|

市場調查報告書

商品編碼

1836442

汽車壓力感測器:市場佔有率分析、行業趨勢、統計數據和成長預測(2025-2030 年)Automotive Pressure Sensors - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

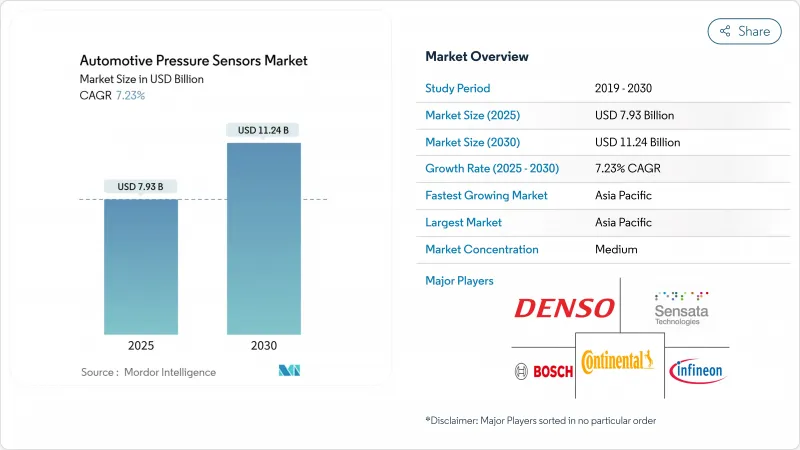

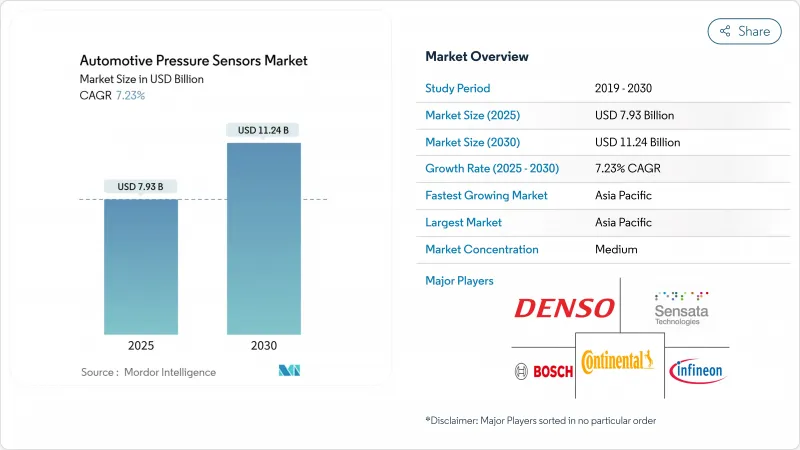

預計汽車壓力感測器市場規模到 2025 年將達到 79.3 億美元,到 2030 年將達到 112.4 億美元,複合年成長率為 7.23%。

隨著製造商用固態設備取代機械儀表,並將數據輸入軟體定義的汽車平臺,市場需求強勁。電力推進系統、自動線控刹車系統以及全球統一的排放氣體法規都要求每輛車配備更多的壓力節點,推高了感測器數量和平均價格。亞太地區在產量和新能源汽車部署方面繼續保持領先地位,而歐洲和北美正在升級車輛,以符合歐盟通用安全法規II,該法規要求所有新車型都必須配備輪胎壓力監測裝置。同時,供應商正在投資碳化矽和電容式MEMS設計,以承受更高的排氣溫度和更低的電池冷卻液壓力,從而擴大了汽車壓力感測器市場的潛在範圍。

全球汽車壓力感測器市場趨勢與洞察

政府強制安裝TPMS

監管機構現在將胎壓資料視為第一線安全資訊。自2024年7月起,歐盟《通用安全法規II》將要求所有新乘用車、巴士、卡車和拖車必須安裝胎壓監測系統 (TPMS)。美國已經頒布了類似的規定,南美洲和東南亞各國政府也正在起草相應的法規。原始設備製造商正在利用強制的無線骨幹網路來分層進行胎面磨損分析和雲端警報,提升感測器的價值,並青睞那些提供通過網路安全審核的加密通訊協定的供應商。

