|

市場調查報告書

商品編碼

1842572

簧片感測器:市場佔有率分析、行業趨勢、統計數據和成長預測(2025-2030 年)Reed Sensor - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

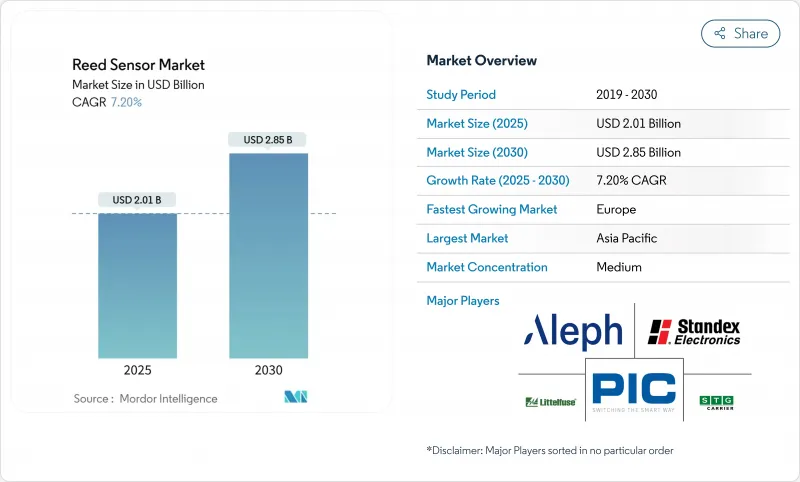

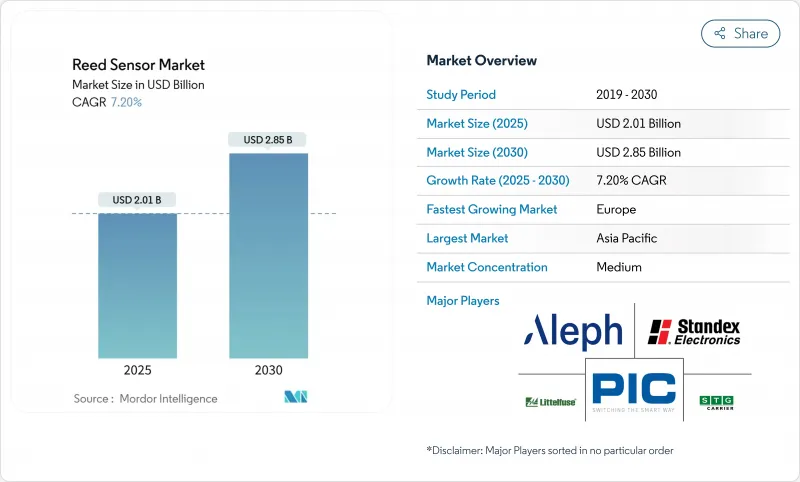

預計 2025 年簧片感測器市場規模將達到 20.1 億美元,預計 2030 年將達到 28.5 億美元,預測期內(2025-2030 年)的複合年成長率為 7.20%。

電動車電池組、氫燃料電池堆和戶外智慧電錶機殼對本質安全開關的需求不斷成長,推動了這項擴張。磁簧感應器市場憑藉其無火花運作、零待機功耗以及在惡劣條件下20年久經考驗的現場可靠性,繼續捍衛其在固態霍爾和TMR替代品領域的市場地位。亞太地區仍然是生產領域的領導者,歐洲監管機構對可再生能源和功能安全的推動推動了該地區的快速成長。競爭強度適中,全球領導者利用規模效應、垂直整合的玻璃加工以及奈米結構觸點等材料創新來延長產品壽命並降低成本。

全球磁簧感應器市場趨勢與洞察

低功耗智慧電網電錶的普及

公共產業擴大將傳統傳統儀錶替換為20年免維護的智慧型設備,並指定使用簧片開關進行脈衝計數,因為磁驅動技術可實現零待機功耗。密封設計可防止室外機殼凝結,使其使用壽命從-40°C延長至+85°C。 Gridpertise等公司已大規模部署簧片開關,目前已超過1.08億台,證明了簧片開關設計的可擴充性。波蘭的Tauron Dystrybucja公司已透過依賴磁脈衝完整性的自動抄表服務為560萬客戶提供服務。到2030年,電網的持續數位化將持續推動對穩定可靠、獨立於電池的開關的需求。

