|

市場調查報告書

商品編碼

1844713

親水性塗料:市場佔有率分析、產業趨勢、統計數據和成長預測(2025-2030 年)Hydrophilic Coatings - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

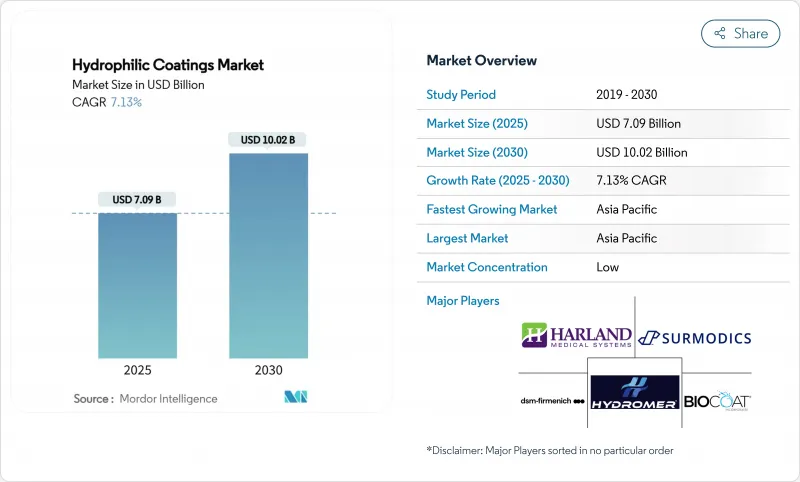

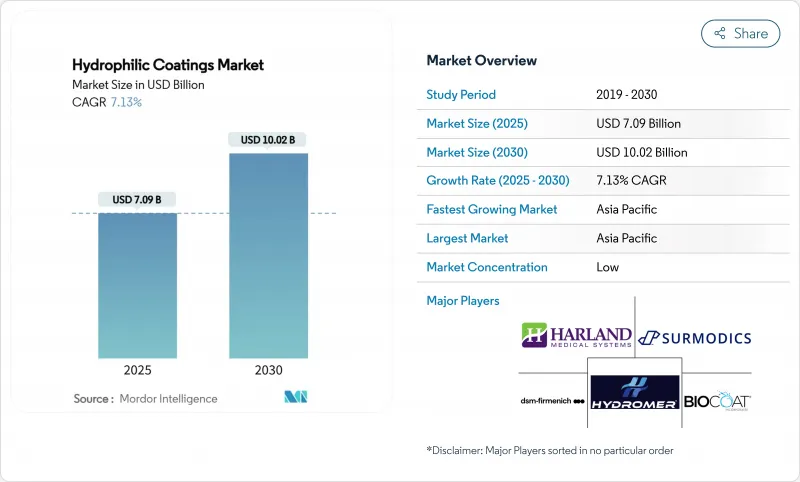

親水性塗料市場規模預計在 2025 年為 70.9 億美元,預計到 2030 年將達到 100.2 億美元,預測期內(2025-2030 年)的複合年成長率為 7.13%。

醫療、光學和汽車應用領域的快速應用,加上嚴格的永續性要求,支撐了這一成長。聚合物基板仍佔據主導地位,但奈米顆粒表面正在蠶食其領先地位,而亞太地區正透過地理飛輪效應重塑全球供應鏈。醫療設備價格壓力的增加、PFAS法規的收緊以及對耐用性的擔憂繼續制約著其擴張,但持續的材料創新、精簡的沉積技術以及日益壯大的無PFAS解決方案生態系統正在釋放機會。

全球親水性塗料市場趨勢與洞察

醫療保健應用需求不斷成長

醫療設備設計師依靠親水性塗層來減少微創手術中的插入力和血栓症。臨床證據表明,它們可以將導管摩擦降低高達70%,從而實現更順暢的血管導航和更短的手術時間。兼具潤滑性、抗菌和抗血栓劑的塗層正日益普及,尤其是在神經血管支架領域。表面改質的導流片可以減少血小板黏附,並減少雙重抗血小板治療的需求。醫院目前優先使用具有此類多功能層的支架。同時,產學合作正在加速臨床前檢驗,進一步促進其應用。

塗層材料創新

奈米顆粒基底材料集高親水性、耐磨性和控制釋放功能於一身,重新定義了性能上限。二氧化矽-聚丙烯酸配方即使在輕微磨損下也能保持超親水性,解決了長期存在的耐久性問題。像starPEG-肝素這樣的響應性水凝膠能夠承受導管置入過程中的剪切力,同時提供按需抗凝血。這些進展開啟了全新的產品架構,塗層在不影響機械完整性的情況下,兼具表面潤滑和治療功能的雙重作用。