擴大電動動力傳動系統生產

純電動平台在冷卻液迴路、線控刹車電路和密封冷媒系統中引入了額外的壓力節點。精準的回饋可防止熱失控,並最佳化快速充電溫度視窗。中國組裝商在每個模組中整合多個低壓MEMS晶片,而歐洲高階品牌則轉向需要更強電氣隔離的800伏特架構。資料點數量的成長推動了產量和複雜性的提升,這使得在汽車壓力感測器市場中,那些將強大的硬體與電池組健康演算法相結合的供應商受益匪淺。

感測器價格下降和利潤壓力

儘管汽車製造商正在協商將傳統歧管和胎壓監測系統(TPMS)儀表的年度成本降低2-3%,但東南亞的代工廠正在複製成熟的設計,導致利潤率不斷下降。為了保護價格,供應商正在捆綁診斷和預測性維護API,以產生訂閱收入。然而,持續的成本削減目標要求精益封裝、外包測試和大幅縮小晶粒尺寸,這給規模較小的製造商帶來了挑戰,並削弱了汽車壓力感測器市場的短期盈利。

報告中分析的其他促進因素和限制因素

- ADAS 與自動駕駛系統的整合度不斷提高

- 更嚴格的全球排放氣體和燃油經濟性標準

- 半導體供應鏈不穩定

細分分析

乘用車佔據了大部分部署,這不僅反映了全球生產規模,也反映了向電力推進的快速轉變。到 2024 年,乘用車平台將佔據汽車壓力感測器市場佔有率的 65.18%,到 2030 年的複合年成長率將達到 8.15%。隨著豪華車整合自我調整空氣懸吊、主動空氣動力學和預測性煞車服務,應用將會加速。電動轎車將在電池冷卻系統和座艙熱泵中增加低壓節點,從而增加每輛車的感測器數量。商用廂型車和輕型卡車的銷售落後,但正受到需要負載監控和再生煞車最佳化的最後一哩送貨車隊的關注。根據歐盟的新批准,中型和重型卡車面臨強制性的 TPMS 要求,這促使人們採用更廣泛範圍的儀表來應對更苛刻的工作週期。自動駕駛貨運飛機正在採用冗餘壓力迴路來滿足故障操作標準。因此,透過提供跨車型的多樣化產品,供應商可以對沖任何單一領域的周期性疲軟,從而支持汽車壓力感測器市場的持續成長。

第二梯隊的成長來自專用非公路用車,這些車輛的液壓操作和長時間運行推動了對高壓膜片的需求。農業機械透過數位控制輪胎壓力來管理土壤壓實,而施工機械即時追蹤液壓健康狀況。這些感測器配備不銹鋼或陶瓷單元和密封連接器,儘管產量不大,但仍推動了平均售價的上漲。因此,乘用車領域的領先地位與重型應用領域盈利的利基市場並存,豐富了汽車壓力感測器產業的整體價值。

胎壓監測系統將佔 2024 年銷售量的 39.25%,鞏固其作為新法規入口網站的角色。輕型車將配備四到六個輪艙感應器,高級內裝將增加第五個備胎單元。感測器電池壽命可達 10 年,創造類似年金的售後市場。然而,歐盟 7 將推動對廢氣再循環、微粒捕集器和 SCR 劑量子系統的支出增加,這些子系統需要持續的壓力回饋。這些排氣模組的複合年成長率最快,為 10.45%,需要高溫碳化矽晶片,其平均售價是典型 TPMS 單元的兩倍。煞車和 ABS 壓力感測仍將是穩定的核心,但向線控刹車的過渡將提高解析度和冗餘度,從而增加設備的數量。引擎歧管、油晶粒和渦輪增壓感測將持續發展,在壓力波動較大的情況下變得更加精確,即使電氣化不斷發展,仍能維持原有的需求。在所有頻寬中,汽車壓力感測器市場受益於多樣化的應用諮詢,合規投資推動短期飆升,而軟體支援的健康功能則產生長期收益。