採用電動車電池管理

電動和氫動力汽車的電池組需要可靠、無火花的定位和洩漏檢測。大陸集團的電動馬達轉子溫度感測器將溫度誤差降低至3°C,並透過磁體最佳化提高效率。霍尼韋爾的電解洩漏感測器採用密封觸點,避免點火源,並為熱失控事件提供20分鐘的預警窗口。馬夸特公司將簧片元件應用於氫電池電壓監測器,可在災難性故障發生前發現氫氣洩漏。電動車的加速普及將推動簧片感測器市場達到2.1個百分點的複合年成長率。

固態感測器替代品

霍爾效應和TMR IC現已配備封裝內診斷功能並符合ASIL-D標準,這增加了汽車轉向和踏板模組的競爭壓力。電感線性感測器在12毫米範圍內的精度可達±0.85%,超過了典型的引線公差。這些固態技術的進步導致磁簧感應器市場的複合年成長率下降了1.4個百分點,儘管價格敏感的警報器和液位計仍然選擇使用引線元件。

細分分析

到2024年,表面黏著技術元件將佔據簧片感測器市場佔有率的38.7%。受工業自動化趨勢的推動,用於氣缸的螺紋筒感測器將以8.3%的複合年成長率成長,這將推動簧片感測器市場的整體成長。簧片感測器產業仍將保留用於傳統電器的通孔型感測器,而法蘭封裝將確保航太對密封的需求。 Firecracker封裝非常適合筆記型電腦蓋檢測,因為高尺寸至關重要。在預測期內,SMD的採用將減少組裝工作量,為穿戴式裝置帶來設計機遇,並為主要供應商維持規模化價格優勢。

螺紋筒體產品的需求,加上棕地工廠中回饋點數量的激增,正在產生持續的吸引力。圓柱形外殼可保護接觸點免受油污和金屬碎屑的侵蝕,從而降低保固索賠率。預計到2030年,此類重型設備的磁簧感應器市場規模將以8.3%的複合年成長率成長,新增6.3億美元的收益。生產線製造商青睞無需更換支架即可改裝的螺紋嵌件,這表明機械相容性可以保護簧片感測器市場免於被快速替代。

到2024年,A型開關將佔據簧片感測器市場的41.3%,因為其常開電路可為安防和液位警報提供故障安全邏輯。然而,由於電池供電的物聯網標籤需要接近零的靜態電流,鎖存型E型開關的複合年成長率最高,將達到8.6%。奈米結構觸點的進步使其使用壽命延長了四倍,加速了其在智慧電錶和資產追蹤設備中的應用。

Form B 常閉型用於暖通空調 (HVAC) 風扇防護罩,而 Form C 轉換接點則由 PLC 控制的製程閥支援。預計到 2030 年,雙穩態 Form E 型磁簧感應器市場規模將達到 4.2 億美元,這將推動傳統磁簧繼電器向佔空比無線節點的轉變。由於這些設備無需通電即可保持其狀態,維護團隊可以降低維護頻率,從而顯著節省營運成本,從而增強簧片感測器行業的整體應用曲線。

簧片感測器市場按安裝類型(表面黏著技術、PCB通孔等)、接觸位置(A型(SPST-NO)、B型(SPST-NC)、其他)、開關能力(低壓/訊號(小於30V)、中壓(30-200V)、其他)、應用(汽車、家電、其他)和地區細分。市場預測以美元計算。

區域分析

受中國2,850億元人民幣感測器經濟規模和高密度玻璃管製造基地的推動,到2024年,亞太地區將佔據簧片感測器市場的40.4%。國家鼓勵電動車在地採購和智慧工廠建設的政策,正推動汽車製造商轉向國內領先供應商,但進口特殊玻璃仍然是高壓等級產品的基礎。日本的精密製程控制和韓國的智慧型手機組裝確保了穩定的大眾消費,而印度乘用車製造業則推動了新型車門敏捷功能的安裝,從而提振了整體需求。

