|

市場調查報告書

商品編碼

1836558

管道塗料:市場佔有率分析、行業趨勢、統計數據和成長預測(2025-2030 年)Pipe Coatings - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

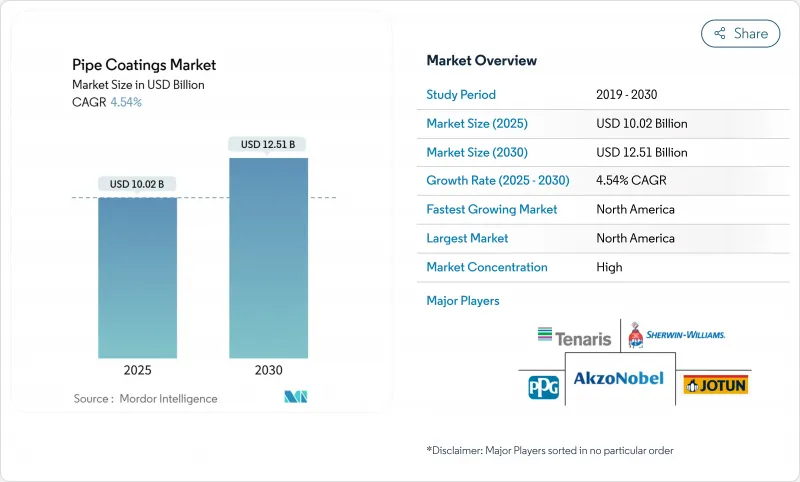

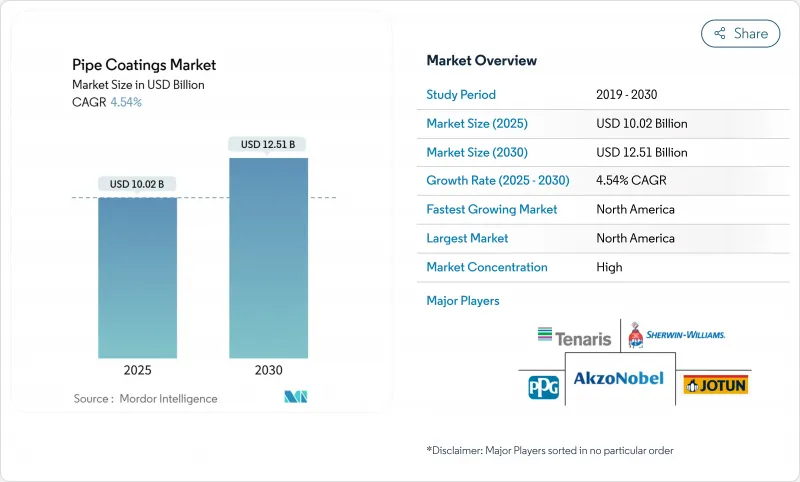

管道塗料市場規模預計在 2025 年達到 100.2 億美元,預計到 2030 年將達到 125.1 億美元,預測期內(2025-2030 年)的複合年成長率為 4.54%。

新管道投資的不斷增加、穩定的資產維護計劃以及更嚴格的安全法規,正在維持石油天然氣、水利和工業領域對防護整理加工劑的需求。北美頁岩油開發以及歐洲液化天然氣和氫氣計畫正在推動產能的強勁成長,而亞太地區的城市擴張將推動長期結構性成長。雙組分聚氨酯噴塗系統、石墨烯增強水性塗料和低溫固化粉末等技術進步正在擴大應用範圍並降低生命週期成本。永續性的壓力正促使採購團隊轉向水性和粉末解決方案,但溶劑型解決方案在嚴苛環境中仍站穩腳跟,因為可靠的性能至關重要。高性能化學品是日益激烈的競爭的核心,全球供應商正在擴展特種產品線,以確保獲得海上、高壓和氫氣服務的訂單。

全球管道塗料市場趨勢與洞察

頁岩氣產能增加加速維修週期

北美營運商正在快速建造新的和現有的管道,這推動了對能夠抵禦硫化氫、二氧化碳和微生物侵蝕的堅固塗料的需求。由於Oleoductos del Valle油田的擴建,預計到2025年,阿根廷瓦卡穆埃爾塔油田的產能將加倍,達到54萬桶/天,從而相應地縮短了維護窗口和重塗間隔。配方師為此設計了一層厚厚的環氧塗層和一層耐磨的胺甲酸乙酯外塗層,可在現場一次完成施工,從而減少操作員的停機時間。

