|

市場調查報告書

商品編碼

1844591

間二甲苯:市場佔有率分析、產業趨勢、統計、成長預測(2025-2030)Meta-Xylene - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

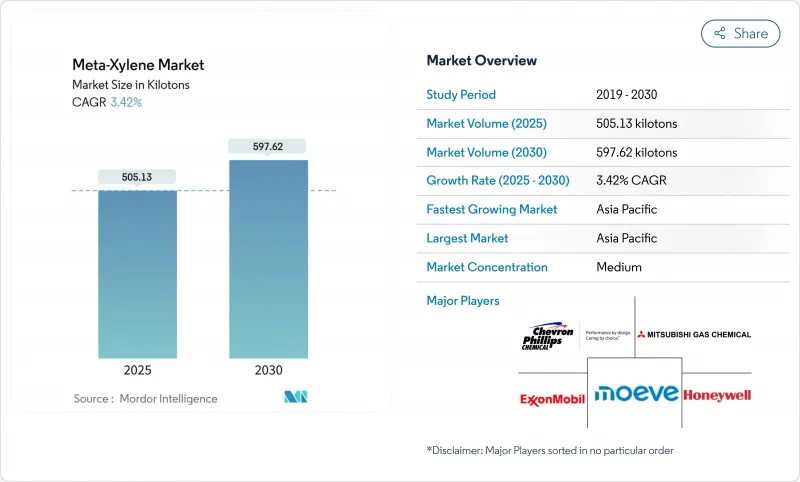

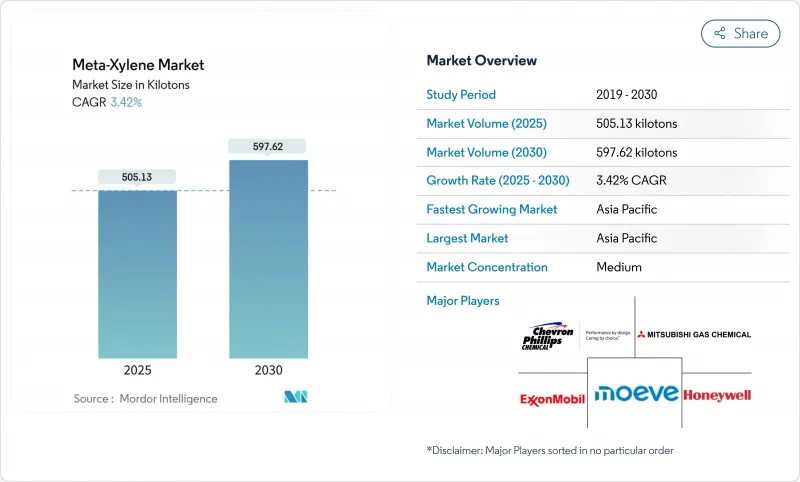

間二甲苯市場規模預計在 2025 年為 505.13 千噸,預計到 2030 年將達到 597.62 千噸,預測期內(2025-2030 年)的複合年成長率為 3.42%。

PET 和不飽和聚酯樹脂 (UPR) 的持續消費以及向低 VOC 和生物基塗料原料的轉變正在支撐產量成長,因為生產商利用間二甲苯作為間苯二甲酸的唯一原料。中國、印度和中東綜合芳烴聯合裝置的產能擴張正在平衡供需,而先進的萃取技術正在降低單位成本並提高純度閾值。在需求方面,控制溶劑排放的監管壓力正在減少整體溶劑用量,同時提高間二甲苯在優質高固態塗料中的平衡蒸發率的價值。隨著原油價格波動持續影響芳烴價差,跨國能源和化學巨頭與地區龍頭企業之間不斷變化的動態正在重塑競爭格局。

