|

市場調查報告書

商品編碼

1836585

聚合物乳劑:市場佔有率分析、產業趨勢、統計數據和成長預測(2025-2030)Polymer Emulsions - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

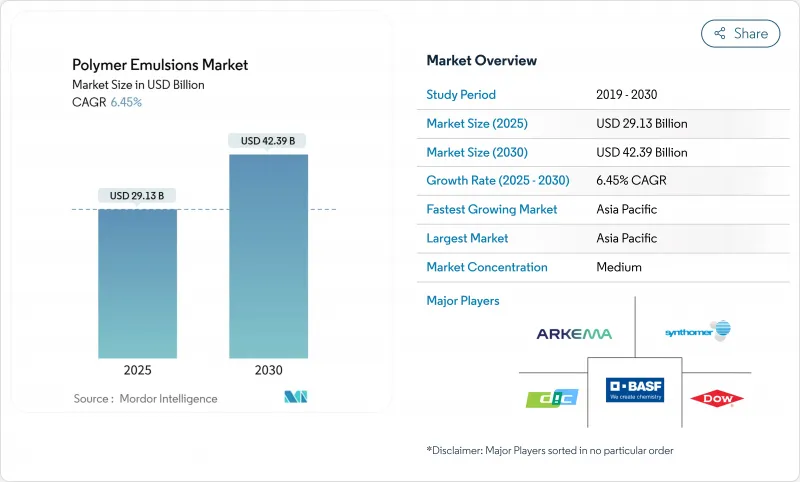

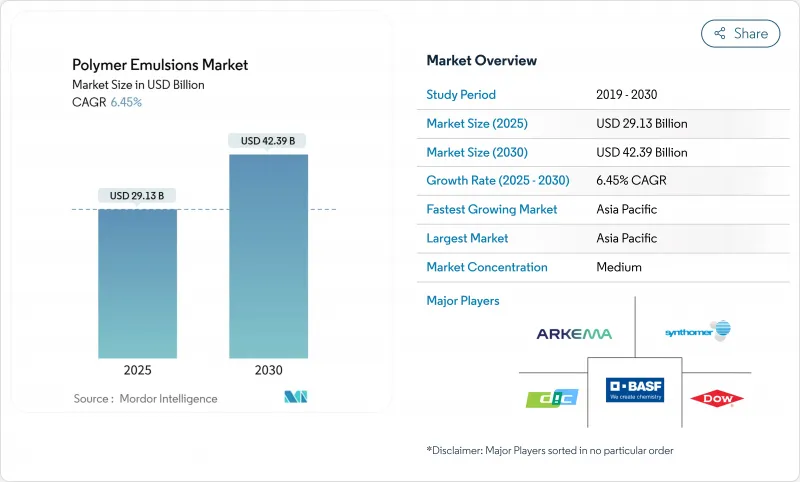

預計 2025 年聚合物乳劑市場價值將達到 291.3 億美元,預計到 2030 年將達到 423.9 億美元,預測期內(2025-2030 年)的複合年成長率為 6.45%。

全球空氣品質法規日益嚴格,加速了水性系統取代溶劑型技術,尤其是在建築塗料和工業整理加工劑,推動了該領域的成長。無界面活性劑光引發乳液聚合技術的最新突破也促進了該領域的應用,該技術可降低加工能耗並提高膠體穩定性。 pubs.rsc.org。歐洲對溶劑型膠黏劑的監管禁令,以及北美和亞洲對低揮發性有機化合物(VOC)的要求,正在推動包裝、汽車和建築價值鏈朝向永續化學方向發展。供應商正積極應對,推出生物基單體、可再生能源驅動的工廠以及數位化指導的配方平台,以加快新產品的上市時間。

全球聚合物乳劑市場趨勢與洞察

亞洲建築業繁榮推動低VOC水性塗料的轉變

隨著亞洲特大城市以創紀錄的速度不斷增加住房和基礎設施,對符合嚴格排放標準的水性內外牆塗料的需求也日益成長。中國最新的空氣品質規劃和印度國家建築規範的更新,均提倡使用揮發性有機化合物(VOC)含量不超過50克/公升的塗料,這正迅速推動溶劑型醇酸樹脂的替代品。製造商紛紛推出耐腐蝕、低氣味的丙烯酸乳膠漆,例如Lamberty的ESACOTE AC 509。健康和安全優勢、易於清潔以及降低工人暴露限值,推動了人們對這些系統的青睞,並產生了超越單純合規性的積極反饋,鞏固了聚合物乳劑市場的長期需求。

