|

市場調查報告書

商品編碼

1693725

歐洲半導體材料:市場佔有率分析、行業趨勢和統計數據、成長預測(2025-2030 年)Europe Semiconductor Materials - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

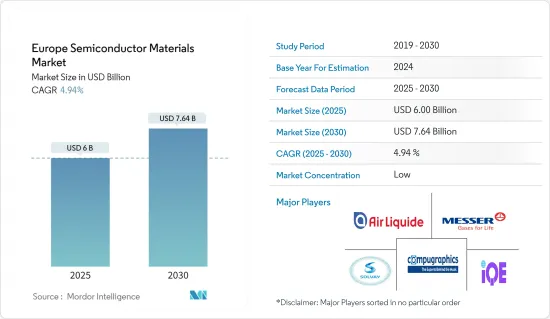

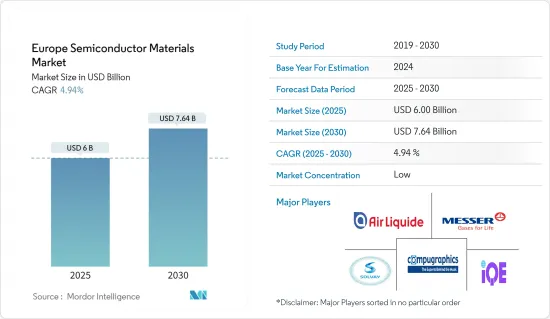

預計 2025 年歐洲半導體材料市場規模為 60 億美元,到 2030 年將達到 76.4 億美元,預測期內(2025-2030 年)的複合年成長率為 4.94%。

半導體材料是電子產業的關鍵技術創新之一。矽(Si)、鍺(Ge)和砷化鎵(GaAs)等材料的採用使電子製造商能夠取代傳統的熱敏設備,這些設備會使電子產品變得笨重且不便攜。

關鍵亮點

- 矽是目前市面上最常見的半導體設備。但對更小、更快的積體電路日益成長的需求正在將矽的效率推向極限,導致許多業內專家擔心矽可能很快就會達到莫耳定律的極限。同時,各種研究舉措正在進行,以開發新材料,推動研究市場的創新。

- 此外,由於生產先進節點積體電路、異質整合和 3D 記憶體架構需要更多的處理步驟,半導體產業正在加速發展,預計這將增加晶圓製造和封裝材料的消費量,從而增加對半導體材料的需求。

- 提高能源效率並因此減少任何電子設備運作中的損耗是普遍的行業趨勢。因此,預計節能組件的需求將強勁成長,特別是在從電動車驅動裝置到充電站和電源等能源密集型應用領域。

- 半導體產業被認為是最複雜的產業之一。這是因為他們的製造涉及多個流程和各種產品,並且面臨著充滿挑戰的環境,包括動盪的電子市場和不可預測的需求。

- 包括歐洲在內的全球範圍內爆發的新冠肺炎疫情嚴重擾亂了受訪市場的供應鏈和生產。市場上的許多終端用戶產業也受到了疫情的影響,進而對市場產生了負面影響。

歐洲半導體材料市場趨勢

半導體材料的技術進步與產品創新

- 隨著新材料和新製造方法的發現,半導體正在從切割或形成薄盤或晶片的剛性基板轉向更柔軟的塑膠材料甚至紙張。基板越來越軟的趨勢使得一系列裝置成為可能,從發光二極體到太陽能電池到電晶體。

- 此外,2022 年 12 月,開發新晶片製造方法的英國新興企業Pragmatic Semiconductor 從投資者那裡籌集了 3,500 萬美元。該公司營運晶片製造工廠,生產可彎曲而不會斷裂的軟性處理器。最值得注意的是,此處理器不含矽。 2022 年,Pragmatic 和 Arm 展示了 PlasticArm,這是一種由安裝在塑膠基板上的金屬氧化物電晶體組成的軟體處理器。

