|

市場調查報告書

商品編碼

1690923

固體級熱塑性丙烯酸(珠)樹脂:市場佔有率分析、產業趨勢和成長預測(2025-2030)Solid-grade Thermoplastic Acrylic (Beads) Resin - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

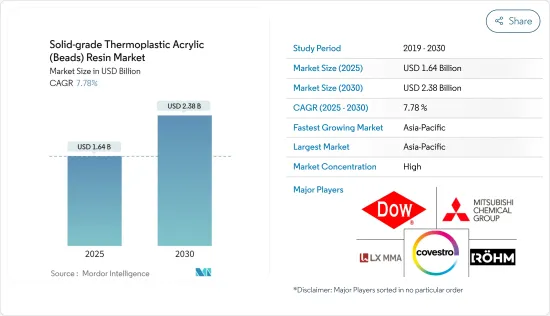

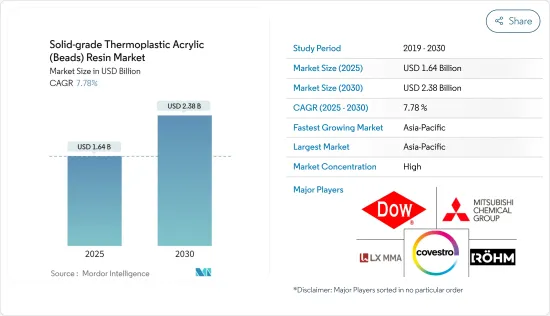

固體級熱塑性丙烯酸樹脂市場規模預計在 2025 年為 16.4 億美元,預計到 2030 年將達到 23.8 億美元,預測期內(2025-2030 年)的複合年成長率為 7.78%。

由於全國範圍內的封鎖和保持社交距離的規定,導致供應鏈中斷以及各種製造和建設活動關閉,COVID-19 疫情對 2020 年的市場產生了負面影響。然而,自從限制解除以來,情況正在逐漸改善。各行業對室內外油漆和塗料的需求不斷增加,預計將對研究市場產生正面影響。

關鍵亮點

- 短期內,油漆和塗料行業的擴張以及固體級熱塑性丙烯酸(珠)樹脂提供的各種好處是推動市場需求的因素之一。

- 相反,政府對原料的嚴格監管阻礙了市場的成長。

- 電動車產業的擴張可能會在未來幾年為市場創造機會。

- 預計亞太地區將主導市場,並在預測期內實現最高的複合年成長率。

固體熱塑性丙烯酸(珠狀)樹脂的市場趨勢

在油漆和塗料行業的使用日益增多

- 固體級熱塑性丙烯酸(珠狀)樹脂廣泛用於油漆和被覆劑配方。此外,這些樹脂主要用於工業塗料、建築塗料、交通塗料和捲材塗料等油漆和塗料領域。

- 固體級熱塑性丙烯酸(珠)樹脂是油漆和塗料的強力黏合劑。這些樹脂易溶於有機溶劑和紫外線單體。它也可溶於二甲苯、酯和酮。

- 這些樹脂可與多種基材黏合,包括金屬、塑膠和水泥材料。此外,它還耐用、有光澤、耐鹼、乾燥速度快,並且易於黏附在各種基材上。固體級熱塑性丙烯酸樹脂也用於木材塗料和電子塗料。

- 根據《塗料世界》報告,2021年各國各類塗料出口總合將達249億美元,而2020年為216億美元,且逐年呈現顯著成長。此外,預計到 2022 年全球油漆和塗料市場價值將達到約 1,980 億美元。

- 根據《塗料世界》的報告,亞洲是油漆和塗料行業最大的地區,佔全球市場佔有率的近45%,其次是北美,佔23%,拉丁美洲佔7%,中東和非洲佔6%。

- 亞太地區持續的經濟實力以及對基礎設施、機械、製造設備等需求的相應成長預計將推動該地區對油漆和被覆劑的需求。此外,在鋼鐵、化工、石油和天然氣、製造和建築等終端用戶產業,生產設施的擴建和投資的增加可能會帶來新的機會。