汽車原始設備製造商需要環保的防刮塗層

北美和歐洲的汽車組裝現在指定使用水性底漆-中塗-透明塗層組合,以滿足耐溶劑性要求,同時減少碳排放。配方師正在採用帶有自交聯嵌段的混合聚氨酯-丙烯酸基質,以提供硬度和耐刮擦性。太陽化學的WATERSOL AC系列產品就反映了這一進步,其被覆劑具有高光澤度和低微刮擦性,同時可將揮發性有機化合物(VOC)減少高達90%。隨著主流性能障礙的消除,品牌所有者正在將永續性認證推向市場,並加速全球汽車工廠的銷售量成長。

揮發性丁二烯和丙烯酸酯單體定價

原料價格的快速波動正在擠壓乳膠生產商的利潤,尤其是與石腦油成本波動相關的苯乙烯-丁二烯等級。合約配方很少會超過季度調整一次,這使得供應商面臨價格飆升的風險。然而,短期波動可能會繼續給盈利帶來壓力,並推遲產能升級。

報告中分析的其他促進因素和限制因素

- 歐盟禁止使用溶劑型黏合劑,推動乳液在包裝領域的應用

- 在紡織和造紙工業的應用日益增多

- 與重防腐應用中的溶劑型塗料相比的性能差異

細分分析

2024年,丙烯酸樹脂佔銷售量的45%,2025年銷售額達131.1億美元。由於廣泛的兼容性、可靠的耐候性和快速的監管核准,該細分市場鞏固了其作為裝飾塗料、密封膠和感壓標籤預設平台的地位。塞拉尼斯EcoVAE牌號兼具低氣味和A級耐擦洗性,可滿足綠色建築專案的要求。苯乙烯丁二烯乳膠仍然是紙張塗料和地毯背襯的經濟高效的選擇,儘管隨著再生纖維品質的提高,其成長仍然溫和。醋酸乙烯酯聚合物在石膏和膩子化合物中保持穩定的需求,因為柔韌性是這些化合物的必需品。 「其他」叢集,包括有機矽改質和生物基乳液,正在醫用薄膜等高利潤的利基領域選擇性擴張。同時,聚氨酯分散體是成長最快的細分市場,複合年成長率為6.9%。這是由高階汽車、軟包裝和特殊地板塗料應用推動的,這些應用要求產品韌性、透明度和耐水解性,因此價格更高。總體而言,產品多樣化支撐了聚合物乳劑市場的韌性。

低碳排放的推動正在刺激對無界面活性劑光引發製程的投資,這些製程可減少泡沫和揮發性有機化合物 (VOC)。實驗室研究表明,無需傳統皂基體系即可獲得55%固態的穩定晶格,從而簡化合規性和廢水處理流程。整合這些方法的供應商將獲得先發優勢。擴大生物丙烯酸和糖根丁二烯的生產規模,應能進一步降低生命週期影響評分,與主要下游品牌的範圍3目標保持一致,並強化推動聚合物乳劑產業永續性的概念。

到2024年,油漆和塗料將佔總需求的46%,價值134億美元。嚴格的揮發性有機化合物(VOC)法規正在推動裝飾、防護和汽車系統轉向水性平台。 Lamberti的直接金屬丙烯酸塗料乾膜厚度為120微米,具有相當的耐溶劑腐蝕性,展現了性能均等性如何使其在重載應用中得到應用。隨著軟包裝和建築膠帶逐步淘汰溶劑型丙烯酸塗料,黏合劑和地毯背襯的複合年成長率最高,達到7.1%。水性壓敏膠由於能夠耐受冷凍儲存和紫外線照射,其性能正在不斷提升。

紙張和紙板市場保持穩定,但正在發生質的變化。含有叔碳酸乙烯基酯的水性阻隔材料提高了防潮防油性能,使得用單一材料結構取代聚乙烯擠出杯和托盤成為可能。紡織品、皮革和新興的3D列印黏合劑則填補了「其他」領域的空白。在每個細分市場中,數位配色和線上黏度控制系統降低了批次差異,進一步規範了水性應用,並提升了聚合物乳劑市場的發展軌跡。