- 莫耳定律推動了計算設備的進步,使其變得更小、更快、更便宜。因此,半導體產業必須解決如何將最初為幾微米開發的製程轉移到幾奈米量級的連接點形成的挑戰。

- 在歐盟資助的FACIT(複合半導體快速退火用於新技術整合)計劃中,科學家成功地將III-V族材料銦鎵砷(InGaAs)與矽鍺(SiGe)技術結合,並製造出了CMOS晶片。新開發的製程適合晶片的大規模生產,這使其成為晶片製造商的可行選擇。企劃團隊開發了一種工藝,可以使用相同的 350-400 毫米大型 Si 晶圓整合 InGaAs、SiGe 和 Si CMOS 層。科學家設想這種方法可以在奈米層級上進一步縮小和微型化 CMOS 技術。

消費性電子產品成長

- 半導體材料的開發是電子產業最重大的技術進步之一。這種材料因其高電子遷移率、寬動作溫度範圍和低能量要求而受到青睞。大多數家用電子電器產品都使用半導體。行動電話、電腦、遊戲機、微波爐、冰箱等都採用積體電路、二極體、電晶體等半導體元件。

- 電力電子技術所使用的半導體材料直接影響系統效率。電力電子系統用於行動電話和家用電子電器產品,將電能從一種形式轉換為另一種形式並調節其能量水平。其中之一就是碳化矽(SiC)。特別是,SiC 具有使其能夠在高溫和高電位下運作的特性,從而可以製造出更小的組件並提高功率轉換效率。因此,該領域的進步推動了對 SiC 等材料的迫切需求。

- 電子製造商延長電池壽命的需求正在推動對 SiC 半導體材料的需求。消費性電子產品製造商正在升級其產品中的電池。該領域的市場擴張是由消費者對低充電設備的需求所推動的。該市場SiC半導體的主要消費者是智慧型手機、穿戴式裝置和其他主要家用電子電器產品的製造商。

- 製造商和政府正在開發能夠在相對較短的時間內為設備充電的智慧型手機充電器。因此,它們的額定電流從 0.5 毫安培增加到 5 毫安培。 USB-C 和板載轉接器中的 SiC 半導體對於維持所需的電流和電壓等級至關重要。穿戴式裝置市場和個人電腦市場都遵循著類似的軌跡。未來幾代車載充電器和 USB-C 轉接器中的 GaN 和 SiC 設備將具有超高功率密度。 OPPO、One Plus、摩托羅拉、三星和蘋果等製造商分銷這些快速充電適配器已成為其行銷策略的主要內容。

歐洲半導體材料產業概況

歐洲半導體材料市場競爭適中,由幾家大公司組成。市場似乎相當集中。新玩家的進入門檻很高。新進入者必須適應高資本要求,而市場技術密集的性質使得市場先驅者必須密切追蹤技術發展。

- 2022 年 10 月-IQE(國際量子外延)PLC 與 SK Silicon 簽署策略合作協議,共同開發和商業化複合半導體產品。 IQE 和 SK Ultron 將專注於開發和交付基於 SiC(碳化矽)上 GaN(氮化鎵)的創新外延片,用於無線通訊市場的射頻應用,以及基於 Si(矽)上 GaN 的創新外延片,用於各種市場的電力電子應用。

- 2022 年 7 月-BASF和工業株式會社(TODA)宣布進一步擴大其位於日本小野田工廠的BASF戶田電池材料有限責任公司(BTBM)的生產能力。此次擴建將增加高鎳正極活性材料的供應,使電池產能達到每年45GWh。此次擴張將為工業和消費產業的二次電池和合金生產中的半導體製造商帶來更多利益。

其他福利

- Excel 格式的市場預測 (ME) 表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 研究範圍

第2章調查方法

第3章執行摘要

第4章 市場洞察

- 市場概覽

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 消費者議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭對手之間的競爭強度

- 產業價值鏈/供應鏈分析

- COVID-19 市場影響

第5章市場動態

- 市場促進因素

- 半導體材料的技術進步與產品創新

- 家用電子電器產品需求不斷成長

- OSAT/封裝公司的需求增加

- 市場限制

- 製造過程的複雜性

第6章市場區隔

- 按應用

- 製造

- 製程化學

- 光掩模

- 電子氣體

- 光阻劑

- 濺鍍靶材

- 矽

- 其他製造應用

- 包裝

- 基板

- 導線架

- 陶瓷封裝

- 鍵合線

- 封裝樹脂(液體)

- 晶片黏接材料

- 其他包裝應用

- 製造

- 按最終用戶產業

- 消費性電子產品

- 通訊業

- 製造業

- 車

- 能源公共產業

- 其他

第7章競爭格局

- 公司簡介

- Solvay SA

- Messer SE & Co. KGaA

- Air Liquide SA

- Compugraphics(MacDermid Alpha Electronics Solutions)

- International Quantum Epitaxy PLC(IQE PLC)

- BASF SE

- Henkel AG & Co. KGaA

- Caplinq Europe BV

第8章 市場展望

The Europe Semiconductor Materials Market size is estimated at USD 6.00 billion in 2025, and is expected to reach USD 7.64 billion by 2030, at a CAGR of 4.94% during the forecast period (2025-2030).