在車內,智慧安全氣囊模組利用氣壓資訊來改善乘員分類。下一代空調控制系統利用蒸氣壓縮監測來最佳化電動車常用熱泵的冷媒充填量。駕馭控制系統整合高速10 kHz壓力感知器,用於調節半主動式減震器。隨著感測器數量的增加,連接複用數位匯流排正在取代類比線路,從而減輕線束重量並提高可靠性。感測器種類的不斷擴展表明,汽車壓力感測器市場正在從單一用途的類比儀表向為集中式域控制器提供資料的聯網數位節點持續轉型。

汽車壓力感知器市場報告按車輛類型(乘用車、輕型商用車、其他)、應用(胎壓監測系統 (TPMS)、其他)、壓力類型(絕對壓力、差壓、其他)、感測器技術(壓阻式 MEMS、其他)、銷售管道(OEM 安裝、售後市場)和地區細分。市場預測以銷售額(美元)和銷售量(單位)表示。

區域分析

亞太地區是汽車壓力感測器市場的銷售引擎,2024年將以49.66%的市佔率位居榜首。隨著中國加快電動車生產步伐,並採用多個低壓節點以確保電池安全,預計到2030年,該地區的複合年成長率將達到9.66%。 「國家內容授權」獎勵MEMS(微機電系統)的國內採購,從而減少對進口的依賴,本地製造商正受益於此。印度正在古吉拉突邦和泰米爾納德邦擴大其汽車組裝叢集,培育區域感測器供應鏈以及動力傳動系統電子元件。日本將保持在微加工工具領域的領先地位,為全球品牌提供外包晶圓製造服務。政府對智慧移動實驗室的補貼將縮短該地區的設計週期,並增強其競爭力。

北美正經歷著監管拉動和技術推動的雙重驅動。美國國家公路交通安全管理局(NHTSA)關於胎壓通訊協定(TPMS)的規定和美國環保署(EPA)的排放標準確保了基準需求,而矽谷的軟體堆疊則加速了向偏向數位壓力協議的集中式領域的轉變。總部位於底特律的原始設備製造商(OEM)正在實現電池組組裝和溫度控管整合的本地化,從而增加了國產感測器的數量。隨著加拿大重型卡車產業採用高精度胎壓控制以提高燃油經濟性,感測器的應用範圍擴展到職業應用。墨西哥的二級供應商生態系統提供模製外殼和導線架沖壓件,支援整個汽車壓力感測器市場的區域成本最佳化。

歐洲的政策情勢最具挑戰性。歐7強制要求即時廢氣監測,推動了碳化矽高溫感測器的廣泛應用。通用安全法規要求所有車型安裝胎壓監測系統 (TPMS),從而提高了拖車和乘用車的感測器密度。德國高階汽車製造商指定使用雙冗餘煞車壓力模組,用於3級自動駕駛認證。法國和義大利正在投資振興整合先進電池冷卻液感測技術的電動公車計劃。東歐工廠正在吸引新的MEMS封裝投資,並利用通用市場中具有競爭力的勞動力。總體而言,協調一致的法規和成熟的終端用戶將穩定汽車壓力感測器市場的長期需求。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章 市場狀況