區域分析

預計亞太地區將佔2025年銷售額的41.2%,達到120億美元,到2030年複合年成長率將達到7.3%。中國、印度、印尼和越南的建築業蓬勃發展,推動了建築乳膠漆的大量消費,而當地汽車製造商則正在應用耐刮擦水性面漆。跨國供應商在中國和越南等新興中心擴大產能,縮短了前置作業時間,並保護了買家免受運費波動的影響。日本和韓國專注於高性能利基市場,例如光學薄膜、導電塗料和環保皮革塗飾,其雄厚的國內研發實力確保了產品的高價格。

北美是第二大地區。美國正在推動水性塗料在家居裝修、基礎設施和電動車製造領域的應用。對低氣味、快乾配方的需求正促使供應商部署新一代丙烯酸-聚氨酯混合塗料。加拿大木材塗飾和包裝塗料的消費保持健康。墨西哥的家電和汽車組裝廠正在快速擴張,這提振了當地需求,而近岸外包趨勢正在推動塗料供應鏈向南轉移。

歐洲是一個至關重要的市場,其發展受到歐盟嚴格的溶劑減量指令的影響。德國、法國、英國和義大利正在實施綠色建築標準,加速了裝飾塗料和工業維護產品的轉型。德國、法國、英國和義大利已禁止使用溶劑型貼合黏劑,推動了水性膠合劑在軟包裝生產線中的快速應用。同時,由於VAM(醋酸乙烯酯/丙烯醯胺)供應週期性中斷導致的原料限制凸顯了供應安全隱患,促使加工商在東歐和中東地區尋找雙源。

雖然南美洲、中東和非洲的佔有率較小,但其發展勢頭引人注目。巴西受益於基礎設施建設和住房項目,這些項目正在擴大乳膠砂漿的使用。沙烏地阿拉伯和阿拉伯聯合大公國新建的丙烯酸乳液工廠正在向歐洲和亞洲出口產品,從而改變貿易流向。南非正在透過政府支持的道路和住房計劃來支持非洲的消費,這些計畫需要耐用、低VOC塗料。在這些新興地區,各國政府擴大參考世界衛生組織 (WHO) 的室內空氣品質指南,使當地法規與全球規範保持一致,並確保對聚合物乳劑的持續需求。

其他福利

- Excel 格式的市場預測 (ME) 表

- 3個月的分析師支持

目錄

第1章 引言

第2章研究假設與市場定義

- 調查範圍

- 調查方法

第3章執行摘要

第4章 市場狀況

- 市場概況

- 市場促進因素

- 亞洲建築業繁榮推動低VOC水性塗料的轉型

- 北美和歐洲汽車原始設備製造商對環保防刮塗層的需求

- 歐盟禁止使用溶劑型黏合劑,推動乳液在包裝領域的應用

- 海灣合作理事會國家丙烯酸乳液工廠產能擴張

- 在紡織和造紙工業的應用日益增多

- 市場限制

- 揮發性丁二烯和丙烯酸酯單體定價

- 與溶劑型重防腐蝕塗料相比的性能差異

- 歐洲VAM供應中斷

- 價值鏈分析

- 波特五力分析

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭的激烈程度

- 供需分析

- 目前和計劃的重大計劃

- 貿易分析

- 目前供需情況

第5章市場規模及成長預測(金額)

- 依產品類型

- 丙烯酸纖維

- 苯乙烯丁二烯(SB)乳膠

- 醋酸乙烯酯聚合物

- PVA均聚物

- 其他醋酸乙烯酯

- 聚氨酯(PU)分散體

- 其他

- 按用途

- 油漆和被覆劑

- 黏合劑和地毯背襯

- 紙和紙板

- 其他

- 按最終用戶產業

- 建築/施工

- 汽車和運輸

- 包裝

- 木材/家具

- 紡織品和服裝

- 其他(化學品和一般製造業)

- 固態分餾

- 高固態(超過 55%)

- 中等固態(45-55)

- 低固態(低於 45%)

- 按地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 其他亞太地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 其他歐洲國家

- 南美洲

- 巴西

- 阿根廷

- 其他南美

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 其他中東和非洲地區

- 亞太地區

第6章 競爭態勢

- 市場集中度

- 策略性舉措(併購、合資、資金籌措)

