|

市場調查報告書

商品編碼

1836632

汽車離合器:市場佔有率分析、行業趨勢、統計數據和成長預測(2025-2030 年)Automotive Clutch - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

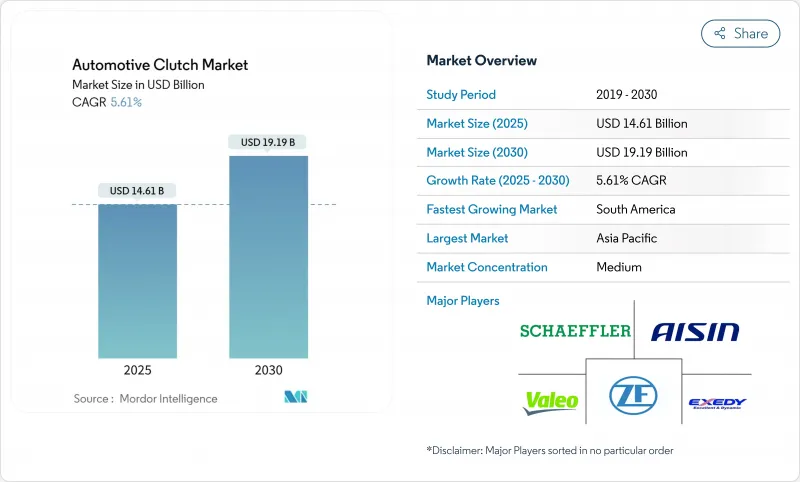

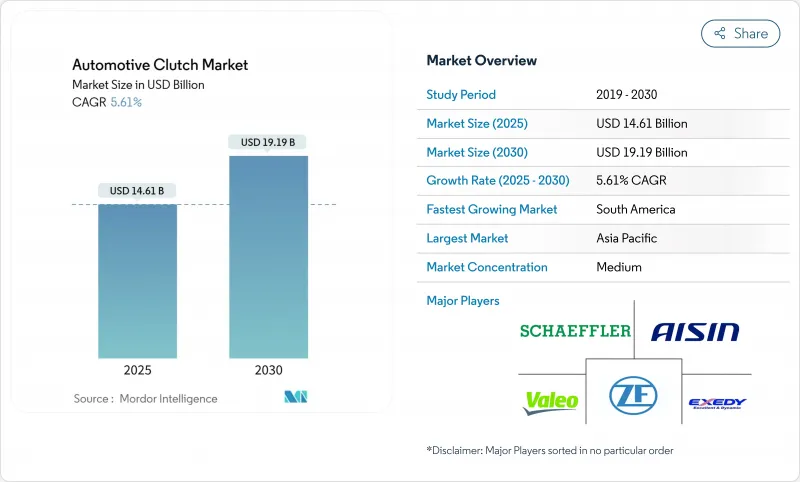

預計 2025 年汽車離合器市場價值將達到 146.1 億美元,到 2030 年預計將達到 191.9 億美元,複合年成長率為 5.61%。

雙離合器變速箱 (DCT) 技術的普及、全球二氧化碳排放法規的收緊以及輕型汽車產量(尤其是在亞太地區)的強勁成長,為這一前景提供了支撐。由於新型車輛擴大將輕度混合動力系統與電子驅動相結合,從而提高換檔速度和效率,需求主要以原始設備製造商 (OEM) 層面為主。然而,由於車輛車齡超過 12 年,且純電動車 (BEV) 減少了傳統摩擦離合器的安裝數量,同時保持了更換需求,售後市場銷量依然保持強勁。競爭動態正在改變。領先的供應商正在將其機械技術與軟體和電子設備相結合,以支援混合動力架構並捍衛其市場佔有率。最顯著的例子是捨弗勒與 Vitesco Technologies 的合併。

