suppliers. Regulations such as the FDA's Human Foods Program and EU Regulation 2025/40 are amplifying the shift toward non-metallic formulations that avoid metal-ion migration. Across end-uses, the e-commerce boom forces brand owners to choose oxygen management technologies that remain effective during weeks-long journeys through complex fulfilment networks, sustaining medium-term growth for the oxygen scavengers market.

Global Oxygen Scavengers Market Trends and Insights

Rapid Growth in Fresh-Ready & Chilled Packaged Meals

Shifts in consumer habits toward convenience foods have widened deployment of active oxygen management across meat, seafood and deli categories. Brand owners integrate sachet-free scavenging layers into thermoformed trays so products remain color-stable throughout extended chilled storage and retail display. Regional supermarket chains cite reduced waste and improved merchandising flexibility as key benefits, prompting co-packers to specify solutions that activate rapidly at low temperatures. Equipment suppliers are therefore adapting high-speed tray-sealing lines to accommodate multilayer films pre-loaded with scavenging resins that do not compromise seal integrity. This adoption dynamic feeds a steady order pipeline for film extruders located in the United States and Germany, reinforcing baseline growth for the oxygen scavengers market.

Stricter Pharmacopeia Limits on Residual Oxygen in Drug Packs

The latest USP and EMA guidelines cap residual oxygen in parenteral and solid-dose packs, urging drug makers to validate barrier systems that sustain <=0.5% oxygen throughout the stated shelf life. Polymer-based scavengers such as Colorcon's PharmaKeep series can function across 10-90% relative humidity, addressing drug-product moisture sensitivity while avoiding metal-ion risks. the European regulations are following similar trajectories, with the EU's revised food contact material regulations effective March 2025 introducing enhanced purity requirements and migration limits that affect pharmaceutical packaging materials .Contract development organizations embed such additives directly into polyolefin blisters, which simplifies line qualification versus separate sachets. These advances are most visible in biologics, where trace oxygen can catalyze protein degradation, and in moisture-reactive small-molecule therapies that require multi-year stability data.

Metal-Ion Contamination & Sensory-Taint Concerns

Iron-based sachets release trace ions that can catalyze oxidative reactions in sensitive nutraceuticals and lead to metallic off-notes in premium teas and coffees. Regulatory auditors now require migration testing under worst-case humidity, prompting some brand owners to exclude ferrous systems entirely for high-value SKUs. Polymer encapsulation methods lower direct contact risk, yet they raise raw-material costs that smaller manufacturers struggle to absorb. This trade-off tempers near-term penetration of traditional sachets in pharmaceutical and specialty-food channels, restraining a portion of the oxygen scavengers market.

Other drivers and restraints analyzed in the detailed report include:

- Expansion of Aseptic Cold-Chain Meal-Kit Logistics

- Commercialization of Nanocomposite Polymer Scavengers

- Cost-Effective and High-Barrier Film Substitutes

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Metallic formulations retained 57.89% oxygen scavengers market share in 2024 thanks to established supply chains, rapid absorption kinetics and low unit cost. The segment's scale advantage translates into volume contracts with global meat processors and snack producers, anchoring the oxygen scavengers market size for entry-level applications. However, non-metallic systems are growing at an 8.60% CAGR, the fastest among all material groups. Polymer-integrated variants eliminate the need for end-of-line sachet insertion, which shortens changeover time on high-speed fill-and-seal lines. Enzyme and ascorbic-acid formulations further widen options for halal, kosher and clean-label brands that restrict metallic additives. Pharmaceutical audits increasingly cite polymer systems' compatibility with humidity-controlled warehouses, encouraging blister-film extruders to adopt Amosorb and PharmaKeep concentrates. Continuous R-&D around nanocomposite catalysts suggests non-metallic solutions could erode iron's lead beyond 2030, especially if unit prices align with mainstream snack food budgets. Collectively, these dynamics reinforce material-segment diversity within the oxygen scavengers market.

Second-generation chemistries also align with recycling mandates because they embed scavenging capacity in mono-material PET or PP structures rather than laminated foil, an approach that supports circular-economy targets under EU Regulation 2025/40. Resin suppliers have demonstrated bottle-to-bottle recyclability with minimal haze increase, satisfying beverage-brand commitments to 30% recycled content by 2030. Meanwhile, metallic sachet makers counter by optimizing powder particle size and adding moisture-absorbing buffers that delay premature activation during ocean transit. Competition across material platforms therefore centers on balancing activation control, unit economics and downstream recycling performance, a contest that will shape procurement decisions for both converters and global CPG buyers in the oxygen scavengers market.