- 市場概況

- 市場促進因素

- 政府強制安裝TPMS

- 電動動力傳動系統產量增加

- ADAS 與自動駕駛系統的整合度不斷提高

- 全球排放和燃油經濟性法規更加嚴格

- 基於 SiC 的高溫感測器開創了排氣側用例

- OTA預後診斷需要自我診斷智慧感測器

- 市場限制

- 感測器價格上漲和利潤壓力

- 半導體供應鏈的波動

- TPMS訊號欺騙帶來的網路風險

- 複雜的多標準認證負擔

- 價值/供應鏈分析

- 監管狀況

- 技術展望

- 五力分析

- 新進入者的威脅

- 買方的議價能力

- 供應商的議價能力

- 替代品的威脅

- 競爭對手之間的競爭強度

第5章市場規模與成長預測:價值(美元)與數量(單位)

- 按車輛類型

- 搭乘用車

- 輕型商用車

- 中大型商用車

- 按用途

- 輪胎壓力監測系統(TPMS)

- 煞車助力器和 ABS

- 引擎和燃料/歧管管理

- 廢氣再循環/後處理

- 安全氣囊和安全約束系統

- 車輛動力學和 ESC

- 按壓力類型

- 絕對壓力

- 表壓(密封/通風)

- 微分

- 真空/低壓

- 透過感測器技術

- 壓阻式MEMS

- 電容式MEMS

- 共振/晶體

- 光電子,其他

- 按銷售管道

- OEM 適配

- 售後市場

- 按地區

- 北美洲

- 美國

- 加拿大

- 北美其他地區

- 南美洲

- 巴西

- 阿根廷

- 其他南美

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 其他歐洲國家

- 亞太地區

- 中國

- 日本

- 印度

- 韓國

- 其他亞太地區

- 中東和非洲

- 阿拉伯聯合大公國

- 沙烏地阿拉伯

- 埃及

- 南非

- 其他中東和非洲地區

- 北美洲

第6章 競爭態勢

- 市場集中度

- 策略趨勢

- 市佔率分析

- 公司簡介

- Robert Bosch GmbH

- Continental AG

- Sensata Technologies, Inc.

- DENSO Corporation

- Infineon Technologies AG

- STMicroelectronics NV

- NXP Semiconductors NV

- Texas Instruments Incorporated

- Autoliv Inc.

- Allegro MicroSystems, LLC

- TE Connectivity Ltd.

- Honeywell International Inc.

- Analog Devices, Inc.

- Melexis NV

- Aptiv PLC

- Amphenol Advanced Sensors

- Alps Alpine Co., Ltd.

- Bourns, Inc.

- Nidec-Copal Electronics

第7章 市場機會與未來展望

The automotive pressure sensors market size was USD 7.93 billion in 2025 and is projected to reach USD 11.24 billion by 2030, reflecting a healthy 7.23% CAGR.

Robust demand arises as manufacturers replace mechanical gauges with solid-state devices that feed data into software-defined vehicle platforms. Electric propulsion, autonomous-ready brake-by-wire systems, and globally harmonized emission limits each call for more pressure nodes per vehicle, lifting both unit volumes and average sensor value. Asia-Pacific continues to set the pace in production scale and new-energy-vehicle rollouts, while Europe and North America upgrade fleets to comply with the EU General Safety Regulation II that obliges tire pressure monitoring on every new vehicle class . Meanwhile, suppliers invest in silicon-carbide and capacitive MEMS designs that survive hotter exhaust and lower battery-coolant pressures, expanding the total addressable scope of the automotive pressure sensors market.

Global Automotive Pressure Sensors Market Trends and Insights

Government Mandates for TPMS Fitment

Regulators now treat tire-pressure data as frontline safety information. From July 2024, the EU General Safety Regulation II requires TPMS on every new passenger car, bus, truck, and trailer . Comparable mandates already exist in the United States, while South American and Southeast Asian governments draft matching rules. OEMs exploit the mandatory wireless backbone to layer tread-wear analytics and cloud alerts, increasing sensor value, and they prefer vendors offering encrypted protocols that pass cybersecurity audits.