- 根據美國塗料協會的報告,2022年美國建築塗料市場規模約159億美元。預計到2023年底將達到170億美元以上。

- 加拿大約有 260 家油漆和塗料製造商。加拿大的油漆和塗料製造業規模比美國小,佔年GDP的比重不到0.5%。

- 歐洲擁有許多大型塗料產業,其中主要經濟體有德國、法國、義大利、西班牙。由於該地區有幾家老字型大小企業,預計預測期內油漆和塗料行業將會擴大。德國是歐洲領先的油漆和塗料生產國之一。根據 Haltermann Carless 介紹,該國每年生產約 260 萬噸油漆和被覆劑,用於汽車、建築、一般工業和防腐等各種用途。

- 隨著結構性改革的進行,中東和非洲對工業塗料的需求預計將強勁。此外,沙烏地阿拉伯宣布了「2030願景」及其伴隨的國家轉型計畫(NTP),帶動了醫療保健和教育等各個領域的投資增加。

- 由於所有這些因素,預計固體級熱塑性丙烯酸(珠)樹脂市場在預測期內將穩定成長。

亞太地區佔市場主導地位

- 預計亞太地區將主導市場。以國內生產毛額計算,中國是該地區最大的經濟體。中國和印度是世界上成長最快的新興經濟體之一。

- 根據《塗料世界》的報告,到2022年,亞太地區仍將是全球油漆和塗料產業最具活力的地區。這是因為強勁的經濟成長和有利的人口趨勢使該地區多年來成為全球成長最快的油漆和塗料市場。

- 預計亞太地區的中產階級人口將會增加,同時可支配所得也會增加。這促進了該地區住宅領域的擴張。因此,隨著建築業的發展,已成為建築塗料最重要的市場之一。

- 此外,亞太地區是世界上成長最快的地區,新興工業化國家數量不斷成長。工業成長刺激了對能源基礎設施的需求,進而推動了對油漆和塗料的需求。然而,由於新冠疫情導致的工廠關閉,亞太地區油漆和塗料市場的成長並不均衡,導致需求大幅波動。

- 此外,由於運輸、建築、建築施工、電子、石油和天然氣、太陽能和其他工業領域對丙烯酸複合材料、油漆和塗料的需求增加,預計未來幾年亞太地區固體級熱塑性丙烯酸(珠狀)樹脂的消費水準將大幅上升。

- 亞洲將成為最大的地區,佔全球市場佔有率的近45%,到2022年將達到900億美元。亞洲最大的子區域是大中華區,佔亞洲油漆和塗料市場的近58%。

- 根據歐洲塗料協會統計,中國有近1萬家塗料製造商。全球大多數主要塗料製造商都在中國設有製造地,包括立邦塗料、阿克蘇諾貝爾、中國船舶塗料、PPG工業、BASF和艾仕得塗料。油漆和塗料公司正在加大對該國的投資。

- 2022 年,印度塗料產業價值超過 6,200 億印度盧比(80 億美元)。過去二十年來,它一直保持著兩位數的穩定成長,是全球成長最快的塗料經濟體。該國有 3,000 多家塗料製造商,幾乎所有全球公司都在那裡運作。建築塗料約佔整個市場的75%,而工業塗料佔25%。

- 根據《塗料世界》報道,泰國是最具活力的油漆和塗料市場之一。泰國的油漆和塗料市場高度集中,前四大公司(TOA Paint (Thailand) Public Company Limited、Akzo Nobel Paints (Thailand) Company Limited、Jotun Thailand Limited 和 Berger)佔據了 75% 以上的市場佔有率。

- 根據經濟產業省統計,2021年日本合成樹脂塗料產量約101萬噸,塗料產量龐大。 2021 年塗料總產量從 2020 年的 150 萬噸增加至約 153 萬噸。

- 韓國的油漆和塗料市場是亞太地區第四大市場。 KCC、Samhwa Paints、Kangnam Jevisco(前身為 Kunsul Chemical Industrial Company,俗稱 KCI)、Noroo Paints 和 Chokwang Paints 是主要的油漆和塗料製造商。它們在韓國油漆和塗料市場佔據主導地位,累積市場佔有率約為 75%,推動了丙烯酸在該行業的使用率提高。