全球間二甲苯市場趨勢與洞察

PET 和 UPR 生產對間苯二甲酸的需求不斷成長

間苯二甲酸可提高改質PET的熱穩定性和氣體阻隔性能,使其成為高階瓶裝、薄膜和工業纖維的必需材料。當溫度超過標準PET閾值時,汽車和電子產品製造商會指定使用間苯二甲酸改質PET,這增強了對間二甲苯的拉動需求。創新管道越來越依賴5-夫喃甲醇(HMF)等可再生原料,一旦達到商業規模,隨著品牌所有者追求碳減排目標,生物基路線預計將在未來十年內獲得市場佔有率。在UPR中,間苯二甲酸可為風力發電機渦輪機機艙和海洋複合材料提供高耐腐蝕性,從而支援亞太地區造船廠和歐洲海上設施結構應用的成長。因此,對PET和UPR的雙重需求將對間二甲苯市場的發展軌跡產生最強烈的正面影響。

轉向高固態/低VOC工業塗料

美國環保署 (EPA) 2024 年《危害通報標準》更新版收緊了二甲苯衍生物的標籤限制,促使配方設計師轉向仍依賴間二甲苯有效控制黏度的高固態系統。歐洲的脫碳藍圖同樣鼓勵低 VOC 塗料,並敦促以間二甲苯溫和的蒸發特性取代更輕、蒸發更快的溶劑。雖然水性塗料降低了總溶劑含量,但高階建築和工業維護產品仍繼續使用間二甲苯作為成膜助劑,從而在整個預測期內保持需求。

毒性和可燃性特徵推動更嚴格的暴露限制

美國有毒物質與疾病登記署 (ATSDR) 已強調慢性二甲苯暴露可能引發神經系統問題,歐洲監管機構正在考慮降低 8 小時時間加權平均 (TWA) 職業暴露限值。加強通風、安裝火花阻火系統和個人防護設備會增加生產成本,尤其是在小型或獨立設施中。在可行的情況下,塗料製造商正在嘗試替代溶劑,但間二甲苯獨特的溶解性和加工特性使其無法完全替代,從而減少了需求,但並未消除需求。

細分分析

到2024年,間苯二甲酸產量將佔間二甲苯市場規模的最大佔有率,達到46.17%,證實了該領域在高性能寶特瓶和耐腐蝕UPR層壓板領域的強勁地位。向生物基間苯二甲酸的轉變正在推進,預計到2030年,其複合年成長率將達到6.90%。歐洲和日本的早期採用者已開始認證物料平衡程序,以獲取品牌商的溢價,而亞洲生產商正在毗鄰生質能供應走廊建設待開發區設施。

從中期來看,儘管對2,4-二甲基苯胺和2,6-二甲基苯胺的毒性監管擔憂,但其衍生的農業化學品和醫藥中間體仍可能維持利基市場需求。溶劑應用雖然絕對噸位下降,但由於特種電子和醫藥清潔領域需要間二甲苯較窄的沸程,因此表現出價值韌性。總體而言,應用結構正在從依賴大宗溶劑轉向利潤率更高的樹脂和特種化學品應用,儘管整體成長溫和,但整體盈利有所提升。

間二甲苯市場報告按用途(間苯二甲酸、2,4-二甲基苯胺和2,6-二甲基苯胺等)、終端用戶行業(建築和基礎設施、包裝、汽車和運輸等)、純度/等級(高純度間二甲苯、工業級間二甲苯等)和地區(亞太地區、北美、歐洲、南美、中東和非洲)細分。市場預測以噸為單位。

區域分析

預計到2024年,亞太地區將佔全球銷售量的53.45%,到2030年的複合年成長率為5.50%。中國舟山芳烴中心和廣東中海殼牌合資企業將分別提高區域自給率,並抑制來自美國和歐洲的進口。印度870億美元的石化藍圖旨在2035年將國內二甲苯產能提升至550萬噸,確保下游聚酯、塗料和醫藥原料的供應。由於來自中國的出口競爭日益激烈,日本和韓國面臨結構性利潤壓力,迫使它們轉向高純度特殊產品和差異化配方。

北美憑藉其卓越的分離技術、豐富的頁岩油資源以及接近性龐大的塗料基本客群,依然具有重要的戰略意義。然而,不斷上升的能源成本壓力和日益嚴格的環保合規要求正在推高營運成本。雪佛龍可能以150億美元收購菲利普斯66(Phillips 66)在CPChem的股份,這凸顯了該地區企業追求規模和原料整合優勢的整合趨勢。墨西哥新興的汽車價值鏈刺激了對溶劑和樹脂的需求,但嚴重依賴從美國的進口,凸顯了USMCA關稅穩定的重要性。