製造成本高

與標準塗層相比,多步驟合成、無塵室沉積和嚴格的品質測試使製造成本增加了30-40%,從而擠壓了對價格敏感的導管和導管導引線線的淨利率。專業知識集中在少數幾家供應商手中,限制了規模經濟,並增加了原始設備製造商(OEM)的轉換成本。製程自動化和卷對捲紫外線固化系統正在縮短週期時間,但資金需求限制了小型公司的進入。

細分分析

奈米粒子基板的複合年成長率達7.80%,侵蝕了聚合物48%的收益佔有率。埃洛石奈米管增強環氧丙烯酸酯乳化的耐久性顯著提升,經鹽霧暴露16天後仍保持無銹,而傳統聚合物僅為9天。玻璃上接觸角達162°的超疏水性二氧化矽塗層,展現了奈米技術優勢在不同基板間的轉移。

儘管製造商繼續青睞聚合物,因為它們經濟高效、易於量產,但將奈米二氧化矽和層狀矽酸鹽嵌入聚合物基質的混合設計正在重塑基材的層級結構。這些混合材料將靈活的加工窗口與增強的耐磨性相結合,模糊了類別界限。金屬和玻璃基板繼續填補生物相容性和光學透明度至關重要的細分領域,但奈米級中間層也正在增強其附著力和耐腐蝕性能。

至2024年,浸塗技術將維持42%的收入佔有率。然而,等離子體和紫外光接枝製程的年成長率為7.7%,這些製程擴大能夠在複雜的幾何形狀上實現客製化的表面化學,且不會產生溶劑殘留。引發氣相沉積(iCVD)技術可以形成梯度聚合物層,從而提高疏冰性能,並在不同溫度下保持親水性。

噴塗和狹縫模頭生產線縮短了週期時間,並提高了導管產量。化學氣相沉積技術可實現協同組成的共沉澱,將水接觸角降低至43.2°,並提高塗層的均勻性和生命週期穩定性。

區域分析

到2024年,亞太地區將佔全球銷售額的32%,年增率將達7.90%。中國政府的醫療保健支出以及中國中高階導管製造的擴張將支撐強勁的設備需求。日本公司正在完善其精密沉澱,而韓國電子巨頭則正在為影像感測器採用親水塗層,鞏固其在該地區的領先地位。

北美佔據關鍵的市場地位,擁有強大的醫療設備產品線和嚴格的美國要求,這些要求鼓勵優質塗料的發展。 EPA對PFAS的分類為快速再製造帶來了壓力,這使得擁有合規、高潤滑性化學品的國內供應商成為先行者。

永續性要求是歐洲市場的核心。即將推出的 PFAS 法規 REACH 正在加速向水性和紫外光固化系統的轉型,推動低 VOC 聚氨酯和環氧分散體的創新。當地原始設備製造商正在與材料專家合作,以在合規期限之前檢驗接觸角和細胞毒性性能。

拉丁美洲和中東及非洲正在興起,但仍在發展中,巴西導管製造商採用承包塗層模組來擴大出口,沙烏地阿拉伯根據「2030願景」投資先進材料,以促進區域對醫學認可塗層技術的需求。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場狀況

- 市場概況

- 市場促進因素

- 醫療保健應用需求不斷成長

- 塗層材料創新

- 光學和電子工業的進步

- 永續塗料的監管支持

- 符合歐洲 VOC 標準的水性和紫外線固化配方

- 市場限制

- 製造成本高

- 耐用性和性能問題

- 原物料價格波動

- 價值鏈分析

- 監理展望

- 五力分析

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

第5章市場規模及成長預測(金額)

- 透過基板

- 聚合物

- 玻璃/陶瓷

- 金屬

- 奈米顆粒相容

- 透過成膜技術

- 浸塗

- 噴霧和狹縫式

- 等離子和紫外線接枝

- 化學沉澱

- 其他技術

- 按用途

- 導管和導管導引線

- 支架和植入

- 光學鏡片和眼鏡鏡片

- 汽車感測器和攝影機

- 建築和太陽能玻璃

- 其他(海洋、紡織、航太)

- 按最終用戶產業

- 醫療設備

- 光學和光電

- 車

- 運輸/海運

- 其他行業

- 按地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 其他亞太地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 義大利

- 法國

- 其他歐洲國家

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地區

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 其他中東和非洲地區

- 亞太地區

第6章 競爭態勢

- 市場集中度

- 策略舉措

- 市佔率(%)/排名分析

- 公司簡介

- Aculon

- Applied Medical Coatings

- AST Products Inc.

- Biocoat Incorporated

- Coatings2Go

- dsm-firmenich

- Formacoat

- Harland Medical Systems, Inc.

- Hydromer

- Mitsubishi Chemical America, Inc.

- PPG Industries Inc.

- Specialty Coating Systems Inc.

- Surface Solutions Group LLC

- Surmodics Inc.