- 此外,馬來西亞的油漆塗料產業是東南亞地區最先進的產業之一,擁有約80家大、中、小型油漆塗料製造商。

- 澳洲油漆工業聯合會(APMF)是監督該國油漆和塗料行業運作的官方機構。日本有220多家塗料製造商。主要企業包括多樂士集團、PPG工業公司、宣偉、阿克蘇諾貝爾、艾仕得和Haymes Paints。

- 因此,預計上述因素將在預測期內推動亞太地區對固體級熱塑性樹脂(珠粒)的需求。

固體級熱塑性丙烯酸(珠狀)樹脂產業概況

固體級熱塑性丙烯酸(珠狀)樹脂市場本質上是整合的。市場的主要企業包括(不分先後順序)科思創股份公司、陶氏化學公司、三菱化學公司、LX MMA 和羅姆有限公司。

其他福利

- Excel 格式的市場預測 (ME) 表

- 3個月的分析師支持

目錄

第1章 引言

- 調查前提條件

- 研究範圍

第2章調查方法

第3章執行摘要

第4章 市場動態

- 驅動程式

- 油漆和塗料行業的擴張

- 固體級熱塑性丙烯酸(珠狀)樹脂的優勢

- 限制因素

- 政府對原物料的嚴格監管

- 價值鏈分析

- 波特五力分析

- 供應商的議價能力

- 買家的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

第5章市場區隔

- 應用

- 丙烯酸複合樹脂

- 油漆和塗料

- 線圈塗布

- 工業塗料

- 建築塗料

- 交通運輸塗料

- 其他

- 地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 其他亞太地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 義大利

- 法國

- 其他歐洲國家

- 其他

- 南美洲

- 中東和非洲

- 亞太地區

第6章 競爭格局

- 併購、合資、合作與協議

- 市場排名分析

- 主要企業策略

- 公司簡介

- Chansieh Enterprises Co. Ltd.

- Covestro AG

- Dow

- Heyo Enterprises Co. Ltd.

- LX MMA

- Makevale Group

- Mitsubishi Chemical Corporation

- Pioneer Chemicals Co. Ltd.

- Polyols & Polymers Pvt. Ltd.

- Rohm Gmbh

- Suzhou Direction Chemical Co. Ltd.

- Trinseo

第7章 市場機會與未來趨勢

- 電動汽車產業的擴張

The Solid-grade Thermoplastic Acrylic Resin Market size is estimated at USD 1.64 billion in 2025, and is expected to reach USD 2.38 billion by 2030, at a CAGR of 7.78% during the forecast period (2025-2030).

The COVID-19 pandemic negatively impacted the market in 2020 due to nationwide lockdowns and social distancing mandates which led to supply chain disruption and the closure of various manufacturing industries and construction activities. However, the sector is recovering well since restrictions were lifted. Increasing demand for paints and coatings from different sectors in interior and exterior applications is expected to impact the studied market positively.

Key Highlights

- Over the short term, the expansion of the paint and coatings industry and the various benefits offered by solid-grade thermoplastic acrylic (beads) resins are some of the factors driving the market demand.

- Conversely, stringent government regulations regarding raw materials hinder the market's growth.

- Expansion of the electric vehicle industry is likely to create opportunities for the market in the coming years.

- The Asia-Pacific region is expected to dominate the market and is also likely to witness the highest CAGR during the forecast period.

Solid-grade Thermoplastic Acrylic (Beads) Resin Market Trends

Increasing Usage in the Paints and Coatings Industry

- Solid-grade thermoplastic acrylic (beads) resins are widely used in the formulation of paints and coatings. Furthermore, these resins are used primarily in industrial, architectural, transportation, and coil coatings in the paints and coatings segment.

- Solid-grade thermoplastic acrylic (beads) resins are a strong binder for paints and coatings. These resins can be easily dissolved in organic solvents or UV monomers. They are also soluble in xylene, esters, and ketones.

- These resins offer adhesion to multiple substrates such as metal, plastics, and cementitious. Furthermore, they are durable, have a high gloss, offer good alkali resistance, are fast drying, and easily adhere to a broad substrate range. Solid-grade thermoplastic acrylic resins are also used in wood coatings, electronic coatings, and others.