高性能塗料擴大用於保護管道免受腐蝕

腐蝕成本迫使資產所有者採用具有自修復功能、耐膜下腐蝕並延長檢查週期的內襯。雙組分聚氨酯系統與環氧密封塗層相結合,可提供強大的附著力和不透水的表面,從而能夠在狹窄空間內快速進行現場修復。在海上管線中,單一故障就可能危及安全和生產執行時間,因此,擴大採用由熱熔粘合環氧樹脂、耐磨外塗層和聚乙烯外包裝組成的多層結構。

新發現能源蘊藏量的營運挑戰

在3000公尺深的海底施工,塗層必須承受超出常規規範的靜水壓力和溫差。美國管道和危險材料安全管理局(Pipeline and Hazardous Materials Safety Administration,簡稱PASS)支持的研究正在考慮將厚聚合物包裹層與犧牲複合材料層結合,以減輕海底安裝過程中的衝擊損傷。進入限制也使檢查變得複雜,增加了首次驗證塗層完整性的困難。

報告中分析的其他促進因素和限制因素

- 亞太地區基礎建設發展與工業化

- 東南亞灌溉和農業活動的增加

- 非開挖PE管在市政供水的應用日益廣泛

細分分析

預計到2024年,環氧樹脂和聚氨酯產品將佔管道塗料市場規模的40.76%,到2030年,複合年成長率將達到4.91%,超過整體市場。環氧樹脂對噴砂鋼材具有可靠的附著力,而聚氨酯面漆則具有耐磨性和紫外線穩定性。現場施工人員青睞雙組分噴塗鑽機,這種設備可以一次噴塗750微米的塗層,縮短了帶電作業的周轉時間。

聚乙烯和聚丙烯因其低水分擴散性和機械柔韌性,在輸水和區域供熱應用中仍然很受歡迎。在管道外圍,水泥基包裹層和瀝青瓷漆可提供強大的機械保護,但環境限制限制了它們的廣泛應用。交聯多層解決方案結合了熔結環氧樹脂和耐磨覆蓋層,目前正在保護定向鑽井段等高衝擊區域,展現了混合系統如何持續提升性能基準。

到2024年,外部塗層將佔據管道塗層市場佔有率的78.19%,因為營運商優先保護埋地鋼管免受土壤中氯化物侵蝕和雜散電流的影響。由於北美和歐洲管道網格的老化,預計到2030年,該類別的複合年成長率將達到5.18%。採用環氧樹脂底漆和黏合劑的三層聚乙烯纏繞材料由於其在濕回填條件下的附著力和機械韌性,仍將佔據主導地位。

內襯雖然收益不高,但當流動效率和減少硫化氫點蝕的效果能夠證明資本支出合理時,其預算正在增加。低剪切環氧內襯可以透過提高有效吞吐量和節省泵浦的能源消耗,在幾年內抵消安裝成本。未來的成長將取決於煉油廠的瓶頸消除和量化摩擦損失的智慧清管數據,從而說服業主將內襯專案擴展到酸性服務集輸管線之外。

區域分析

預計到 2024 年,北美將佔總營收的 31.54%,到 2030 年將以 5.31% 的最快複合年成長率成長。該地區受益於頁岩氣產量的上升、遠距天然氣走廊的擴張以及《2025 年洩漏檢測規則》等加強的安全法規。管道所有者正在為高硬度胺甲酸乙酯面漆和自修復環氧樹脂分配更大的預算,以最大限度地減少未來在偏遠地區的挖掘。

亞太地區的成長主要由中國、印度和印尼推動,這些地區的水、能源和化學管道數量正在增加。塗料供應商必須設計出能夠在季風潮濕環境下可靠固化並能抵抗熱帶真菌的系統。當地粉末製造商正在提高產能,以滿足預先的倉儲訂單,以支持中國五年規劃中的大型基礎設施項目。

歐洲仍在推進新的液化天然氣和天然氣進口管道建設,而氫氣試點通道則需要新的防滲透層。塗層配方製造商正在與測試實驗室合作,檢驗聚合物-金屬複合阻隔層,使其能夠在100巴的壓力下持續數十年捕獲氫分子。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場狀況