歐洲面臨最嚴峻的營運挑戰,高昂的能源成本和嚴格的碳排放政策阻礙了對大宗芳烴的新投資。 《歐洲綠色新政》的碳邊境調整機製或許能在一定程度上保護國內生產,但也增加了行政管理的複雜性。殼牌宣布將在2030年前退出基礎化學品市場,這標誌著國際能源巨頭將資本重新配置到液化天然氣和可再生能源領域。剩餘的歐洲生產商將專注於生物基間苯二甲酸和循環PET原料,並利用氣候中性材料的監管獎勵。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場狀況

- 市場概況

- 市場促進因素

- PET 和 UPR 生產對間苯二甲酸的需求不斷成長

- 轉向高固態/低VOC工業塗料

- 提高PX-MX芳烴聯合裝置的產能

- 油漆和塗料行業需求增加

- 汽車產業擴張

- 市場限制

- 透過毒性和可燃性概況加強暴露監管

- 原油價格波動對芳烴價差產生連鎖反應

- 資本密集型異構體分離技術阻礙新進者

- 價值鏈分析

- 五力分析

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 產業競爭

第5章市場規模及成長預測(數量)

- 按用途

- 間苯二甲酸

- 2,4-和2,6-二甲基苯胺

- 溶劑

- 其他用途(農藥中間體等)

- 按最終用戶產業

- 建築和基礎設施

- 包裝

- 汽車和運輸

- 藥品及農藥

- 電氣和電子

- 按純度和等級

- 99.9% 或更高 MX(高純度)

- 工業級 MX

- 混合二甲苯流

- 按地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 其他亞太地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 其他歐洲國家

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地區

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 其他中東和非洲地區

- 亞太地區

第6章 競爭態勢

- 市場集中度

- 策略舉措

- 市佔率(%)/排名分析

- 公司簡介

- Avantor, Inc.

- Chevron Phillips Chemical Company LLC

- Exxon Mobil Corporation

- Hengli Petrochemical

- Honeywell International Inc.

- JXTG Nippon Oil & Energy

- LOTTE Chemical CORPORATION

- MITSUBISHI GAS CHEMICAL COMPANY, INC.

- Moeve

- Shell Chemicals

- S-OIL CORPORATION

- Suzhou Jiutai Group Co., Ltd.

- Vizag Chemicals

第7章 市場機會與未來展望

The Meta-Xylene Market size is estimated at 505.13 kilotons in 2025, and is expected to reach 597.62 kilotons by 2030, at a CAGR of 3.42% during the forecast period (2025-2030).

Sustained PET and unsaturated polyester resin (UPR) consumption, together with a shift toward low-VOC and bio-based coating ingredients, underpins volume growth as producers leverage meta-xylene's role as the sole feedstock for isophthalic acid. Capacity additions inside integrated aromatics complexes across China, India, and the Middle East keep supply aligned with demand, while advanced extraction technologies lower unit costs and improve purity thresholds. On the demand side, regulatory pressure to curb solvent emissions is simultaneously reducing overall solvent volumes yet elevating the value of meta-xylene's balanced evaporation rate in premium, high-solids paints. As crude price volatility continues to influence aromatics spreads, the evolving dynamics among multinational energy-chemical giants and regional champions are reshaping the competitive landscape.

Global Meta-Xylene Market Trends and Insights

Growing Demand for Isophthalic Acid in PET & UPR Production

Isophthalic acid enhances thermal stability and gas-barrier performance in modified PET, making it indispensable for premium bottles, films and industrial fibers. Automotive and electronics manufacturers specify isophthalic acid-modified PET when temperatures exceed standard PET thresholds, reinforcing pull-through demand for meta-xylene. Innovation pipelines increasingly rely on renewable feedstocks such as 5-hydroxymethylfurfural (HMF); once commercial scale is reached, bio-based routes are expected to capture share within the next decade as brand owners pursue carbon-reduction goals. In UPR, isophthalic acid delivers higher corrosion resistance in wind-turbine nacelles and marine composites, supporting structural applications growth across Asia-Pacific shipyards and European offshore installations. The dual demand from PET and UPR accordingly registers the strongest positive impact on the meta-xylene market trajectory.