全球汽車離合器市場趨勢與洞察

OEM快速轉向雙離合器和自動變速箱

雙離合器變速箱 (DCT) 的效率比液力變矩器自動變速箱 (Turn Converter Automatic Transmission) 高出 28%,使汽車製造商能夠在不影響性能的情況下實現車輛二氧化碳排放目標,從而推動汽車市場從高階細分市場向大眾細分市場的更廣泛轉變。隨著零件通用的提高,單位成本下降,使得 6 速和 8 速雙離合器變速箱 (DCT) 能夠應用於 B-Class 和 C-Class 車型。像麥格納 48V 雙離合器變速箱 (DCT) 這樣的混合動力汽車將內燃機和電力推進系統緊密整合,使引擎的離岸滑行更加平穩。商用車原始設備製造商 (OEM) 正在採用混合動力自動手排變速箱 (HAT) 來降低遠距運輸的油耗,這推動了對具有更高熱容量的重型離合器的需求。

新興經濟體輕型汽車產量增加

隨著汽車製造商推進動力傳動系統本地化並利用區域供應鏈,中國和印度組裝產量的不斷成長將維持核心需求。在印度,政府的獎勵措施鼓勵新工廠批量配置手動離合器,而不斷提升的車型配置也整合了自動化選配配置,這增加了高階摩擦材料的應用機會。在中國,經歷了動盪的2024年後,產量趨於穩定,隨著本土品牌採用雙離合器變速箱(DCT)以保持競爭力,推動了單位價值的成長。在亞洲以外,巴西和墨西哥是可靠零件更換週期的基礎驅動力。都市化的加速將推動二、三線城市網約車車隊的成長,在這些城市,走走停停的強制規定加速了車輛的磨損,從而推動了售後市場的銷售量。

隨著純電動車的普及,傳統離合器將會被淘汰。

中國的目標是到2020年,電動車佔新車銷售的45%。歐洲的原始設備製造商也積極推進電氣化藍圖,直接用固定傳動比的電力驅動聯軸器取代傳統的摩擦離合器。然而,混合動力架構在高速公路巡航過程中仍然使用分離離合器來分離引擎。通用汽車在基於離合器的混合動力齒輪組方面的專利活動表明,電動傳動系統對複雜嚙合系統的持續需求。

報告中分析的其他促進因素和限制因素

- 嚴格的二氧化碳排放目標推動了對節能離合器的需求

- 輕度混合動力架構採用48V電子離合器系統

- CVT動力傳動系統在入門級車輛中日益普及

細分分析

雖然到2024年,手排變速箱仍將佔據汽車離合器市場的65.10%,但雙離合器變速箱已成為成長最快的細分市場,2025年至2030年的複合年成長率將達到9.19%。這一成長將由小型車的主流應用推動,因為這類車的成本差距正在縮小,監管壓力也鼓勵提高效率。雙離合器系統的汽車離合器市場規模預計將隨著八速設計的出現而成長,因為八速設計在保持性能的同時,還能更嚴格地控制引擎轉速。

在雙踏板架構中,供應商正在重新設計摩擦組件,使其配備低慣性輪轂和高導電性襯套,以限制怠速時的阻力矩。採埃孚的8速濕式雙離合器變速箱(DCT)實現了28%的損耗降低,標誌著一項支援輕度混合動力P2配置的技術轉變。重型卡車的自動手排變速箱(AMT)採用單副軸或雙副軸,並結合耐高溫有機襯套,為車隊營運商提供了節省燃油的選擇,而無需承擔全混合動力的成本。總而言之,這些趨勢將使離合器技術保持多樣性,並在未來十年內保持整個汽車離合器市場的強勁成長勢頭。

2024年,乘用車將滿足74.57%的需求,而中型和重型卡車將成為成長最快的領域,隨著混合動力傳動系統在區域和城市配送中越來越受歡迎,其複合年成長率將達到7.88%。與重型平台相關的汽車離合器市場規模受益於更高的單位成本,因為需要多片組和更大的熱質量來處理斜坡起步時的扭矩峰值。