Escalating Electrified-Powertrain Production

Battery-electric platforms introduce extra pressure nodes in coolant loops, brake-by-wire circuits, and closed refrigerant systems; accurate feedback prevents thermal runaway and optimizes fast-charge temperature windows. Chinese assemblers embed several low-pressure MEMS dice per module, whereas European premium brands migrate to 800-volt architectures needing stronger electrical isolation. The growing datapoint count enlarges both volume and complexity, rewarding suppliers that marry robust hardware with pack-health algorithms inside the automotive pressure sensors market.

Sensor Price-Erosion and Margin Pressure

Automakers negotiate yearly 2-3% cost reductions on legacy manifold and TPMS gauges, while Southeast Asian contract foundries replicate mature designs, compressing margins. To defend pricing, suppliers bundle diagnostics and predictive-maintenance APIs that create subscription revenue. Nonetheless, relentless cost-down targets demand lean packaging, outsourced test, and aggressive die shrinks, challenging smaller firms and tempering short-term profitability inside the automotive pressure sensors market.

Other drivers and restraints analyzed in the detailed report include:

- Rising Integration of ADAS and Autonomous Systems

- Stricter Global Emission and Fuel-Economy Norms

- Semiconductor Supply-Chain Volatility

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Passenger cars dominate deployments, reflecting both global production scale and the rapid shift toward electric propulsion. In 2024, passenger platforms held 65.18% of the automotive pressure sensors market share and are tracking an 8.15% CAGR to 2030. Adoption accelerates as luxury marques integrate adaptive air suspension, active aerodynamics, and predictive brake servicing. Electric sedans place additional low-pressure nodes in battery chillers and cabin heat pumps, expanding sensor counts per vehicle. Commercial vans and light trucks trail in volume yet attract attention from last-mile delivery fleets that demand load monitoring and regenerative braking optimization. Medium and heavy trucks face EU mandates for TPMS on new approvals, spurring higher-range gauges that thrive in harsher duty cycles. Autonomous freight pilots employ redundant pressure circuits to satisfy fail-operational criteria. Consequently, diversified offerings across vehicle classes allow suppliers to hedge cyclical softness in any single segment, supporting sustainable gains for the automotive pressure sensors market.

Second-tier growth comes from specialized off-highway vehicles where hydraulic workloads and extended duty drive demand for high-proof-pressure diaphragms. Agricultural machinery integrates digital tire inflation control for soil compaction management, while construction equipment adopts real-time hydraulic health tracking. Though unit volumes are modest, ASPs rise because these sensors pack stainless or ceramic cells and sealed connectors. Passenger car leadership therefore coexists with profitable niches in heavy applications, enriching the overall value capture of the automotive pressure sensors industry.

Tire pressure monitoring systems generated 39.25% of 2024 revenue, cementing their role as the entry point for new regulations. Each light vehicle carries four to six wheel-well sensors, and premium fitments add a fifth spare-wheel unit. Sensor batteries last up to 10 years, creating an annuity-like aftermarket. Yet Euro 7 shifts incremental expenditure toward exhaust gas recirculation, particulate trap, and SCR dosing subsystems that now need continuous pressure feedback. These exhaust modules post the fastest 10.45% CAGR and require high-temperature silicon-carbide dies that command double the ASP of common TPMS units. Brake and ABS pressure sensing remains a steady core, though migration to brake-by-wire introduces finer resolution and redundancy that raise device count. Engine manifold, fuel rail, and turbo boost sensing evolve toward higher accuracy at large pressure swings, keeping legacy demand intact even as electrification proceeds. Across every bandwidth, the automotive pressure sensors market benefits from diversified application pull, with compliance spend fueling near-term spikes and software-enabled health features creating longer-cycle revenue.