Shift Toward High-Solids/Low-VOC Industrial Coatings

The United States Environmental Protection Agency's 2024 Hazard Communication Standard update tightened labeling norms for xylene derivatives, pushing formulators toward higher-solids systems that still rely on meta-xylene for effective viscosity control. Europe's decarbonization roadmap similarly incentivizes low-VOC coatings, driving substitution of lighter, faster-evaporating solvents in favor of meta-xylene's more moderate evaporation profile. Although waterborne paints reduce aggregate solvent volumes, premium architectural and industrial maintenance products continue to incorporate meta-xylene as a coalescent aid, preserving demand through the forecast period.

Toxicological & Flammability Profile Driving Stricter Exposure Limits

The Agency for Toxic Substances and Disease Registry (ATSDR) underscores neurological concerns linked to chronic xylene exposure, prompting European regulators to contemplate lowering the 8-hour TWA occupational limit. Implementing enhanced ventilation, spark-proof handling systems, and personal protective equipment raises production costs, especially for small or standalone facilities. Where viable, coatings producers experiment with alternative solvents, yet meta-xylene's unique solvency and processing characteristics hinder full substitution, tempering but not eliminating demand.

Other drivers and restraints analyzed in the detailed report include:

- Capacity Expansions in Integrated PX-MX Aromatics Complexes

- Increasing Demand from Paints and Coatings Sector

- Crude-Oil Price Volatility Cascading to Aromatics Spreads

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Isophthalic acid production accounted for the largest share of the meta-xylene market size, at 46.17% in 2024, underscoring the segment's entrenched role in high-performance PET bottles and corrosion-resistant UPR laminates. The progressive switch toward bio-based isophthalic acid, projected to grow at 6.90% CAGR to 2030, signals a structural realignment in feedstock sourcing as renewable chemistries enter commercial deployment. Early adopters in Europe and Japan already certify mass-balance routines to capture brandowner premiums, while Asian producers erect greenfield units adjacent to biomass supply corridors.

Over the medium term, pesticide and pharmaceutical intermediates derived from 2,4- and 2,6-xylidine will preserve niche demand despite regulatory concerns around toxicology. Solvent applications shrink in absolute tonnage but exhibit value resilience where specialty electronics and pharmaceutical cleaning require meta-xylene's narrow boiling range. Taken together, the application mix is migrating from bulk solvent dependency toward higher-margin resin and specialty chemical use, elevating overall profitability despite moderate headline growth.

The Meta-Xylene Market Report is Segmented by Application (Isophthalic Acid, 2, 4- & 2, 6-Xylidine, and More), End-User Industry (Construction & Infrastructure, Packaging, Automotive & Transportation, and More), Purity/Grade (High-Purity MX, Industrial-Grade MX, and More), and Geography (Asia-Pacific, North America, Europe, South America, Middle East and Africa). The Market Forecasts are Provided in Terms of Volume (tons).

Geography Analysis

Asia-Pacific captured 53.45% of global volumes in 2024 and is forecast to clock a 5.50% CAGR through 2030, driven by vertically integrated complexes across China and India that harness feedstock flexibility and scale economics. China's Zhoushan aromatics hub and Guangdong CNOOC-Shell joint venture each broaden regional self-sufficiency, curbing import requirements from the United States and Europe. India's USD 87 billion petrochemical blueprint seeks to raise domestic xylene capacity to 5.5 million t by 2035, securing raw material availability for downstream polyester, coatings, and pharma corridors. Japan and South Korea confront structural margin pressure as Chinese exports intensify competition, spurring these economies to pivot toward high-purity specialties and differentiated formulations.

North America retains strategic significance through superior separation technologies, abundant shale-derived naphtha and proximity to a vast coatings customer base. However, upward pressure on energy costs and tightening environmental compliance increase operating expenditure. Chevron's potential USD 15 billion acquisition of Phillips 66's CPChem stake underscores the region's consolidation trajectory as companies chase scale and feedstock integration benefits. Mexico's emerging automotive value chain stimulates solvent and resin demand but relies heavily on United States imports, illustrating the importance of the USMCA's tariff stability.