伊頓專為 DT12 和 i-Shift 等自動手排變速箱設計的重型離合器凸顯了這一機遇,並採用高速氣流設計,以便在啟動停止工況下散熱。氫燃料卡車 Pilot 則提供了另一個利基市場,它將單級變速箱與分離離合器結合,將泵浦和壓縮機分開。乘用車混合動力傳動系統透過在引擎和變速箱之間插入 P2 或 P3 模組來實現電動導航,擴展了離合器的適用性。因此,即使純電動車 (BEV) 市場不斷擴張,汽車離合器市場仍能維持不同車型的均衡分佈。

區域分析

受中國生產規模和印度政策驅動的製造業成長的支撐,亞太地區將在2024年維持49.65%的汽車離合器市場。到2030年,該地區的複合年成長率將達到5.41%,這反映了內燃機市場需求的穩定以及混合動力汽車部署的加速。日本和韓國是電子執行領域的領導者,將透過指定整合式電子離合器模組來推高平均單價。隨著全球汽車製造商供應鏈多元化並確保離合器大規模在地採購,東協組裝商將吸引新的投資。

南美洲是成長最快的地區,複合年成長率高達6.77%。巴西和其他南美洲國家不斷成長的汽車保有量支撐了強勁的汽車更換率。新的區域貿易獎勵正在推動新增運力,都市區貨運電氣化試點計畫正在引入混合動力AMT變速箱,從而提升每輛車的貨運量。阿根廷老化的車隊嚴重依賴獨立售後市場,供應商的擴張範圍已超越了原廠通路。

北美和歐洲的複合年成長率分別為3.21%和2.81%,但這兩個地區都實施最嚴格的排放氣體和顆粒物法規。美國平均燃料效率(CAFE)規定每年需提升2%,並鼓勵原始設備製造商將輕度混合動力模組與高效離合器結合。歐洲的歐7法規限制了煞車和離合器的磨損碎屑,加速了無銅襯片和輕量化板的採用。俄羅斯以及中東和非洲地區則因本地組裝和都市區車輛保有量增加而貢獻了增量。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場狀況

- 市場概況

- 市場促進因素

- OEM快速轉向雙離合器和自動變速箱

- 新興國家輕型汽車產量增加

- 嚴格的二氧化碳排放目標推動了對節能離合器的需求

- 採用48V電子離合器系統打造輕度混合動力架構

- 輕量複合摩擦材料,符合整體車輛 MPG 標準

- 二、三線城市對符合排放標準的計程車改裝需求不斷增加

- 市場限制

- 純電動車的廣泛應用消除了傳統離合器

- CVT動力傳動系統在入門級汽車中日益普及

- 雙品質飛輪可靠性問題導致保固成本上升

- 無銅摩擦材料強制規定擾亂供應鏈

- 價值/供應鏈分析

- 監管狀況

- 技術展望

- 波特五力分析

- 新進入者的威脅

- 買家/消費者的議價能力

- 供應商的議價能力

- 替代品的威脅

- 競爭對手之間的競爭強度

第5章市場規模與成長預測(價值,十億美元)

- 按傳動類型

- 手動的

- 自動變速器(變矩器)

- 自動手排變速箱(AMT)

- 雙離合器變速箱(DCT)

- 其他(電子離合器、CVT離合器組等)

- 按車輛類型

- 搭乘用車

- 輕型商用車

- 中大型商用車

- 非公路用車(農業、建築)

- 按下離合器組件

- 離合器圓盤和輪轂

- 壓板和蓋

- 分離軸承/工作缸

- 飛輪(單質量和雙質量)

- 驅動系統(液壓、電液、電子)

- 按銷售管道

- OEM

- 售後市場

- 按地區

- 北美洲

- 美國

- 加拿大

- 北美其他地區

- 南美洲

- 巴西

- 阿根廷

- 其他南美

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 俄羅斯

- 其他歐洲國家

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 其他亞太地區

- 中東和非洲

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 南非

- 其他中東和非洲地區

- 北美洲

第6章 競爭態勢

- 市場集中度

- 策略趨勢

- 市佔率分析

- 公司簡介

- Schaeffler AG

- Valeo SA

- ZF Friedrichshafen AG

- EXEDY Corporation

- Aisin Corporation

- Eaton Corporation plc

- BorgWarner Inc.