Inside the cabin, smart airbag modules employ barometric pressure information to improve occupant classification. Next-generation climate control leverages vapor-compression monitoring to optimize refrigerant charge in heat pumps common to EVs. Ride-control systems embed fast 10 kHz pressure pick-ups to regulate semi-active dampers. As sensor counts expand, multiplexed digital buses replace analog lines, simplifying harness weight and boosting reliability. The widening scope underlines how the automotive pressure sensors market continues to migrate from single-purpose analog gauges to networked digital nodes that feed centralized domain controllers.

The Automotive Pressure Sensors Market Report is Segmented by Vehicle Type (Passenger Cars, Light Commercial Vehicles, and More), Application (Tire Pressure Monitoring System (TPMS), and More), Pressure Type (Absolute, Differential, and More), Sensor Technology (Piezoresistive MEMS, and More), Sales Channel (OEM-Fitted and Aftermarket), and Geography. The Market Forecasts are Provided in Terms of Value (USD) and Volume (Units).

Geography Analysis

Asia-Pacific remains the volume engine for the automotive pressure sensors market, leading with 49.66% share in 2024. The region is further projected to grow with a 9.66% CAGR by 2030, as China accelerates electric-vehicle production and embeds multiple low-pressure nodes for battery safety. Local makers benefit from national content mandates that incentivize domestic MEMS sourcing, reducing import reliance. India scales automotive assembly clusters in Gujarat and Tamil Nadu, fostering regional sensor supply chains alongside powertrain electronics. Japan sustains leadership in micro-machining tools, feeding outsourced wafer fabrication for global brands, while South Korea leverages its consumer-electronics fabs to push sensor miniaturization. Government subsidies for smart mobility labs keep regional design cycles short, enhancing competitiveness.

North America combines regulatory pull with technology push. NHTSA rules on TPMS and EPA emission standards ensure baseline demand, while Silicon Valley software stacks accelerate the shift to centralized domains that favor digital pressure protocols. Detroit OEMs localize battery pack assembly and thermal management integration, increasing domestic sensor content. Canada's heavy-truck sector adopts high-accuracy tire inflation control for fuel-efficiency gains, extending sensor use into vocational applications. Mexico's Tier-2 ecosystem supplies molded housings and lead frame stampings, supporting regional cost optimization across the automotive pressure sensors market.

Europe's policy landscape is the most stringent. Euro 7 legislation forces real-time exhaust monitoring, driving uptake of SiC high-temperature sensors . The General Safety Regulation obliges TPMS on every vehicle class, elevating sensor density in trailers and coaches. Germany's premium OEMs specify dual-redundant brake pressure modules for Level-3 autonomous approval. France and Italy channel recovery funds into electric-bus projects that integrate advanced battery coolant sensing. Eastern European plants attract new MEMS packaging investments, exploiting competitive labor while staying inside the common market. Altogether, synchronized regulations and sophisticated end-users stabilize long-run demand across the automotive pressure sensors market.

- Robert Bosch GmbH

- Continental AG

- Sensata Technologies, Inc.

- DENSO Corporation

- Infineon Technologies AG

- STMicroelectronics N.V.

- NXP Semiconductors N.V.

- Texas Instruments Incorporated

- Autoliv Inc.

- Allegro MicroSystems, LLC

- TE Connectivity Ltd.

- Honeywell International Inc.

- Analog Devices, Inc.

- Melexis NV

- Aptiv PLC

- Amphenol Advanced Sensors

- Alps Alpine Co., Ltd.

- Bourns, Inc.