Europe confronts the steepest operating challenges, with high utility costs and stringent carbon policies discouraging fresh investment in commodity aromatics. The European Green Deal's evolving carbon-border adjustment mechanism may partially shield domestic output yet adds administrative complexity. Shell's announcement to exit base chemicals by 2030 typifies how international energy majors reallocate capital toward LNG and renewables. Remaining European producers emphasize bio-based isophthalic acid and circular PET feedstocks, capitalizing on regulatory incentives for climate-neutral materials.

- Avantor, Inc.

- Chevron Phillips Chemical Company LLC

- Exxon Mobil Corporation

- Hengli Petrochemical

- Honeywell International Inc.

- JXTG Nippon Oil & Energy

- LOTTE Chemical CORPORATION

- MITSUBISHI GAS CHEMICAL COMPANY, INC.

- Moeve

- Shell Chemicals

- S-OIL CORPORATION

- Suzhou Jiutai Group Co., Ltd.

- Vizag Chemicals

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Growing demand for isophthalic acid in PET and UPR production

- 4.2.2 Shift toward high-solids/low-VOC industrial coatings

- 4.2.3 Capacity expansions in integrated PX-MX aromatics complexes

- 4.2.4 Increasing demand from paints and coatings sector

- 4.2.5 Expansion of the automotive sector

- 4.3 Market Restraints

- 4.3.1 Toxicological and flammability profile driving stricter exposure limits

- 4.3.2 Crude-oil price volatility cascading to aromatics spreads

- 4.3.3 Capital-intensive isomer separation technology deterring newcomers

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Industry Rivalry

5 Market Size and Growth Forecasts (Volume)

- 5.1 By Application

- 5.1.1 Isophthalic Acid

- 5.1.2 2,4- and 2,6-Xylidine

- 5.1.3 Solvents

- 5.1.4 Other Applications (Pesticide Intermediates, etc.)

- 5.2 By End-user Industry

- 5.2.1 Construction and Infrastructure

- 5.2.2 Packaging

- 5.2.3 Automotive and Transportation

- 5.2.4 Pharmaceuticals and Agrochemicals

- 5.2.5 Electrical and Electronics

- 5.3 By Purity/Grade

- 5.3.1 Greater than or equal to 99.9 % MX (High-Purity)

- 5.3.2 Industrial-Grade MX

- 5.3.3 Mixed Xylenes Stream

- 5.4 By Geography

- 5.4.1 Asia-Pacific

- 5.4.1.1 China

- 5.4.1.2 India

- 5.4.1.3 Japan

- 5.4.1.4 South Korea

- 5.4.1.5 Rest of Asia-Pacific

- 5.4.2 North America

- 5.4.2.1 United States

- 5.4.2.2 Canada

- 5.4.2.3 Mexico

- 5.4.3 Europe

- 5.4.3.1 Germany

- 5.4.3.2 United Kingdom

- 5.4.3.3 France

- 5.4.3.4 Italy

- 5.4.3.5 Rest of Europe

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Rest of South America

- 5.4.5 Middle East and Africa

- 5.4.5.1 Saudi Arabia

- 5.4.5.2 South Africa

- 5.4.5.3 Rest of Middle-East and Africa

- 5.4.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share(%)/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Avantor, Inc.

- 6.4.2 Chevron Phillips Chemical Company LLC

- 6.4.3 Exxon Mobil Corporation

- 6.4.4 Hengli Petrochemical

- 6.4.5 Honeywell International Inc.

- 6.4.6 JXTG Nippon Oil & Energy

- 6.4.7 LOTTE Chemical CORPORATION

- 6.4.8 MITSUBISHI GAS CHEMICAL COMPANY, INC.

- 6.4.9 Moeve

- 6.4.10 Shell Chemicals

- 6.4.11 S-OIL CORPORATION

- 6.4.12 Suzhou Jiutai Group Co., Ltd.

- 6.4.13 Vizag Chemicals

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-Need Assessment