歐洲是成長最快的地區,到2030年,複合年成長率將達到8.6%,因為歐7法規加強了功能安全性,並要求離岸風力發電使用密封限位開關。 SICK和Endress+Hauser成立的合資公司擁有730名員工,是流程分析領域區域整合的典範,該公司整合了簧片觸點以實現可靠的流量測量。北歐公用事業公司也將電子機械儀表替換為智慧終端,實現了銷售成長。一家德國機械製造商正在將螺紋筒感測器整合到氣動滑塊中,從而增強了該地區工業簧片的銷售量。

北美正以中等個位數的健康速度發展。公共指定戶外智慧電錶的使用壽命為20年,通常依賴簧片脈衝觸點。 Littelfuse 2025年第一季營收5.54億美元,凸顯了需求的韌性,因為資料中心配電和電動車服務設備推動了感測器的普及。航太對軍用規格玻璃和接點的需求確保了美國利基供應商的收益。墨西哥一家輕型卡車工廠增加了車門和安全帶開關,加拿大的一個可再生能源計劃擴大了高壓應用的機會。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場狀況

- 市場概況

- 市場促進因素

- 低功耗智慧電網電錶的普及

- 採用電動車電池管理

- 工業4.0維修和自動化

- 智慧家庭和物聯網設備的興起

- 氫燃料電池安全系統

- 用於一次性醫療設備的小型感測器

- 市場限制

- 固態(霍爾/TMR)感知器更換

- 高振動區域的可靠性問題

- 玻璃管供應鏈限制

- 高密度電動車動力傳動系統中的EMI問題

- 產業價值鏈分析

- 監管狀況

- 技術展望

- 產業吸引力-波特五力分析

- 新進入者的威脅

- 買方的議價能力

- 供應商的議價能力

- 替代品的威脅

- 競爭對手之間的競爭

- 宏觀經濟因素如何影響市場

第5章市場規模及成長預測(金額)

- 按安裝類型

- 表面黏著技術(SMD)

- PCB通孔

- 螺紋筒

- 法蘭/扁平封裝

- 圓柱形/爆竹形

- 槓桿臂

- 浮動/水平

- 其他

- 按接觸位置

- A型(SPST-NO)

- B型(單刀單擲-常閉)

- C型(SPDT)

- E型(閉鎖型)

- 其他

- 按切換容量

- 低電壓/訊號(<30 V)

- 中壓(30-200 V)

- 高電壓(>200 V)

- 大電流(>1A)

- 高耐熱性

- 其他

- 按用途

- 車

- 家電

- 工業自動化與機器人

- 安全與安保系統

- 醫療保健和醫療設備

- 資訊科技/通訊

- 其他應用

- 按地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 南美洲

- 巴西

- 阿根廷

- 智利

- 南美洲其他地區

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 俄羅斯

- 其他歐洲國家

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 台灣

- 馬來西亞

- 澳洲

- 其他亞太地區

- 中東和非洲

- 中東

- 阿拉伯聯合大公國

- 沙烏地阿拉伯

- 土耳其

- 其他中東地區

- 非洲

- 南非

- 奈及利亞

- 其他非洲國家

- 北美洲

第6章 競爭態勢

- 市場集中度

- 策略舉措

- 市佔率分析

- 公司簡介

- Littelfuse Inc.

- Standex Electronics Inc.

- PIC GmbH

- Aleph Holdings Co. Ltd.

- STG Germany GmbH

- Coto Technology Inc.

- Reed Switch Developments Corp.

- ZF Friedrichshafen AG

- Reed Relays & Electronics India Ltd.

- WIKA Instruments India Pvt Ltd.

- HSI Sensing

- Magnasphere Corp.

- Hamlin Electronics(Littelfuse)

- Sensata Technologies

- Comus International

- MEDER electronic

- Schneider Electric(SE)

- SMC Corporation

- NTE Electronics Inc.

- TE Connectivity

- OKI Sensor Device Corp.

- Changjiang Electronics Tech

- Zhejiang Xurui Electronic Co.