- According to the Coating World report, the combined exports of various types of paint from all countries amounted to around USD 24.9 billion in 2021, compared to USD 21.6 billion in 2020. It also indicates a notable increase in years. Furthermore, the global paints and coatings market stood at around USD 198 billion in 2022.

- For the paints and coatings industry, Asia is the largest region, with nearly 45% of the global market share, followed by Europe with a 23% share, North America with a 19% share, Latin America with a 7% share, and the Middle East and Africa with a 6% share, as per the Coating World report.

- Asia-Pacific region's continuing economic strength and corresponding increasing need for infrastructure, machinery, manufacturing units, and others are likely to propel the demand for paints and coatings in the region. In addition, expanding production units and increasing investments in the area will likely offer newer opportunities in the end-user industries such as iron and steel, chemical, oil and gas, manufacturing, construction, and others.

- According to the report of the American Coatings Association, in 2022, the market value of architectural coatings in the United States was around USD 15.9 billion. It will likely reach more than USD 17 billion by the end of 2023.

- Canada includes around 260 paint and coating manufacturers. Canada's domestic paint and coating manufacturing industries are fewer than the United States and contribute less than 0.5% to its annual GDP.

- Europe is home to many large paint industries, with the four largest mainland economies, including Germany, France, Italy, and Spain. The presence of several well-established players in the region is projected to expand the paints and coatings segment over the forecast period. Germany is among the leading producers of paints and coatings in Europe. According to Haltermann Carless, the country produces approximately 2.6 million tons of paints and coatings annually, used in various applications such as automotive, architectural, general industry, corrosion protection, and others.

- Due to the region's increasing structural reforms, the Middle East and African regions are anticipated to witness strong demand for industrial coatings. In addition, the announcement of Vision 2030, coupled with the associated National Transformation Plan (NTP), increased investments in various sectors, including healthcare and education in Saudi Arabia.

- Due to all such factors, the market for solid-grade thermoplastic acrylic (beads) resins is expected to grow steadily during the forecast period.

Asia-Pacific Region to Dominate the Market

- Asia-Pacific region is expected to dominate the market. In the area, China is the largest economy in terms of GDP. China and India are among the fastest emerging economies in the world.

- As per the report by Coatings World, the Asia-Pacific region continued to be the most dynamic in the paint and coatings industry worldwide in 2022. It happened to owe to strong economic growth coupled with favorable demographic trends that have made this region the fastest-growing paint and coatings market across the globe for many years.

- The Asia-Pacific region is anticipated to witness an increasing middle-class population coupled with rising disposable income. It facilitated the expansion of the residential sector in the area. Hence, it is the most significant architectural coatings market due to the construction industry's development.

- In addition, Asia-Pacific is the fastest-growing region in the world, with more and more countries becoming newly industrialized. This industrial growth is fuelling the demand for energy infrastructure, which is also multiplying, driving the need for paints and coatings. However, due to COVID-19 pandemic-induced lockdowns, the paints and coatings market growth in the Asia-Pacific region was uneven, resulting in large swings in demand.

- Moreover, the consumption levels of solid-grade thermoplastic acrylic (beads) resins in the Asia-Pacific region are expected to rise at a significant rate in the coming years, owing to the increasing demand for acrylic composites, paints, and coatings from the transportation, architectural, building, and construction, electronics, oil and gas, solar power, and other industrial sectors.

- Asia is the largest region, with nearly 45% of the global market share, amounting to USD 90 billion in 2022. Within Asia, the largest sub-region is Greater China which accounts for almost 58% of the Asian paint and coatings market.

- According to European Coatings, nearly 10,000 coatings manufacturers are located in China. Most leading global coating manufacturers, such as Nippon Paint, AkzoNobel, Chugoku Marine Paints, PPG Industries, BASF SE, and Axalta Coatings, have manufacturing bases in China. Paints and coatings companies have been increasingly growing investments in the country.

- In 2022, the Indian Paint Industry was valued at over INR 62,000 crores (USD 8 billion). It is the fastest-growing paint economy globally, with stable double-digit growth over the last two decades. The country includes over 3,000 paint manufacturers, with nearly all global companies present. Architectural paints constitute around 75% of the overall market, and industrial paints take a 25% share.