- Magneti Marelli SpA

- Continental AG

- LuK

- WABCO(ZF CV Systems)

- Setco Automotive Ltd.

- FCC Co., Ltd.

- Zhejiang Tieliu Clutch Co., Ltd.

- Nissin Kogyo Co., Ltd.

- Haldex AB

- Twin Disc Inc.

- Transtar Industries Inc.

- Helix Auto Transmission

- Sachs

第7章 市場機會與未來展望

The automotive clutch market is valued at USD 14.61 billion in 2025 and is forecast to reach USD 19.19 billion by 2030, expanding at a 5.61% CAGR.

DCT technology adoption, tightening global CO2 rules, and steady light-vehicle production growth, particularly in Asia-Pacific, underpin this outlook. OEM-level demand dominates because new models increasingly pair mild-hybrid systems with electronic actuation that improves shift speed and efficiency. Meanwhile, aftermarket volumes remain resilient as vehicle fleets age well past 12 years, sustaining replacement demand even as battery-electric vehicles (BEVs) reduce installations of conventional friction clutches. Competitive dynamics are changing: leading suppliers are bundling mechanical know-how with software and electronics to protect their share while positioning for hybrid architectures, most visibly in Schaeffler's merger with Vitesco Technologies, which folds power electronics into a historic clutch portfolio.

Global Automotive Clutch Market Trends and Insights

Rapid OEM Shift Toward Dual-Clutch & Automated Transmissions

DCT efficiency advantages of up to 28% over torque-converter automatics allow carmakers to hit fleet CO2 targets without detracting from performance, prompting broad migration from premium to mass-market segments. Unit costs fall as component commonality rises, making six- and eight-speed DCTs viable for B- and C-segment cars. Hybrid variants such as Magna's 48 V DCT merge combustion and electric propulsion within tight packaging, enabling smoother engine-off coasting. Commercial-vehicle OEMs adopt hybrid automated manuals to cut fuel burn on long-haul routes, reinforcing demand for heavy-duty clutches with higher thermal capacity.

Rising Light-Vehicle Production in Emerging Economies

Expanding assembly volumes in China and India sustain core demand as automakers localize drivetrains and leverage regional supply chains. Government incentives in India encourage new plants that specify high-volume manual clutches, yet rising trim levels integrate automated options, adding premium friction-material opportunities. In China, output stabilized after 2024 turbulence, and local brands now adopt DCTs to stay competitive, driving incremental unit value. Outside Asia, Brazil and Mexico collectively field a base that fuels a dependable parts replacement cycle. Urbanization accelerates ride-hailing fleets in Tier-2 and Tier-3 cities, where stop-and-go duty accelerates wear and lifts aftermarket volumes.

Escalating BEV Penetration Eliminating Conventional Clutches

China targets a 45% EV share of new-vehicle sales by decade-end, and European OEMs deploy aggressive electric roadmaps, directly substituting the traditional friction clutch with fixed-ratio e-drive couplings. Nonetheless, hybrid architectures still use disconnect clutches to de-link engines at highway cruise. Patent activity from General Motors on clutch-based hybrid gearsets demonstrates the ongoing need for sophisticated engagement systems even in electrified drivelines.

Other drivers and restraints analyzed in the detailed report include:

- Stringent CO2 Targets Driving Demand for Fuel-Efficient Clutches

- Adoption of 48-V e-Clutch Systems for Mild-Hybrid Architectures

- Rising Popularity of CVT Powertrains in Entry-Level Cars

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Manual units still represented 65.10% of the automotive clutch market in 2024, yet the dual-clutch transmissions emerged as the fastest-growing segment at 9.19% CAGR from 2025-2030. That growth rides on mainstream adoption in compact cars, where cost gaps have narrowed and regulatory pressure rewards efficiency. The automotive clutch market size for dual-clutch systems is forecast to rise in tandem with eight-speed designs that maintain performance while controlling engine speed more tightly.