Semiconductor materials represent one of the significant innovations in the electronics industry. By employing materials such as silicon (Si), germanium (Ge), and gallium arsenide (GaAs), electronics manufacturers have been able to replace traditional thermal devices that made electronic items heavy and non-portable.

Key Highlights

- Silicon is the most popular semiconductor element available in the current market scenario. However, the increasing demand for ever-smaller, faster-integrated circuits has pushed the efficiency of the material to its limits, with many industry experts fearing silicon will soon reach the limits of Moore's Law. In the meantime, various research initiatives are being undertaken to develop new materials, driving innovation in the studied market.

- Moreover, with the miniaturization trend gaining momentum in the semiconductor industry, the demand for semiconductor materials is also expected to grow as manufacturing advanced node ICs, heterogeneous integration, and 3D memory architectures require more processing steps, driving higher wafer fabrication and packaging materials consumption as a result.

- Higher energy efficiency and resulting lower losses in all electronic operations is a general trend in the industry. As such, the demand for energy-efficient components is expected to grow strongly, especially in energy-intensive applications, from electric vehicle drives to charging stations and power supplies.

- The semiconductor industry is considered one of the most complex industries. This is because more than several processing steps and various products are involved in their manufacturing and the harsh environment it faces, e.g., the volatile electronic market and the unpredictable demand.

- The outbreak of the COVID-19 pandemic worldwide, including in Europe, significantly disrupted the supply chain and production of the market studied. Many end-user industries of the market were also affected by the pandemic, which, in turn, had a negative impact on the market.

Europe Semiconductor Materials Market Trends

Technical Advancement and Product Innovation of the Semiconductor Materials

- Semiconductors are moving away from rigid substrates, cut or formed into thin discs or wafers, to more flexible plastic material and paper, all due to new material and fabrication discoveries. The trend toward more flexible substrates has led to numerous devices, from light-emitting diodes to solar cells and transistors.

- Moreover, in December 2022, Pragmatic Semiconductor Ltd, a UK-based startup developing a new approach to chip production, raised USD 35 million from investors. The company operates a chip fabrication facility, or fab, that manufactures flexible processors that bend without breaking. Most notably, the processors do not contain silicon. In 2022, Pragmatic and Arm Ltd demonstrated a flexible processor, PlasticArm, which consists of metal-oxide transistors implemented on a plastic substrate.

- Moore's law has been driving advances in computing devices as they keep getting smaller, faster, and cheaper. Thus, the semiconductor industry needs to address the challenge of how to migrate processes that were once developed for a few microns to be able to form junctions that are a few nanometers in scale.

- Within the project FACIT (fast annealing of compound semiconductors for integration of new technologies), which is funded by the European Union, scientists have successfully combined III-V materials, indium, gallium, and arsenide (InGaAs), with silicon germanium (SiGe) technology to create CMOS chips. The newly developed process is compatible with high-volume chip fabrication, which makes it a viable option for chip manufacturers. Using the same large-sized Si wafer of 350-400 mm, the project team has developed a process that allows the integration of InGaAs, SiGeand Si CMOS layers. Scientists have considered this method as a way of further shrinking and scaling CMOS technology at a nanometer level.

Consumer Electronics to Witness the Growth

- The creation of semiconductor materials is one of the most significant technological advances in the electronics industry. Because of its high electron mobility, wide operating temperature range, and low energy need, the material is well-liked. Semiconductors are used in the majority of consumer electronics. Mobile phones, computers, game consoles, microwaves, and refrigerators all employ semiconductor components, including integrated circuits, diodes, and transistors.