- 市場概況

- 市場促進因素

- 頁岩氣產能增加加速維修週期

- 擴大採用高性能塗料來保護管道防腐

- 亞太地區基礎建設發展與工業化

- 東南亞灌溉和農業活動的增加

- 歐洲對能源基礎設施的需求不斷成長

- 市場限制

- 新發現能源蘊藏量的營運挑戰

- 非開挖PE管在市政供水的應用日益廣泛

- 來自可再生能源替代品的競爭

- 價值鏈分析

- 五力分析

- 供應商的議價能力

- 買方的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

第5章 市場規模及成長預測(金額)

- 依材料類型

- 聚乙烯和聚丙烯

- 環氧樹脂/聚氨酯

- 水泥和混凝土

- 煤焦油瓷漆

- 瀝青瓷漆

- 依表面積

- 管道外塗層

- 管道內塗層

- 按成分

- 粉末

- 溶劑型液體

- 水性液體

- 按最終用戶產業

- 石油和天然氣

- 用水和污水處理

- 礦業

- 農業

- 化學加工和運輸

- 基礎設施

- 其他最終用戶產業

- 按地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 其他亞太地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 其他歐洲國家

- 南美洲

- 巴西

- 阿根廷

- 其他南美

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 其他中東和非洲地區

- 亞太地區

第6章 競爭態勢

- 市場集中度

- 策略趨勢

- 市佔率(%)/排名分析

- 公司簡介

- 3M

- AW Chesterton Company

- Abdel Hadi A. Al-Qahtani & Sons Group of Companies

- Aegion Corporation(Bayou)

- Akzo Nobel NV

- Allan Edwards, Inc.

- Axalta Coating Systems, LLC

- BASF

- Bauhuis BV

- Blocher Oberflachentechnik GmbH

- Borusan Mannesmann

- Celanese Corporation

- CENERGY HOLDINGS

- Dura-Bond Industries

- GBA Products Co Ltd

- Hempel A/S

- Jotun

- LyondellBasell Industries Holdings BV

- Mutares SE & Co. KGaA

- Nippon Paint Holdings Co., Ltd.

- PERMAA-PIPE International Holdings, Inc.

- PPG Industries, Inc.

- Tenaris

- The Sherwin-Williams Company

- Wasco Berhad

第7章 市場機會與未來展望

The Pipe Coatings Market size is estimated at USD 10.02 billion in 2025, and is expected to reach USD 12.51 billion by 2030, at a CAGR of 4.54% during the forecast period (2025-2030).

Mounting investment in new pipelines, a steady asset maintenance schedule, and stricter safety rules sustain demand for protective finishes across oil and gas, water, and industrial segments. North America's shale build-out and Europe's LNG and hydrogen plans keep capacity additions steady, while Asia-Pacific's urban expansion drives long-term structural growth. Technology advances, such as dual-component polyurethane spray systems, graphene-enhanced water-based options, and low-temperature cure powders, are widening application windows and lowering life-cycle costs. Sustainability pressures steer procurement teams toward waterborne and powder solutions, yet solvent systems retain a foothold in harsher environments where proven performance records matter most. Competitive intensity centers on high-performance chemistries, with global suppliers scaling specialized lines to secure offshore, high-pressure, and hydrogen service orders.

Global Pipe Coatings Market Trends and Insights

Increasing Shale Gas Capacity Additions Accelerating Maintenance Cycles

North American operators are fast-tracking new and legacy pipelines, lifting demand for robust coatings that tolerate hydrogen sulfide, carbon dioxide, and microbial attack. With capacity in Argentina's Vaca Muerta field set to double to 540,000 bpd in 2025 because of Oleoductos del Valle's expansion, comparable maintenance windows are shortening, and re-coating intervals are tightening. Formulators respond with thicker epoxy layers and abrasion-resistant urethane overcoats that can be field-applied in a single pass, reducing downtime for operators.

Rising Adoption of High-Performance Coatings for Corrosion Protection in Pipelines

Corrosion costs have put pressure on asset owners to adopt linings that self-heal, resist under-film corrosion, and extend inspection cycles. Dual-component polyurethane systems paired with epoxy seal coats show strong adhesion and an impermeable surface, enabling quick spot repairs in confined spaces. Offshore lines, where a single failure jeopardizes safety and production uptime, are now specified with multi-layer builds that combine fusion-bonded epoxy, abrasion-resistant overcoats, and outer polyethylene wraps.