Across two-pedal architectures, suppliers are re-engineering friction packs with low-inertia hubs and high-conductivity liners that limit drag torque at idle. ZF's 8-speed wet DCT illustrates the technology shift, offering 28% loss reduction and supporting mild-hybrid P2 configurations. Automated manual transmissions (AMTs) in heavy trucks deploy single or twin countershafts coupled with high-heat organic linings, giving fleet operators a fuel-saving alternative without the cost of full hybrids. Together, these trends sustain broad diversity in clutch technology and preserve overall automotive clutch market momentum through the decade.

Passenger cars delivered 74.57% of demand in 2024, but medium and heavy trucks are the fastest-rising slice, expanding at 7.88% CAGR as hybrid drivetrains proliferate in regional haul and urban delivery. The automotive clutch market size attached to heavy-duty platforms benefits from higher unit value per vehicle, since multi-plate packs and greater thermal mass are needed to handle torque peaks during launch on grades.

Eaton's heavy-duty clutches, engineered for automated manuals such as DT12 and I-Shift, underscore this opportunity and include high-velocity airflow designs that dissipate heat under stop-start duty. Hydrogen-fuel truck pilots pair single-stage gearboxes with disconnect clutches that isolate pumps and compressors, offering another niche. In passenger cars, hybrid powertrains extend clutch relevance by inserting P2 or P3 modules between the engine and transmission to enable electric sailing. Consequently, the automotive clutch market maintains a balanced exposure across vehicle classes even as BEVs expand.

The Automotive Clutch Market Report is Segmented by Transmission Type (Manual, Automatic, AMT, DCT, and More), Vehicle Type (Passenger Cars, LCV, and More), Clutch Component (Clutch Disc and Hub, Pressure Plate and Cover, Release Bearing/Slave Cylinder, and More), Sales Channel (OEM and Aftermarket), and Geography. The Market Forecasts are Provided in Terms of Value (USD) and Volume (Units).

Geography Analysis

Asia-Pacific maintained a 49.65% share of the automotive clutch market in 2024, underpinned by China's production scale and India's policy-fueled manufacturing uptick. Regional CAGR of 5.41% through 2030 reflects stable internal combustion demand plus accelerating hybrid rollouts. Japan and South Korea, leaders in electronic actuation, drive higher average unit value by specifying integrated e-clutch modules. ASEAN assemblers attract new investment as global OEMs diversify supply chains, ensuring localized clutch sourcing at scale.

South America is the fastest-growing geography at 6.77% CAGR, fueled by a larger vehicle population in Brazil and other South American countries that sustains robust replacement volumes. New regional trade incentives spark fresh capacity commitments, while urban freight electrification trials integrate hybrid AMTs that lift content per vehicle. Argentina's aging fleet leans heavily on the independent aftermarket, widening supplier exposure beyond OEM channels.

North America and Europe show modest 3.21% and 2.81% CAGRs, respectively, yet both regions impose the toughest emissions and particulate rules. CAFE mandates in the United States stipulate 2% annual efficiency gains, encouraging OEMs to pair mild-hybrid modules with high-efficiency clutches. European Euro 7 standards limit brake and clutch wear particles, accelerating the adoption of copper-free linings and lightweight plates. Russia and the Middle East and Africa contribute incremental growth tied to localized assembly and rising urban ownership.

- Schaeffler AG

- Valeo SA

- ZF Friedrichshafen AG

- EXEDY Corporation

- Aisin Corporation

- Eaton Corporation plc

- BorgWarner Inc.

- Magneti Marelli SpA

- Continental AG

- LuK

- WABCO (ZF CV Systems)

- Setco Automotive Ltd.

- FCC Co., Ltd.

- Zhejiang Tieliu Clutch Co., Ltd.

- Nissin Kogyo Co., Ltd.

- Haldex AB

- Twin Disc Inc.

- Transtar Industries Inc.