- As per the Coatings World, Thailand is one of the most vibrant paints and coatings markets. Thailand's paints and coatings market is highly consolidated in nature, with the top four players [TOA Paint (Thailand) Public Company Limited, Akzo Nobel Paints (Thailand) Company Limited, Jotun Thailand Limited, and Berger Co. Ltd] accounting for more than 75% of market share.

- According to the Ministry of Economy, Trade, and Industry (Japan), the production volume of synthetic resin paints in Japan amounted to approximately 1.01 million metric tons in 2021, making up an enormous production volume of paints. Overall, paints' production volume increased to nearly 1.53 million metric tons in 2021, compared to 1.50 million metric tons in 2020.

- The South Korean paint and coating market is the fourth-largest in the Asia-Pacific region. KCC, Samhwa Paints, Kangnam Jevisco (formerly Kunsul Chemical Industrial Company, popularly called KCI), Noroo Paints, and Chokwang Paints are the primary paint and coating producers. They dominate the South Korean paints and coating market with a cumulative market share of approximately 75%, enhancing acrylic acid usage in the industry.

- Furthermore, catered by about 80 large, mid-sized, and small-scale paint and coatings producers, the Malaysian paints and coatings industry is one of the most advanced product offerings in the Southeast Asian region.

- The Australian Paint Manufacturers' Federation Inc. (APMF) is the official association that monitors the functioning of the paints and coatings industry in the country. There were more than 220 manufacturers of paints and coatings in the country. The major companies include Dulux Group, PPG Industries, Sherwin-Williams, Akzo Nobel, Axalta, and Haymes Paints.

- Thus, the above factors are expected to propel the demand for solid-grade thermoplastic resins (beads) in the Asia-Pacific region during the forecasted period.

Solid-grade Thermoplastic Acrylic (Beads) Resin Industry Overview

The solid-grade thermoplastic acrylic (beads) resin market is consolidated in nature. Some of the major players in the market include Covestro AG, Dow, Mitsubishi Chemical Corporation, LX MMA, and Rohm GmbH, among others (not in any particular order).

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Expansion of the Paints and Coatings Industry

- 4.1.2 Benefits of Solid-grade Thermoplastic Acrylic (beads) Resins

- 4.2 Restraints

- 4.2.1 Stringent Government Regulations Related to Raw Materials

- 4.3 Industry Value Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Buyers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size in Volume)

- 5.1 Application

- 5.1.1 Acrylic Composite Resins

- 5.1.2 Paints and Coatings

- 5.1.2.1 Coil Coatings

- 5.1.2.2 Industrial Coatings

- 5.1.2.3 Architectural Coatings

- 5.1.2.4 Transportation Coatings

- 5.1.3 Other Applications

- 5.2 Geography

- 5.2.1 Asia-Pacific

- 5.2.1.1 China

- 5.2.1.2 India

- 5.2.1.3 Japan

- 5.2.1.4 South Korea

- 5.2.1.5 Rest of Asia-Pacific

- 5.2.2 North America

- 5.2.2.1 United States

- 5.2.2.2 Canada

- 5.2.2.3 Mexico

- 5.2.3 Europe

- 5.2.3.1 Germany

- 5.2.3.2 United Kingdom

- 5.2.3.3 Italy

- 5.2.3.4 France

- 5.2.3.5 Rest of Europe

- 5.2.4 Rest of the World

- 5.2.4.1 South America

- 5.2.4.2 Middle-East and Africa

- 5.2.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 Chansieh Enterprises Co. Ltd.

- 6.4.2 Covestro AG

- 6.4.3 Dow

- 6.4.4 Heyo Enterprises Co. Ltd.

- 6.4.5 LX MMA

- 6.4.6 Makevale Group

- 6.4.7 Mitsubishi Chemical Corporation

- 6.4.8 Pioneer Chemicals Co. Ltd.

- 6.4.9 Polyols & Polymers Pvt. Ltd.

- 6.4.10 Rohm Gmbh

- 6.4.11 Suzhou Direction Chemical Co. Ltd.

- 6.4.12 Trinseo

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Expansion of the Electric Vehicle Industry