Operational Challenges in Newly Discovered Energy Reserves

Coatings applied at 3,000 m water depth endure hydrostatic pressures and temperature differentials that stretch legacy specifications. Research backed by the Pipeline and Hazardous Materials Safety Administration is examining thick polymer wraps combined with sacrificial composite layers to mitigate impact damage during seabed installation. Access constraints also complicate inspection, raising the stakes for first-time coating integrity.

Other drivers and restraints analyzed in the detailed report include:

- Growing Infrastructure and Industrialization in the Asia-Pacific Region

- Rise in Irrigation and Agricultural Activities in Southeast Asia

- Rising Adoption of Trenchless PE Pipe in Municipal Water Supply

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Epoxy and polyurethane products accounted for 40.76% of the pipe coatings market size in 2024 and are forecast to outpace the aggregate market at a 4.91% CAGR through 2030. Epoxies deliver proven adhesion over grit-blasted steel, while polyurethane top coats bring abrasion resistance and UV stability. Field crews favor dual-component spray rigs that can lay down a 750-micron build in one pass, shrinking turnaround time on live lines.

Polyethylene and polypropylene maintain traction in water transmission and district heating because of their low moisture diffusion and mechanical flexibility. At the fringes, cementitious wraps and asphalt enamel serve heavy-duty mechanical protection, yet environmental constraints are curbing further uptake. Cross-linked multilayer solutions that combine fusion-bonded epoxy with abrasion-resistant overlays now protect high-impact areas such as directional drill sections, demonstrating how hybrid systems continue to elevate performance baselines.

External finishes represented 78.19% of the pipe coatings market share in 2024 as operators prioritized safeguarding buried steel from soil-borne chloride attack and stray current. The category is predicted to post a 5.18% CAGR until 2030 as pipeline grids age in North America and Europe. Three-layer polyethylene wraps incorporating epoxy primers and adhesive ties remain a mainstay because they couple adhesion with mechanical toughness under wet backfill conditions.

Internal linings, although accounting for a smaller revenue pool, are winning budgets where flow efficiency and mitigation of H2S-induced pitting justify capital outlays. Low-shear epoxy linings can raise effective throughput or enable pump energy savings that offset installation expense within a few years. Future growth hinges on refinery debottlenecking and smart pigging data that quantify friction losses, convincing owners to extend internal coating programs beyond sour-service gathering lines.

The Pipe Coatings Market Report Segments the Industry by Material Type (Polyethylene and Polypropylene, Epoxy and Polyurethane, and More), Surface Location (External Pipe Coatings and Internal Pipe Coatings), Formulation (Powder, and More), End-User Industry (Oil and Gas, Water and Wastewater Treatment, Mining, Agriculture, and More), and Geography (Asia-Pacific, North America, Europe, South America, and Middle-East and Africa).

Geography Analysis

North America contributed 31.54% of 2024 revenue and is expected to post the fastest 5.31% CAGR through 2030. The region benefits from shale output growth, long-haul gas corridor expansions, and reinforced safety regulations such as the 2025 leak detection rule. Pipeline owners are allocating larger budgets to high-build urethane topcoats and self-healing epoxies that minimize future dig-ups in remote terrain.

Asia-Pacific's growth is driven by China, India, and Indonesia, adding pipelines for water, energy, and chemicals. Coating suppliers must engineer systems that cure reliably in monsoon humidity and resist tropical fungi. Local powder producers are installing extra capacity to satisfy build-ahead warehousing orders for mega-infrastructure plans under China's Five-Year Program.

Europe presents a two-speed pattern: new LNG and gas import pipes still move forward, while hydrogen pilot corridors demand novel permeation-resistant layers. Coating formulators are partnering with test labs to validate polymer-metal composite barriers capable of confining hydrogen molecules at 100 bar pressure for decades.

- 3M

- A.W. Chesterton Company

- Abdel Hadi A. Al-Qahtani & Sons Group of Companies

- Aegion Corporation (Bayou)

- Akzo Nobel N.V.

- Allan Edwards, Inc.

- Axalta Coating Systems, LLC

- BASF

- Bauhuis B.V.