- 市佔率分析

- 公司簡介

- 3M

- Allnex GmbH

- Akzo Nobel NV

- Arkema

- Asahi Kasei Corporation

- BASF

- Celanese Corporation

- Clariant

- Covestro AG

- DIC CORPORATION

- Dow

- Eastman Chemical Company

- Eni SpA

- Georgia-Pacific

- JSR Corporation

- Kamsons Polymer Limited

- Lamberti SpA

- Mallard Creek Polymers

- Polynt SpA

- Synthomer plc

- The Lubrizol Corporation

- Wacker Chemie AG

- ZEON CORPORATION

第7章 市場機會與未來展望

The Polymer Emulsions Market size is estimated at USD 29.13 billion in 2025, and is expected to reach USD 42.39 billion by 2030, at a CAGR of 6.45% during the forecast period (2025-2030).

Growth is led by tightening global air-quality rules that speed the replacement of solvent technologies with water-based systems, especially in architectural paints and industrial finishes. Accelerated adoption is also supported by recent breakthroughs in surfactant-free photoinitiated emulsion polymerization that reduce processing energy and improve colloidal stability pubs.rsc.org. Regulatory bans on solvent adhesives in Europe, together with parallel low-VOC mandates in North America and Asia, are pushing packaging, automotive, and construction value chains toward sustainable chemistries. Suppliers are responding with bio-based monomers, renewable-energy-powered plants, and digitally guided formulation platforms that compress time-to-market for new grades.

Global Polymer Emulsions Market Trends and Insights

Shift Toward Low-VOC Water-Borne Coatings Fueled by Asia's Construction Boom

Asian megacities continue to add housing and infrastructure at record pace, raising demand for water-based exterior and interior paints that comply with strict emission targets. China's latest air-quality plan and India's updated National Building Code promote coatings below 50 g VOC l-1, spurring rapid substitution of solvent alkyds. Manufacturers answer with acrylic latexes such as Lamberti's ESACOTE AC 509 that pair corrosion resistance with low odor. Health-and-safety benefits, easier cleanup, and fewer worker exposure limits reinforce preference for these systems, creating positive feedback that extends beyond pure compliance and cements long-term demand in the polymer emulsions market.

OEM Automotive Demand for Eco-Friendly Scratch-Resistant Finishes

Vehicle assemblers in North America and Europe now specify water-borne primer-surfacer and clear-coat packages that match solvent durability while cutting carbon footprints. Formulators employ hybrid polyurethane-acrylic matrices with self-cross-linking blocks to achieve hardness and mar resistance. Sun Chemical's WATERSOL AC line illustrates this progress with coatings that deliver high gloss and low micro-scratch while eliminating up to 90% VOCs. With mainstream performance hurdles removed, brand-owners market sustainability credentials, accelerating volume growth across global auto plants.

Volatile Butadiene and Acrylate Monomer Pricing

Rapid feedstock swings compress latex producer margins, especially for styrene-butadiene grades tied to fluctuating naphtha costs. Contract formulas rarely adjust faster than quarterly, exposing suppliers during spikes. Firms diversify procurement and explore sugar-based acrylics to stabilize input budgets, but near-term volatility continues to weigh on profitability and may delay capital upgrades.

Other drivers and restraints analyzed in the detailed report include:

- EU Bans on Solvent-Borne Adhesives Boosting Packaging Emulsion Uptake

- Increased Textile and Paper Industry Usage

- Performance Gap versus Solvent-Borne Coatings in Heavy-Duty Uses

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Acrylic resins controlled 45% of 2024 volume and generated USD 13.11 billion in 2025. The segment benefits from broad compatibility, solid weatherability, and rapid regulatory approvals, cementing its role as the default platform across decorative paints, sealants, and pressure-sensitive labels. Celanese's EcoVAE grades combine low odor with Class A scrub resistance, satisfying green-building schemes. Styrene-butadiene latex remains a cost-efficient choice for paper coating and carpet backing, though growth is modest as recycled fiber quality improves. Vinyl acetate polymers sustain steady demand in plaster and putty compounds where flexibility is essential. The "Others" cluster, including silicone-modified and bio-derived emulsions, expands selectively in high-margin niches such as medical films. Polyurethane dispersions, however, advance fastest at 6.9% CAGR, fueled by premium automotive, flexible packaging, and specialty floor-finish applications where toughness, clarity, and hydrolysis resistance justify higher prices. Collectively, product diversification anchors resilience in the polymer emulsions market.