- Shanghai Kaiyuan Microelectronics

- HOKUYO Automatic Co. Ltd.

第7章 市場機會與未來趨勢

- 閒置頻段和未滿足需求評估

The Reed Sensor Market size is estimated at USD 2.01 billion in 2025, and is expected to reach USD 2.85 billion by 2030, at a CAGR of 7.20% during the forecast period (2025-2030).

Rising demand for intrinsically safe, hermetically sealed switching in electric-vehicle battery packs, hydrogen fuel-cell stacks, and outdoor smart-meter enclosures underpins this expansion. The reed sensor market continues to defend its niche against solid-state Hall and TMR alternatives by offering spark-free operation, zero-standby-power consumption, and proven 20-year field reliability in harsh conditions. Asia-Pacific remains the production engine, but Europe's regulatory push for renewable energy and functional safety drives the fastest regional growth. Competitive intensity is moderate: global leaders leverage scale, vertically integrated glass processing, and material innovations such as nanostructured contacts to stretch product life and lower cost.

Global Reed Sensor Market Trends and Insights

Surge in Low-Power Smart-Grid Metering

Utilities replacing legacy meters with 20-year maintenance-free smart devices increasingly specify reed switches for pulse counting because magnetic actuation draws zero standby power. Hermetic sealing prevents condensation in outdoor enclosures, extending service life across -40 °C to +85 °C. Large-scale rollouts by firms such as Gridspertise-now surpassing 108 million units-confirm the scalability of reed-based designs. Poland's Tauron Dystrybucja already manages 5.6 million customers via automated reading that depends on magnetic pulse integrity. Continued grid digitalization until 2030 sustains demand for robust, battery-independent switching.

EV Battery-Management Adoption

Battery packs in electric and hydrogen vehicles require spark-free, reliable position and leakage sensing. Continental's e-Motor Rotor Temperature Sensor trims temperature error to 3 °C, improving magnet optimization for efficiency. Honeywell's electrolyte-leak sensor offers a 20-minute warning window for thermal-runaway events, using hermetically sealed contacts to avoid ignition sources. Marquardt applies reed elements in hydrogen cell voltage monitors to catch H2 leaks before catastrophic failure. Accelerating EV adoption, therefore, adds a 2.1 percentage-point lift to the reed sensor market CAGR.

Solid-State Sensor Substitution

Hall and TMR ICs now ship with in-package diagnostics and ASIL-D compliance, raising competitive pressure in automotive steering and pedal modules. Inductive linear sensors achieve +-0.85% accuracy over 12 mm, eclipsing typical reed tolerances. These solid-state gains shave 1.4 percentage points from the reed sensor market CAGR, though price-sensitive alarms and liquid-level gauges still choose reed parts.

Other drivers and restraints analyzed in the detailed report include:

- Industrial-4.0 Retrofits and Automation

- Smart-Home and IoT Device Proliferation

- Reliability Issues in High-Vibration Zones

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Surface-mount devices delivered 38.7% of the reed sensor market share in 2024, reflecting automated pick-and-place economics on high-volume consumer boards. Threaded-barrel sensors for pneumatic cylinders shape the strongest 8.3% CAGR, aligned with the industrial automation wave that lifts overall reed sensor market growth. The reed sensor industry also retains through-hole models for legacy appliances, while flange packages secure aerospace demand for hermeticity. Firecracker formats suit laptop lid detection, where profile height is paramount. Over the forecast period, SMD adoption lowers assembly labor, widens design wins in wearables, and sustains at-scale pricing advantages for leading suppliers.

Demand for threaded-barrel products pairs with a proliferation of cylinder-count feedback points in brownfield factories, creating sustained pull. Cylindrical housings safeguard contacts from oil and metal shavings, keeping warranty claims low. The reed sensor market size for these rugged units is forecast to expand at an 8.3 % CAGR to 2030, translating into USD 0.63 billion of incremental revenue. Line builders prefer threaded inserts because they retrofit without bracket changes, illustrating how mechanical compatibility protects the reed sensor market from quick substitutability.