- Blocher Oberflachentechnik GmbH

- Borusan Mannesmann

- Celanese Corporation

- CENERGY HOLDINGS

- Dura-Bond Industries

- GBA Products Co Ltd

- Hempel A/S

- Jotun

- LyondellBasell Industries Holdings B.V.

- Mutares SE & Co. KGaA

- Nippon Paint Holdings Co., Ltd.

- PERMAA-PIPE International Holdings, Inc.

- PPG Industries, Inc.

- Tenaris

- The Sherwin-Williams Company

- Wasco Berhad

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Increasing Shale Gas Capacity Additions Accelerating Maintenance Cycles

- 4.2.2 Rising Adoption of of High Performance Coatings for Corrosion Protection in Pipelines

- 4.2.3 Growing Infrastructure and Industrialization in the Asia-Pacific Region

- 4.2.4 Rise in Irrigation and Agricultural Activities in Southeast Asia

- 4.2.5 Accelerating Demand for Energy Infrastructure in Europe

- 4.3 Market Restraints

- 4.3.1 Operational Challenges in Newly Discovered Energy Reserves

- 4.3.2 Rising Adoption of Trenchless PE Pipe in Municipal Water Supply

- 4.3.3 Competition from Renewable Energy Substitutes

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts (Value)

- 5.1 By Material Type

- 5.1.1 Polyethylene and Polypropylene

- 5.1.2 Epoxy and Polyurethane

- 5.1.3 Cement and Concrete

- 5.1.4 Coal Tar Enamel

- 5.1.5 Asphalt Enamel

- 5.2 By Surface Location

- 5.2.1 External Pipe Coatings

- 5.2.2 Internal Pipe Coatings

- 5.3 By Formulation

- 5.3.1 Powder

- 5.3.2 Solvent-Borne Liquid

- 5.3.3 Water-Borne Liquid

- 5.4 By End-User Industry

- 5.4.1 Oil and Gas

- 5.4.2 Water and Wastewater Treatment

- 5.4.3 Mining

- 5.4.4 Agriculture

- 5.4.5 Chemical Processing and Transport

- 5.4.6 Infrastrure

- 5.4.7 Other End-User Industry

- 5.5 Geography

- 5.5.1 Asia-Pacific

- 5.5.1.1 China

- 5.5.1.2 India

- 5.5.1.3 Japan

- 5.5.1.4 South Korea

- 5.5.1.5 Rest of Asia-Pacific

- 5.5.2 North America

- 5.5.2.1 United States

- 5.5.2.2 Canada

- 5.5.2.3 Mexico

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Rest of Europe

- 5.5.4 South America

- 5.5.4.1 Brazil

- 5.5.4.2 Argentina

- 5.5.4.3 Rest of South America

- 5.5.5 Middle-East and Africa

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 South Africa

- 5.5.5.3 Rest of Middle-East and Africa

- 5.5.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share(%)/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 3M

- 6.4.2 A.W. Chesterton Company

- 6.4.3 Abdel Hadi A. Al-Qahtani & Sons Group of Companies

- 6.4.4 Aegion Corporation (Bayou)

- 6.4.5 Akzo Nobel N.V.

- 6.4.6 Allan Edwards, Inc.

- 6.4.7 Axalta Coating Systems, LLC

- 6.4.8 BASF

- 6.4.9 Bauhuis B.V.

- 6.4.10 Blocher Oberflachentechnik GmbH

- 6.4.11 Borusan Mannesmann

- 6.4.12 Celanese Corporation

- 6.4.13 CENERGY HOLDINGS

- 6.4.14 Dura-Bond Industries

- 6.4.15 GBA Products Co Ltd

- 6.4.16 Hempel A/S

- 6.4.17 Jotun

- 6.4.18 LyondellBasell Industries Holdings B.V.

- 6.4.19 Mutares SE & Co. KGaA

- 6.4.20 Nippon Paint Holdings Co., Ltd.

- 6.4.21 PERMAA-PIPE International Holdings, Inc.

- 6.4.22 PPG Industries, Inc.

- 6.4.23 Tenaris

- 6.4.24 The Sherwin-Williams Company

- 6.4.25 Wasco Berhad

7 Market Opportunities and Future Outlook

- 7.1 White-Space and Unmet-Need Assessment

- 7.2 Growth in Deep-Water Exploration and Production

- 7.3 Industrial Expansion in Middle-East and Africa