The push for lower embodied carbon spurs investment in surfactant-free photoinitiated processes that tame foaming and cut VOCs. Laboratory work shows stable lattices at 55% solid without traditional soap systems, which can simplify compliance and effluent treatment. Suppliers integrating these methods stand to capture early-mover premiums. As bio-acrylic and sugar-route butadiene scale, life-cycle impact scores should fall further, aligning with scope-3 targets of major downstream brands and reinforcing the sustainability narrative driving the polymer emulsions industry.

Paints and coatings consumed 46% of 2024 demand, equal to USD 13.40 billion in 2025. Stringent VOC caps encourage conversion of decorative, protective, and automotive systems to water-borne platforms. Lamberti's direct-to-metal acrylic, which matches solvent corrosion protection at 120 µm dry film, exemplifies how performance parity unlocks heavy-duty adoption. Adhesives and carpet backing record the fastest 7.1% CAGR as flexible packaging and construction tapes phase out solvent acrylics. Water-borne pressure-sensitives now withstand freezer storage and UV exposure, broadening their function set.

Paper and paperboard remain steady but are undergoing qualitative change. Water-based barriers incorporating vinyl ester of Versatic acid improve moisture and oil resistance, allowing substitution of polyethylene-extruded cups and trays with single-material structures. Textile, leather, and emerging 3-D printing binders fill the diverse "Others" bucket. Across segments, digital color-matching and inline viscosity control systems reduce batch variability, further normalizing water-borne use and lifting the polymer emulsions market trajectory.

The Polymer Emulsions Market Report Segments the Industry by Product Type (Acrylics, Styrene Butadiene (SB) Latex, Vinyl Acetate Polymers, Polyurethane (PU) Dispersions, and Others), Application (Paints and Coatings, Adhesives and Carpet Backing, and More), Solid Content (High Solids, Medium Solids, and Low Solids), and Geography (Asia-Pacific, North America, Europe, South America, and Middle East and Africa).

Geography Analysis

Asia-Pacific commanded 41.2% of revenue in 2025, equivalent to USD 12.00 billion, and is projected to grow at 7.3% CAGR through 2030. Building booms in China, India, Indonesia, and Vietnam consume vast volumes of architectural latex, while regional automakers apply scratch-resistant water-borne topcoats. Capacity additions by multinational suppliers in China and emerging hubs such as Vietnam shorten lead times and shield buyers from freight swings. Japan and South Korea concentrate on high-performance niches-optical films, conductive coatings, and eco-friendly leather finishes-where domestic research and development depth secures premium pricing.

North America sits as the second-largest region. The United States drives water-borne adoption in remodeling, infrastructure, and EV manufacturing. Demand for low odor and rapid-dry formulations pushes suppliers to roll out next-generation acrylic-PU hybrids. Canada maintains healthy consumption in wood finishes and packaging grades. Mexico's fast-expanding appliance and automotive assembly plants lift local demand, aided by near-shoring trends that draw coatings supply chains southward.

Europe remains a pivotal market shaped by the EU's aggressive solvent-reduction mandates. Germany, France, the United Kingdom, and Italy implement national green-building codes that accelerate switch-overs in decorative paints and industrial maintenance products. The bloc's ban on solvent-borne laminating adhesives propels swift uptake of water-borne chemistries in flexible packaging lines. Meanwhile, feedstock constraints from periodic VAM outages underscore supply-security concerns, pushing converters to qualifying dual sourcing in Eastern Europe and the Middle East.

South America and the Middle East and Africa hold smaller shares yet exhibit notable momentum. Brazil benefits from infrastructure and housing programs that expand latex mortar use. The Middle East leverages feedstock advantage; new acrylic emulsion plants in Saudi Arabia and the UAE export to Europe and Asia, altering trade flows. South Africa anchors African consumption with government-backed road and housing projects that call for durable low-VOC coatings. Across these emerging regions, governments increasingly reference the World Health Organization indoor air guidelines, aligning local regulations with global norms and ensuring sustained demand for the polymer emulsions market.

- 3M

- Allnex GmbH

- Akzo Nobel N.V.

- Arkema

- Asahi Kasei Corporation

- BASF

- Celanese Corporation

- Clariant

- Covestro AG

- DIC CORPORATION

- Dow

- Eastman Chemical Company

- Eni S.p.A.

- Georgia-Pacific

- JSR Corporation

- Kamsons Polymer Limited

- Lamberti S.p.A.