- Power electronics use semiconductor materials, which directly impact system efficiency. Power electronics systems are used by mobile phones and home appliances to convert electrical power from one form to another and regulate its energy level. One of these is silicon carbide (SiC), which has characteristics that, among other things, enable operation at higher temperatures and higher electrical potential, resulting in smaller components and greater power conversion efficiency. Thus, advancements in this area immediately raise the need for materials like SiC.

- The requirement for electronic makers to extend battery life is fuelling the demand for SiCmaterial semiconductors. Manufacturers of consumer gadgets are upgrading the batteries in their products. The market expansion of this sector is driven by consumer desire for low-charging gadgets. The primary consumers of SiC semiconductors in this market are the manufacturers of smartphones, wearable devices, and other major consumer electronics.

- Manufacturers and governments are creating smartphone chargers that can charge the device in a relatively short period. Therefore, the current rating for these has increased from 0.5 milliamps to 5 milliamps. The USB-C and On Board adapters' SiC semiconductors are essential for sustaining the necessary current and voltage levels. The wearable device and PC markets have both followed a similar trajectory. GaNand SiC Devices in the future generation of onboard chargers and USB-C adapters provide ultra-high power density. The distribution of these fast-charging adapters by producers like OPPO, One Plus, Motorola, Samsung, and Apple is the cornerstone of their marketing tactics.

Europe Semiconductor Materials Industry Overview

The European semiconductor materials market is reasonably competitive and consists of several major players. The market appears to be moderately concentrated. The market poses high barriers to entry for new firms. New entrants must be content with high capital requirements, while the technology-intensive nature of the market makes it imperative for market players to closely track technological developments.

- October 2022 - IQE (International Quantum Epitaxy) PLC entered into a strategic collaboration agreement with SK silicon to develop and commercialize compound semiconductor products. IQE and SK Ultron will focus on developing and delivering innovative epi wafers based upon GaN (Gallium Nitride) on SiC (Silicon Carbide) for radio frequency applications in the wireless communications market and GaN on Silicon (Si) for power electronics applications across various markets.

- July 2022 - BASF and Toda Kogyo Corp. (TODA) announced that they would further expand the production capacity of BASF TODA Battery Materials LLC (BTBM) at the Onoda site in Japan. This expansion increases the supply of high nickel cathode active materials for up to 45 GWh cell capacity per year. This expansion would increase benefits for the semiconductor manufacturers in manufacturing rechargeable batteries and alloys across industrial and consumer industries.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Consumers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitute Products

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Industry Value Chain/Supply Chain Analysis

- 4.4 Impact of COVID-19 on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Technical Advancement and Product Innovation of the Semiconductor Materials

- 5.1.2 Rising Demand for Consumer Electronics Goods

- 5.1.3 Increased Demand from OSAT/Packaging Companies

- 5.2 Market Restraints

- 5.2.1 Complexity in the Manufacturing Process

6 MARKET SEGMENTATION

- 6.1 By Application

- 6.1.1 Fabrication

- 6.1.1.1 Process Chemicals

- 6.1.1.2 Photomasks

- 6.1.1.3 Electronic Gases

- 6.1.1.4 Photoresists Ancillaries

- 6.1.1.5 Sputtering Targets

- 6.1.1.6 Silicon

- 6.1.1.7 Other Fabrication Applications

- 6.1.2 Packaging

- 6.1.2.1 Substrates

- 6.1.2.2 Lead Frames

- 6.1.2.3 Ceramic Packages

- 6.1.2.4 Bonding Wire

- 6.1.2.5 Encapsulation Resins (Liquid)

- 6.1.2.6 Die Attach Materials

- 6.1.2.7 Other Packaging Applications

- 6.1.1 Fabrication

- 6.2 By End-user Industry

- 6.2.1 Consumer Electronics

- 6.2.2 Telecommunication

- 6.2.3 Manufacturing

- 6.2.4 Automotive

- 6.2.5 Energy and Utility

- 6.2.6 Other End-User Industries

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Solvay SA

- 7.1.2 Messer SE & Co. KGaA

- 7.1.3 Air Liquide SA

- 7.1.4 Compugraphics (MacDermid Alpha Electronics Solutions)

- 7.1.5 International Quantum Epitaxy PLC (IQE PLC)

- 7.1.6 BASF SE

- 7.1.7 Henkel AG & Co. KGaA

- 7.1.8 Caplinq Europe BV