- Nidec-Copal Electronics

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions & Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Government mandates for TPMS fitment

- 4.2.2 Escalating electrified-powertrain production

- 4.2.3 Rising integration of ADAS and autonomous systems

- 4.2.4 Stricter global emission and fuel-economy norms

- 4.2.5 SiC-based high-temperature sensors open exhaust-side use-cases

- 4.2.6 OTA prognostics require self-diagnosing smart sensors

- 4.3 Market Restraints

- 4.3.1 Sensor price-erosion and margin pressure

- 4.3.2 Semiconductor supply-chain volatility

- 4.3.3 Cyber-risk of TPMS signal spoofing

- 4.3.4 Complex multi-standard certification burden

- 4.4 Value/Supply-Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces

- 4.7.1 Threat of New Entrants

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Bargaining Power of Suppliers

- 4.7.4 Threat of Substitutes

- 4.7.5 Intensity of Competitive Rivalry

5 Market Size & Growth Forecasts (Value (USD) and Volume (Units))

- 5.1 By Vehicle Type

- 5.1.1 Passenger Cars

- 5.1.2 Light Commercial Vehicles

- 5.1.3 Medium and Heavy Commercial Vehicles

- 5.2 By Application

- 5.2.1 Tire Pressure Monitoring System (TPMS)

- 5.2.2 Brake Booster and ABS

- 5.2.3 Engine and Fuel/Manifold Management

- 5.2.4 Exhaust Gas Recirculation/After-treatment

- 5.2.5 Airbag and Safety Restraint Systems

- 5.2.6 Vehicle Dynamics and ESC

- 5.3 By Pressure Type

- 5.3.1 Absolute

- 5.3.2 Gauge (Sealed/Vent)

- 5.3.3 Differential

- 5.3.4 Vacuum/Low-pressure

- 5.4 By Sensor Technology

- 5.4.1 Piezoresistive MEMS

- 5.4.2 Capacitive MEMS

- 5.4.3 Resonant/Quartz

- 5.4.4 Opto-electronic and Others

- 5.5 By Sales Channel

- 5.5.1 OEM-Fitted

- 5.5.2 Aftermarket

- 5.6 By Geography

- 5.6.1 North America

- 5.6.1.1 United States

- 5.6.1.2 Canada

- 5.6.1.3 Rest of North America

- 5.6.2 South America

- 5.6.2.1 Brazil

- 5.6.2.2 Argentina

- 5.6.2.3 Rest of South America

- 5.6.3 Europe

- 5.6.3.1 Germany

- 5.6.3.2 United Kingdom

- 5.6.3.3 France

- 5.6.3.4 Italy

- 5.6.3.5 Rest of Europe

- 5.6.4 Asia-Pacific

- 5.6.4.1 China

- 5.6.4.2 Japan

- 5.6.4.3 India

- 5.6.4.4 South Korea

- 5.6.4.5 Rest of Asia-Pacific

- 5.6.5 Middle East and Africa

- 5.6.5.1 United Arab Emirates

- 5.6.5.2 Saudi Arabia

- 5.6.5.3 Egypt

- 5.6.5.4 South Africa

- 5.6.5.5 Rest of Middle East and Africa

- 5.6.1 North America

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (Includes Global Level Overview, Market Level Overview, Core Segments, Financials as Available, Strategic Information, Market Rank/Share for Key Companies, Products and Services, SWOT Analysis, and Recent Developments)

- 6.4.1 Robert Bosch GmbH

- 6.4.2 Continental AG

- 6.4.3 Sensata Technologies, Inc.

- 6.4.4 DENSO Corporation

- 6.4.5 Infineon Technologies AG

- 6.4.6 STMicroelectronics N.V.

- 6.4.7 NXP Semiconductors N.V.

- 6.4.8 Texas Instruments Incorporated

- 6.4.9 Autoliv Inc.

- 6.4.10 Allegro MicroSystems, LLC

- 6.4.11 TE Connectivity Ltd.

- 6.4.12 Honeywell International Inc.

- 6.4.13 Analog Devices, Inc.

- 6.4.14 Melexis NV

- 6.4.15 Aptiv PLC

- 6.4.16 Amphenol Advanced Sensors

- 6.4.17 Alps Alpine Co., Ltd.

- 6.4.18 Bourns, Inc.

- 6.4.19 Nidec-Copal Electronics

7 Market Opportunities & Future Outlook

- 7.1 White-space & Unmet-Need Assessment