Form A switches commanded 41.3% of the reed sensor market in 2024 because normally-open circuits provide fail-safe logic in security and liquid-level alarms. Latching Form E designs, however, log the highest 8.6% CAGR as battery-run IoT tags seek near-zero quiescent current. Advancements in nanostructured contacts quadruple life cycles, bolstering uptake in smart meters and asset trackers.

Form B normally-closed types cater to HVAC fan guards, while Form C changeover contacts find traction in PLC-controlled process valves. The reed sensor market size for bistable Form E models is set to reach USD 0.42 billion by 2030, capitalizing on the migration of legacy reed relays to duty-cycled wireless nodes. As these devices remember state without power, maintenance teams cut service frequency, adding quantifiable OPEX savings that reinforce the adoption curve across the reed sensor industry.

Reed Sensor Market is Segmented by Mounting Type (Surface Mount, PCB Through-Hole, and More), Contact Position (Form A (SPST-NO), Form B (SPST-NC), and More), Switching Capability (Low-Voltage/Signal (<30 V), Medium-Voltage (30-200 V), and More), Application (Automotive, Consumer Electronics and Home Appliances, and More), and Geography. The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific generated 40.4% of the reed sensor market revenue in 2024, powered by China's CNY 285 billion sensor economy and its dense glass-tube manufacturing base. National incentives for local content in electric vehicles and smart factories steer OEMs toward domestic reed suppliers, yet imported specialty glass still underpins high-voltage grades. Japan's precision process control and South Korea's smartphone assembly ensure steady high-volume consumption, while India's passenger-car build-out triggers new door-ajar fitments that raise overall demand.

Europe is the fastest-growing region at an 8.6% CAGR through 2030 as Euro 7 rules tighten functional safety and as offshore wind farms require hermetically sealed limit switches. SICK and Endress+Hauser's 730-staff joint venture exemplifies regional consolidation in process analytics that integrates reed contacts for reliable flow measurement. Nordic utilities swapping 100% of electromechanical meters for smart endpoints also lift volumes. German machine builders embed threaded-barrel sensors into pneumatic slides, reinforcing the region's pull on industrial-grade reed volume.

North America advances at a healthy mid-single-digit pace. Utilities specify 20-year outdoor smart meters that often rely on reed pulse contacts; state decarbonization mandates accelerate rollouts. Littelfuse's USD 554 million Q1 2025 revenue underscores demand resilience, with data-center power distribution and EV service equipment fueling sensor uptake. Aerospace requirements for Mil-Spec glass and contacts keep US niche suppliers profitable. Mexico's light-truck plants add door and seat-belt switches, while Canadian renewables projects expand high-voltage application opportunities.

- Littelfuse Inc.

- Standex Electronics Inc.

- PIC GmbH

- Aleph Holdings Co. Ltd.

- STG Germany GmbH

- Coto Technology Inc.

- Reed Switch Developments Corp.

- ZF Friedrichshafen AG

- Reed Relays & Electronics India Ltd.

- WIKA Instruments India Pvt Ltd.

- HSI Sensing

- Magnasphere Corp.

- Hamlin Electronics (Littelfuse)

- Sensata Technologies

- Comus International

- MEDER electronic

- Schneider Electric (SE)

- SMC Corporation

- NTE Electronics Inc.

- TE Connectivity

- OKI Sensor Device Corp.

- Changjiang Electronics Tech

- Zhejiang Xurui Electronic Co.

- Shanghai Kaiyuan Microelectronics

- HOKUYO Automatic Co. Ltd.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Surge in low-power smart-grid metering

- 4.2.2 EV battery-management adoption

- 4.2.3 Industrial-4.0 retrofits and automation

- 4.2.4 Smart-home and IoT device proliferation

- 4.2.5 Hydrogen fuel-cell safety systems

- 4.2.6 Disposable medical-device mini-sensors

- 4.3 Market Restraints

- 4.3.1 Solid-state (Hall/TMR) sensor substitution

- 4.3.2 Reliability issues in high-vibration zones

- 4.3.3 Glass-tube supply-chain constraints

- 4.3.4 EMI issues in dense EV powertrains

- 4.4 Industry Value Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Industry Attractiveness - Porter's Five Forces Analysis