- Teleflex Incorporated

第7章 市場機會與未來展望

The Hydrophilic Coatings Market size is estimated at USD 7.09 billion in 2025, and is expected to reach USD 10.02 billion by 2030, at a CAGR of 7.13% during the forecast period (2025-2030).

Surging adoption across medical, optical and automotive applications, coupled with stricter sustainability mandates, underpins this growth. Polymer substrates still dominate but nanoparticle-enabled surfaces are eroding that lead, while Asia-Pacific delivers a geographic flywheel effect that is redrawing global supply chains. Intensifying price pressure on medical devices, tightening PFAS regulations and durability concerns continue to temper expansion; nevertheless, continuous materials innovation, streamlined deposition techniques and an expanding eco-system of PFAS-free solutions are widening commercial opportunities.

Global Hydrophilic Coatings Market Trends and Insights

Rising Demand in Healthcare Applications

Medical device designers rely on hydrophilic coatings to lower insertion forces and mitigate thrombosis in minimally invasive procedures. Clinical evidence shows up to 70% reduction in catheter friction, enabling smoother vascular navigation and shorter procedure times. Coatings that blend lubricity with antimicrobial or antithrombotic agents are gaining traction, especially for neurovascular stents, where surface-modified flow diverters reduce platelet adhesion and may lessen dual-antiplatelet therapy requirements. Hospitals now prioritize devices with such multifunctional layers because they shorten recovery and curb infection risk. In parallel, academic-industry collaborations are accelerating pre-clinical validation, further lifting adoption.

Technological Innovations in Coating Materials

Nanoparticle-enabled substrates redefine performance ceilings by combining high hydrophilicity, abrasion resistance, and controlled-release capability. Silica-poly(acrylic-acid) formulations retain super-hydrophilicity under mild wear, tackling a long-standing durability gap. Responsive hydrogels such as starPEG-heparin withstand shear forces during catheter deployment while delivering on-demand anticoagulation. These advances open new product architectures where coatings deliver dual roles-surface lubricity plus therapeutic functionality-without compromising mechanical integrity.

High Production Costs

Multi-step synthesis, clean-room deposition and intensive quality testing add 30-40% to manufacturing costs versus standard coatings, squeezing margins in price-sensitive catheter and guidewire lines. Specialized know-how remains concentrated among a handful of suppliers, limiting economies of scale and elevating switching costs for OEMs. Although process automation and roll-to-roll UV-cure systems are trimming cycle times, capital requirements deter smaller entrants.

Other drivers and restraints analyzed in the detailed report include:

- Advancements in Optical and Electronics Industries

- Regulatory Support for Sustainable Coatings

- Durability and Performance Concerns

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Nanoparticle-enabled substrates posted 7.80% CAGR and are eroding polymer's 48% revenue stronghold. Halloysite nanotube-reinforced epoxy acrylate emulsions showed zero rusting after 16 days of salt-spray exposure compared with 9 days for conventional polymers, signalling a clear durability leap. Superhydrophobic silica coatings with 162° contact angles on glass illustrate cross-substrate migration of nanotechnology benefits.

Manufacturers continue to favor polymers for cost-effective volume output, but hybrid designs that embed nano-silica or layered silicates within polymer matrices are reshaping the substrate hierarchy. These hybrids merge flexible processing windows with enhanced abrasion resistance, blurring category lines. Metal and glass substrates retain niche roles where biocompatibility or optical clarity are critical, yet even here, nanoscale interlayers are elevating adhesion and corrosion performance.

Dip-coating retained 42% revenue share in 2024. However, plasma and UV-graft routes, growing 7.7% annually, increasingly allow tailor-made surface chemistries on complex geometries without solvent carryover. Initiated Chemical Vapor Deposition (iCVD) creates gradient polymer layers that improve ice-phobicity and maintain hydrophilicity across temperature swings.

Spray and slot-die lines shrink cycle times, meeting rising catheter output targets. Chemical vapor deposition methods enable co-deposition of synergistic components, driving water contact angles down to 43.2°, thereby boosting coating uniformity and lifecycle stability.

The Hydrophilic Coatings Market Report Segments the Industry by Substrate (Polymer, Glass/Ceramic, and More), Deposition Technology (Dip-Coating, Spray and Slot-Die, and More), Application (Catheters and Guidewires, Stents and Implantables, and More), End-User Industry (Medical Devices, Optics and Photonics, and More), and Geography (Asia-Pacific, North America, Europe, South America, and Middle East and Africa).

Geography Analysis

Asia-Pacific generated 32% of global revenue in 2024 and will accelerate at 7.90% a year. Government healthcare spending and mid- to high-end catheter manufacturing expansion in China underpin robust device demand. Japanese firms refine precision deposition, and Korean electronics giants deploy hydrophilic coatings in image sensors, cementing regional leadership.