- Helix Auto Transmission

- Sachs

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Rapid OEM shift toward dual-clutch and automated transmissions

- 4.2.2 Rising light-vehicle production in emerging economies

- 4.2.3 Stringent CO2 targets driving demand for fuel-efficient clutches

- 4.2.4 Adoption of 48-V e-clutch systems for mild-hybrid architectures

- 4.2.5 Lightweight composite friction materials to meet fleet-wide MPG norms

- 4.2.6 Growing retrofit demand in Tier-2/3 cities for emission-compliant taxis

- 4.3 Market Restraints

- 4.3.1 Escalating BEV penetration eliminating conventional clutches

- 4.3.2 Rising popularity of CVT powertrains in entry-level cars

- 4.3.3 Dual-mass-flywheel reliability issues causing warranty cost spikes

- 4.3.4 Upcoming copper-free friction-material mandates disrupting supply chains

- 4.4 Value / Supply-Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Threat of New Entrants

- 4.7.2 Bargaining Power of Buyers/Consumers

- 4.7.3 Bargaining Power of Suppliers

- 4.7.4 Threat of Substitute Products

- 4.7.5 Intensity of Competitive Rivalry

5 Market Size and Growth Forecasts (Value, USD Billion)

- 5.1 By Transmission Type

- 5.1.1 Manual

- 5.1.2 Automatic (Torque-Converter)

- 5.1.3 Automated Manual Transmission (AMT)

- 5.1.4 Dual-Clutch Transmission (DCT)

- 5.1.5 Others (e-Clutch, CVT Clutch Packs, etc.)

- 5.2 By Vehicle Type

- 5.2.1 Passenger Cars

- 5.2.2 Light Commercial Vehicles

- 5.2.3 Medium and Heavy Commercial Vehicles

- 5.2.4 Off-Highway (Agricultural and Construction)

- 5.3 By Clutch Component

- 5.3.1 Clutch Disc and Hub

- 5.3.2 Pressure Plate and Cover

- 5.3.3 Release Bearing/Slave Cylinder

- 5.3.4 Flywheel (Single and Dual-Mass)

- 5.3.5 Actuation Systems (Hydraulic, Electro-Hydraulic, Electronic)

- 5.4 By Sales Channel

- 5.4.1 OEM

- 5.4.2 Aftermarket

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Rest of North America

- 5.5.2 South America

- 5.5.2.1 Brazil

- 5.5.2.2 Argentina

- 5.5.2.3 Rest of South America

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Spain

- 5.5.3.6 Russia

- 5.5.3.7 Rest of Europe

- 5.5.4 Asia-Pacific

- 5.5.4.1 China

- 5.5.4.2 India

- 5.5.4.3 Japan

- 5.5.4.4 South Korea

- 5.5.4.5 Rest of Asia-Pacific

- 5.5.5 Middle East and Africa

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 United Arab Emirates

- 5.5.5.3 South Africa

- 5.5.5.4 Rest of Middle East and Africa

- 5.5.1 North America

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share, Products and Services, and Recent Developments)

- 6.4.1 Schaeffler AG

- 6.4.2 Valeo SA

- 6.4.3 ZF Friedrichshafen AG

- 6.4.4 EXEDY Corporation

- 6.4.5 Aisin Corporation

- 6.4.6 Eaton Corporation plc

- 6.4.7 BorgWarner Inc.

- 6.4.8 Magneti Marelli SpA

- 6.4.9 Continental AG

- 6.4.10 LuK

- 6.4.11 WABCO (ZF CV Systems)

- 6.4.12 Setco Automotive Ltd.

- 6.4.13 FCC Co., Ltd.

- 6.4.14 Zhejiang Tieliu Clutch Co., Ltd.

- 6.4.15 Nissin Kogyo Co., Ltd.

- 6.4.16 Haldex AB

- 6.4.17 Twin Disc Inc.

- 6.4.18 Transtar Industries Inc.

- 6.4.19 Helix Auto Transmission

- 6.4.20 Sachs

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-Need Assessment