- 4.7.1 Threat of New Entrants

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Bargaining Power of Suppliers

- 4.7.4 Threat of Substitutes

- 4.7.5 Intensity of Competitive Rivalry

- 4.8 Impact of Macroeconomic Factors on the Market

5 MARKET SIZE AND GROWTH FORECASTS (VALUES)

- 5.1 By Mounting Type

- 5.1.1 Surface Mount (SMD)

- 5.1.2 PCB Through-Hole

- 5.1.3 Threaded Barrel

- 5.1.4 Flange/Flat Pack

- 5.1.5 Cylindrical/Firecracker

- 5.1.6 Lever Arm

- 5.1.7 Float/Level

- 5.1.8 Others

- 5.2 By Contact Position

- 5.2.1 Form A (SPST-NO)

- 5.2.2 Form B (SPST-NC)

- 5.2.3 Form C (SPDT)

- 5.2.4 Form E (Latching)

- 5.2.5 Others

- 5.3 By Switching Capability

- 5.3.1 Low-Voltage/Signal (<30 V)

- 5.3.2 Medium-Voltage (30-200 V)

- 5.3.3 High-Voltage (>200 V)

- 5.3.4 High-Current (>1 A)

- 5.3.5 High-Temp-Resistant

- 5.3.6 Others

- 5.4 By Application

- 5.4.1 Automotive

- 5.4.2 Consumer Electronics and Home Appliances

- 5.4.3 Industrial Automation and Robotics

- 5.4.4 Safety and Security Systems

- 5.4.5 Healthcare and Medical Devices

- 5.4.6 Telecommunications and IT

- 5.4.7 Other Applications

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 South America

- 5.5.2.1 Brazil

- 5.5.2.2 Argentina

- 5.5.2.3 Chile

- 5.5.2.4 Rest of South America

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Spain

- 5.5.3.6 Russia

- 5.5.3.7 Rest of Europe

- 5.5.4 Asia-Pacific

- 5.5.4.1 China

- 5.5.4.2 India

- 5.5.4.3 Japan

- 5.5.4.4 South Korea

- 5.5.4.5 Taiwan

- 5.5.4.6 Malaysia

- 5.5.4.7 Australia

- 5.5.4.8 Rest of Asia-Pacific

- 5.5.5 Middle East and Africa

- 5.5.5.1 Middle East

- 5.5.5.1.1 United Arab Emirates

- 5.5.5.1.2 Saudi Arabia

- 5.5.5.1.3 Turkey

- 5.5.5.1.4 Rest of Middle East

- 5.5.5.2 Africa

- 5.5.5.2.1 South Africa

- 5.5.5.2.2 Nigeria

- 5.5.5.2.3 Rest of Africa

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Littelfuse Inc.

- 6.4.2 Standex Electronics Inc.

- 6.4.3 PIC GmbH

- 6.4.4 Aleph Holdings Co. Ltd.

- 6.4.5 STG Germany GmbH

- 6.4.6 Coto Technology Inc.

- 6.4.7 Reed Switch Developments Corp.

- 6.4.8 ZF Friedrichshafen AG

- 6.4.9 Reed Relays & Electronics India Ltd.

- 6.4.10 WIKA Instruments India Pvt Ltd.

- 6.4.11 HSI Sensing

- 6.4.12 Magnasphere Corp.

- 6.4.13 Hamlin Electronics (Littelfuse)

- 6.4.14 Sensata Technologies

- 6.4.15 Comus International

- 6.4.16 MEDER electronic

- 6.4.17 Schneider Electric (SE)

- 6.4.18 SMC Corporation

- 6.4.19 NTE Electronics Inc.

- 6.4.20 TE Connectivity

- 6.4.21 OKI Sensor Device Corp.

- 6.4.22 Changjiang Electronics Tech

- 6.4.23 Zhejiang Xurui Electronic Co.

- 6.4.24 Shanghai Kaiyuan Microelectronics

- 6.4.25 HOKUYO Automatic Co. Ltd.

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 White-Space and Unmet-Need Assessment