North America has a significant position in the market, buoyed by deep medical-device pipelines and strict FDA performance expectations that reward premium coatings. EPA's PFAS classification forces rapid reformulation; domestic suppliers that secure compliant, high-lubricity chemistries gain early mover status.

Europe's market centres on sustainability mandates. Imminent REACH curbs on PFAS accelerate migration toward water-borne and UV-cure systems, fostering innovation in low-VOC polyurethane and epoxy dispersions. Local OEMs partner with materials specialists to validate contact-angle and cytotoxicity performance ahead of compliance deadlines.

Latin America and the Middle East & Africa remain nascent but rising. Brazil's catheter producers incorporate turnkey coating modules as they scale exports, while Saudi Arabia invests in advanced materials under Vision 2030, nurturing regional demand for medically approved coating technologies.

- Aculon

- Applied Medical Coatings

- AST Products Inc.

- Biocoat Incorporated

- Coatings2Go

- dsm-firmenich

- Formacoat

- Harland Medical Systems, Inc.

- Hydromer

- Mitsubishi Chemical America, Inc.

- PPG Industries Inc.

- Specialty Coating Systems Inc.

- Surface Solutions Group LLC

- Surmodics Inc.

- Teleflex Incorporated

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Rising Demand in Healthcare Applications

- 4.2.2 Technological Innovations in Coating Materials

- 4.2.3 Advancements in Optical and Electronics Industries

- 4.2.4 Regulatory Support for Sustainable Coatings

- 4.2.5 VOC-Compliant Water-borne and UV-Cure Formulations in Europe

- 4.3 Market Restraints

- 4.3.1 High Production Costs

- 4.3.2 Durability and Performance Concerns

- 4.3.3 Volatility in Raw Material Prices

- 4.4 Value Chain Analysis

- 4.5 Regulatory Outlook

- 4.6 Porter's Five Forces

- 4.6.1 Bargaining Power of Suppliers

- 4.6.2 Bargaining Power of Buyers

- 4.6.3 Threat of New Entrants

- 4.6.4 Threat of Substitutes

- 4.6.5 Degree of Competition

5 Market Size and Growth Forecasts (Value )

- 5.1 By Substrate

- 5.1.1 Polymer

- 5.1.2 Glass / Ceramic

- 5.1.3 Metal

- 5.1.4 Nanoparticle-Enabled

- 5.2 By Deposition Technology

- 5.2.1 Dip-Coating

- 5.2.2 Spray and Slot-Die

- 5.2.3 Plasma and UV-Graft

- 5.2.4 Chemical Vapor Deposition

- 5.2.5 Other Technologies

- 5.3 By Application

- 5.3.1 Catheters and Guidewires

- 5.3.2 Stents and Implantables

- 5.3.3 Optical and Eyewear Lenses

- 5.3.4 Automotive Sensors and Cameras

- 5.3.5 Architectural and Solar Glass

- 5.3.6 Others (Marine, Textile, Aerospace)

- 5.4 By End-User Industry

- 5.4.1 Medical Devices

- 5.4.2 Optics and Photonics

- 5.4.3 Automotive

- 5.4.4 Transportation and Marine

- 5.4.5 Other Industries

- 5.5 By Geography

- 5.5.1 Asia-Pacific

- 5.5.1.1 China

- 5.5.1.2 India

- 5.5.1.3 Japan

- 5.5.1.4 South Korea

- 5.5.1.5 Rest of Asia-Pacific

- 5.5.2 North America

- 5.5.2.1 United States

- 5.5.2.2 Canada

- 5.5.2.3 Mexico

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 Italy

- 5.5.3.4 France

- 5.5.3.5 Rest of Europe

- 5.5.4 South America

- 5.5.4.1 Brazil

- 5.5.4.2 Argentina

- 5.5.4.3 Rest of South America

- 5.5.5 Middle East and Africa

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 South Africa

- 5.5.5.3 Rest of Middle East and Africa

- 5.5.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share(%)/ Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Aculon

- 6.4.2 Applied Medical Coatings

- 6.4.3 AST Products Inc.

- 6.4.4 Biocoat Incorporated

- 6.4.5 Coatings2Go

- 6.4.6 dsm-firmenich

- 6.4.7 Formacoat

- 6.4.8 Harland Medical Systems, Inc.

- 6.4.9 Hydromer

- 6.4.10 Mitsubishi Chemical America, Inc.

- 6.4.11 PPG Industries Inc.

- 6.4.12 Specialty Coating Systems Inc.

- 6.4.13 Surface Solutions Group LLC

- 6.4.14 Surmodics Inc.

- 6.4.15 Teleflex Incorporated

7 Market Opportunities and Future Outlook

- 7.1 Development of Eco-Friendly Coatings

- 7.2 White-space and Unmet-need Assessment