- Mallard Creek Polymers

- Polynt S.p.A.

- Synthomer plc

- The Lubrizol Corporation

- Wacker Chemie AG

- ZEON CORPORATION

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

2 Study Assumptions and Market Definition

- 2.1 Scope of the Study

- 2.2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Shift Toward Low-VOC Water-borne Coatings Fueled by Asia's Construction Boom

- 4.2.2 OEM Automotive Demand for Eco-Friendly Scratch-Resistant Finishes in North America and Europe

- 4.2.3 EU Bans on Solvent-Borne Adhesives Boosting Packaging Emulsion Uptake

- 4.2.4 Capacity Expansions of Acrylic Emulsion Plants in GCC Nations

- 4.2.5 Increased Textile and Paper Industry Usage

- 4.3 Market Restraints

- 4.3.1 Volatile Butadiene and Acrylate Monomer Pricing

- 4.3.2 Performance Gap vs. Solvent-borne Coatings in Heavy-Duty Uses

- 4.3.3 VAM Supply Disruptions in Europe

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces Analysis

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Intensity of Rivalry

- 4.6 Supply and Demand Analysis

- 4.6.1 Major Current and Planned Projects

- 4.6.2 Trade Analysis

- 4.6.3 Current Supply and Demand Scenario

5 Market Size and Growth Forecasts (Value)

- 5.1 By Product Type

- 5.1.1 Acrylics

- 5.1.2 Styrene-Butadiene (SB) Latex

- 5.1.3 Vinyl Acetate Polymers

- 5.1.3.1 PVA Homopolymer

- 5.1.3.2 Other Vinyl Acetates

- 5.1.4 Polyurethane (PU) Dispersions

- 5.1.5 Others

- 5.2 By Application

- 5.2.1 Paints and Coatings

- 5.2.2 Adhesives and Carpet Backing

- 5.2.3 Paper and Paperboard

- 5.2.4 Others

- 5.3 By End-User Industry

- 5.3.1 Building and Construction

- 5.3.2 Automotive and Transportation

- 5.3.3 Packaging

- 5.3.4 Wood and Furniture

- 5.3.5 Textile and Apparel

- 5.3.6 Others (Chemicals and General Manufacturing)

- 5.4 By Solid Content

- 5.4.1 High Solids (more than 55 %)

- 5.4.2 Medium Solids (45-55 %)

- 5.4.3 Low Solids (less than 45 %)

- 5.5 Geography

- 5.5.1 Asia-Pacific

- 5.5.1.1 China

- 5.5.1.2 India

- 5.5.1.3 Japan

- 5.5.1.4 South Korea

- 5.5.1.5 Rest of Asia-Pacific

- 5.5.2 North America

- 5.5.2.1 United States

- 5.5.2.2 Canada

- 5.5.2.3 Mexico

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Rest of Europe

- 5.5.4 South America

- 5.5.4.1 Brazil

- 5.5.4.2 Argentina

- 5.5.4.3 Rest of South America

- 5.5.5 Middle East and Africa

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 South Africa

- 5.5.5.3 Rest of Middle East and Africa

- 5.5.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves (Mergers and Acquisitions, JVs, Funding)

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global-level Overview, Market-level Overview, Core Segments, Financials, Strategic Information, Market Rank/Share, Products and Services, Recent Developments)

- 6.4.1 3M

- 6.4.2 Allnex GmbH

- 6.4.3 Akzo Nobel N.V.

- 6.4.4 Arkema

- 6.4.5 Asahi Kasei Corporation

- 6.4.6 BASF

- 6.4.7 Celanese Corporation

- 6.4.8 Clariant

- 6.4.9 Covestro AG

- 6.4.10 DIC CORPORATION

- 6.4.11 Dow

- 6.4.12 Eastman Chemical Company

- 6.4.13 Eni S.p.A.

- 6.4.14 Georgia-Pacific

- 6.4.15 JSR Corporation

- 6.4.16 Kamsons Polymer Limited

- 6.4.17 Lamberti S.p.A.

- 6.4.18 Mallard Creek Polymers

- 6.4.19 Polynt S.p.A.

- 6.4.20 Synthomer plc

- 6.4.21 The Lubrizol Corporation

- 6.4.22 Wacker Chemie AG

- 6.4.23 ZEON CORPORATION

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-Need Assessment

- 7.2 Emerging Market for Bio-based Emulsion Polymer