The Global Oxygen Scavenger Market Reports Segments the Industry by Type (Metallic Oxygen Scavengers and Non-Metallic Oxygen Scavengers), End-User Industry (Food and Beverage, Pharmaceutical, Oil and Gas, Power and More), and Geography (Asia-Pacific, North America, South America, Europe, and Middle East and Africa). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific accounted for 38.05% of 2024 demand and is projected to deliver a 7.50% CAGR to 2030, underpinned by China's expanding pharmaceutical export base and India's rapid capacity additions in flexible-film conversion. Governments across the region continue to subsidize cold-chain logistics and set national targets for food-waste reduction, stimulating adoption of active barrier solutions. The region benefits from established supply chains for raw materials and growing demand from food processing industries that serve both domestic and export markets. Mitsubishi Gas Chemical's strong presence in the region through subsidiaries like MGC AGELESS Co., Ltd. in Japan and AGLESS (THAILAND) CO., LTD. demonstrates the established infrastructure supporting oxygen scavenger production and distribution.

North America represents a mature but technically advanced arena for the oxygen scavengers market. Stringent FDA oversight mandates exhaustive migration testing and drives demand for fully documented polymer formulations. Brand owners prioritize solutions compatible with mechanical recycling targets under state-level extended producer responsibility rules. Canadian meat processors, dealing with export voyages toward Asia, specify high-capacity sachets and automated insertion equipment, sustaining steady replacement demand. Mexico's rising convenience-food sector further supports regional growth, although cost pressures favour a mix of passive and active barriers.

Europe mirrors North American regulatory drivers but layers additional circular-economy ambitions. EU Regulation 2025/40 will require all packaging to be recyclable by 2030, spurring investments in mono-material structures with embedded scavenging capability. Large beverage groups in France and Germany pilot PET bottle preforms containing non-metallic additives, aligning oxygen protection with deposit-return systems. Eastern European film extruders increasingly import polymer concentrates from Western suppliers, bridging technology gaps and spreading adoption. The Middle East & Africa and South America trail in absolute volume yet show accelerating interest as modern grocery retail formats expand. Across these emerging regions, demonstration projects funded by development banks illustrate the spoilage-reduction benefits of active oxygen management, pointing toward steady medium-term demand inflows for the oxygen scavengers market.

- Accepta Water Treatment

- Arkema

- Avient Corporation

- BASF

- Clariant

- Desiccare Inc.

- Ecolab

- MITSUBISHI GAS CHEMICAL COMPANY, INC.

- Multisorb

- Solenis

- Veolia

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions & Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Rapid Growth in Fresh-Ready and Chilled Packaged Meals

- 4.2.2 Stricter Pharmacopeia Limits on Residual Oxygen in Drug Packs

- 4.2.3 Expansion of Aseptic Cold-Chain Mealkit Logistics

- 4.2.4 Commercialisation of Nanocomposite Polymer Scavengers

- 4.2.5 E-commerce Demand for Longer Transit Shelf-Life

- 4.3 Market Restraints

- 4.3.1 Metal-Ion Contamination & Sensory-Taint Concerns

- 4.3.2 Cost-Fffective and High-Barrier Film Substitutes

- 4.3.3 Volatile Iron-Ore and Specialty Catalyst Price Swings

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Degree of Competition

5 Market Size & Growth Forecasts (Value)

- 5.1 By Type

- 5.1.1 Metallic Oxygen Scavengers

- 5.1.2 Non-metallic Oxygen Scavengers

- 5.2 By End-user Industry

- 5.2.1 Food and Beverage

- 5.2.2 Pharmaceutical

- 5.2.3 Oil and Gas

- 5.2.4 Power

- 5.2.5 Chemical

- 5.2.6 Pulp and Paper

- 5.2.7 Other End-user Industries (Water and Waste-Water Treatment, etc.)

- 5.3 By Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 South Korea

- 5.3.1.5 Thailand

- 5.3.1.6 Indonesia

- 5.3.1.7 Vietnam

- 5.3.1.8 Malaysia

- 5.3.1.9 Philippines

- 5.3.1.10 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 France

- 5.3.3.4 Italy

- 5.3.3.5 Spain

- 5.3.3.6 Russia

- 5.3.3.7 NORDIC Countries

- 5.3.3.8 Turkey

- 5.3.3.9 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Colombia

- 5.3.4.4 Rest of South America

- 5.3.5 Middle East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 United Arab Emirates

- 5.3.5.3 Qatar

- 5.3.5.4 South Africa

- 5.3.5.5 Nigeria

- 5.3.5.6 Egypt

- 5.3.5.7 Rest of Middle East and Africa

- 5.3.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share (%)/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products & Services, and Recent Developments)

- 6.4.1 Accepta Water Treatment

- 6.4.2 Arkema

- 6.4.3 Avient Corporation

- 6.4.4 BASF

- 6.4.5 Clariant

- 6.4.6 Desiccare Inc.

- 6.4.7 Ecolab

- 6.4.8 MITSUBISHI GAS CHEMICAL COMPANY, INC.

- 6.4.9 Multisorb

- 6.4.10 Solenis

- 6.4.11 Veolia

7 Market Opportunities & Future Outlook

- 7.1 White-space & unmet-need assessment